Académique Documents

Professionnel Documents

Culture Documents

Forged Brass Spring Loaded Check & Lever Operated Gate Valves

Transféré par

tanvir04169Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Forged Brass Spring Loaded Check & Lever Operated Gate Valves

Transféré par

tanvir04169Droits d'auteur :

Formats disponibles

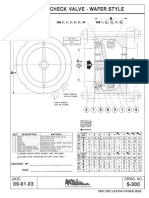

Forged Brass

Spring Loaded Check &

Lever Operated Gate Valves

700

Threaded ends to ANSI B1.20.1

B-GL

Large port

Each valve individually tested Quick opening

1.8 Deeper threads improved Lever operated

connections NPT ends ANSI ASME B1.20.1

200 PSI non-shock cold water, Class 125 WSP, 200 WOG

oil, gas

May be installed horizontally

or vertically

C A

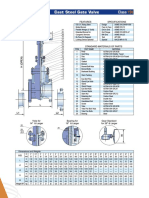

N A M E / M AT E R I A L N A M E / M AT E R I A L

1. Body / Forged Brass ASTM B283; C37700 1. Lever / Cast Aluminum ASTM B85-A03840.

H

2. Stem / Hostaform (POM) B 2. Cap / Brass ASTM B283-C37700.

3. Spring / 316 Stainless Steel 3. Cap Gasket / Saltal K (asbestos free).

4. Disc / Rubber NBR 70SH 4. Screw / UNI 5739 Gal. Steel ASTM A563

C

5. Connector/Forged Brass ASTM B283; C37700 5. Gland Nut / <3" Brass ASTM B124-C37700

P

6. Sealant / Loctite

C

6. GlandStem / <2.5" Brass ASTM B124-C37700 *

7. Gland / AF/15/MA (asbestos free).

8. Stem / Brass ASTM B283-C37700.

D 9. Disks / <1" Brass ASTM B124-C37700

WARNING: Do not use for reciprocating

air compressor service. 10. Body / Bronze ASTM B62-C83600.

4" Forged Brass ASTM B283-C37700.

optional: also available with solder ends * 2.5" & over: Forged Brass ASTM B283-C37700.

(CXC) 1" & over: Forged Brass ASTM B283-C37700.

m D I M E N S I O N S m m D I M E N S I O N S m

size (in) /41 3

/8 1

/2 3

/4 1 11/4 11/2 2 21/2 3 4 size 10 15 20 25 32 40 50 65 80 100

A 27 27 30 37 45 56 63 79 103 120 155 mm/in 3

/8 1

/2 3

/4 1 11/4 11/2 2 21/2 3 4

mm/in 1.06 1.06 1.18 1.46 1.77 2.20 2.48 3.11 4.06 4.72 6.10 A 80 80 100 100 120 136 165 205 205 255

C 10 10 11 12 13 14 15 16 18 20 22 mm/in 3.15 3.15 3.94 3.94 4.72 5.35 6.50 8.07 8.07 10.04

mm/in 0.39 0.39 0.43 0.47 0.51 0.55 0.59 0.63 0.71 0.79 0.87 B 40 40 48 55 62 68 81 108 121 148

H 45 45 48 53 59 67 70 80 93 102 119 mm/in 1.57 1.57 1.89 2.17 2.44 2.68 3.19 4.25 4.76 5.83

mm/in 1.77 1.77 1.89 2.09 2.32 2.64 2.76 3.15 3.66 4.02 4.69 C 15 15 20 25 37 40 47 58 72 82

P 8 10 15 20 25 32 40 50 65 80 100 mm/in 0.59 0.59 0.79 0.98 1.46 1.57 1.85 2.28 2.80 3.23

mm/in 0.31 0.39 0.59 0.79 0.98 1.26 1.57 1.97 2.56 3.15 3.94 D 44 48 51 57 61 67 77 93 101 115

Cv(G/M) 3.2 4.5 8 12 21 28 47 70 105 185 mm/in 1.73 1.89 2.01 2.24 2.40 2.64 3.03 3.66 3.98 4.53

pc/case 80 180 90 72 48 48 12 4 4 4 CV 5.5 10.6 17 28 69 118 185 330 485 770

net/pc(lb) 0.22 0.24 0.35 0.70 1.06 1.06 1.63 4.14 4.40 7.41 Weights 0.82 0.82 1.50 1.70 2.20 3.13 4.19 7.50 9.48 16.84

net/ctn(lb) 19.32 44.00 33.79 52.58 52.80 52.80 21.34 18.26 19.32 31.37 lb/ kg 0.37 0.37 0.68 0.77 1.00 1.42 1.90 3.40 4.30 7.64

S E A T R A T I N G S E A T R A T I N G

PSIG KPAG PSIG KPAG

200 1379

200 1379

100 689

100 689

0 0 0 0

-20 0 50 100 150 200 250 300 366 392 (F) -20 0 50 100 150 200 250 300 366 392 (F)

-29 -18 10 38 66 93 121 149 185 200 (C) -29 -18 10 38 66 93 121 149 185 200 (C)

MAS

MAS CA

CA 08/05

0304

Vous aimerez peut-être aussi

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniPas encore d'évaluation

- V3-GAN-A125 Gate Valve SpecificationDocument1 pageV3-GAN-A125 Gate Valve SpecificationArthur DeiparinePas encore d'évaluation

- Relief ValveDocument2 pagesRelief ValveRobertoPas encore d'évaluation

- Connection Dimension QTY: For Customer ApprovalDocument1 pageConnection Dimension QTY: For Customer ApprovalAsif HaqPas encore d'évaluation

- Red White Bronze Gate Valve Specs & DetailsDocument1 pageRed White Bronze Gate Valve Specs & DetailsSergio DjbucaneroPas encore d'évaluation

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitPas encore d'évaluation

- V5-GRS-A125: Gate ValveDocument1 pageV5-GRS-A125: Gate ValveChristian oliverosPas encore d'évaluation

- LT11100300 TB No. 3 - Attachments PDFDocument67 pagesLT11100300 TB No. 3 - Attachments PDFVedran KosanovicPas encore d'évaluation

- Butterfly ValvesDocument27 pagesButterfly ValvesИгорьPas encore d'évaluation

- Omn Fac 406Document52 pagesOmn Fac 406vinodPas encore d'évaluation

- Cast Steel Gate Valve Class 150 & 300 SpecificationsDocument4 pagesCast Steel Gate Valve Class 150 & 300 Specificationsarmin heidariPas encore d'évaluation

- HidraulicaDocument4 pagesHidraulicaAntonio Anatoly Viamont PintoPas encore d'évaluation

- 504 Milwaukee Valve AngleDocument1 page504 Milwaukee Valve Anglemax_powerPas encore d'évaluation

- FT Valvula Compuerta Clase 800 SWDocument1 pageFT Valvula Compuerta Clase 800 SWFernando CarreñoPas encore d'évaluation

- Keystone Butterfly Valve F 631Document4 pagesKeystone Butterfly Valve F 631Robi KeiPas encore d'évaluation

- Gala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BDocument7 pagesGala Valve Fire Fighting Catalogue 2018 V#5 - A4 - BChhomPas encore d'évaluation

- Cast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Document4 pagesCast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Sushil ChauhanPas encore d'évaluation

- Selection of Materials For Welding-1Document2 pagesSelection of Materials For Welding-1Alex joseph alexPas encore d'évaluation

- Bellows Sealed Matering Valves BM Series (Ms-01-23) R3Document4 pagesBellows Sealed Matering Valves BM Series (Ms-01-23) R3herysyam1980Pas encore d'évaluation

- 4261 Targ P TP 202 001 H7Document1 page4261 Targ P TP 202 001 H7SantiagoNicolásBergesioPas encore d'évaluation

- Ball Check ValveDocument2 pagesBall Check ValveHardik ShahPas encore d'évaluation

- KITZ - Cast Iron - 125FCL&125FCYDocument2 pagesKITZ - Cast Iron - 125FCL&125FCYdanang hadi saputroPas encore d'évaluation

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanPas encore d'évaluation

- Exhaust Gas Piping Specification-5ADocument2 pagesExhaust Gas Piping Specification-5AbhaskarPas encore d'évaluation

- Globe Valves - ASME Class 900 & 1500: Flanged EndDocument1 pageGlobe Valves - ASME Class 900 & 1500: Flanged EndMunishTrichyPas encore d'évaluation

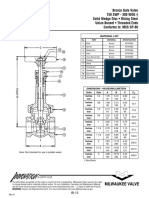

- Bronze Gate Valve 150 SWP - 300 WOG Solid Wedge Disc - Rising Stem Union Bonnet - Threaded Ends Conforms To: MSS SP-80Document1 pageBronze Gate Valve 150 SWP - 300 WOG Solid Wedge Disc - Rising Stem Union Bonnet - Threaded Ends Conforms To: MSS SP-80Soham SantraPas encore d'évaluation

- Cast Carbon Steel Strainers for Class 150, 300 & 600 Pipe SystemsDocument2 pagesCast Carbon Steel Strainers for Class 150, 300 & 600 Pipe SystemsJose RiosPas encore d'évaluation

- Butterfly Valves GuideDocument28 pagesButterfly Valves GuideLAWRENCEPas encore d'évaluation

- Technical Datasheet Combination ValveDocument5 pagesTechnical Datasheet Combination ValveNorman GarduñoPas encore d'évaluation

- Cast Iron Gate Valve ANSI-150 Series A1GA1-A150 - A1GA2-A150Document1 pageCast Iron Gate Valve ANSI-150 Series A1GA1-A150 - A1GA2-A150izatPas encore d'évaluation

- Anexo 8 - Válvula de CompuertaDocument37 pagesAnexo 8 - Válvula de CompuertaclulloaPas encore d'évaluation

- Cast Steel Float & Thermostatic Steam Trap FT450: Construction MaterialsDocument2 pagesCast Steel Float & Thermostatic Steam Trap FT450: Construction MaterialsPedroPas encore d'évaluation

- GL 125 150Document1 pageGL 125 150FABIOPas encore d'évaluation

- NZ - Valvula de BolaDocument2 pagesNZ - Valvula de Bolajorge manuelPas encore d'évaluation

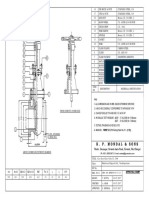

- Schem DrawingDocument2 pagesSchem DrawingMohamed ArafaPas encore d'évaluation

- Anexo 4 - Válvula de GloboDocument22 pagesAnexo 4 - Válvula de GloboclulloaPas encore d'évaluation

- RV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESDocument64 pagesRV/RR - DETAIL DRAWING OF RESILIENT SEATED AND BUTTERFLY VALVESduc22198Pas encore d'évaluation

- Piping Class Detail: ENI Database PROJ: JA0051 REV: 2 DOC: CAFC-00-SP-P-00OO30Document1 pagePiping Class Detail: ENI Database PROJ: JA0051 REV: 2 DOC: CAFC-00-SP-P-00OO30Asma GouasmiaPas encore d'évaluation

- 350 MM Gate Valve-ModelDocument1 page350 MM Gate Valve-ModelTanmoy DuttaPas encore d'évaluation

- Toyo Stainless Steel Valves PDFDocument16 pagesToyo Stainless Steel Valves PDFvirgilius lopezPas encore d'évaluation

- Class 150 Cast Carbon Steel Gate ValveDocument1 pageClass 150 Cast Carbon Steel Gate Valvearief sugiartoPas encore d'évaluation

- Fox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesDocument5 pagesFox ™ Triple Effect Air Vent + Anti Water Hammer: FeaturesNicolás Polito MuñozPas encore d'évaluation

- Van bướm thường điều khiển khí nénDocument1 pageVan bướm thường điều khiển khí nénAutoma Viet NamPas encore d'évaluation

- FNW FigDocument1 pageFNW Fighamzabayat2338Pas encore d'évaluation

- Valvula Warren-2155-5nDocument2 pagesValvula Warren-2155-5nFernando castellano castroPas encore d'évaluation

- Plummech Check ValvesDocument1 pagePlummech Check ValvesNguyễn Đăng PhúcPas encore d'évaluation

- Shinyi Catalogue 2017Document64 pagesShinyi Catalogue 2017Huy NguyễnPas encore d'évaluation

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzPas encore d'évaluation

- FMAE31Document2 pagesFMAE31Amr ATTIAPas encore d'évaluation

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingUNNIKRISHNAN NAIRPas encore d'évaluation

- 207AB Válvulas RWVDocument1 page207AB Válvulas RWVПабло Рамирес РамиресPas encore d'évaluation

- How To Order Alfa Forged Gate, Globe, and Check ValvesDocument1 pageHow To Order Alfa Forged Gate, Globe, and Check ValvesAndri AjaPas encore d'évaluation

- h525-b84b Hydrant With Alpha BaseDocument4 pagesh525-b84b Hydrant With Alpha BaseRogPas encore d'évaluation

- Filtro DuplexDocument8 pagesFiltro DuplexGuillermo ArandaPas encore d'évaluation

- Piping Class CS1 300 4Document3 pagesPiping Class CS1 300 4rakicbg100% (1)

- V4-CWD-A200: Double Door Check ValveDocument1 pageV4-CWD-A200: Double Door Check ValveArthur DeiparinePas encore d'évaluation

- Cast Iron Swing Check Valve Spec SheetDocument2 pagesCast Iron Swing Check Valve Spec SheetevelingonPas encore d'évaluation

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- API 6D Wafer Style Dual Plate Check Valves: Fig No: MV-1220Document15 pagesAPI 6D Wafer Style Dual Plate Check Valves: Fig No: MV-1220VIVEK TIWARIPas encore d'évaluation

- California Air Tools 10020C-22050 Owner's Manual 3-17 PDFDocument17 pagesCalifornia Air Tools 10020C-22050 Owner's Manual 3-17 PDFtanvir04169Pas encore d'évaluation

- Cem3581 TDocument1 pageCem3581 Ttanvir04169Pas encore d'évaluation

- Apollo 32-100 Series Regular Port Threaded Bronze Ball ValveDocument1 pageApollo 32-100 Series Regular Port Threaded Bronze Ball Valvetanvir04169Pas encore d'évaluation

- Bray 52 BrochureDocument6 pagesBray 52 Brochuretanvir04169Pas encore d'évaluation

- 8314Document4 pages8314tanvir04169Pas encore d'évaluation

- 73 PDFDocument4 pages73 PDFtanvir04169Pas encore d'évaluation

- Silent CheckDocument3 pagesSilent Checktanvir04169Pas encore d'évaluation

- ASCO 40 Pressure SensorDocument3 pagesASCO 40 Pressure Sensortanvir04169100% (1)

- 750 Gallon Vertical TankDocument1 page750 Gallon Vertical Tanktanvir04169Pas encore d'évaluation

- Silent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer StyleDocument2 pagesSilent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer Styletanvir04169Pas encore d'évaluation

- Instructions For Installing Series LF23B, LF123LP, LFN250 and LFN250BDocument2 pagesInstructions For Installing Series LF23B, LF123LP, LFN250 and LFN250Btanvir04169Pas encore d'évaluation

- APCO Silent Check PDFDocument8 pagesAPCO Silent Check PDFtanvir04169Pas encore d'évaluation

- Engineers and Geoscientists ActDocument32 pagesEngineers and Geoscientists Acttanvir04169Pas encore d'évaluation

- APEGBC Code of Ethics ensures safety and integrityDocument1 pageAPEGBC Code of Ethics ensures safety and integrityprithvikhannaPas encore d'évaluation

- A Guide To Copyright - Canadian Intellectual Property OfficeDocument13 pagesA Guide To Copyright - Canadian Intellectual Property Officetanvir04169Pas encore d'évaluation

- Apegbc BylawsDocument21 pagesApegbc Bylawstanvir04169Pas encore d'évaluation

- NPPE Exam - Multiple Choice Sample ExamDocument13 pagesNPPE Exam - Multiple Choice Sample ExamM G78% (18)

- How To Apply For A New PassportDocument6 pagesHow To Apply For A New Passporttanvir04169Pas encore d'évaluation

- PPE Sample QuestionDocument3 pagesPPE Sample Questiontanvir04169Pas encore d'évaluation

- Environmental Tech.Document31 pagesEnvironmental Tech.csyena28225Pas encore d'évaluation

- SHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsDocument8 pagesSHIP HANDLING WITH ESCORT TUGS A REFERENCE MANUAL FOR MASTERS PILOTS GIANO Tug SpecsMahmoud ElsherifPas encore d'évaluation

- Emergency Stop Valve PDFDocument4 pagesEmergency Stop Valve PDFMauricio GarciaPas encore d'évaluation

- Mks ConfigDocument5 pagesMks ConfigGabura TaniaPas encore d'évaluation

- Insulation Coordination 52 kV SystemDocument5 pagesInsulation Coordination 52 kV SystemSahil BhagatPas encore d'évaluation

- Cisco Expressway IP Port Usage For Firewall Traversal Deployment Guide X12 5Document60 pagesCisco Expressway IP Port Usage For Firewall Traversal Deployment Guide X12 5JodiePas encore d'évaluation

- Dod P 16232FDocument24 pagesDod P 16232FArturo PalaciosPas encore d'évaluation

- TUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILDocument4 pagesTUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILFaturrachman Nanu Rengga WisnuPas encore d'évaluation

- 4 LoopsDocument30 pages4 LoopsThirukkuralkaniPas encore d'évaluation

- QlikView Business Intelligence Tool OverviewDocument11 pagesQlikView Business Intelligence Tool OverviewMithun LayekPas encore d'évaluation

- Robohawks Team HandbookDocument11 pagesRobohawks Team Handbookapi-376756259Pas encore d'évaluation

- Control your ship with Kobelt electronic controlsDocument36 pagesControl your ship with Kobelt electronic controlsBERANGER DAVESNE DJOMALIA SIEWEPas encore d'évaluation

- Project-BOQ - (Excluding VUP, LVUP)Document127 pagesProject-BOQ - (Excluding VUP, LVUP)Shivendra KumarPas encore d'évaluation

- Payables Open Interface Import in Oracle Apps R12Document11 pagesPayables Open Interface Import in Oracle Apps R12sudharshan79Pas encore d'évaluation

- Catalogo-Wellhead-Marvic (Valvulas WKM EXPANDING)Document41 pagesCatalogo-Wellhead-Marvic (Valvulas WKM EXPANDING)mantilla7Pas encore d'évaluation

- Wall Climbing Surveillance Robot ReportDocument79 pagesWall Climbing Surveillance Robot Reportneha gupta100% (3)

- NOx Control of Kiln and Preheater Complete AnalysisDocument129 pagesNOx Control of Kiln and Preheater Complete AnalysisAnonymous sfY8T3q0100% (2)

- Aniosyme DD1 SDSDocument6 pagesAniosyme DD1 SDSSherwin CruzPas encore d'évaluation

- CRI PumpsDocument13 pagesCRI Pumpscrigroups0% (1)

- WT Lab ManualDocument44 pagesWT Lab ManualVenkatanagasudheer Thummapudi100% (1)

- Partition WallDocument24 pagesPartition WallSHRADDHA GHUGEPas encore d'évaluation

- MWD Log Quality & StandardsDocument168 pagesMWD Log Quality & StandardsHamed Sadeghi100% (1)

- Tacloban Master Training Schedule (January-June 2012) For Web New FormatDocument5 pagesTacloban Master Training Schedule (January-June 2012) For Web New FormatFariq AdlawanPas encore d'évaluation

- Wae 22462 AuDocument8 pagesWae 22462 AuDaniel ManolePas encore d'évaluation

- Part Number Part Name Part Number Part Name: Weichai Power WD10 Engine Spare Parts For EngineeringDocument3 pagesPart Number Part Name Part Number Part Name: Weichai Power WD10 Engine Spare Parts For EngineeringMd. Arefin Shawon100% (1)

- Irc - 24-2010 PDFDocument128 pagesIrc - 24-2010 PDFkiranPas encore d'évaluation

- Manufacturing of Urea Through Synthetic Ammonia Project ReportDocument5 pagesManufacturing of Urea Through Synthetic Ammonia Project ReportvishnuPas encore d'évaluation

- Joker User Guide 3dlabgang Rev2019 12Document14 pagesJoker User Guide 3dlabgang Rev2019 12HD's RC ChannelPas encore d'évaluation

- 319918Document4 pages319918Daniel BilickiPas encore d'évaluation

- Smart Card TechnologyDocument37 pagesSmart Card TechnologyShailesh GuptaPas encore d'évaluation