Académique Documents

Professionnel Documents

Culture Documents

ITP Format - Excel GEP 1120

Transféré par

raghuvarmaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ITP Format - Excel GEP 1120

Transféré par

raghuvarmaDroits d'auteur :

Formats disponibles

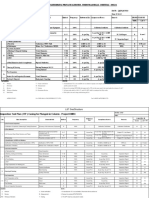

Doc. No.

: FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Base Frame Fabrication

Designation: ITP - 01

SUPPLIER: Cumberland International LLC

Page : 1 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

1 Skid Base Frame Drawing Skid Drawing Skid / Design Conformity to Project Specifications Approved Drawing

R R R R

Weld Procedure & Welder Qualification

Welding Procedures & Qualification of

to AWS D1.1 and Specification for Approved WPS/PQR & Welder

2 Welders Approval WPS/ PQR & Welder WPS/ PQR & Welder Qualification Weld Procedure & Welder Qualification

Pressure Containing Equipment - Qualification

Qualification

Welding and Weld Inspection.

R R R R

Material Certification in compliance with

Material Inspection for Skid Base Check material specification to EN Material Specification EN 10025 Gr

3 Specification for Certification and EN 10204 3.1 Material Certification

Frame 10204 3.1 S275

Marking of Materials

R R R R

Visual & Dimensional Check to

4 Fit-up Inspection- Skid Base Frame Skid specifications & Dimensions As per approved Skid Drawing Fit-up inspection report

approved Skid Drawing

Visual & Dimensional Check to H W W W

Inspection Final Welding of skid base approved Skid Drawing & Skid Specifications -Dimensions &

5 As Approved Skid Drawing Visual and Dimensional report

frames Specification / Welding and Weld visual inspection

Inspection

W W R R

15% of weld joints, NDE Procedure - Compliance with AWS D1.1 & approved Magnetic Particle (MT) Inspection Test

6 Magnetic Particle (MT) Inspection Structural Weld Integrity

Steel Structures MPT procedure Report

H W W W

Final painting and verification of surface Approved Painting rprocedure & DFT Measuring / Adherence Check /

7 Protective Coating finish / thickness Painting Specification Surface finish / DFT compliance with project paint Surface Preparation & Protective

and Procedure specifications Coating Report

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Electrolyser Cells

Designation: ITP - 02

SUPPLIER: Cumberland International LLC

Page : 2 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

1 Drawing Review Review of Manufacturer's Drawing Cell Design / Dimensions GA Drawing Approval Approved GA Drawing

R R R R

2 Test Procedure Review Review of Test Procedure Test procedure Conformance to project specifications Reviewed Test Procedure

R R R R

Check Material Certification as per Data Material Specification u/PVC / Material Certification in compliance with Material Certificate of Conformity to EN

3 Electrolyser Housing Inspection

Sheets, & Outline Drawing of Electrolyzer Polypropylene project materials specification 10204 2.1

R R R R

Material Certification in compliance with

4 Titanium Cell Component Inspection Material Traceability Procedure Material Specification ASTM B265 EN 10204 3.1 Material Certification

project materials specification

H W W R

Visual & Dimensional Inspection to

Conformance to Data Sheets & Outline

5 Electrolyser Assembly & Test Inspection Manufacturers Data Sheets and Outline Specifications & Dimensions Visual / Dimensional Check Certificate

Drawing of Electrolyzer

Drawing of Electrolyzer

H H H W

Hydrostatic Test Procedure - Applicable standard, code, Approvide Test Pressure ( 9 barg) conforming to Test Pressure Held. Without leakage /

6 Hydro test report

Electrolyzer Cell hydro test Procedure & Documents BS 4994 deformation

H W W W

Final painting and verification of surface Painting records demonstrating

Paint, Surface Preparation& Surface

7 Protective Coating finish / thickness as per Painting compliance with project paint Surface finish & Painting Report

Finish

Specification & Procedure specifications

H W W w

Tag plate as per Equipment Nameplate Tag Plate details as per approved Visual Inspection as per approved

8 Tag Plate Inspection Report

List and Drawing drawing Drawings

H R R R

Data Sheets & Outline Drawing of Conformance to Data Sheets & Outline

9 Final Documentation Approved Drawing of Electrolyzer Certificate of Conformity

Electrolyzer Drawing of Electrolyzer

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: CPVC Pipe Work

Designation: ITP - 03

SUPPLIER: Cumberland International LLC

Page : 3 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Pipe Material:CPVC Material Certificate of Conformity to EN

1 Pipe Materials Manufacturers Pipe Specification Conformance to specification

10204 Gr 2.1

H R R R

Manufacturers Standard Cementing / Manufacturers Standard Cementing /

2 Fabrication / cementing Cementing / Jointing Procedure Procedure Approval

Jointing Procedure Jointing Procedure

H W W W

Hydro Test Procedure / Piping Dimensions as per Isometrics , Hydro

3 Testing / Inspection Dimensions and Test Pressure Held Test Certificate

Isometrics Test Pressure

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: GRP (GRVE) Hypochlorite Storage Tank

Designation: ITP - 04

SUPPLIER: Cumberland International LLC

Page : 4 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Data Sheet of Sodium Hypochlorite

Storage Tanks, Outline and

Sodium Hypochlorite Storage Tanks -

Document, Drawing & Calculation Construction Drawing for Sodium Document, Drawing & Calculation

1 Tank Design / Dimensions Data Sheet Outline and Construction

Approval Hypochlorite Storage Tanks & Approval

Drawing & Calculation Sheets approval

Calculation Sheets of Sodium

Hypochlorite Storage Tanks

R R R R

Test Procedure in compliance with all Conformance to project specifications &

2 Test Procedure Review Review of Test Procedure Reviewed Test Procedure

ASME RTP-1 requirements ASME RTP-1

R R R R

Material Certification in compliance with

Check Material as per Data Sheet of Material Specification Glass Reinforced

3 Check Material Specification Specification for Certification and Material Certificate of Conformity

Sodium Hypochlorite Storage Tanks Vinyl-ester

Marking of Materials

H W W R

Visual & Dimensional Inspection to Conformance to Outline and

Specifications & Dimensions including Visual / Dimensional Check

4 Dimensional Check Final Assembly Outline and Construction Drawing for Construction Drawing for Sodium

internals and accessories Certificate/report

Sodium Hypochlorite Storage Tanks Hypochlorite Storage Tanks

H H H R

No leakage or deformation/ Check No leakage or deformation/Conformity Hydrotest Certificate and Clearance

5 Hydrostatic Test. Tank Hydrotest Procedure

cleanliness after Hydrotest to check report

H W W W

Final painting and verification of surface

6 Protective Coating finish / thickness as per Painting Paint & Surface Finish Approved Painting procedure Surface finish & Painting Report

Specification & Procedure

H W W R

Tag plate as per Equipment Nameplate Tag Plate details as per approved Visual Inspection as per approved

7 Tag Plate Inspection Report`

List and Drawing drawing Drawing

H R R R

8 Final Documentation Order / specifications Conformance to Order / Specification Conformance to Order / Specification Inspection Report`

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Hydrogen Dilution Blowers

Designation: ITP - 05

SUPPLIER: Cumberland International LLC

Page : 5 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Approval of Hydrogen Removal Blower Hydrogen Removal Blower Data Sheet

1 Document & Drawing Approval Blower Design / Dimensions Document & Drawing Approval

Data Sheet & Performance & Performance Curve

R R R R

Conformance to project specifications &

2 Test Procedure Review Review of Test Procedure Test procedure Reviewed Test Procedure

BS848

R R R R

Check Material as per Data Sheets & Positive Material Identification/Fan

Check material specification to EN Material Certification in compliance with

3 Performance Curve of Hydrogen Casing - SS316/Impeller Material- EN 10204 3.1 Material Certification

10204 3.1 EN 10204 3.1 & Project Specifications

Removal Blower SS316

R R R R

Conformance to Hydrogen Removal

Visual & Dimensional Inspection to

Blower Data Sheet & Performance

Blower Assembly Inspection & Data Sheet & Performance Specifications & Visual / Dimensional Check

Curve/Outline and Cross Sectional

4 Mechanical Running / Performance Curve/Outline and Cross Sectional Dimensions/Conformance to Order / Certificate/Test Report & Characteristic

Drawing/Conformance to Blower data

Test Drawing/Blower Testing Procedure Specification/Frequency / Distance Curve/Noise Report

sheet and Performance curves/

including noise test procedure

< 80dBA at 1m

R R R R

Final painting and verification of surface

5 Protective Coating Paint & Surface Finish Approved painting procedure Surface finish & Painting Report

finish / thickness

H W W W

Tag plate as per Equipment Nameplate Tag Plate details as per approved

6 Tag Plate Visual Inspection per approved Drawing Inspection Report

List and Drawing drawing

H R R R

7 Final Documentation Order / Specification Conformance to Order / Specification Conformance to Order / Specification Certificate of Conformity

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: FRP Hypochlorite Dosing Pumps

Designation: ITP - 06

SUPPLIER: Cumberland International LLC

Page : 6 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

roval of Hypochlorite Dosing Pumps Hypochlorite Dosing Pumps Data Sheet

Data Sheet & Performance Curve & & Performance Curve & Outline and

1 Document & Drawing Approval Pump Design / Dimensions Document & Drawing Approval

Outline and Cross Sectional Cross Sectional Drawing approval.

Drawing,Reference to ASME B73.1 Conformance to ASME B73.1

R R R R

Check Material as per Data Sheets & Material Certification in compliance with Material Certificate of Conformity to EN

Check material specification to EN Casing & Impeller Material - FRP/Shaft

2 Performance Curve of Hypochlorite EN 10204 2.1/Material Certification in 10204 2.1/ EN 10204 3.1 Material

10204 Material - 42CrMo4

Dosing Pumps compliance with EN 10204 3.1 Certification

R R R R

Centrifugal Pump Test procedure

Conformance to Hypochlorite Dosing

3 Pump Assembly Inspection & Test including Mechanical Conformance to Order / Specification Test Report & Characteristic Curve

Pumps data sheet, Performance curves

Running/Performance Test

R R R R

Visual & Dimensional Inspection to

Conformance to Hypochlorite Dosing

Data Sheet & Performance Curve &

Pumps Data Sheet & Performance

4 Visual and Dimensional Inspection Outline and Cross Sectional Drawing of Specifications & Dimensions Visual / Dimensional Check Certificate

Curve & Outline and Cross Sectional

Hypochlorite Dosing Pump Reference

Drawing . Conformance to ASME B73.1

to ASME B73.1

H H H W

Approved hydro test procedure/Test

Approved hydro test procedure/

5 Hydrostatic Test Pressure as per approved data sheet Test Pressure Held. Without leakage Test Report/Certificate

standard specification ASME 31.3

(1.5 x Design Pressure)

H W W R

Manufacturers standard noise test

6 Noise testing Frequency / Distance < 80dBA at 1m Noise Report

procedure

H R R R

Painting records demonstrating

Final painting and verification of surface Surface Preparation, Paint & Surface

7 Painting Inspection compliance with project paint Painting Report

finish / thickness Finish

specifications

H W W W

Tag plate as per Equipment Nameplate Tag Plate details as per approved

8 Tag Plate Approved Data Sheet & Drawings Inspection Report

List and Drawing drawing

H R R R

9 Final Documentation Order / Specification Conformance to Order / Specification Conformance to Order / Specification Certificate of Conformity

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Motors

Designation: ITP - 07

SUPPLIER: Cumberland International LLC

Page : 7 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

H R R R

Conformance to Order / Motor

Motor Datasheets, Performance Conformance to Order / Specification / Datasheets, Performance Curves, Motor Datasheets, Performance

1 Check Motor Specification Curves, Routine Test and Type Test Datasheets / Performance Curves of Routine Test & Type Test Certificate / Curves, Routine Test and Type Test

Certificates the motor Project specifications / Relevant IEC Certificates

Standards and Frame Agreements

H R R R

Ingress Protection as per appropriate

Ingress Protection as per appropriate

2 Motor Specification Ingress Protection Rating datasheet, Relevant IEC Standards and Certificate of Conformity

motor datasheet

Frame Agreements

H R R R

Explosion protection as per appropriate

Explosion protection as per appropriate

3 Motor Specification Explosion Protection Rating motor datasheet, Relevant IEC Hazardous Rating Certificate

motor datasheet

Standards and Frame Agreements

H R R R

Manufacturers Standard ISO 12944

classification C5I paint Contractor Review, Company Approval, Company Approval of Manufacturers

Compliance with project paint

4 Protective Coating specificationManufacturers Standard Relevant IEC Standards and Frame Standard & paint specification

specifications

ISO 12944 classification C5I paint Agreements /Certificate of Compliance

specification

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Transmitters and Indicators

Designation: ITP - 08

SUPPLIER: Cumberland International LLC

Page : 8 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Compliance to Order & specification Certificate of Conformity

R R R R

Material Specification EN 10204 3.1 Material Certification

Manufacturers Standard Test R R R R

Differential Pressure Transmitter/ Calibration of Instrument Conformance to Order, Approved Data Calibration certificate

1 Procedures / Purchase Order /

Pressure Transmitter sheet & Project Specification

Approved Data sheet R R R R

IP rating IP Rating Certificate

R R R R

Hazardous Area Classification

Hazardous Area Classification

Certificate

R R R R

Compliance to Order & specification Certificate of Conformity

R R R R

Material Specification - Thermowell EN 10204 3.1 Material Certification

Manufacturers Standard Test R R R R

Calibration of Instrument Conformance to to Order, Approved Calibration certificate

2 Temperature Transmitter & Thermowell Procedures / Purchase Order /

Data sheet & Project Specification.

Approved Data Sheet

R R R R

IP rating IP Rating Certificate

R R R R

Hazardous Area Classification

Hazardous Area Classification

Certificate

R R R R

Compliance to Order & specification Certificate of Conformity

R R R R

Material Specification - Flow Tube EN 10204 3.1 Material Certification

Manufacturers Standard Test

R R R R

Flow Transmitter/Meter/Indicator Procedures / Purchase Order / Conformance to to Order, Approved

3 (Rotameter), Flowtube, Thermal Mass Approved Data Sheets: Magnetic Flow Calibration of Instrument Data Sheets: Thermal Mass Flow Meter Calibration certificate

Flow Meter & Magnetic Flow Meter Meter Thermal Mass Flow Meter , Flow Project Specification

R R R R

Indicator - Rotameter. IP Rating IP Rating Certificate

R R R R

Hazardous Area Classification

Hazardous Area Classification

Certificate

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Transmitters and Indicators

Designation: ITP - 09

SUPPLIER: Cumberland International LLC

Page : 9 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Compliance to Order & specification Certificate of Conformity

R R R R

Material Specification EN 10204 3.1 Material Certification

Manufacturers Standard Test R R R R

Calibration of Instrument Conformance to to Order, Approved Calibration certificate

1 Level Transmitter Procedures / Purchase Order /

Data sheet & Project Specification

Approved Data Sheet R R R R

IP Rating IP Rating Certificate

R R R R

Hazardous Area Classification

Hazardous Area Classification

Certificate

R R R R

Compliance to Order & specification Certificate of Conformity

R R R R

Material Specification - Wetted Part Red wet stamped Verified True copy

Only EN 10204 3.1 Material Certification

Differential Pressure Gauge / Pressure Instrument Data Sheets: Differential

R R R R

Gauge (Indicator)/ Magnetic Level Pressure Gauge , Pressure Gauge , Calibration of Instrument Conformance to to Order, Approved Calibration certificate

2

Gauge/ Level Gauge/Temperature Magnetic Level Gauge, Level Gauge , Data sheet

Gauge Temperature Gauge R R R R

IP Rating IP Rating Certificate

R R R R

Hazardous Area Classification

Hazardous Area Classification

Certificate

R R R R

Compliance to Order & specification Certificate of Conformity

Conformance to Purchase Order &

3 Flushing Ring Purchase Order & Specification

Material Specification - Wetted Part Specification R R R R

EN 10204 3.1 Material Certification

Only

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Transmitters and Indicators

Designation: ITP - 10

SUPPLIER: Cumberland International LLC

Page : 10 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Compliance to Order & specification Certificate of Conformity

R R R R

Material Specification - Probe (Sensor) EN 10204 3.1 Material Certification

R R R R

Calibration of Instrument Calibration certificate

Manufacturers Standard Test

Conformance to Order, Approved Data

1 Conductivity Anaylser & Probe (Sensor) Procedures / Purchase Order / R R R R

IP Rating sheet & Project Specification IP Rating Certificate

Approved Data sheet

Hazardous Area Classification R R R R

Hazardous Area Classification

Certificate

R R R R

Compliance to Order & specification Certificate of Conformity

H W W R

Tag plates as per Equipment Tag Plate details as per approved

2 Tag Plates Approved Drawing Inspection Report

Nameplate List and Drawing drawing

H R R R

Instrument Air Tube & Fittings

Material Grade - SS 316 6% Mo, Material Certification in compliance with

3 Materials / Valves / Manifolds / Material Traceability Procedure EN 10204 3.1 Material Certification

Hasteloy / Monel project materials specification

Fabrication

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Instrumentation: Control & On-off Valves and

Accessories

Designation: ITP - 011

SUPPLIER: Cumberland International LLC

Page :11 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

Thickness & Dimensional Check R R R R

Casting Inspection

Certificates

R R R R

Material Specification EN 10204 3.1 Material Certification

R R R R

Visual & Dimensional Inspection Visual & Dimensional Inspection Report

Conformance to to Order, Approved R R R R

Purchase Order / Specification / Seat Leakage Test Seat Leakage Test Certificate

1 Pressure Relief Valve Data sheet /Project

Approved Data Sheet

Specifications/Pressure Relief Devices

R R R R

Hydrotest Hydrotest Certificate

Test / Calibration / Simulated Action R R R R

Test / Calibration Certificate

(Popping Test)

R R R R

Compliance to Order & specification Certificate of Conformity

Thickness & Dimensional Check R R R R

Casting Inspection

Certificates

R R R R

Red wet stamped Verified True copy

Material Specification

EN 10204 3.1 Material Certification

Positive Alloy Material Identification R R R R

2 Positive Material Identification

Report

R R R R

Visual & Dimensional Inspection Visual & Dimensional Inspection Report

Conformance to to Order, Approved R R R R

Purchase Order / Specification / Seat Leakage Test Seat Leakage Test Certificate

Thermal Relief Valve (SS 316) Data sheet, Project Specifications and

Approved Data Sheet

Pressure Relief Devices

R R R R

Hydrotest Hydrotest Certificate

Test / Calibration / Simulated Action R R R R

Test / Calibration Certificate

(Popping Test)

3 R R R R

Painting Inspection for SS 316 Paint Inspection Report for SS 316

R R R R

Compliance to Order & specification Certificate of Conformity

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Sodium Hypochlorite Generator

Designation: ITP - 12

SUPPLIER: Cumberland International LLC

Page :12 of 22

S.No

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

Thickness & Dimensional Check R R R R

Casting Inspection

Certificates

R R R R

Material Specification EN 10204 3.1 Material Certification

R R R R

Visual & Dimensional Inspection Visual & Dimensional Inspection Report

R R R R

Pressure Control Valve Purchase Order / Specification / Seat Leakage Test Conformance to to Order, Approved Seat Leakage Test Certificate

1

Approved Data Sheet Data sheet / Project Specifications

R R R R

Hydrotest Hydrotest Certificate

R R R R

Test / Calibration / Simulated Action Test / Calibration Certificate

R R R R

Compliance to Order & specification Certificate of Conformity

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment:Instrumentation: Control & On-off Valves and

Accessoriesr

Designation: ITP - 13

SUPPLIER: Cumberland International LLC

Page :13 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

Thickness & Dimensional Check R R R R

Casting Inspection

Certificates

R R R R

Material Specification EN 10204 3.1 Material Certification

R R R R

Visual & Dimensional Inspection Visual & Dimensional Inspection Report

R R R R

Seat Leakage Test Seat Leakage Test Certificate

Conformance to to Order, Approved R R R R

Flow Control Valve including Purchase Order / Specification /

1 Hydrotest Data sheet/Conformance to to Order, Hydrotest Certificate

accesorries Approved Data Sheet

Approved Data sheet

Test / Calibration Certificate / Function R R R R

Test / Calibration / Simulated Action /

Test Report with control valve signature

Function Test

record

Hazardous Area Classification R R R R

Hazardous Area Classification

Certificate

R R R R

Compliance to Order & specification Certificate of Conformity

R R R R

Thickness & Dimensional Check

Casting Inspection

Certificates

R R R R

Material Specification EN 10204 3.1 Material Certification

R R R R

Visual & Dimensional Inspection Visual & Dimensional Inspection Report

R R R R

Seat Leakage Test Seat Leakage Test Certificate

R R R R

urchase Order / Specification / Hydrotest Conformance to to Order, Approved Hydrotest Certificate

2 On- Off Valve

Appproval of data sheet Data sheet & Project Specifications

R R R R

Test / Calibration / Simulated Action Test / Calibration Certificate

Hazardous Area Classification R R R R

Hazardous Area Classification

Certificate

R R R R

Painting Inspection Paint Inspection Report

R R R R

Compliance to Order & specification Certificate of Conformity

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Instrumentation: Control & On-off Valves and

Accessorie

Designation: ITP - 14

SUPPLIER: Cumberland International LLC

Page :14 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Compliance to Order Conformance to Order & Project Certificate of Conformity

1 Solenoid Valve Purchase Order / Valve Specifications/Conformance to

Specification Material Certificate of Conformity to BS R R R R

Material Specification

EN 10204 2.1

R R R R

Compliance to Order Conformance to Order & Project Certificate of Conformity

2 Needle Valve Purchase Order / Valve List Specifications/Conformance to

Material Certificate of Conformity to BS R R R R

Material Specification Specification

EN 10204 2.1

R R R R

Compliance to Order Conformance to Order & Project Certificate of Conformity

3 Air Filter Regulator Purchase Order / Valve List Specifications/Conformance to

Specification Material Certificate of Conformity to BS R R R R

Material Specification

EN 10204 2.1

R R R R

Conformance to Order & Project

Compliance to Order Certificate of Conformity

Specifications

R R R R

Eductor Drawing with Material Material Certificate of Conformity to BS

4 Eductor Material Specification Conformance to Specification

Specification EN 10204 2.1

R R R R

Conformance to Order & Project

Hydrotest Hydrotest Certificate

Specifications

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Transformer/ Rectifier

Designation: ITP - 15

SUPPLIER: Cumberland International LLC

Page :15 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

1 Document & Drawings Approval Specification & Drawing T/R Design / Dimensions Document & Drawings Approval Approved Document & Drawings

R R R R

Review of Manufacturers FAT Test Procedure Approval according to

2 Test Procedure Approval Test Procedure Approved Test procedure

Procedure IEC 60076 & 60146

R R R R

Dimensions Conformance to Approved GA Drawing Dimensional Check Certificate

Purchase Order / Specification/ Data Material Certification in compliance with R R R R

3 Enclosure Examination Material specification Stainless Steel EN 10204 3.1 Material Certification

Sheet EN 10204 3.1

R R R R

Ingress Protection Rating Conformance to specification Ingress Protection Certificate

R R R R

Visual/Dimensional

R R R R

Clearances

Conformance to specification. R R R R

4 Final Assembly Purchase Order / Specification Fasteners Tight Datasheet / Specification for Final Inspection Checklist

Transformer/Rectifier R R R R

Fuses correct & installed

R R R R

Wiring segregation

R R R R

5 Hazardous Area Classification Specification & Drawings Hazardous Area Classification Conformance to specification Hazardous Rating Certificate

R R R R

Flash / IR Test

Control Circuit Test Conformance to specification.

Manufacturers Approved FAT

6 Functional Test (FAT) Datasheet / Specification for Test Report

Procedures

Output Control, Limit Protection Transformer/Rectifier

Heat Run & Continuty test of wiring

R R R R

7 Heat Exchanger Hydrotest Manufacturers Test Procedure No Leakage No Leakage Hydrotest Certificate

R R R R

Final painting and verification of surface

Surface Preparation, Final Paint & project paint specifications & approved Certificate of Conformity / Protective

8 Protective Coating finish / thickness as per Painting

Surface Finish/Thickness Verification painting procedure Coating Report

Specification & Procedure

H W W R

Tag plate as per Equipment Nameplate Tag Plate details as per approved

9 Tag Plate Visual Inspection Inspection Report

List and Drawing drawing

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Cables & Cable Accessories

Designation: ITP - 16

SUPPLIER: Cumberland International LLC

Page :16 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Conformance to Order & Specification Certificate of Conformity

R R R R

Purchase Order / Specification. Conformance to Order & Specification.

1 Cables Glands Instrument/Power Cable and Cable Instrument/Power Cable and Cable

R R R R

Gland Schedule with Specification Gland Schedule with Specification

Hazardous Area Classification

Hazardous Area Classification

Certificate R R R R

R R R R

Conformance to Order, Specification,

Purchase Order / Painting Specification Material Certificate of Conformity to BS

2 Cable Tray - Material & Accessories Conformance to Order & Specification Project Specification and Painting

and Galvanizing Procedure EN 10204 Gr 2.1, Galvanizing Report

Specification and Procedure

R R R R

Purchase Order / Specification.

Conformance to Order, Specification &

3 Cables & Cable Accessories Instrument/Power Cable and Cable Conformance to Order & Specification Certificate of Conformity

Project Specification

Gland Schedule with Specification

R R R R

Visual/ Dimensional Check Visual / Dimensional Check Report

R R R R

Material Certificate of Conformity to BS

Material Specification

EN 10204 Gr 2.1

Purchase Order / Specification / Conformance to Order / Specification /

R R R R

approved drawings/ Data Sheets. approved drawings / Data Sheets.

4 Junction Box Conformance to Order & Specification Junction Box Drawing with Terminal Certificate of Conformity

Junction Box Drawing with Terminal

Arrangement & Wiring Diagram Arrangement & Wiring Diagram

R R R R

IP Rating IP65

R R R R

Hazardous Area Certificate Exi

R R R R

Material Certificate of Conformity to BS

5 Earthing Rings Purchase Order & Specification Conformance to Order & Specification Correct Material & Specification

EN 10204 Gr 2.1

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Manual Valves (CPVC)

Designation: ITP - 17

SUPPLIER: Cumberland International LLC

Page :17 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

Thickness & Dimensional Check R R R R

Casting Inspection

Certificates

Red wet stamped Verified True copy R R R R

Material Specification

EN 10204 3.1 Material Certification

Conformance to Order, Manufacturers R R R R

Purchase Order, Manufacturers Valve Seat Leakage Test Seat Leakage Test Certificate

1 Metalic Valves Inspection Valve Specification, Project

Specification, Project Specifications

Specification , Valve List R R R R

Hydrotest Hydrotest Certificate

R R R R

Compliance to Order & Specification Certificate of Conformity

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Manual Valves (Stainless Steel)

Designation: ITP - 18

SUPPLIER: Cumberland International LLC

Page :18 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

Thickness & Dimensional Check R R R R

Casting Inspection

Certificates

R R R R

Material Specification EN 10204 3.1 Material Certification

Positive Alloy Material Identification R R R R

Positive Material Identification

Conformance to Order, Manufacturers Report

Purchase Order, Manufacturers Valve

1 Metalic Valves Inspection Valve Specification, Project R R R R

Specification, Project Specifications Seat Leakage Test Seat Leakage Test Certificate

Specification

R R R R

Hydrotest Hydrotest Certificate

R R R R

Compliance to Order & Specification Certificate of Conformity

Thickness & Dimensional Check R R R R

Casting Inspection

Certificates

R R R R

Material Specification EN 10204 3.1 Material Certification

Metalic Valves Inspection R R R R

Positive Alloy Material Identification

Positive Material Identification

Conformance to Order, Manufacturers Report

Purchase Order, Manufacturers Valve

2 Valve Specification, Project R R R R

Specification, Project Specifications

Seat Leakage Test Specification Seat Leakage Test Certificate

(Butterfly Valve)

R R R R

Hydrotest Hydrotest Certificate

R R R R

Compliance to Order & Specification Certificate of Conformity

R R R R

Painting records demonstrating

Final painting and verification of surface Surface Preparation, Final Paint & Certificate of Conformity / Protective

3 Protective Coating compliance with project paint

finish / thickness Surface Finish/Thickness Verification Coating Report

specifications

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Acid wash tank

Designation: ITP - 19

SUPPLIER: Cumberland International LLC

Page : 19 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Data Sheet of Acid Wash Tank &

Acid wash tank Document & Drawing Acid Wash Tank - Data Sheet &

1 Outline and Construction Drawing for Tank Design / Dimensions approved drawing

Approval Outline and Construction Drawing

Acid Wash Tank

R R R R

Test Procedure in compliance with all Conformance to project specifications &

2 Test Procedure Review Review of Test Procedure Reviewed Test Procedure

ASME RTP-1 requirements ASME RTP-1

H W W R

Check Material as per Data Sheet of Material Specification Glass Reinforced Material Certification in compliance with Material Certificates of Conformity to

3 Check Material Certification

Acid Wash Tank Vinyl-ester EN 10204 2.1 EN 10204 2.1

H W W W

Visual & Dimensional Inspection to Conformance to Outline and

Specifications & Dimensions including

4 Dimensional Check - Final Asssembly Outline and Construction Drawing for Construction Drawing for Acid Wash Visual / Dimensional Check Certificate

internals and accessories

Acid Wash Tank Tank

H H H W

5 Hydrostatic Test Tank Hydrotest Procedure No leakage or deformation No leakage or deformation Hydrotest Certificate

H W W W

Final painting and verification of surface Painting records demonstrating

6 Protective Coating finish / thickness as per Painting Paint & Surface Finish compliance with project paint Certificate of Conformity

Specification & Procedure specifications

H W W W

Tag plate as per Equipment Nameplate Tag Plate details as per approved

7 Tag Plate Visual Inspection Inspection Report

List and Drawing drawing

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Acid Wash Pump

Designation: ITP - 01

SUPPLIER: Cumberland International LLC

Page : 20 of 22

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

S.No Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

Approval of Acid dosing Pump Data Approval of Acid dosing Pump Data R R R R

Sheet & Performance Curve & Outline Sheet & Performance Curve & Outline

1 Document & Drawing Approval Pump Design / Dimensions Document & Drawing Approval

and Cross Sectional Drawing. and Cross Sectional Drawing.

Reference to ASME B73.1 Reference to ASME B73.1

R R R R

2 Test Procedure Review Review of Test Procedure Test procedure Conformance to project specification Reviewed Test Procedure

R R R R

Casing & Impeller Material - Material Certification in compliance with Material Certificate of Conformity to EN

Polypropylene EN 10204 2.1 10204 2.1

Check Material as per Data Sheets &

Check material specification to EN

3 Performance Curve of Acid dosing R R R

10204 2.1

Pump Material Certification in compliance with

Shaft Material - 39NiCrM03 EN 10204 3.1 Material Certification

EN 10204 3.1

H R R R

Visual & Dimensional Inspection to Conformance to Acid dosing Pump

Specifications & Dimensions Visual / Dimensional Check Certificate

Data Sheet & Performance Curve Data Sheet & Performance Curve

R R R R

Centrifugal Pump Test procedure

nformance to Acid Wash Pump data Test Report , Noise test report &

including - Mechanical Conformance to Order / Specification

sheet and Performance curves Characteristic Curve

Running/Performance Test / Noise test

4 Pump Assembly Inspection & Test H H W R

Pressure as per approved data sheet

Hydrotest Test Pressure Held. Without leakage. Test Report/Certificate

(1.5 x Design Pressure) Test

H R R R

Painting records demonstrating

Final painting and verification of surface

Painting inspection compliance with project paint Painting Report

finish / thickness

specifications

H W W R

Tag plate as per Equipment Nameplate Tag Plate details as per approved

5 Tag Plate Approved Data Sheet & Drawings Inspection Report

List and Drawing drawing

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Lifting / Spreader Beam, Lifting Eyes, Slings &

Shackles

Designation: ITP - 21

SUPPLIER: Cumberland International LLC

Page : 21 of 22

S.No Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations Applicable standard, code,Procedure &

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

Conformance to Specification for

Liftng / Spreader Beam Drawing

1 Lifting / Spreader Beam Drawing Lifting / Spreader Beam Design Transportation, Rigging and Erection of Approved Drawing

Approval

Equipment

R R R R

Conformance to Specification for

Lifting / Spreader Beam Design Lifting / Spreader Beam Design

2 Lifting / Spreader Beam Design Transportation, Rigging and Erection of Approved Calculations

Calculations Approval Calculations

Equipment

R R R RR

Material Inspection for Liftng / Spreader check material specification to EN Material Specification EN 10025 Gr Material Certification in compliance with

3 EN 10204 3.1 Material Certification

Beam 10204 3.1 S275 EN 10204 3.1

R R R R

Welder Qualification & Procedure Weld Procedure & Welder Qualification Approved WPS/PQR & Welder

4 WPS/ PQR & Welder Qualification Weld Procedure & Welder Qualification

Approva to AWS D.1 Qualification

W W W R

As approved Lifting / Spreader Beam

Visual & Dimensional Check to Drawing . Completed as per WPS/PQR

Inspection Final Welding of Liftng / Lifting / Spreader Beam Dimensions /

5 approved Lifting / Spreader Beam - Steel Structures. Conformance to Dimensional & Visual Check Certificate

Spreader Beam Weld Integrity

Drawing Specification for Transportation,

Rigging and Erection of Equipment

H W R R

MPI (15% of weld joints) NDE Compliance with ASME V Article 7 /

6 Magnectic partical test (MPT) Structural Weld Integrity MPI report

Procedure - Steel Structures ASME VIII Div 2 App 9 Art 9-1

H W W W

Conformance to Specification for

7 Proof Testing of Lifting Beam Proof Testing of Lifting / Spreader Beam Structural Integrity Transportation, Rigging and Erection of Test Certificate

Equipment

H W W R

Conformance to Specification for

Proof Testing of Lifting Eyes, Slings &

8 Lifting Eyes, Slings & Shackles Structural Integrity Transportation, Rigging and Erection of Test Certificate

Shackles

Equipment

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Doc. No. : FORM-JP-POSE-025

Eni Muara Bakau B.V. JANGKRIK Complex Project FPU

Rev : 00

Electrochlorination Package INSPECTION & TEST PLAN

Doc Ref : 220801DMGB27365

PO reference: 982087

Equipment: Whole Package Assembly

Designation: ITP - 01

SUPPLIER: Cumberland International LLC

Page : 22 of 22

S.NO

Applicable standard, code,Procedure & Characteristic to be verified Acceptance Criteria Record document SUPPLIER CONTRACTOR CLIENT THIRD PARTY Comments

Description of Control or Test Operations

Documents

Rev Act & Sign Act & Sign Act & Sign Act & Sign

R R R R

1 Approval of Test Procedures FAT Procedures Test Procedures Client Approval Approved Procedure

H W W W

Project Specification for Electrical

2 Continuity Check Continuity Passed Continuity Test Checklist

Requirements for Package Equipment

H W W W

Test Pressure held without leakage /

3 Pneumatic Test for Major Pipes Piping - General Design No leakage or deformation Test Report

deformation

H W R R

Function Check (On-Off and Control Instrumentation - Control and On-Off

4 Functions for its intended use. Passed Functional Test Test Report

Valves) Valves

H W W W

5 Final Overall Inspection FAT Procedures Conformance to Project Specification Conformance to Project Specifications Checklist

H W W W

6 Check cleanliness and dryness Visual Inspection Standard of Cleanliness and Dryness Integrity of Overall Cleanliness Checklist

H W W W

Integrity of Overall Finish & compliance

7 Painting inspection Painting Specification and Procedure No scratches, chips or blemishes Checklist

with project paint specifications

H W W R

Preservation and Rust Prevention Conformance to Purchase Order /

8 Rust prevention and protection Conformance to Project Specification Approved Procedure

Procedure &. Galvanizing Procedure Specification

H W W W

Packing, Marking and Transportation

9 Packing inspection Integrity of Packing Conformance to Project Specification Approved Procedure

Procedure

H W W R

Conformance to Purchase Order /

10 Sunshades for Field Instruments Purchase Order & Specification Correct Material & Dimension Certificate of Conformity

Specification

R R R R

Conformance to Purchase Order / Conformance to Purchase Order /

11 Customer Release Note Clients Standard Inspection Release Certificate (IRC)

Specification Specification

H R R R

Conformance to Purchase Order / Conformance to Purchase Order /

12 Manufacturing Record Book MRB Index Manufacturing Record Book

Specification Specification

H : Hold (Work cannot proceed without the concerned party(ies) signing off the inspection activity, unless a waiver has been received by SUPPLIER in writing from CONTRACTOR) W : Witness (Work can go ahead without presence of CONTRACTOR, similar with Hold point Notification for inspection shall be issued to CONTRACTOR by SUPPLIER)

R : Review (Reports/Records/certificates/Procedures to be reviewed by CONTRACTOR) S : SurveillanceMonitoring (presence of CONTRACTOR is not mandatory, No notification is required)

A : Approval

SUPPLIER CONTRACTOR CLIENT THIRD PARTY

Comments (if any) Comments (if any) Comments (if any) Comments (if any)

Vous aimerez peut-être aussi

- BRB Cables PVCDocument30 pagesBRB Cables PVCMorsed Al Mamun75% (40)

- Minimum Quality Requirements For Epc Contractors PDFDocument47 pagesMinimum Quality Requirements For Epc Contractors PDFUmair Awan100% (2)

- Inspection and Test Plan For New Pressure VesselDocument2 pagesInspection and Test Plan For New Pressure VesselCak Nhass0% (1)

- Surface Area of Steel SectionsDocument12 pagesSurface Area of Steel Sectionsraghuvarma50% (2)

- Surface Area of Steel SectionsDocument12 pagesSurface Area of Steel Sectionsraghuvarma50% (2)

- KUWS&DBoard SR 2018-19Document63 pagesKUWS&DBoard SR 2018-19Radhakrishna KPPas encore d'évaluation

- INSPECTION & TEST PLAN FOR FLUE GAS AND AIR DUCTSDocument1 pageINSPECTION & TEST PLAN FOR FLUE GAS AND AIR DUCTStreyPas encore d'évaluation

- Inspection and Test PlantDocument121 pagesInspection and Test PlantMajid Dixon89% (9)

- CHECKLIST Light Fixture Material InspectionDocument3 pagesCHECKLIST Light Fixture Material Inspectionalisha karimPas encore d'évaluation

- Inspection and Test Plan-Structural Steel C011Document2 pagesInspection and Test Plan-Structural Steel C011FurqanPas encore d'évaluation

- Inspection and Test Plan Piping Work ActivitiesDocument2 pagesInspection and Test Plan Piping Work ActivitiesAbram Berkat100% (2)

- Itp For Construction of Precast FoundationDocument7 pagesItp For Construction of Precast FoundationKhyle Laurenz Duro100% (1)

- Inspection and Test Plan For Piping (PP/FRP Piping)Document2 pagesInspection and Test Plan For Piping (PP/FRP Piping)Anonymous EyK4vt6Y100% (1)

- Part 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksDocument5 pagesPart 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksErickson Malicsi100% (2)

- NanoGrout CFGDocument3 pagesNanoGrout CFGimzee25100% (2)

- Inspection and Test Plan Rev.0Document3 pagesInspection and Test Plan Rev.0คุณพ่อน้อง บิ๊กบอสPas encore d'évaluation

- Quality Audit Plan EniDocument16 pagesQuality Audit Plan EniNaveed Ahmed Get-InfoPas encore d'évaluation

- Flange Management Register PDFDocument1 pageFlange Management Register PDFsudeesh kumar100% (1)

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanPas encore d'évaluation

- Itp For Carbon Steel PipeDocument9 pagesItp For Carbon Steel PipehamedpdmsPas encore d'évaluation

- Bed 2381 Q Itp XX 000 00 PDFDocument1 pageBed 2381 Q Itp XX 000 00 PDFKareem GhazyPas encore d'évaluation

- ITP For PipingDocument3 pagesITP For PipingAbdullah Al Jubayer100% (1)

- ITP For Electric HeatersDocument5 pagesITP For Electric Heatersakram husseinPas encore d'évaluation

- 00251900DAST66718 - EXCO00 (Rev. A)Document7 pages00251900DAST66718 - EXCO00 (Rev. A)Mustafa msiPas encore d'évaluation

- Qa-Qc Quality PDFDocument60 pagesQa-Qc Quality PDFNaveed Ahmed Get-InfoPas encore d'évaluation

- QA/QC Procedure Ensures High Quality ConstructionDocument18 pagesQA/QC Procedure Ensures High Quality Constructionerwin hidayat100% (1)

- Inspection & Test Plan For Fabrication, Erection & Testing of Piping SystemDocument4 pagesInspection & Test Plan For Fabrication, Erection & Testing of Piping SystemAbdullah Al Jubayer100% (4)

- Quality Plan for GPL Construction ProjectDocument23 pagesQuality Plan for GPL Construction Projectmayank dixitPas encore d'évaluation

- Inspection Test Plan Fin Tube Heat ExchangerDocument4 pagesInspection Test Plan Fin Tube Heat ExchangerSenthil Kumar100% (2)

- T-4.896.425 - C01 - MS ITP For Hot Cold Insulation WorksDocument20 pagesT-4.896.425 - C01 - MS ITP For Hot Cold Insulation Worksshahid imamPas encore d'évaluation

- Inspection Test Plan ITP v3Document22 pagesInspection Test Plan ITP v3Luis Gabriel Bautista100% (1)

- S-000-1676-0001V - 11 - ITP For Piping WorkDocument47 pagesS-000-1676-0001V - 11 - ITP For Piping WorkVO DINH TRI100% (2)

- Inspection and Test Plan For Above Ground FRP Piping Fabrication & Erection at FieldDocument3 pagesInspection and Test Plan For Above Ground FRP Piping Fabrication & Erection at FieldGohel100% (1)

- 000-A-EE-0230015-514 Rev0Document20 pages000-A-EE-0230015-514 Rev0Hasan YeşilçamPas encore d'évaluation

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelPas encore d'évaluation

- Water Tank Fabrication QAPDocument2 pagesWater Tank Fabrication QAPYOGESHPas encore d'évaluation

- NCR Log Sheet (CBPL)Document6 pagesNCR Log Sheet (CBPL)lavekushPas encore d'évaluation

- Non - Conformance ReportDocument2 pagesNon - Conformance ReportXOXOXOXO XOXOXOXOPas encore d'évaluation

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoPas encore d'évaluation

- L&T GeoStructure casing inspection planDocument2 pagesL&T GeoStructure casing inspection plansanil50% (2)

- ITP For ChilledPump and Pressurization Unit (Testing and Commissioning) 1Document5 pagesITP For ChilledPump and Pressurization Unit (Testing and Commissioning) 1akram hussein100% (1)

- Final Inspection Release NoteDocument2 pagesFinal Inspection Release NoteMark ThrelfallPas encore d'évaluation

- NCT-SCN-000-E06-00002: Site Query on NDT Personnel QualificationDocument1 pageNCT-SCN-000-E06-00002: Site Query on NDT Personnel QualificationCharles KingPas encore d'évaluation

- Inspection & Test Plan for Simple Package EquipmentDocument2 pagesInspection & Test Plan for Simple Package Equipmentxajo50% (2)

- Piping Inspection and Test PlanDocument22 pagesPiping Inspection and Test PlanHaythem Ben Zid100% (1)

- QAC Monthly ReportDocument12 pagesQAC Monthly ReportUbaidullah KhanPas encore d'évaluation

- Inspection and Test Plan (Itp) For ElectricalDocument38 pagesInspection and Test Plan (Itp) For ElectricalJames Pol JumarangPas encore d'évaluation

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument10 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priPas encore d'évaluation

- Owner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionDocument5 pagesOwner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionLuqman OsmanPas encore d'évaluation

- Inspection and Test Plan for Fuel Oil Piping SystemDocument2 pagesInspection and Test Plan for Fuel Oil Piping Systemachusanachu100% (1)

- Document Number: P1066-Ctd-Qac-Itp-003 Document Title: Inspection & Test Plan For Fabrication, Erection & Testing of Piping WorkDocument16 pagesDocument Number: P1066-Ctd-Qac-Itp-003 Document Title: Inspection & Test Plan For Fabrication, Erection & Testing of Piping WorkEILA545 QAQCPas encore d'évaluation

- Site Quality ManualDocument376 pagesSite Quality ManualsPas encore d'évaluation

- AYC IC & ITP - GRP Shade InstallationDocument7 pagesAYC IC & ITP - GRP Shade Installationmoytabura96Pas encore d'évaluation

- Inspection and Test Plan (ITP) - LatestDocument1 pageInspection and Test Plan (ITP) - LatestMariam Mousa100% (1)

- Itp PipingDocument15 pagesItp PipingEkhy Transmisi100% (1)

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimPas encore d'évaluation

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisPas encore d'évaluation

- Building InspectionsDocument2 pagesBuilding InspectionsSuresh DevarajanPas encore d'évaluation

- MEP Site Construction FlowchartDocument5 pagesMEP Site Construction FlowchartAlaa AnwerPas encore d'évaluation

- Ibb Mcup & Modification of K-12 Building: Inspection and Test Plan FOR Architectural WorksDocument19 pagesIbb Mcup & Modification of K-12 Building: Inspection and Test Plan FOR Architectural WorksShewale PravinPas encore d'évaluation

- Sample MRB Index For ENIDocument1 pageSample MRB Index For ENIAnanthu Krishnan100% (1)

- Field Engg Change ControlDocument9 pagesField Engg Change Controlmoytabura96Pas encore d'évaluation

- Plumbing, SanitaryDocument2 pagesPlumbing, Sanitarykumarakash122392Pas encore d'évaluation

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimPas encore d'évaluation

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanPas encore d'évaluation

- Typical - Package ITPDocument23 pagesTypical - Package ITPrandyPas encore d'évaluation

- P Handbook SecurityForces 2017Document138 pagesP Handbook SecurityForces 2017Nanda Win LwinPas encore d'évaluation

- Comparing ACCR and ACSR conductor performance under short circuit conditionsDocument79 pagesComparing ACCR and ACSR conductor performance under short circuit conditionsraghuvarmaPas encore d'évaluation

- E-Tender For AMC of Wind Turbine GeneratorsDocument37 pagesE-Tender For AMC of Wind Turbine GeneratorsraghuvarmaPas encore d'évaluation

- Design of SwitchyardDocument107 pagesDesign of SwitchyardPritamPas encore d'évaluation

- Planned PS Under REZ-66 5GW Connectivity LTA DetailsDocument1 pagePlanned PS Under REZ-66 5GW Connectivity LTA DetailsraghuvarmaPas encore d'évaluation

- Solar PV DC String CableTests Isc and VocDocument1 pageSolar PV DC String CableTests Isc and VocraghuvarmaPas encore d'évaluation

- ACSR Conductor SizingDocument13 pagesACSR Conductor SizingraghuvarmaPas encore d'évaluation

- 4Mw Wind Power Project: Tender DocumentDocument153 pages4Mw Wind Power Project: Tender DocumentpramjitPas encore d'évaluation

- P Handbook SecurityForces 2017Document138 pagesP Handbook SecurityForces 2017Nanda Win LwinPas encore d'évaluation

- Proline Promag W 400 EnglischDocument56 pagesProline Promag W 400 EnglischraghuvarmaPas encore d'évaluation

- Saunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesDocument6 pagesSaunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesJose Gregorio FerrerPas encore d'évaluation

- Improve manufacturing performance through loop checkingDocument8 pagesImprove manufacturing performance through loop checkingOhaneje Uzoma67% (3)

- Classification of Heat ExchangersDocument77 pagesClassification of Heat Exchangers4605566vivek100% (1)

- Paints Coating Failure Defects GOOD PDFDocument46 pagesPaints Coating Failure Defects GOOD PDFVasileios Iliopoulos100% (1)

- Proline Promag W 400 EnglischDocument56 pagesProline Promag W 400 EnglischraghuvarmaPas encore d'évaluation

- 8426 Guide PressureDocument8 pages8426 Guide PressurehainguyenbkvhvPas encore d'évaluation

- AlNimr Steel Book PDFDocument52 pagesAlNimr Steel Book PDFraghuvarmaPas encore d'évaluation

- PL205 Brochure ApV3 PDFDocument2 pagesPL205 Brochure ApV3 PDFraghuvarmaPas encore d'évaluation

- BK 123Document60 pagesBK 123Fadlul Akbar HerfiantoPas encore d'évaluation

- Thermal Power PlantDocument17 pagesThermal Power PlantraghuvarmaPas encore d'évaluation

- Astm A 179Document2 pagesAstm A 179raghuvarmaPas encore d'évaluation

- PL205 Brochure Asv3 PDFDocument2 pagesPL205 Brochure Asv3 PDFraghuvarmaPas encore d'évaluation

- Paints Coating Failure Defects GOOD PDFDocument46 pagesPaints Coating Failure Defects GOOD PDFVasileios Iliopoulos100% (1)

- Additional Equipment: PCPL Airlift AeratorsDocument2 pagesAdditional Equipment: PCPL Airlift AeratorsraghuvarmaPas encore d'évaluation

- PL205 Brochure Eqv1 PDFDocument2 pagesPL205 Brochure Eqv1 PDFraghuvarmaPas encore d'évaluation

- PL205 Brochure SV3 PDFDocument2 pagesPL205 Brochure SV3 PDFraghuvarmaPas encore d'évaluation

- Subject: Request For Cancellation of EjariDocument1 pageSubject: Request For Cancellation of EjariraghuvarmaPas encore d'évaluation

- Agro SurfactantsDocument4 pagesAgro SurfactantsJanakiram Yarlagadda100% (1)

- Jomo Kenyatta University of Agriculture and TechnologyDocument16 pagesJomo Kenyatta University of Agriculture and TechnologyJoe NjorePas encore d'évaluation

- Test Limits & FrequencyDocument9 pagesTest Limits & FrequencySangram MundePas encore d'évaluation