Académique Documents

Professionnel Documents

Culture Documents

Technical Specification For Field Erected Fuel Oil Storage Tanks

Transféré par

cchristt2584Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Specification For Field Erected Fuel Oil Storage Tanks

Transféré par

cchristt2584Droits d'auteur :

Formats disponibles

Ref. (Department/Year/Serial No.

) Rev

SPEL/EN M&SG/11/099 2

Subject/Title Place Date

Technical specification for Field Erected Gurgaon 11-01-2012

Fuel Oil Storage Tanks Author(s) Department Tel. Signature

Abhijit Saha SPEL EN M&SG 6065 AS sgd

Project

Signature for Release by Dept. Concerned Signature for External Release by

MALACAS - TG5 (for Contents, Handling, Distribution) Sales & Marketing Dept. (Not

Required for Approval Documents)

Handling Instructions

Unrestricted Neeraj Sharma SPEL EN M&SG 4139 NS sgd

Proj.-Code UA Contents Code Doc. Ident. No.

PE1012 XW01 2511 481718647

Summary*) Pages of Text: 17 Appendices: -

This document includes the technical purchase specification for Field Erected Fuel Oil Storage-

Tanks for Malacas - TG5 Project.

Distribution (add "f.i.o.", if only Summary is distributed for information):

Rev Vers. Date Page(s) Author(s)

Initials

Initials for

Release

Chris Moering E F ES EN ORL PEM A 14.10.11 17 AS NS

Chris Moering E F ES EN ORL PEM 0 17.11.11 17 AS NS

Chris Moering E F ES EN ORL PEM 1 23.11.11 17 AS NS

Chris Moering E F ES EN ORL PEM 2 11.01.12 17 AS NS

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Energy Inc. Orlando, FL express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 2 of 17

Storage Tanks

Handling: Unrestricted

Revision Sheet

Revision Revision Date Section Description of Change

A 14.10.2011 All FIRST ISSUE

0 17.11.2011 All CHANGE AS PER COMMENTS

1 23.11.2011 All CHANGE AS PER COMMENTS

AND REVISION MARKED IN

TRIANGLE

2 11.01.2012 All RELEASED FOR EXECUTION

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 3 of 17

Storage Tanks

Handling: Unrestricted

Index

S. No. Description Page Number

1.0 SCOPE................................................................................................................................................ 4

2.0 GENERAL REQUIREMENTS ....................................................................................................... 4

2.1 WORK TO BE PROVIDED................................................................................................................. 4

2.2 APPLICABLE PUBLICATIONS ......................................................................................................... 4

3.0 DETAILED REQUIREMENTS ...................................................................................................... 6

3.1 DESCRIPTION OF SERVICE ............................................................................................................. 6

3.2 DESIGN AND OPERATION CONDITIONS ........................................................................................ 6

3.3 MATERIALS .................................................................................................................................... 7

3.4 DESIGN AND CONSTRUCTION FEATURES ..................................................................................... 7

3.5 SPECIAL TOOLS ............................................................................................................................ 10

3.6 TANK CLEANING AND PAINTING................................................................................................. 10

3.7 QUALITY ASSURANCE .................................................................................................................. 11

3.8 MARKING ...................................................................................................................................... 11

4.0 INSTALLATION ............................................................................................................................ 11

5.0 TESTING ......................................................................................................................................... 12

5.1 MATERIAL TESTS ......................................................................................................................... 12

5.2 FIELD TESTS ................................................................................................................................. 12

6.0 INFORMATION TO BE SUBMITTED ....................................................................................... 13

6.1 WITH BID ...................................................................................................................................... 13

6.2 AFTER AWARD ............................................................................................................................. 13

TABLE 1 PROJECT REQUIREMENTS FOR FIELD ERECTED FUEL OIL STORAGE TANK . 14

TABLE 2 TECHNICAL DATA SUPPLIED BY CONTRACTOR FOR FIELD ERECTED FUEL

OIL STORAGE TANK............................................................................................................................... 16

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 4 of 17

Storage Tanks

Handling: Unrestricted

1.0 SCOPE

This Specification covers the requirements for the engineering, design, fabrication, delivery,

unloading, storage, erection, and field testing of two (2) fuel oil storage tanks including tank

internal piping, accessories as specified in TABLE 1, "PROJECT REQUIREMENTS FOR

FIELD ERECTED FUEL OIL STORAGE TANK".

2.0 GENERAL REQUIREMENTS

2.1 Work to be provided

Contractor shall furnish all labor, supervision, materials, tools and equipment required for

the completion of the following Work as specified herein:

Engineer, design, fabricate, deliver, unload, store and erect two (2) fuel oil storage

tanks (single wall) complete with tank internal piping, ladders, safety cages, walkways,

platforms and all accessories as specified herein.

Furnish and install level instrumentation as specified in TABLE 1.

Perform cleaning and protective coating of oil storage tanks, appurtenances and

accessories.

Perform field testing of fuel oil storage tanks and accessories.

Furnish all documentation.

2.2 Applicable Publications

The latest edition and addenda of the following publications in effect on the date of Contract

Award are part of this Specification.

American Petroleum Institute (API)

API Standard 650 Welded Steel Tanks for Oil Storage

API Standard 2000 Venting Atmospheric and Low Pressure Storage Tanks

API RP 2003 Protection Against Ignition Arising Out of Static, Lightning and Stray

Currents

API RP 2350 Overfill Protection for Storage Tanks in Petroleum Facilities

American Society of Mechanical Engineers (ASME)

ASME/ANSI 16.5 Pipe Flanges and Flanged Fittings

ASME/ANSI 16.21 Nonmetallic Flat Gaskets for Pipe Flanges

ASME B31.1 Power Piping

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 5 of 17

Storage Tanks

Handling: Unrestricted

ASME Boiler and Pressure Vessel Code (BPVC)

Section IX, Welding and Brazing Qualifications

American Society for Testing and Materials (ASTM)

ASTM A36 Structural Steel

ASTM A105 Forgings, Carbon Steel, for Piping Components

ASTM A106 Seamless Carbon Steel Pipe for High-Temperature Service

ASTM A283 Low and Intermediate Tensile Strength Carbon Steel Plates, Shapes

and Bars

ASTM A307 Carbon Steel Externally Threaded Standard Fasteners

ASTM A563 Carbon and Alloy Steel Nuts

Environmental Protection Agency (EPA)

Factory Mutual Loss Prevention Data Sheet 7-88

(FM) (FM 7-88)

UBC 1997 Universal Building Code

American Welding Society (AWS)

D1.1 Structural Welding Code

National Fire Protection Agency (NFPA)

NFPA 850 Recommended Practice for Fire Protection for Electric Generating

Plants and High Voltage Direct Current Converter Stations

American Society of Civil Engineers (ASCE)

ASCE 7-05 Minimum Design Load for Buildings and Other Structures

Steel Structure Painting Council (SSPC)

SSPC - SP-10 Near -White Blast Cleaning

SSPC - PA 1 Shop, Field, and Maintenance Painting of Steel

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 6 of 17

Storage Tanks

Handling: Unrestricted

3.0 DETAILED REQUIREMENTS

3.1 Description of Service

The fuel oil storage tanks, provided under this specification, will be used to store Fuel Oil

specified in TABLE 1.

3.2 Design and Operation Conditions

Tanks shall be provided as specified herein and in accordance with TABLE 1.

Tanks shall be designed and fabricated in accordance with API Standard 650. Lightning

protection shall be provided.

Tanks shall be designed for temperature, pressure, and storage capacity specified in

TABLE 1, and for operation in the environment and ambient conditions specified in TABLE

1.

Provision for Nitrogen Blanketing shall be provided by Contractor.

Contractor shall supply a roof-mounted level indicator, which shall be designed in

accordance with TABLE 1.

Corrosion allowance over the calculated API Standard 650 thickness for tank plates shall

be as specified in TABLE 1.

The tanks shall be designed for the roof live loads in accordance with the requirements of

the ASCE 7-05 code. The tanks shall be designed for wind and seismic loads in

accordance with the requirements of ASCE 7-05 code. Refer to TABLE 1 and API Standard

650 and the following criteria:

Wind Loads IBC2003

Basic wind speed - 100 miles per hour

Wind Exposure Category C

Wind Importance Factor Iw = 1.15

Seismic Loads

Seismic loads shall be determined in accordance with UBC 1997

Seismic Zone 4

Soil type - SD

Ladder, platform and walkway design shall be in accordance with the requirements in the

UBC1997 Building Code and API Standard 650.

Level indication design shall be in accordance with requirements in the UBC1997 Building

Code, NFPA and the API Standard 650 and API RP2350.

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 7 of 17

Storage Tanks

Handling: Unrestricted

3.3 Materials

Materials for the tanks, tank piping, stairways, ladders, walkways, and accessories shall be

as specified as follows:

Tank-shell, roof, and bottom plates

ASTM A283, Grade C, ASTM A36, or equivalent in accordance with API 650

Structural steel for ladder, walkways, platforms, bracing, and supporting members shall be

galvanized:

ASTM A36 or equivalent in accordance with API 650

Pipe and Nozzles

ASTM A106, Seamless Grade B or equivalent

Flanges

ASTM A105 or equivalent

Bolting

ASTM A307, A563 or equivalent

Where the material for a specific component is not specified, an appropriate material for the

application shall be selected by Contractor and approved by PURCHASER.

Structural materials and fasteners exposed to atmosphere, such as manway covers, stairs,

ladders, platforms, and handrails, shall be hot-dipped galvanized. Exposed steel members

thinner than 3/16-inch shall be hot-dipped galvanized.

3.4 Design and Construction Features

3.4.1 General design and construction features for each tank

Tank shall be vertical, cylindrical, fixed roof type, with butt-welded construction. Tank

shall be constructed in accordance with all applicable codes and regulations, as

specified herein and in accordance with additional special requirements as stated in

TABLE 1.

Tank storage capacity shall be based on useable capacity from outlet connection to

bottom of overflow connection.

The tank shall be built on top of a concrete ring-wall foundation, which will be designed

by A/E in accordance with contractor requirements. Contractor may submit an option

price for providing the tank foundation and performing structural backfill to support it

per geotech report and "Civil Construction Specification" Section 02224.

A supported or self-supporting roof design in accordance with API Standard 650 shall

be used. A frangible roof-to-shell design shall be used.

The tank shall be constructed with a double bottom for leak prevention and detection

purposes. The inner tank bottom holding the tank's oil contents shall be leak-tight and

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 8 of 17

Storage Tanks

Handling: Unrestricted

properly supported to withstand the weight of the tank's contents without deformation.

The leak detection volume between the two (2) bottoms of the tank shall be provided

with three (3) -inch NPT half-couplings on the perimeter of the tank wall spaced at 120

degrees around the tank. The three (3) -inch connections shall be used to connect the

Purchaser's supplied leak detection system and shall be located at the lowest point on

the tank wall. The space between the two (2) bottoms of the tank and the design of the

support arrangement for the tank bottoms shall facilitate leak detection by allowing any

leakage to drain to the three (3) leak detection connections at the perimeter.

The double bottom design of the tank shall accommodate the required water draw-off

sump without creating an inaccessible low point within the leak detection volume.

All tank joints shall be constructed so that openings in the shell and shell

reinforcements shall not intersect longitudinal or girth joints.

All piping shall be in accordance with ASME B31.1 - Power Piping.

An exterior caged ladder and one (1) connecting platform shall be provided. Ladders,

platforms, handrail and safety cages shall be hot dip galvanized.

Walkways around the perimeter of the tank complete with handrails and toe plates,

shall be provided at the top of the tank. Other connecting walkways as specified in

TABLE 1 shall be provided.

The locations of the nozzles, manways, ladder, and platform shall be approved by the

PURCHASER prior to release of Contractor's outline drawing of the tank for fabrication.

All tank manways shall have hinged, bolted flange-type covers complete with gaskets,

bolts and nuts, and welded-on handgrips or lifting lugs. Manways shall be circular.

Minimum size shall be 24".

All roof manways and equipment hatches shall have reinforced roof structure around

the roof openings for expected work to be carried on through roof openings.

Wall thickness, manway sizes, and vents shall be based on API Standard 650

guidelines unless otherwise specified herein.

Anchor bolt sizes, numbers and locations shall be determined by Contractor. Anchor

bolts (if required) to be supplied and installed by Contractor.

Water draw-off sump shall be provided for the tank in accordance with API Standard

650. Contractor shall provide piping and water drain valve. The water drain valve shall

be of anti-freeze type.

A level indicator readable from grade shall be installed on the exterior of the tank as

detailed in TABLE 1 (Level gauge tape system).

Tank shall be provided with a minimum of four (4) ground lug pads welded near the

base of the tank, 90 degrees apart to accommodate ground system connections.

A fire fighting foam system in accordance with NFPA 850 shall be provided by the

Contractor.

The requirement for a floating suction within the tanks shall be provided by contractor.

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 9 of 17

Storage Tanks

Handling: Unrestricted

Contractor shall design and provide conservation vent and overflow line to work with a

seller-provided Nitrogen blanketing system. Contractor shall provide conservation vent

at the top of the tank as well as Nitrogen inlet flange. The overflow line shall be

designed to keep nitrogen inside the tank with either overflow seal or other means

which shall be approved by purchasers engineer.

3.4.2 Welding Requirements

All welding procedures, welders, and welding operators shall be qualified in

accordance with the requirements of ASME and AWS.

Qualified welding procedures shall be submitted to the PURCHASER for approval prior

to the start of any work.

All welding shall be performed in accordance with Contractor's written procedures and

the requirements of API Standard 650.

All welds shall be inspected, tested, and repaired in accordance with the requirements

of API Standard 650.

The qualifications of the field inspection personnel engaged by the Contractor shall be

submitted for PURCHASER's approval.

3.4.3 Connections

Flanged connections shall be in accordance with ASME/ANSI B16.5 and shall be

provided with gaskets. Gasket shall be flat ring type and suitable for fuel oil.

Dimensional requirements shall be in accordance with ASME/ANSI B16.21.

All welded connections two (2") inch and smaller shall have socket-welding ends

unless otherwise specified in TABLE 1.

The tank shall be provided with all necessary openings and connections.

The location, size, type and quantity of all openings, connections (including instrument

connections), and fittings shall be provided as per Purchasers drawings. Locations

may be subject to change during engineering and design prior to release of

Contractor's drawing for fabrication, at no additional cost to Buyer.

Nozzles having a nominal diameter of twelve (12") inches or greater shall have a

minimum nozzle length of ten (10") inches. Nozzles having nominal diameters between

and including two and one half (2-1/2") and ten (10") inches shall have a minimum

nozzle length of six (6") inches. Nozzles having nominal diameters between and

including one half (1/2") and two (2") inches shall have a minimum nozzle length of four

(4") inches.

Nozzles shall be reinforced in accordance with the requirements of API Standard 650.

Nozzles color coding shall comply with API requirements.

Holes shall not be made in shell plate for erection purposes.

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 10 of 17

Storage Tanks

Handling: Unrestricted

Lugs or other projections on the interior shell surface shall be removed and any sharp-

edged projection of weld metal shall be chipped or ground from the plate. Any sharp-

edged scars shall be filled with weld metal and ground smooth.

All appurtenances that require welding to the tank shell shall be installed and tested

prior to the hydrotest.

3.4.4 Corrosion Allowance

Corrosion allowance shall be provided as specified in TABLE 1. A connection for a

sacrificial anode cathodic protection system shall be provided.

3.5 Special Tools

Contractor shall supply one (1) complete set of all special tools required for the

maintenance of the tanks.

3.6 Tank Cleaning and Painting

All tank surfaces shall be free of mill scale, heat treating scale, heavy oxide, organic matter,

dirt, slag, or any flux, other well splatter, oil, grease, or any other foreign materials.

Tank plates shall be blast cleaned in Contractor's shop to clean metal and shall be cleaned

of all blast cleaning abrasive. Surface preparation shall be abrasive blasting to SSPC-SP-

10, per Siemens Document ZDX566-DS00-000-4181-02 - "Paint Specification for BOP

Equipment."

External surfaces including the underside of the tank bottoms and all structural steel, with

the exception of machine finished surfaces and edges prepared for field welding for a

distance of 1-1/2 inch from the weld edge, shall be given one (1) shop coat of the corrosion

resistant primer specified in TABLE 1.

All edges prepared for field welding shall be protected against corrosion with one (1) coat of

rust inhibiting coating applied after inspection and cleaning in Contractor's shop.

Upon completion of field welding, all weld joints shall be wire brushed clean and exterior

weld joints shall be given one (1) coat of same corrosion resistant primer applied on the

external surfaces in Contractor's shop, in accordance with coating manufacturer's

requirements.

Protective coatings suitable for the storage of the diesel fuel IR3 oil or grade 55 kerosene

shall be applied on the tank interior and exterior in accordance with TABLE 1 requirements.

The detailed protective coating and painting systems and application methods shall be

submitted with bid and subject to Engineer's approval prior to the commencement of work.

Different color for different layers of coating shall be used for ease of coating monitoring.

Before each layer is applied, previous coating shall be touched up where necessary by way

of rust removal and cleaning, in accordance with the coating manufacturer's specification.

The final topcoat shall be reapplied completely if required.

Field touch-up shall consist of prime coating of connections, including bolt heads and nuts,

after their installation and inspection, and touch-up of abrasions of the shop coat.

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 11 of 17

Storage Tanks

Handling: Unrestricted

Suitable lining materials shall be used to protect the tank interior. Linings shall be applied in

accordance with the manufacturer's recommendations and Table 1.

All construction involving pockets or crevices that will not drain or that cannot be properly

sandblasted and lined shall be avoided.

All weld spatter shall be removed. All sharp edges shall be ground to a minimum 1/8"

(3mm) radius.

The completed lining shall be checked for pinholes, holidays, and bare areas with a Tinkor

Rasor Model APW Spark Tester or equivalent at a minimum of 1500 volts. Any pinholes

shall be removed by grinding out the coating area to the shell plate, followed by an

inspection to assure the appropriate surface profile exists before reapplication of the

coating. Repairs shall be in accordance with the lining manufacturer's recommendations.

All of the above work shall be done in accordance with SSPC PA- I, Contractor's written

procedures and coating manufacturer's requirements.

3.7 Quality Assurance

The PURCHASERs Engineer shall be permitted free entry to all parts of the Contractor's

plant concerned with the Contract whenever any work under the Contract is being

performed.

Mill and shop inspection shall not release the Contractor from responsibility for replacing

any defective material and for repairing any defective workmanship that may be discovered

in the field.

Welding Materials and Procedures: Conform to API Standard 650, AWS and ASME Codes

and applicable state labor regulations. Submit welding procedures, welder qualifications,

painting and coating procedures for Engineer review and approval prior to commencing any

work.

A detailed quality plan (QA/QC) shall be submitted to the PURCHASERs Engineer for

review and approval prior to the commencement of the work.

3.8 Marking

A stainless steel nameplate shall be attached to each tank in a clearly visible, easily

accessible location as described in API Standard 650.

The nameplate shall be the API Standard 650 monogrammed nameplate carrying the

information prescribed in API Standard requirements. PURCHASERs Engineer's

identifying tank number and information shall be included.

Tank numbers, tank inlet and tank outlet pipes labels shall be marked clearly on the tank

wall. Detailed font size and design shall be coordinated with the Owner prior to tank

fabrication.

4.0 INSTALLATION

The Contractor shall furnish all labor, supervision, materials, tools, and equipment

necessary to complete this work.

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 12 of 17

Storage Tanks

Handling: Unrestricted

Laydown area shall be agreed with the PURCHASER before commencement of work.

Laydown area within the Owner's property is minimal.

The fabrication and erection recommendations of API Standard 650 shall be followed.

The Contractor shall obey all Plant regulations while conducting work at the Owner's facility

including safety, fire, traffic, and security regulations.

Contractor shall repair all defects found in any stage of the installation. All defects found in

welds shall be called to the attention of the PURCHASER and their approval shall be

obtained before the defects are repaired. All completed repairs shall be subject to the

approval of the PURCHASER. Acceptance criteria shall be in accordance with API

Standard 650.

5.0 TESTING

5.1 Material Tests

Certified mill test reports for pressure retaining materials shall be prepared in accordance

with ASTM specifications and shall include actual mechanical and chemical properties.

5.2 Field Tests

PURCHASER reserves the right to witness field tests. Contractor shall notify PURCHASER

of the field tests at least fifteen (15) days in advance of the dates of the tests.

Methods of inspecting joints shall be submitted to the PURCHASER prior to the

commencement of the work. The methods shall be in accordance with the API Standard

650.

Upon completion of welding of each tank bottom, a vacuum box test shall be applied to the

weld joints in accordance with the requirements of API Standard 650. This shall also

include the tank sidewall to bottom weld.

Upon completion of welding of the tank roof, visual inspection shall be applied to the weld

joints in accordance with the requirements of API Standard 650.

Upon completion of the entire tank and prior to the connection of any permanent external

piping, the tank shell shall be filled with water and hydrostatically tested in accordance with

API Standard 650. All connections, pumping, blind flanges, nuts, bolts, and gaskets as

required to perform the test shall be provided, installed and removed by the Contractor.

Water for hydrostatic testing will be provided by and disposed of by PURCHASER / Owner

prior to finish painting.

Repairs of defects discovered after the tank has been tested or filled with water for testing

shall be made with the water level at least 1 foot below the point being repaired or, if repairs

are on or near the tank bottom, with the tank empty. Repairs shall not be attempted on any

tank that is filled with oil or on any tank that has contained oil until the tank has been

emptied, cleaned, and gas freed in a safe manner.

All tank openings shall be appropriately protected against entrance of dirt, dust, moisture, or

other deleterious materials during and after the completion of the field test.

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 13 of 17

Storage Tanks

Handling: Unrestricted

Certified reports of all field tests and repairs shall be prepared and submitted by the

Contractor.

6.0 INFORMATION TO BE SUBMITTED

6.1 With Bid

Bidder shall complete the Master Document List Fuel Oil Storage Tank Documents (MDL)

and include with the bid. After acceptance by the Purchaser, the data will become part of

the Contract Documents.

6.2 After Award

Submittal requirements are listed in Master Document List.

Contractor shall submit documents in accordance with Siemens Power Generation

specification 22T7177 "Supplier Document Submittal Process", including use of a Master

Document List (MDL) listing and describing the documents to be provided and the promise

issue dates. See attached MDL for specific requirements.

The following are minimum submittal requirements for the purpose of satisfying the bid

evaluation. Failure to submit this information will be grounds for rejection of the Bid.

Preliminary base loading for foundation design. Base loads shall be accurate to plus-

or-minus 10 percent of the final base loads.

Preliminary anchor bolt requirements and arrangement.

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 14 of 17

Storage Tanks

Handling: Unrestricted

TABLE 1

PROJECT REQUIREMENTS FOR FIELD ERECTED FUEL OIL STORAGE TANK

SHEET 1 OF 2

Spec. Para Item

Quantity of Tanks required: Two (2)

Design and Operating Conditions:

Design Temperature (Min/Max) 59F/98F

Design Pressure Atmospheric

- Design Storage Capacity (usable capac-

6000 m3. (each tank)

ity)

Nominal Outer Diameter 86 feet

Nominal Wall Height 40 feet

Maximum Overall Tank Height: To be determined by Contractor

Tank Operating Temperature 59F/98F

Tank Operating Pressure Atmospheric

1/8" Tank Bottom and Tank

Corrosion Allowance

Shell

Roof Live Load - Minimum 25 psf

Lightning protection: Required

Ambient Conditions:

Pressure Atmospheric

Temperature 59F/98F

Relative Humidity 60% to 80%

Maximum Wind Speed Per Paragraph 3.2

Seismic Load Per Paragraph 3.2

Oil Type

Content B5

Maximum Filling Rate 2x375 gpm

Maximum Emptying Rate 2x320 gpm

Design and Construction Features:

Foundation Type: Concrete ring beam

Anchor Bolting: Determined by Contractor.

- Protective Coating:

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 15 of 17

Storage Tanks

Handling: Unrestricted

TABLE 1

PROJECT REQUIREMENTS FOR FIELD ERECTED FUEL OIL STORAGE TANK

SHEET 2 OF 2

Spec.

Item

Para

- Surface Preparation Abrasive blast to SSPC-SP-10

Epoxy phenolic two (2) coat sys-

- Tank bottom and first 3 feet of tank in-

tem.(ROAE*: Carboline Phenoline

terior

187 at 4-6 mils)

Inorganic zinc ethyl silicate (ROAE*:

Carbozinc 11 at 2-4 mils)

Two pack zinc rich epoxy

- Tank exterior including roof: (ROAE*: Carbozinc 859 at 3-5 mils)

- Primer: Two pack epoxy (*ROAE: Car-

- Primer Touch-Up: boguard 890 at 4-6 mils)

- Intermediate: Two pack aliphatic polyurethane

- Final Coat: (*ROAE: Carbothane 134 HG at 2-3

mils)

*ROAE = Recommended or ap-

proved equal

Color selection will be provided Later

Leak Detection System:

- Double bottom construction with three (3) -inch NPT half-coupling spaced at

120 degrees at perimeter of tank.

Special Tank Accessories:

- Tank level gauge tape system on exterior of tank.

- Roof-mounted level indicator.

Tank Internal Piping :

- Tank fill

- Fuel return

- Water sump drain from Tank

Fire Protection System :

- Foam System

-

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 16 of 17

Storage Tanks

Handling: Unrestricted

TABLE 2

TECHNICAL DATA SUPPLIED BY CONTRACTOR FOR FIELD ERECTED FUEL OIL

STORAGE TANK

SHEET 1 OF 2

The following technical data sheets for each tank shall be completed by Contractor and submitted

with the Bid:

Manufacturer:

Name:

Location:

1. Design Code

2. Design Pressure, psig

3. Design Temperature, F

4. Empty Weight, lb

5. Flooded Weight, lb

6. Inner Tank Diameter, ft

7. Inner Tank Wall Height, ft

8. Inner Tank Roof Height, ft

9. Outer Tank (Dike) Diameter, ft

10. Outer Tank (Dike) Height, ft

11. Storage Capacity, gallon

12. Materials (ASTM No. & Grade)

Shell Material

Plate Thickness, in

Roof Material

Plate Thickness, in

Bottom Material

Plate Thickness, in

Steel for Stairways, ladders, Platforms, Walkways,

and Supporting Members

Piping

Flanges & Nozzles

Bolts & Nuts

13. Protective Coating

Surface Finish

Primer coat (interior)

Top Coat (interior)

Primer Coat (exterior)

Top Coat (exterior)

Guarantee, years

14. Dimensional outline drawing of the tank showing overall dimensions, location of piping,

and nozzle connections.

Drawing Title:

Drawing No.:

15. Bottom liner description

16. Leak detection system description

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Document Technical specification for Field Erected Fuel Oil Page: 17 of 17

Storage Tanks

Handling: Unrestricted

TABLE 2

TECHNICAL DATA SUPPLIED BY CONTRACTOR FOR FIELD ERECTED FUEL OIL

STORAGE TANK

SHEET 2 OF 2

17. Level indication system description

18. Internal piping description

19. Tank accessories description

20. Double-bottom tank design description

21. Water sump details and description

22. List of technical exceptions to Specifications

The reproduction, transmission or use of this document or its contents is not permitted without

Siemens Power Engineering Pvt Ltd. express written authority. Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved.

MALACAS - TG5 DOC NO. SPEL/EN M&SG/11/099 REV -2

Sheet: 1 of 1

MASTER DOCUMENT LIST Template - UNID# 481718647

Yellow cells indicate the Cog Engineer to provide information - Orange cells indicate the Buyer to provide information Note to Buyer & Cog:

(SAP PROJECT #) PKZ #: PE1012 Project Name: MALACAS - TG5 Numeric revision inidates a quality

ERSR Sequence #: Sequence Description: Technical Specification for Fuel Oil Storage Tanks approved MDL from the buyer

Unit #: 01 Siemens Drwg./Spec. #: SPEL/EN M&SG/11/099 Rev: 0 Alpha revisions inidcates the

Buyer: PO Release Date: MDL is in the negotitations stage

Cog Eng: Abhijit Saha/ Chris Moering Contractual Ship Date:

Siemens SAP Supplier No: Supplier Contact Name: Country:

Siemens SAP Supplier Company Name: Supplier Contact Phone #: PDM Exchange?

Siemens SAP PD2 Purchase Order: Supplier Contact Group E-mail:

Distribution

Supplier to Confirm for Valid Reviewers Siemens Data

Allow External Publishing

COG Duration (Calendar

Project Eng. Manager

Supply Mgmt. (Lead

For Design - AE # 1

For Design - AE # 2

Thermal Equipment

Engineer of Record

Environmental Eng

Reviewer Duration

Delivery Required

Relative Delivery

Civil Engineering

(Calendar Days)

Comments /

Mechanical Eng

Process Group

Calendar Days

Architect Eng

MV Electrical

HV Electrical

LV Electrical

Plant Layout

Instructions

Constructor

Customer

Cog Eng

DCC

As-Built

Buyer)

Item #

Days)

Doc LD

I&C

Title of Document Type EDL Apply? ACTUAL DUE DATE

Dimensional outline drawing of the tank showing overall

1 dimensions, location of piping, and nozzle connections

Design Calculation of Field Erected Fuel Oil Storage Tanks

2

3 Bottom liner description

4 Leak detection system description

5 Level indication system description

6 Internal piping description

7 Tank accessories description

8 Double-bottom tank design description

9 Water sump details and description

10 List of technical exceptions to Specifications

11 Drawing of metal mechanical works applicable

12 Drawing of Fire Prevention System (1:100 scale)

13 Fire fighting system description

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

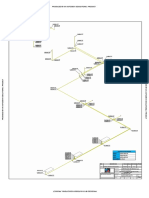

DESIGN DATA BUILDING LEGEND

I R A

1. CODE / STANDARD: API STANDARD 650

A 2. NOMINAL CAPACITY / NET WORKING CAPACITY: 6000m

Dome type 3. TANK SIZE: DIAMETER: 26200mm TOTAL HEIGHT: 12000mm A

4. PRODUCT STORED: FUEL OIL

F 5. CORROSION ALLOWANCE (mm): SHELL: 3.2 BOTTOM: 3.2 ROOF and STRUCT. : 3.2 STRUCTURALS: 0

6. SHELL DESIGN: API 650

L 7. ROOF DESIGN: - FRANGIBLE JOINT: YES

B B

8. MAX. DESIGN PRESSURE ATMOSPHERIC WORKING PRESSURE: Atmospheric LEGEND

9. DESIGN TEMPERATURE Min. 57F ; Max. 98F WORKING TEMPERATURE: min. 57F max.98F

10. EARTHQUAKE DESIGN: Seismic Zone=4.0 Soil Type =SD

P1 P2 P3 E H

N 11. WIND LOADS: 100miles/hr

12. WELD EXAMINATION / LIQUID PENETRANT: API650

C C

MATERIAL SPECIFICATION / TYPES OF INSPECTION DOCUMENTS NOTES 1. END OF PIPES ARE TO BE FITTED WITH DIVERTER PLATES TO MINIMIZE

AGITATION OF TANK CONTENTS.

2. CONTRACTORS SHALL FURNISH FLANGED CONNECTIONS SUITABLE FOR

1. SHELL PLATES: ASTM A 283,GR.C,ASTM A 36 OR EQUIVALENT 3.1.B FOR FOAM PIPING .

3. SUPPORT LUGS SHALL BE PROVIDED BY CONTRACTOR ON TANK

V=6000m3 Reinforcement Ring 2. ROOF PLATES: ASTM A 283,GR.C,ASTM A 36 OR EQUIVALENT 3.1.B

EXTERIOR FOR SUPPORT OF EXTERNAL TANK PIPING, EXTERNAL

PIPING WILL BE BY OTHERS.

4. LEAK DETECTION CONNECTIONS (3 TOTAL) PLACED AS CLOSEN AS

POSSIBLE TO THE BOTTOM, SPACED 120 AROUND THE TANK.

D 3. BOTTOM PLATES: ASTM A 283,GR.C,ASTM A 36 OR EQUIVALENT 3.1.B 5. CONNECTIONS FOR SACRIFICIAL ANODE D

4. ANNULAR BOTTOM PLATES ASTM A 283,GR.C,ASTM A 36 OR EQUIVALENT CATHODIC PROTECTION SYSTEM (BY OTHERS) SHALL BE PROVIDED.

3.1.B 6.LOCATIONS OF NOZZLES MUST BE DEFINED LATER ON.

5. MAIN STRUCTURES: ASTM A 283,GR.C,ASTM A 36 OR EQUIVALENT 3.1.B (*)-DIMENSIONS OF NOZZLES MUST BE CONFIRMED LATER ON.

EN 10204 7.THE HEIGHT OF SEALING LEG SHALL BE CALCULATED BASED ON

6. SECONDARY STRUCT: ASTM A 283,GR.C,ASTM A 36 OR EQUIVALENT 3.1.B NITROGEN BLANKETING PRESSURE..

C B 7. FLANGES: ASTM A 105/ANSI B16.5 3.1.B GRAPHIC SCALE

E 8. PIPES: ASTM A 106 Gr. B/ANSI B36.10 3.1.B E

9. BOLTS: ASTM A 307,A563 OR EQUIVALENT 3.1.B

J O 10. NUTS: ASTM A 307,A563 OR EQUIVALENT 3.1.B

K D 11. GASKETS: NON-METALLIC

12. PAINTING: AS PER SPECIFICATION REFERENCE DRAWINGS

F F

S ROOM IDENTIFICATION SYSTEM

G

M G

Double Bottom Construction

H ELEVATION H

J

55 S

120

B

FOR INFORMATION ONLY J

P 90 KEY PLAN

PLANT

NORTH

K K

MANHOLE AND NOZZLE TABULATION

L MARK QUANT. SIZE NOZZLES FLANGES TYPE SERVICE NOTES L

TYPE

C 1 6"(*) FLGRF ASME B 16.5/150# Inlet

10 O D 1 6"(*) FLGRF ASME B 16.5/150# Outlet

P 175 L 1 10"(*) FLGRF ASME B 16.5/150# Overflow Outlet

M D 0 180 Walkway M 1 6"(*) FLGRF ASME B 16.5/150# Drain

M

E 1 4"(*) FLGRF ASME B 16.5/150# Return

O 1 6"(*) FLGRF ASME B 16.5/150# Spare With Blind FL

350 H K 190 G 1 2"(*) FLGRF ASME B 16.5/150# Water Draw off

H 1 3"(*) FLGRF ASME B 16.5/150# Recirculation

J 195 S 3 1/2"(*) NPT --- Leak Detection connection

N

340 E G 200 N 1 3"(*) FLGRF ASME B 16.5/150# Level Switch

N

K 1 1.5"(*) FLGRF ASME B 16.5/150# Temperature- TI

P1,P2,P3 3 6"(*) FLGRF ASME B 16.5/150# Foam

330 S C S 210 I 1 --- --- --- Conservation Vent

F 1 2"(*) FLGRF ASME B 16.5/150# Nitrogen Inlet

P Projekt/Project PKZ/PC

P

Plateform & Ladders UNID

MALACAS TG-5

UA/DCCType

PE1012

Inhaltskennzeichen

Contents code

XXXXX

A N R Variante

Variant

XXXX

Zhl-Nr.

XXXX

Serial no. XXXX

P M 220 5. ROOF NOZZLES

Ursprung-Nr.

Origin no.

erstellt mit

Created with SP3D Abtlg.

Dept. SPEL

Q B 295 L 270 245 228.5 MARK QUANT. SIZE NOZZLES

TYPE FLANGES TYPE SERVICE NOTES

a 2011-10-14 A.S. sgd N. S. sgd FIRST ISSUE

300

Index Datum bearb. geprft

275 R 1 --- --- --- Level Instrument Tank Roof

80

Rev. Date Coord. Checked nderungshinweise/Details of revision

Gewicht

Weight

Format

Format ANSI E Mastab

Scale NTS Spez.

Specs.

J 1 3"(*) FLGRF ASME B 16.5/150# Level Instrument Datum / Date Name / Name Titel/Title

Mae nicht abgreifbar / Not to scale

gezeich.

Drawn 2011-10-14 G.K Sharma. sgd PLAN VIEW AT 0.00m

B 2 24" --- ASME B 16.5/150# Shell Manhole bearb.

Coord. 2011-10-14 A.Saha. sgd

PLAN

geprft

2011-10-14 N.Sharma. sgd

A 1 24" --- ASME B 16.5/150#

Checked

Roof Manhole Copyright (C) Siemens FIELD ERECTED FUEL OIL STORAGE TANKS

R All Rights Reserved

Handhabung

SPECIFICATION DRAWING

Handling

Zeichnungs-Nr. Index/Rev.

Drawing no.

Export classification AL: ECCN:

a

PE1012-XXXXX-XXXX-XXXXXX

20

The reproduction, transmission or use of this document or its contents is Goods labeled with "AL not equal to N" are subject to European or German export authorization when being Blatt-Nr.

not permitted without express written authority. exported out of the EU. Goods labeled with "ECCN not equal to N" are subject to US reexport authorization. Sheet no.

Offenders will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are reserved. Copyright (C) Siemens AG 2011 Even without a label, or with label "AL:N" or "ECCN:N", authorization may be required due to the final

whereabouts and purpose for which the goods are to be used. 1/1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

clh019xxxxxxx.sha

Vous aimerez peut-être aussi

- WM01 Weldingmap GNCDocument1 pageWM01 Weldingmap GNCcchristt2584Pas encore d'évaluation

- HOJA TECNICA Modulo D7039 PDFDocument8 pagesHOJA TECNICA Modulo D7039 PDFcchristt2584Pas encore d'évaluation

- AG Piping Specification SPEL en M SG 12 002 Rev0Document31 pagesAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584Pas encore d'évaluation

- Documents - MX Grinnellfirepanel PDFDocument8 pagesDocuments - MX Grinnellfirepanel PDFcchristt2584Pas encore d'évaluation

- 83V 1ceng0000Document2 pages83V 1ceng0000cchristt2584Pas encore d'évaluation

- FMM-100 Series Die-Cast Metal Fire Alarm Manual StationsDocument2 pagesFMM-100 Series Die-Cast Metal Fire Alarm Manual Stationscchristt2584Pas encore d'évaluation

- MA3000 Installation ManualDocument48 pagesMA3000 Installation Manualcchristt2584Pas encore d'évaluation

- 03aiv. DFP4 2012 C10 Technical Data PDFDocument2 pages03aiv. DFP4 2012 C10 Technical Data PDFcchristt2584Pas encore d'évaluation

- FMM-7045 Series Multiplex Addressable Manual StationsDocument2 pagesFMM-7045 Series Multiplex Addressable Manual Stationscchristt2584Pas encore d'évaluation

- Battery Calc v1 - 04 111810Document18 pagesBattery Calc v1 - 04 111810cchristt2584Pas encore d'évaluation

- Station Manual An-SgxseriesDocument2 pagesStation Manual An-Sgxseriescchristt2584Pas encore d'évaluation

- Model A240 Indicator PostDocument5 pagesModel A240 Indicator Postcchristt2584Pas encore d'évaluation

- D7030X Series LED AnnunciatorsDocument1 pageD7030X Series LED Annunciatorscchristt2584Pas encore d'évaluation

- d2300cps - SiemensDocument2 pagesd2300cps - Siemenscchristt2584Pas encore d'évaluation

- Flujometro Digital Ttfm100 Handleiding f1 NG Uk Rev231Document124 pagesFlujometro Digital Ttfm100 Handleiding f1 NG Uk Rev231cchristt2584Pas encore d'évaluation

- "DS" Series 70% "T" Series 85% "KO" Series 95% "H3" Series 90% "SL" Series 85% "HS" Series 90%Document1 page"DS" Series 70% "T" Series 85% "KO" Series 95% "H3" Series 90% "SL" Series 85% "HS" Series 90%cchristt2584Pas encore d'évaluation

- OMRON MK-I-S RelayDocument13 pagesOMRON MK-I-S Relaycchristt2584Pas encore d'évaluation

- Call Today: 800-264-8958: Diversified Air Systems, Inc. Firetrace TechnologyDocument9 pagesCall Today: 800-264-8958: Diversified Air Systems, Inc. Firetrace Technologycchristt2584Pas encore d'évaluation

- 4090 9001+Supervised+IAM+Installation+Manual+Rev+EDocument2 pages4090 9001+Supervised+IAM+Installation+Manual+Rev+Ecchristt2584Pas encore d'évaluation

- ReD AlertDocument1 pageReD Alertcchristt2584Pas encore d'évaluation

- Bonpet Zlozenka EngDocument2 pagesBonpet Zlozenka Engcchristt2584Pas encore d'évaluation

- Kennedy - Modelo 2945A - Poste IndicadorDocument14 pagesKennedy - Modelo 2945A - Poste Indicadorcchristt2584Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Brosur Reckat 2019Document16 pagesBrosur Reckat 2019wika mepPas encore d'évaluation

- Hoofdstuk 4 Heat ReducingDocument3 pagesHoofdstuk 4 Heat Reducingguichen wangPas encore d'évaluation

- Sime Format 24 System Boiler InstDocument36 pagesSime Format 24 System Boiler InstJer CotterPas encore d'évaluation

- Heat Exchangers GasketsDocument46 pagesHeat Exchangers GasketsepalaciosgeiPas encore d'évaluation

- CDG Technical PresentationDocument26 pagesCDG Technical Presentationar desPas encore d'évaluation

- Method Statement of Diesel Generator-Rev 00Document8 pagesMethod Statement of Diesel Generator-Rev 00midhun muraliPas encore d'évaluation

- 555 MMN332Document16 pages555 MMN332khaireddinPas encore d'évaluation

- Pipe Charts: Steel Pipe Steel Pipe Schedule 40Document2 pagesPipe Charts: Steel Pipe Steel Pipe Schedule 40Thái Trần VănPas encore d'évaluation

- Ersatzteilliste KolbenhubpumpeDocument59 pagesErsatzteilliste KolbenhubpumpealiwaPas encore d'évaluation

- Maleic Anhydride Plant - Equipment SummaryDocument13 pagesMaleic Anhydride Plant - Equipment Summarythanosgr1544Pas encore d'évaluation

- ENCH607-F2012-L07-Heat Transfer and Heat Transfer EquipmentDocument113 pagesENCH607-F2012-L07-Heat Transfer and Heat Transfer EquipmentmadithakPas encore d'évaluation

- Ga90 VSD AiiDocument62 pagesGa90 VSD AiiGelap Hitam Mencari PutihPas encore d'évaluation

- Astm D3681Document8 pagesAstm D3681Viswanath100% (1)

- ASME Secc II A SA-106 Specification For Seamless Carbon SteeDocument16 pagesASME Secc II A SA-106 Specification For Seamless Carbon SteeEduardo Arrieta100% (1)

- 7.1 SSIS-Material, Eqiupment ListDocument5 pages7.1 SSIS-Material, Eqiupment ListHector PhamPas encore d'évaluation

- Dynasonics TFX Ultra ManualDocument120 pagesDynasonics TFX Ultra ManualToto SukisnoPas encore d'évaluation

- Piping Presentation - PpsDocument61 pagesPiping Presentation - PpsVijayabarani100% (1)

- Repair Guidelines - Short VersionDocument13 pagesRepair Guidelines - Short Versionfrost27Pas encore d'évaluation

- Welding Chromium-Molybedenum Steel Pipe For Power Plants Induction Heating Becomes An Options For Preheat, Postweld Heat TreatmentDocument6 pagesWelding Chromium-Molybedenum Steel Pipe For Power Plants Induction Heating Becomes An Options For Preheat, Postweld Heat Treatmentروشان فاطمة روشانPas encore d'évaluation

- Compress Air Commissioning ProcedureDocument6 pagesCompress Air Commissioning Procedurevishwas salunkhePas encore d'évaluation

- Fluid Control-ChapC-2 - 2-Solenoid-Valves-Direct-Pilot-Operated-CAT-gbDocument62 pagesFluid Control-ChapC-2 - 2-Solenoid-Valves-Direct-Pilot-Operated-CAT-gbĐặng Trung AnhPas encore d'évaluation

- Impact Test DocumentDocument12 pagesImpact Test DocumentMohamed ElsayedPas encore d'évaluation

- Tube+Fittings+Catalog+Rev +CDocument82 pagesTube+Fittings+Catalog+Rev +ChaggPas encore d'évaluation

- F-14934 Parts BookDocument138 pagesF-14934 Parts BookFredyPas encore d'évaluation

- Single End Sizing TsukudomaDocument20 pagesSingle End Sizing Tsukudomabalanbhoo100% (1)

- 5.a19a PMSDocument5 pages5.a19a PMSS.selvakumarPas encore d'évaluation

- ASME IX ExerciseDocument11 pagesASME IX ExerciseRanaweera Ariyamanjula100% (1)

- ALIA AUF770 Sanitary Type Ultrasonic FlowmeterDocument4 pagesALIA AUF770 Sanitary Type Ultrasonic FlowmeterRexCrazyMindPas encore d'évaluation

- Mini a-LOK BookletDocument162 pagesMini a-LOK BookletjcastelohPas encore d'évaluation

- Saudi Aramco Typical Inspection Plan: Utility Piping Installation - Plant Air & Nitrogen Gas SATIP-L-350-09 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Utility Piping Installation - Plant Air & Nitrogen Gas SATIP-L-350-09 Mechanicalkarthi51289100% (1)