Académique Documents

Professionnel Documents

Culture Documents

A Comparative Study On Using Different Types of Membrane Combination To Treat Sewage Wastewater

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A Comparative Study On Using Different Types of Membrane Combination To Treat Sewage Wastewater

Droits d'auteur :

Formats disponibles

International Journal of Advanced and Innovative Research (2278-7844) / # 1/ Volume 6 issue 9

A Comparative Study on Using Different Types Of Membrane

Combination To Treat Sewage Wastewater

Sachin Tiwari 1 (M Tech Scholar, Raipur Institute of Technology Raipur)

Gaurav Chandrakar 2 (Asst. Professor, Raipur Institute of Technology Raipur)

Abstract In global scenario it lies in the fact that fresh water availability is very less thus the only option left for the maintaining

the sustainable development is the reuse and recycling of the used water with a proper treatment. This project toward the

sustainable development contributes the recycling of sewage water by using Membrane filtration process. The Membrane

filtration process refers the technology based on the combination of membranes in series for the treatment of wastewater and its

reuse. By using the different combinations of membrane the efficiency of water treatment can be optimized both in terms of

effluent efficiencies and in terms of cost. In the process of membrane filtration the solid particulates are rejected by the

membrane. Thus different types of membranes based upon their pore sizes and characteristics were used in a combination and

the most efficient membrane combination has been proposed in this project. The Membrane filtration is basically a suspended

growth activated sludge process that utilizes micro porous membranes for solid/liquid separation rather than secondary

clarifiers. It represents a decisive breakthrough regarding effluent quality by delivering a hygienically pure effluent and by

exhibiting an awfully high operational responsibility. Water supply and treatment demands are foreseen to face tremendous

challenges over the coming decades to meet the alarming demand of water in the country. Various treatment processes have

been predicted and membrane separation process has been identified as one of the possible solutions to meet future demands.

Application and implementation of membrane filtration technique is expected well in treatment of wastewater. Membrane

filtration technology is probably the membrane process which has its wide applicability and has the best prospects for the future

in wastewater treatment. Recent researches have indicated that this technology is becoming accepted and is rapidly becoming

the best available technology for many wastewater treatment applications. Thus, in this project various membranes have been

identified and output quality parameters of each of the membrane is computed by performing the tests over the five main

parameter of the water and have been used in different combinations for the analysis of best output parameter with the

optimized cost.

Introduction

When H2O is employed by folks for domestic, industrial use, then Wastewater is emerges. This project mainly

focuses on effluents produced by domestic use for a range of domestic purposes like laundry, bathing, flushing

bathrooms; water is used for all these things. Generally in laundry water is used for washing of utensils employed

in cookery, vegetables and alternatives food peels, bathing etc. The water emerges by these purposes contains

matter like oils in cookery, oil in hair, detergents, dirt from floors etc. This water is called as sullage or gray

Water. Water is involved in flushing of bathrooms to remove human excretion (human waste) is termed Black

Water or biodegradable pollution. Purification of Gray water is much easier than black water i.e. sewage.

However, apply preponderantly followed in India is to mix these two wastes to discharge into biodegradable

pollution treatment plant in a very residential community/building that has no access to a public sewer.

2017 IJAIR. All Rights Reserved 1

International Journal of Advanced and Innovative Research (2278-7844) / # 1/ Volume 6 issue 9

Methodology

The methodology adopted for use of different combination of membrane in Wastewater treatment plant needs a

systematic approach which includes collection, study and analysis of various data is under following heads:

1. Study and analysis for the requirement of wastewater treatment.

2. Analysis of conveyance system and other treatment process already present in the premises.

3. Detailed Study of the basic processes necessary for the treatment of wastewater.

4. Collection and testing of the sewage wastewater sample.

5. Deciding the effluent standards desired after the treatment process as per its use and under the Central Public

Health and Environment Engineering Organization (CPHEEO) limits.

6. Analyzing different types of membranes available.

7. Computing the effluent quality from different membranes.

8. Computing the effluents quality from the series membrane combination.

9. Performing analysis of the output parameter.

10. Compare all combinations and choose best possible economical / optimal membrane or their series

combination (on the basis of cost parameters and effluent qualities).

11. Suggestion for future expansion of the project.

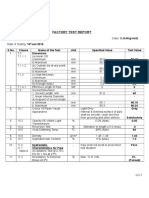

Result

Test Results of Influent Water

The Influent water quality was found by conducting several laboratory tests on the various important parameters like pH, BOD, COD, turbidity, total

suspended solid etc. The test was performed over the 12 Water samples at certain interval and for different places of Jagdalpur city.

The details of the laboratory test results of are given below:

Table 4.2: Test Results of Various Raw Sewage Sample of Jagdalpur City

Oil &

pH BOD Turbidity COD Grease TSS

Parameters (mg/l) (mg/l) (NTU) (mg/l) (mg/l) (mg/l) Place

Sample-1 8.1 345 6.7 371 0.2 212 Haatkachora (Near kendriyaVidhyalaya)

Sample-2 7.9 375 6.9 345 0.1 223 Haatkachora (Near Petrol Pump)

Sample-3 8 341 6.5 352 0 219 Sirhasar Area (Near Tiwari building)

Sample-4 7.8 350 6.5 353 0 215 Sirhasar Area (Near Hanuman Statue)

Sample-5 8.1 321 6.9 356 0.4 210 Vrindavan Colony (Near BSNL office)

Sample-6 7.7 370 7.1 354 0.1 212 Vrindavan Colony (Near Ayyappa Temple)

Sample-7 7.8 368 4.2 351 0 208 Lalbag Area ( Near Suncity)

Sample-8 7.6 351 4.3 363 0 213 Lalbag Area ( Near Ground)

Sample-9 8.2 347 7.1 350 0.8 211 Dharampura ( Near PG College)

Sample-10 7.8 274 7.4 348 0.7 216 Dharampura ( Near Sai Temple)

Sample-11 7.9 278 6.8 364 0 208 Circuit House Road ( Near Mona Lodge)

Sample-12 8.1 312 6.5 332 0 211 Circuit House Road ( Near Kiran Optical)

Average 7.9 336 6.4 353.3 0.2 213.3

2017 IJAIR. All Rights Reserved 2

International Journal of Advanced and Innovative Research (2278-7844) / # 1/ Volume 6 issue 9

Table 4.3: Characteristics of Influent Raw Sewage Water

Parameter Temperature (C) pH (mg/l) BOD (mg/l) TSS (mg/l) Turbidity (NTU)

Maximum RT 8.2 375 223 7.4

Minimum RT 7.6 274 208 4.2

Average RT 7.85 324.5 215.5 5.8

4.3.2 Effluents Test Results through Single Membrane

After done laboratory testing of sample following results are obtained for different types of Membrane -

Table 4.4: Characteristics of Treated Sewage Water thorough Single Membrane

Parameter Temperature (C) pH (mg/l) BOD (mg/l) TSS (mg/l) Turbidity (NTU)

Maximum RT 8 74 75 4.9

Cellulose

Minimum RT 7.6 61 45 4.8

Average RT 7.8 67.5 60 4.85

Parameter Temperature (C) pH (mg/l) BOD (mg/l) TSS (mg/l) Turbidity (NTU)

Charged Polysulphone Maximum RT 8.1 84 84 7.3

Polyacrylonitrile (PAN) Minimum RT 7.5 81 80 4.2

Average RT 7.75 82.5 82 5.75

Parameter Temperature (C) pH (mg/l) BOD (mg/l) TSS (mg/l) Turbidity (NTU)

Polyvinylidene Difluoride Maximum RT 7.9 74 89 7.4

(PVDF) Minimum RT 7.6 76 78 4.2

Average RT 7.65 75 83.5 5.8

Parameter Temperature (C) pH (mg/l) BOD (mg/l) TSS (mg/l) Turbidity (NTU)

Maximum RT 8.3 61 69 6.9

Polyethylene (PE)

Minimum RT 7.9 62 64 4.8

Average RT 8.1 61.5 66.5 5.85

Parameter Temperature (C) pH (mg/l) BOD (mg/l) TSS (mg/l) Turbidity (NTU)

Maximum RT 7.8 71 56 6.4

Polypropylene (PP)

Minimum RT 7.2 69.5 53 4.9

Average RT 7.5 70.25 54.5 5.65

Note: The tests were conduct0ed on a sample collection basis i.e. Random sample was collected among the group of samples and some

modifications were also made in the tests for the experimental procedures.

4.3.3 Effluent Testing Results through Series of Membrane (Average Value)

Table 4.5: Characteristics of Treated Sewage Water through Series of Membrane

Sr. No. Temperature (C) pH (mg/l) BOD (mg/l) TSS (mg/l) Turbidity (NTU) membrane

1 RT 7.4 28.6 37 3.4 Cellulose

2 RT 7.4 34.3 47 4.3 PAN

3 RT 7.4 25.1 46 5.1 PVDF

4 RT 7.4 29.3 42 4.8 PE

5 RT 7.4 26.4 36 4.9 Cellulose PP

6 RT 7.6 25.9 36 3.9 Cellulose

7 RT 7.6 29.4 32 3.8 PAN

8 RT 7.6 34.1 42 3.8 PVDF

9 RT 7.6 24.9 39 4.2 PAN PE

2017 IJAIR. All Rights Reserved 3

International Journal of Advanced and Innovative Research (2278-7844) / # 1/ Volume 6 issue 9

10 RT 7.6 26.3 37 4.3 PP

11 RT 7.4 24.8 56 4.8 Cellulose

12 RT 7.4 31.8 45 4.7 PAN

13 RT 7.4 23.9 48 4.8 PVDF

14 RT 7.4 25.1 67 4.7 PE

15 RT 7.4 28.3 53 4.6 PVDF PP

16 RT 7.5 34.8 48 4.1 Cellulose

17 RT 7.5 29.9 41 4.3 PAN

18 RT 7.5 24.9 42 4 PVDF

19 RT 7.5 31.7 44 4.2 PE

20 RT 7.5 35.1 36 4.6 PE PP

21 RT 7.4 35.9 29 3.9 Cellulose

22 RT 7.4 31.5 36 4.3 PAN

23 RT 7.4 26.3 31 4.1 PVDF

24 RT 7.4 25.7 34 4.2 PE

25 RT 7.4 27.1 37 3.3 PP PP

Table 4.6: Characteristics of Influent and Effluent Sewage Sample

Parameters Influent Sample Effluent Sample From Various Membrane Combination (avg.)

pH (mg/l) 7.6 8.2 7.4 - 7.6

BOD (mg/l) 274 375 23.9 35.9

TSS (mg/l) 208 223 29 67

Turbidity (NTU) 4.2 7.1 3.3 5.1

4.3.4 Analysis of Test Results

Thus, from the testing and analysis of various membranes and their series combinations, it can be concluded that among the various combinations

of membrane following test results are obtained and that series combination of membrane are selected which gives optimized value of effluent

parameters at a reasonable cost. The various water quality parameters are also found within the range as per lay by CPCB.

4.3.4.1 Analysis of Test Result for pH

Table 4.7: pH removal (%)

Combination of membrane CE PAN PVDF PE PP

CE 5.7 5.7 5.7 5.7 5.7

PAN 3.2 3.2 3.2 3.2 3.2

PVDF 5.7 5.7 5.7 5.7 5.7

PE 4.5 4.45 4.45 4.5 4.5

PP 5.7 5.7 5.7 5.7 5.7

4.3.4.2 Analysis of Test Result for BOD Removal

Table 4.8: BOD Removal (%)

Combination of membrane CE PAN PVDF PE PP

CE 91 89.4 92.26 91 92

PAN 92 90.9 89.49 92 92

PVDF 92 90 92.63 92 91

2017 IJAIR. All Rights Reserved 4

International Journal of Advanced and Innovative Research (2278-7844) / # 1/ Volume 6 issue 9

PE 89 90.8 92.32 90 89

PP 89 90.3 91.89 92 92

4.3.4.3 Analysis of Test Results for TSS Removal

Table 4.9: TSS Removal (%)

Combination of membrane CE PAN PVDF PE PP

CE 82.83 78.19 78.65 80.51 83.29

PAN 83.29 85.15 80.51 81.9 82.83

PVDF 74.01 79.12 77.73 68.91 75.41

PE 77.73 80.97 80.51 79.58 79.58

PP 86.54 83.29 85.61 84.22 82.83

4.3.4.4 Analysis of Test Results for Turbidity Removal

Table 4.10: Turbidity Removal (%)

Combination of membrane CE PAN PVDF PE PP

CE 41 26 12.1 17 16

PAN 33 34 34.5 28 26

PVDF 17 19 17.2 19 21

PE 29 26 31 28 22

PP 33 26 29.3 28 43

Conclusion

Municipal water treatment plants monitor drinking, waste and surface water for the presence of various water quality

parameters / microorganisms by Membrane Filtration process. Presently the MF process is essential to treat domestic and

other wastewater. Thus, from the analysis of results obtained from the tests it can be concluded that the combination of

Polypropylene (PP) and Polyethylene (PE) would give the optimum value for various parameters of sewage sample at

optimum cost and efficiency. Treated wastewater may be suggested to be used as secondary purposes like farming,

industrial cooling and horticulture uses

Table 5.1: Final Results

Parameters Output from the Minimum output Maximum output Variation

combination of PP-PE from other from other from others

combinations combinations

pH (mg/l) 7.4 7.4 7.6 ~3%

BOD (mg/l) 25.7 23.9 35.9 7-20%

TSS (mg/l) 34 29 67 14-50%

Turbidity (NTU) 4.2 3.3 5.1 15-22%

Cost (avg.) (INR) 1385 1360 2170 7-35%

References

2017 IJAIR. All Rights Reserved 5

International Journal of Advanced and Innovative Research (2278-7844) / # 1/ Volume 6 issue 9

1. Dr. Seema tiwari, 2015, water quality parameter- a review, international journal of engineering science

invention research & development; vol. I issue ix march 2015, e-issn: 2349-6185.

2. Sanjeev kumar sinha, vikas kumar sinha, samir kr. Pandey, anup tiwari, 2014, a study on the waste water

treatment technology for steel industry: recycle and reuse, volume-03, issue-04, pp-309-315, 2014, e-issn:

2320-0847 p-issn: 2320-0936, american journal of engineering research (ajer).

3. L.h. Andrade, g.e. Motta and m.c.s. Amaral (2013), treatment of dairy waste water with a membrane

bioreactor, brazilian journal of chemical engineering issn 0104-6632, vol.30, no.04, pp. 759-770.

4. Frank c.h. Ni and justin chun-te lin (2013) mbr technology applied in industrial wastewater treatment and

reclamation twelve years experiences in taiwan doi: 10.13140/2.1.3460.9924.

5. S.p. Gorde and m.v. Jadhav (2013) assessment of water quality parameter: a review, int. Journal of

engineering research and applications; issn: 2248-9622, vol.3, issue-6, 2013, pp.2029-2035.

6. Haolong bai, yitong zhou, xuan wang, liping zhang, (2012), the permeability and mechanical properties of

cellulose acetate membranes blended with polyethylene glycol 600 for treatment of municipal sewage,

procedia environmental sciences 16 (2012) 346 351.

7. Hai, f. I. & yamamoto, k. (2011), membrane biological reactors. In p. Wilderer (eds.), treatise on water

science pp. 571-613, university of wollongong, australia.

8. Kevin yeo, 2010, cost analysis of membrane bioreactors to reverse osmosis filters.

9. A. Naghizadeh, a.h. Mahavi, f. Vaezi, k. Naddafi, 2008, evaluation of hollow fiber membrane bioreactor

efficiency for municipal wastewater treatment, iran, j. Environ. Health sci. Eng., 2008, vol.5, no.4, pp.257-268.

10. Jelena radjenovi, marin mato, ivan mijatovi, mira petrovi, dami barcelo, membrane bioreactor (mbr) as an

advanced wastewater treatment technology, hdb env chem vol. 5, part s/2 (2008): 37101, doi

10.1007/698_5_093.

11. Wen, x., sui, p., and huang, x. 2008, exerting ultrasound to control the membrane fouling in filtration of

anaerobic activated sludgemechanism and membrane damage, water sci. Technol. 57, 773779.

12. Journal of environmental management, vol. 88, issue 3, august 2008, pp. 437-447.

13. Judd, s. (2006) the mbr book: principles and applications of membrane bioreactors in water and wastewater

treatment, elsevier, oxford, uk, isbn 1856174816.

14. Wintgens t, melin t, scha fer a, khan s, muston m, bixio d, thoeye c, the role of membrane processes in

municipal wastewater reclamation and reuse, desalination. 2006; 11:271282.

15. Cote p., s. Siverns, and s. Monti, 2005, comparison of membrane-based solutions for water reclamation and

desalination, desalination 182: 251-257

16. Adham s, decarolis j, and pearce w (2004), optimization of various mbr systems for water reclamation phase

iii, agreement no. 01-fc-81-0736, program final report no. 103, april 2004. Denver, co: us department of the

interior, bureau of reclamation.

17. Yuansong weia, renze t. Van houtenb, arjan r. Borgerb, dick h. Eikelboomb, yaobo f, 2003 elsevier ltd,

minimization of excess sludge production for biological wastewater treatment, water research 37 (2003)

44534467.

2017 IJAIR. All Rights Reserved 6

International Journal of Advanced and Innovative Research (2278-7844) / # 1/ Volume 6 issue 9

18. Ahn kh, park ky, maeng sk, hwang jh, lee jw, song kg, choi s., ozonation of wastewater sludge for reduction

and recycling; water sci technol 2002;46(10):717.

19. South australia water corporation, 2001, survey of immersed membrane bioreactor technology.

20. Mujeriego r., t. Asano, 1999, the role of advanced treatment in wastewater reclamation and reuse, water

science and technology 40:1-10

21. Yamamoto k, hiasa m, mahmood t, matsuo t (1989) water sci technol 21:43 membrane bioreactor (mbr) as an

advanced wastewater treatment technology 95

22. Hardt fw, clesceri ls, nemerow nl, washington dr (1970) j water pollution control fed 42:2135

23. Smith cv, gregorio d, talcott rm (1969) 24th annual purdue industrial waste conference purdue university,

lafayette, indiana, usa

24. Stephen chapman, greg leslie and ian law, membrane bioreactors (mbr) for municipal wastewater treatment

an australian perspective.

25. Cpcb, moef and who guidelines.

26. https://en.wikipedia.org/wiki/membrane_bioreactor.

27. tamime, a.y. membrane processing dairy and beverage applications chicester: wiley, isbn 1118457021.

28. Clever, m., jordt, f., knauf, r., rabiger,n., rudebusch, m., hilker- scheibel, r. (1 dec. 2000). process water

production from river water by ultrafiltration and reverse osmosis. Desalination.131 (1-3): 325-336. Doi:

10.1016/s0011-9164(00)90031-6.

2017 IJAIR. All Rights Reserved 7

Vous aimerez peut-être aussi

- Persons Characterization Into Image Sequences Using A Shape MeasureDocument4 pagesPersons Characterization Into Image Sequences Using A Shape MeasureInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Challenges in Implementing The Ethical Norms in Research On Autistic Children in The Indian ContextDocument10 pagesChallenges in Implementing The Ethical Norms in Research On Autistic Children in The Indian ContextInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- A Survey Antenna Design Structure For Massive MIMODocument3 pagesA Survey Antenna Design Structure For Massive MIMOInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- The Effect of Drying On The Phytochemical Composition of Azadirachta Indica Leaf ExtractDocument5 pagesThe Effect of Drying On The Phytochemical Composition of Azadirachta Indica Leaf ExtractInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Eradication of Karuvelam Using A Bioeconomic ModelDocument6 pagesEradication of Karuvelam Using A Bioeconomic ModelInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- A Mining Approach For Detection and Classification Techniques of Tuberculosis DiseasesDocument12 pagesA Mining Approach For Detection and Classification Techniques of Tuberculosis DiseasesInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- CPW-Fed Triangular Multiband Monopole of WIFI, WIMAX & LTEDocument5 pagesCPW-Fed Triangular Multiband Monopole of WIFI, WIMAX & LTEInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- A Compact O-Shaped Printed ACS Fed Monopole Dual-Band Antenna For 2.4 GHZ Bluetooth and 5GHz WLANWiMAX ApplicationsDocument4 pagesA Compact O-Shaped Printed ACS Fed Monopole Dual-Band Antenna For 2.4 GHZ Bluetooth and 5GHz WLANWiMAX ApplicationsInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Design and Verification of ASIP - Dual Modified Key Generator Based Encryption For Cloud StorageDocument6 pagesDesign and Verification of ASIP - Dual Modified Key Generator Based Encryption For Cloud StorageInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- DDR-SDRAM Controller ASIC Design For High Speed InterfacingDocument5 pagesDDR-SDRAM Controller ASIC Design For High Speed InterfacingInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Reduction of Isolation in MIMO Antenna Using Rupee Shaped StructureDocument6 pagesReduction of Isolation in MIMO Antenna Using Rupee Shaped StructureInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- In Vitro and in Vivo Assessment of Theantitrypanosomal Activity of Methanol Leaf Extract of Annona Muricata (Meam) On The Blood Parameters of Trypanasoma Brucei Brucei Infected Albino Rats.Document13 pagesIn Vitro and in Vivo Assessment of Theantitrypanosomal Activity of Methanol Leaf Extract of Annona Muricata (Meam) On The Blood Parameters of Trypanasoma Brucei Brucei Infected Albino Rats.International Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Small Study On Comparing The Presence of Asphaltenes and Maltenes in VG-30 Bitumen With RTFOT (Rolling Thin Film Oven Test)Document3 pagesSmall Study On Comparing The Presence of Asphaltenes and Maltenes in VG-30 Bitumen With RTFOT (Rolling Thin Film Oven Test)International Journal of Advanced and Innovative ResearchPas encore d'évaluation

- A Heuristic SOM Based Hybrid Approach For Liver Patient Disease Data ClassificationDocument6 pagesA Heuristic SOM Based Hybrid Approach For Liver Patient Disease Data ClassificationInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Ultracapacitor Based Upqc For Improved Power Quality of The SystemDocument5 pagesUltracapacitor Based Upqc For Improved Power Quality of The SystemInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- ebServiceompositionwithAuto Suggestionramework PDFDocument4 pagesebServiceompositionwithAuto Suggestionramework PDFInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Hybrid MPPT For Hybrid Energy Conversion SystemDocument7 pagesHybrid MPPT For Hybrid Energy Conversion SystemInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Determining Factors Affecting Critical Success of Construction Project ReviewDocument6 pagesDetermining Factors Affecting Critical Success of Construction Project ReviewInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- SecureandEfficientAccessControlOver P2PCloudStorageSystem PDFDocument5 pagesSecureandEfficientAccessControlOver P2PCloudStorageSystem PDFInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Robust Watermarking Using DWT-SVD & Torus Automorphism (DSTA) Based With High PSNR: A ReviewDocument4 pagesRobust Watermarking Using DWT-SVD & Torus Automorphism (DSTA) Based With High PSNR: A ReviewInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Efficient Algorithm For Big Data ApplicationDocument4 pagesEfficient Algorithm For Big Data ApplicationInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Wind and Seismic Analysis of High Rise Building With and Without Steel Bracing Using ETABSDocument6 pagesWind and Seismic Analysis of High Rise Building With and Without Steel Bracing Using ETABSInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- SurveyonRecommendationSysteminBigData Analytics PDFDocument3 pagesSurveyonRecommendationSysteminBigData Analytics PDFInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- SurveyonCloudComputingwithCloudService Model PDFDocument5 pagesSurveyonCloudComputingwithCloudService Model PDFInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Influence of Various Doses of Herbicides On Weed Flora Population, Yield Attributes and Yield of Transplanted Rice (Oryza Sativa) PDFDocument5 pagesInfluence of Various Doses of Herbicides On Weed Flora Population, Yield Attributes and Yield of Transplanted Rice (Oryza Sativa) PDFInternational Journal of Advanced and Innovative Research100% (1)

- SurveyonCloudComputingwithCloudService Model PDFDocument5 pagesSurveyonCloudComputingwithCloudService Model PDFInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Nearest-ShelterComputationinEvent-DependentSpatial Networksin Disasters PDFDocument5 pagesNearest-ShelterComputationinEvent-DependentSpatial Networksin Disasters PDFInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- SecureandEfficientAccessControlOver P2PCloudStorageSystem PDFDocument5 pagesSecureandEfficientAccessControlOver P2PCloudStorageSystem PDFInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- SurveyonRecommendationSysteminBigData Analytics PDFDocument3 pagesSurveyonRecommendationSysteminBigData Analytics PDFInternational Journal of Advanced and Innovative ResearchPas encore d'évaluation

- Influence of Various Doses of Herbicides On Weed Flora Population, Yield Attributes and Yield of Transplanted Rice (Oryza Sativa) PDFDocument5 pagesInfluence of Various Doses of Herbicides On Weed Flora Population, Yield Attributes and Yield of Transplanted Rice (Oryza Sativa) PDFInternational Journal of Advanced and Innovative Research100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- PET Resistance To H2O2Document2 pagesPET Resistance To H2O2JoanBensonPas encore d'évaluation

- PT Cahayatiara Mustika Scientific Indonesia-Catalog 2016Document212 pagesPT Cahayatiara Mustika Scientific Indonesia-Catalog 2016Dyah Noor Hidayati100% (1)

- Application & Analysis of Banana Stem Fibre Use As Construction MaterialDocument12 pagesApplication & Analysis of Banana Stem Fibre Use As Construction MaterialEditor IJTSRDPas encore d'évaluation

- Sellos T-5610 T-5610QDocument8 pagesSellos T-5610 T-5610QBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- A Combinatorial Approach To Hybrid Enzymes Independent of DNA HomologyDocument5 pagesA Combinatorial Approach To Hybrid Enzymes Independent of DNA HomologyArdiellaputriPas encore d'évaluation

- 21st Century General Chemistry 1Document382 pages21st Century General Chemistry 1Sreedevi Krishnakumar100% (1)

- Fire Characteristics of Styropor FoamsDocument4 pagesFire Characteristics of Styropor FoamsRosman Al-QadriPas encore d'évaluation

- (Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Document459 pages(Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Domenico BarillariPas encore d'évaluation

- Hydrology - Groundwater Net Flow RateDocument16 pagesHydrology - Groundwater Net Flow RatedbircsPas encore d'évaluation

- Makoto Tsubota - Quantum Turbulence: From Superfluid Helium To Atomic Bose-Einstein CondensatesDocument49 pagesMakoto Tsubota - Quantum Turbulence: From Superfluid Helium To Atomic Bose-Einstein CondensatesQMDhidnwPas encore d'évaluation

- 1N4099 1N4135, 1N4614 1N4627Document4 pages1N4099 1N4135, 1N4614 1N4627tommy99Pas encore d'évaluation

- Understanding the nonlinear dynamics of liquid flow with surge tanksDocument12 pagesUnderstanding the nonlinear dynamics of liquid flow with surge tanksLouie Fajardo AbadPas encore d'évaluation

- E-NTU Heat Transfer: LibraryDocument7 pagesE-NTU Heat Transfer: LibrarySergio AymiPas encore d'évaluation

- FTRDocument1 pageFTRanon_127491670Pas encore d'évaluation

- What is Ozone? Explaining its Role in Protecting Earth from UV RadiationDocument1 pageWhat is Ozone? Explaining its Role in Protecting Earth from UV RadiationTenveer BhuttaPas encore d'évaluation

- 4-2 Rha 2Document1 page4-2 Rha 2Dragan LazicPas encore d'évaluation

- Karkim Kar Ben enDocument1 pageKarkim Kar Ben enIqbal batchaPas encore d'évaluation

- Microencapsulation of Cinnamon and Garlic Oils in Beta-CyclodextrinDocument10 pagesMicroencapsulation of Cinnamon and Garlic Oils in Beta-CyclodextrinErman ÇutukPas encore d'évaluation

- USP-NF 857 Ultraviolet-Visible SpectrosDocument12 pagesUSP-NF 857 Ultraviolet-Visible SpectrosAbsheen ZamanPas encore d'évaluation

- Pure Substances Vs MixturesDocument25 pagesPure Substances Vs Mixturesmisterbrowner100% (7)

- Light Fastness of Blue PigmentDocument7 pagesLight Fastness of Blue PigmentShaik DawoodPas encore d'évaluation

- Jose Sentmanat Filter NewsDocument8 pagesJose Sentmanat Filter NewsLeandro ChSanzPas encore d'évaluation

- Requisition To Test For Compressive Strength of Cement Concrete Cubes For Building and Bridge WorksDocument8 pagesRequisition To Test For Compressive Strength of Cement Concrete Cubes For Building and Bridge WorksShivkumarKambalePas encore d'évaluation

- Advanced Fluid Mechanics - Chapter 04 - Very Slow MotionDocument15 pagesAdvanced Fluid Mechanics - Chapter 04 - Very Slow Motionsunil481Pas encore d'évaluation

- J. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideDocument3 pagesJ. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideFernandaIbarraVázquezPas encore d'évaluation

- Separations and Reactors Design Project Production of Allyl ChlorideDocument8 pagesSeparations and Reactors Design Project Production of Allyl ChloridefathiPas encore d'évaluation

- HW Hydraulics (setII) Ch3Document4 pagesHW Hydraulics (setII) Ch3Zairah Francisco100% (1)

- Unsymmetrical Bending: DR Alessandro PalmeriDocument40 pagesUnsymmetrical Bending: DR Alessandro PalmeriPrivat ZouobaPas encore d'évaluation

- Collection of Surface Wipe Samples For Analysis of Semi Volatile Organic Compounds (SVOCs)Document2 pagesCollection of Surface Wipe Samples For Analysis of Semi Volatile Organic Compounds (SVOCs)Berkeley AnalyticalPas encore d'évaluation

- Step By Step Guide to Free Energy Lesson 1Document1 pageStep By Step Guide to Free Energy Lesson 1vandor_ouPas encore d'évaluation