Académique Documents

Professionnel Documents

Culture Documents

Section 3 Table 3.01 - Jahra Pumping Station - Odor Control Calculations

Transféré par

HRK65Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Section 3 Table 3.01 - Jahra Pumping Station - Odor Control Calculations

Transféré par

HRK65Droits d'auteur :

Formats disponibles

Section 3 Table 3.

01 - Jahra Pumping Station - Odor Control Calculations

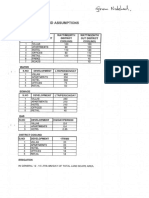

Design data for flow

Soluble [S'] min 8 mg/L

Soluble [S'] max 18 mg/L Design assumption : - Soluble [S'] - passes forward to oxydation in main aeration lanes

Soluble [S'] average 12 mg/L

average daily flow 180000 m3/day

Peak daily flow 270000 m3/day

Minimum daily flow 81000 m3/day

Average daily S' loading 2160 Kg/day

Peak daily S' loading 2160 Kg/day

Minimum daily S' loading 1458 Kg/day

It should be noted that the sulphide content of the flow arriving at KUBD will be increased

according to the additional detention time in the sewer.

Sulphide accumulation is exascerbated by the [SO4]: the low velocity and anoxic conditions occurring due to surcharge

Estimate of sulphide build up in the twin surcharged feeder mains

Cs = 0.0026 x t x CEBOD x (1+0.01d)/d ref WPCF-22

Cs = Increase in [S] mg/L

t = detention time minutes

d = pipe diameter inches 55.0

a = pipe area m2 2.01

CEBOD = 1.07 (T-20)

x BOD = 421

BOD = 300 mg/L

L = 14000 m

T = temperature = 25 deg C

ACE Int'l - Athens Page1 of 3

Eng. R. Corbishly

Section 3 Table 3.01 - Jahra Pumping Station - Odor Control Calculations

Page 32 of 158

Estimation of sulphide release at free surfaces : -

H2S flux from stream surface is calculated according to Pomeroy's formula 0.69 x CA x T x (SV)3/8 (1-q) J [DS]

CA = Turbulence factor '= 1 + [0.17V2]

gdm

T = Temperature coefficient '= 3618 = 1.32 = H2S solubility at 200C

2743 H2S solubility at 340C

S = Energy gradient '= see table m/m

V = Stream velocity '= see table m/s

q = relative H2S saturation level in air '= 0.02 typ. 2% - 20% expressed as decimal fraction

J = Prop'n of dissolved sulphide as H2S '= 0.5

[DS] = Max dissolved sulphides conc in flow '= 18.00 mg/L average flow

g = gravitational constant '= 9.8 m/s 2

dm = mean hydraulic depth '= see table (CSA of flow / wetted perimeter)

Process Nr Area L W D CA [DS''] S V dm Area fluxsf fluxsf total

m2 m m m mg/L m/m m/s m m2 g/m2/hour Kg/h

Inlet well 2 4.3 2.25 2 1.011 18.00 0.002 0.81 1.04 19.35 0.73 0.01

screens 2 8.8 2 2 1.002 18.00 0.002 0.40 1.38 35.2 0.55 0.02

wet well 2 19 10 3 1.001 18.00 0.002 0.12 0.35 380 0.36 0.14

0.17

ACE Int'l - Athens Page2 of 3

Eng. R. Corbishly

Section 3 Table 3.01 - Jahra Pumping Station - Odor Control Calculations

Page 33 of 158

ACE Int'l - Athens Page3 of 3

Eng. R. Corbishly

Section 3 Table 3.01 - Jahra Pumping Station - Odor Control Calculations

Estimate of oxygen requirements for oxidation of sulphides in the aeration basin

Soluble sulphides passed forward to aeration -5 Kg/d Average daily sulphide loading less emissions to the odour control system

Oxidation reaction : - H2S + 2O2 H2SO4

In terms of gram-moles 18 Kg + 32 Kg 50 Kg ie 1 Kg H2S requires 1.78 Kg O2 for destruction)

Oxygen requirement for sulphide removal = -9 Kg/d at average daily flow

Ventilation rates of enclosed process spaces

System Area nr A H V Air changes Vmax main duct branch duct

m2 m m3 nr/h m3/h m3/s m/s m dia nr m3/s m dia

Inlet well 2 19.35 1.5 29.025 5 145 0.0 8 0.08 2 0.02 0.06

screens 2 35.2 1.5 52.8 5 264 0.1 8 0.11 2 0.04 0.08

wet well 2 380 5 1900 5 9500 2.6 8 0.65 4 0.66 0.32

[H2S] in ventilation extract

m3/h Kg/h g/m3 loading ppm % effic'y ppmstack System Wet Chemical scrubber selection

Inlet well 145 0.01 0.097 67.7 99.5

screens 264 0.02 0.074 51.3

wet well 9500 0.14 0.014 9.9

Totals 9909 0.17 0.017 11.8 99.5 0.06 1

ACE Int'l - Athens Page4 of 3

Eng. R. Corbishly

Section 3 Table 3.01 - Jahra Pumping Station - Odor Control Calculations

Page 34 of 158

ACE Int'l - Athens Page5 of 3

Eng. R. Corbishly

Vous aimerez peut-être aussi

- Column Diameter and Hetp CheckDocument6 pagesColumn Diameter and Hetp Checkmayur1980100% (1)

- 3 Phase Separator SpreadsheetDocument4 pages3 Phase Separator SpreadsheetToyinPas encore d'évaluation

- 20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFDocument7 pages20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFahmedPas encore d'évaluation

- Despresurizacion en Recipientes (FW)Document3 pagesDespresurizacion en Recipientes (FW)salcedopozasPas encore d'évaluation

- B41OA Datasheet 2016-2017Document11 pagesB41OA Datasheet 2016-2017Turkan AliyevaPas encore d'évaluation

- GPSA MEG CalculationDocument3 pagesGPSA MEG CalculationChitu Ionut-LaurentiuPas encore d'évaluation

- Discharge Calculator - Flowrates, Jet Properties and Outfall DesignDocument35 pagesDischarge Calculator - Flowrates, Jet Properties and Outfall DesignjnmanivannanmechPas encore d'évaluation

- Dimensioning Ave MariaDocument23 pagesDimensioning Ave MariaOsoba Ismail AbiodunPas encore d'évaluation

- Objective Flow in PipeDocument3 pagesObjective Flow in PipeFatin HazwaniPas encore d'évaluation

- Sequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsDocument37 pagesSequencing Batch Reactor (SBR) Design Calculations - S.I. UnitsOn Gnios Ingeniería67% (6)

- B41OA Data Sheet 2015-2016Document10 pagesB41OA Data Sheet 2015-2016Leanne ChewPas encore d'évaluation

- WellheadModalOil GGDocument4 pagesWellheadModalOil GGKhanz KhanPas encore d'évaluation

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiPas encore d'évaluation

- Data Sheet 2014 2015 PDFDocument6 pagesData Sheet 2014 2015 PDFIdlan IzharPas encore d'évaluation

- Bottomholemodaloil GGDocument3 pagesBottomholemodaloil GGvictor javier nuñez0% (1)

- Jet Properties and Outfall DesignDocument18 pagesJet Properties and Outfall DesignNicolás Solano CondePas encore d'évaluation

- Gas cyclone particle separation calculation and designDocument6 pagesGas cyclone particle separation calculation and designNaduni RanasinghePas encore d'évaluation

- Calculation D44Document6 pagesCalculation D44hilal permanaPas encore d'évaluation

- Document From SuperjimmyDocument4 pagesDocument From SuperjimmyNoverian Ruzqia SyardiPas encore d'évaluation

- Cive1400 200102 PDFDocument16 pagesCive1400 200102 PDFInsta TecchPas encore d'évaluation

- 1.0 Objective: Lab ManualDocument2 pages1.0 Objective: Lab ManualbandarPas encore d'évaluation

- Lecture 2_BOD ModelingDocument24 pagesLecture 2_BOD ModelingArnob SarkerPas encore d'évaluation

- Formula Sheet Ctb3365Dwx - Drinking Water: Element Atomic Mass Element Atomic MassDocument2 pagesFormula Sheet Ctb3365Dwx - Drinking Water: Element Atomic Mass Element Atomic MassGiancarlo Raúl Manrique VillarrealPas encore d'évaluation

- Validation Report On The 2 Phase Line Sizing 3 PDFDocument18 pagesValidation Report On The 2 Phase Line Sizing 3 PDFJoseph MedinaPas encore d'évaluation

- 432_ProjectDocument17 pages432_ProjectApex LoftPas encore d'évaluation

- Data Hasil HE ListyaDocument3 pagesData Hasil HE ListyaFitri Gina GunawanPas encore d'évaluation

- Packed Column DesignDocument6 pagesPacked Column Designyamen-691904Pas encore d'évaluation

- Wet Gas Pseudosteady Production ForecastDocument4 pagesWet Gas Pseudosteady Production ForecastBasit Hameed AwanPas encore d'évaluation

- Pressure Loss Calculation SheetDocument6 pagesPressure Loss Calculation Sheetchuyen.reePas encore d'évaluation

- a4Document4 pagesa4beyzanisandursunPas encore d'évaluation

- Process SizingDocument41 pagesProcess SizingBóng Đá- Quán bia tổng hợp100% (1)

- Đánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDocument1 pageĐánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDuy Nguyễn VănPas encore d'évaluation

- Dispersion of Gases CalculationsDocument4 pagesDispersion of Gases CalculationsPeddy Nesa0% (1)

- C2-Ex1.packed columnBUOGDocument6 pagesC2-Ex1.packed columnBUOGjoker princePas encore d'évaluation

- 6.0 Steam/Condensate Lines Preface: Chart D 3.1Document18 pages6.0 Steam/Condensate Lines Preface: Chart D 3.1Cristhian100% (1)

- Line SizingDocument20 pagesLine SizingAhmed HassanPas encore d'évaluation

- Calculation Procedure For Determination of Approach To Equilibrium For The Methane Reforming ReactionDocument11 pagesCalculation Procedure For Determination of Approach To Equilibrium For The Methane Reforming ReactionmadhunaPas encore d'évaluation

- Vortex current-KERISI CPP - FINALDocument13 pagesVortex current-KERISI CPP - FINALSai SushankPas encore d'évaluation

- Separator Sizing and DesignDocument44 pagesSeparator Sizing and DesignKay EenPas encore d'évaluation

- Dimension Ing 2000 Me CDocument24 pagesDimension Ing 2000 Me COsoba Ismail AbiodunPas encore d'évaluation

- Geotechnical Calculation PK 24+460 & EmbankmentDocument28 pagesGeotechnical Calculation PK 24+460 & EmbankmentSanjay SwamiPas encore d'évaluation

- MBR Process Design Calculations - US UnitsDocument26 pagesMBR Process Design Calculations - US Unitsmuhammad naseemPas encore d'évaluation

- Input Values: Output Values:: Units Converter ForceDocument5 pagesInput Values: Output Values:: Units Converter ForceJeyder GeorgePas encore d'évaluation

- Rivers & Streams: Oxygen Sag Curve AnalysisDocument9 pagesRivers & Streams: Oxygen Sag Curve AnalysiskimjimPas encore d'évaluation

- Lecture 4 - CE 433Document24 pagesLecture 4 - CE 433Boos yousufPas encore d'évaluation

- Natural Abundance of The Stable Isotopes of C, O and HDocument36 pagesNatural Abundance of The Stable Isotopes of C, O and Hkishan kumarPas encore d'évaluation

- Assumptions: "!PROBLEM 8-52"Document1 pageAssumptions: "!PROBLEM 8-52"Kerlos SaeedPas encore d'évaluation

- CE 467 Exam Questions on Water and Wastewater TreatmentDocument4 pagesCE 467 Exam Questions on Water and Wastewater Treatmentfarag alhassiPas encore d'évaluation

- Compressible Flow PDFDocument38 pagesCompressible Flow PDFApple EmiratessPas encore d'évaluation

- OSD Calculation 09238Document10 pagesOSD Calculation 09238Anonymous O404LiV4CPas encore d'évaluation

- Exercise 4 (Env)Document17 pagesExercise 4 (Env)Meryem LamhamdiPas encore d'évaluation

- Water DemandDocument10 pagesWater DemandKristal SepiPas encore d'évaluation

- Tutorial ExtraDocument18 pagesTutorial ExtraNitin RautPas encore d'évaluation

- Pipeline Pressurisation & de Pressurisation CalculationDocument4 pagesPipeline Pressurisation & de Pressurisation Calculationhatakerobot50% (2)

- Water Hammer: D E K C ADocument2 pagesWater Hammer: D E K C AJohn Emmanuel Nicole PalomaresPas encore d'évaluation

- MBBR Wastewater Treatment Basin Sizing and Aeration Calculations - S.I. UnitsDocument30 pagesMBBR Wastewater Treatment Basin Sizing and Aeration Calculations - S.I. Unitsdiego80% (5)

- Gas Hydrates 1: Fundamentals, Characterization and ModelingD'EverandGas Hydrates 1: Fundamentals, Characterization and ModelingDaniel BrosetaPas encore d'évaluation

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportD'EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportPas encore d'évaluation

- Water Consumption BasisDocument6 pagesWater Consumption BasisHRK65Pas encore d'évaluation

- Basic Industrial Wastewater Treatment WorkshopDocument94 pagesBasic Industrial Wastewater Treatment Workshophenry_tan5328Pas encore d'évaluation

- ICS-A02-1103 (B1) Hydraulic Calculations (090110)Document12 pagesICS-A02-1103 (B1) Hydraulic Calculations (090110)HRK65Pas encore d'évaluation

- University Septic Tanks TextDocument68 pagesUniversity Septic Tanks Textdkm455Pas encore d'évaluation

- DAF Recent Advances PaperDocument10 pagesDAF Recent Advances PaperShashi BhushanPas encore d'évaluation

- AJKZERODISCHARGEDocument5 pagesAJKZERODISCHARGEHRK65Pas encore d'évaluation

- Anaerobic Sludge Digestion PDFDocument27 pagesAnaerobic Sludge Digestion PDFHRK65100% (1)

- Metric Refrence ManualDocument49 pagesMetric Refrence ManualHRK65Pas encore d'évaluation

- Biogas To PowerDocument2 pagesBiogas To PowerHRK65Pas encore d'évaluation

- Daf PDFDocument10 pagesDaf PDFHRK65Pas encore d'évaluation

- EXAMPLE1 UASBTreatment Process SWUSTDocument8 pagesEXAMPLE1 UASBTreatment Process SWUSTYannis Thomas100% (1)

- Pressures at Air ValvesDocument1 pagePressures at Air ValvesHRK65Pas encore d'évaluation

- UASB Sewage Design PDFDocument25 pagesUASB Sewage Design PDFHRK65Pas encore d'évaluation

- ETP DesignDocument12 pagesETP DesignHRK650% (1)

- Basic Industrial Wastewater Treatment WorkshopDocument94 pagesBasic Industrial Wastewater Treatment Workshophenry_tan5328Pas encore d'évaluation

- Utility Estimation For DevelopmentsDocument1 pageUtility Estimation For DevelopmentsHRK65Pas encore d'évaluation

- FRP Tanks Comp PDFDocument1 pageFRP Tanks Comp PDFHRK65Pas encore d'évaluation

- University Septic Tanks TextDocument68 pagesUniversity Septic Tanks Textdkm455Pas encore d'évaluation

- State Point AnalysisDocument24 pagesState Point AnalysisHRK65Pas encore d'évaluation

- Air Valve PerformanceDocument2 pagesAir Valve PerformanceHRK65Pas encore d'évaluation

- Techno - Commercial Pump Proposal: Va Tech Wabag LTDDocument12 pagesTechno - Commercial Pump Proposal: Va Tech Wabag LTDHRK65Pas encore d'évaluation

- Extreme Pressures and HeadsDocument2 pagesExtreme Pressures and HeadsHRK65Pas encore d'évaluation

- TANK CYLINDERICAL VERTICAL - OVER GROUND - 2019 Rev1Document11 pagesTANK CYLINDERICAL VERTICAL - OVER GROUND - 2019 Rev1HRK65Pas encore d'évaluation

- LUMPP Waste Water Treatment Solutions 260 001 en ADocument2 pagesLUMPP Waste Water Treatment Solutions 260 001 en AHRK65Pas encore d'évaluation

- Technical Data - Post Dilution System For Poly Range - v1.1Document1 pageTechnical Data - Post Dilution System For Poly Range - v1.1HRK65Pas encore d'évaluation

- Polymer Preparation Units Reference ListDocument2 pagesPolymer Preparation Units Reference ListHRK65Pas encore d'évaluation

- Continuous Polymer Preparation SystemsDocument6 pagesContinuous Polymer Preparation SystemsHRK65Pas encore d'évaluation

- AIRFUNDATUT1 Rev 11Document5 pagesAIRFUNDATUT1 Rev 11HRK65Pas encore d'évaluation

- AIRFUNDATUT1 Rev 11Document5 pagesAIRFUNDATUT1 Rev 11HRK65Pas encore d'évaluation

- Head Loss CalculationsDocument3 pagesHead Loss CalculationsHRK65Pas encore d'évaluation

- Mariseal 270 Version 10Document2 pagesMariseal 270 Version 10Sunny SinghPas encore d'évaluation

- Mașina de Spălat LG WD-10480Document35 pagesMașina de Spălat LG WD-10480bgm7966Pas encore d'évaluation

- Performance Evaluation of Artificial Floating Island For Nutrient Removal IJERTV8IS120022Document5 pagesPerformance Evaluation of Artificial Floating Island For Nutrient Removal IJERTV8IS120022Pavan kashappagoudarPas encore d'évaluation

- Membrane TechnologyDocument26 pagesMembrane TechnologyRajan sigdel100% (3)

- Ichnological Constrains On The Depositional Environment of The Sawahlunto Formation Kandi Northwest Ombilin Basin West Sumatra IndonesiaDocument8 pagesIchnological Constrains On The Depositional Environment of The Sawahlunto Formation Kandi Northwest Ombilin Basin West Sumatra IndonesiaAnonymous ujOX1ELPas encore d'évaluation

- RunoffDocument16 pagesRunoffDibyendu RoyPas encore d'évaluation

- Project Report On Nicotine Based Products (Nicotine Alkaloid, Nicotine Usp, Nicotine Polacrilex, Bitartrate)Document7 pagesProject Report On Nicotine Based Products (Nicotine Alkaloid, Nicotine Usp, Nicotine Polacrilex, Bitartrate)EIRI Board of Consultants and PublishersPas encore d'évaluation

- The Bacteriological Contamination of Archaeological Ceramics 2013Document9 pagesThe Bacteriological Contamination of Archaeological Ceramics 2013Giselle Ossandón S.Pas encore d'évaluation

- Eor Potential For Dulang FieldDocument8 pagesEor Potential For Dulang FieldnikenanthaPas encore d'évaluation

- Review On The Factors Affecting Ultrafiltration Hollow Fiber Membrane Operational Performance in Water TreatmentDocument16 pagesReview On The Factors Affecting Ultrafiltration Hollow Fiber Membrane Operational Performance in Water Treatmentभूषण लोहारPas encore d'évaluation

- Borang G Guideline PDFDocument7 pagesBorang G Guideline PDFsoraya100% (1)

- Vertical Turbine Pump InformationDocument10 pagesVertical Turbine Pump Informationraghu_mn100% (1)

- Jamshoro SoilDocument9 pagesJamshoro SoilAshok KumarPas encore d'évaluation

- 9ARC1991 Vertical Drains Trial at Juru, Malaysia - Performance During Construction, 1991, ThailandDocument6 pages9ARC1991 Vertical Drains Trial at Juru, Malaysia - Performance During Construction, 1991, ThailandfreezefreezePas encore d'évaluation

- CENTROPELET-ZV ZVB-serviseri-ENG N 03 2015Document22 pagesCENTROPELET-ZV ZVB-serviseri-ENG N 03 2015Miloš Stijelja75% (4)

- Qualitative Tests for Assessing Water QualityDocument21 pagesQualitative Tests for Assessing Water QualityjPas encore d'évaluation

- Antimussol UDF LiqDocument10 pagesAntimussol UDF Liqraju_hosssenPas encore d'évaluation

- Substructure design-IIT Roorkee-CED Bhupinder SinghDocument370 pagesSubstructure design-IIT Roorkee-CED Bhupinder SinghRavi Chandra100% (2)

- Road Construction Technical NotesDocument60 pagesRoad Construction Technical NotesSurajWickramasinghaPas encore d'évaluation

- Booklet PPC Jan19Document25 pagesBooklet PPC Jan19MAYURESH PATILPas encore d'évaluation

- Global Care Enviro System Tamil Nadu IndiaDocument10 pagesGlobal Care Enviro System Tamil Nadu IndiaGlobal Care Enviro SystemPas encore d'évaluation

- Robusta Cupping ProtocolsDocument9 pagesRobusta Cupping Protocolswienda100% (1)

- Brackish WaterDocument20 pagesBrackish WaterMarie PeneyraPas encore d'évaluation

- Earthwork Support ShoringDocument3 pagesEarthwork Support Shoringabdella.whateverPas encore d'évaluation

- Irrigation Ashutosh Dikshit IIM ShillongDocument12 pagesIrrigation Ashutosh Dikshit IIM ShillongsudhirnairPas encore d'évaluation

- China: Reservoirs Not Cause of DroughtDocument32 pagesChina: Reservoirs Not Cause of DroughtYousef F.FawazPas encore d'évaluation

- 16AGS - Groundwater Control in Design and Construction of Deep Basement Excavation in Singapore (150910)Document15 pages16AGS - Groundwater Control in Design and Construction of Deep Basement Excavation in Singapore (150910)krainajackaPas encore d'évaluation

- Project On Wheather DataDocument23 pagesProject On Wheather DataDeepesh YadavPas encore d'évaluation

- Water Resources: - Use and Over-Utilization of Surface and Ground Water - Floods, Drought, Conflicts Over WaterDocument48 pagesWater Resources: - Use and Over-Utilization of Surface and Ground Water - Floods, Drought, Conflicts Over Waterprasad_bathePas encore d'évaluation

- Sewage Treatment Unit: Supporting Efficiency. SINCE 1868Document6 pagesSewage Treatment Unit: Supporting Efficiency. SINCE 1868Bensend ThompsonPas encore d'évaluation