Académique Documents

Professionnel Documents

Culture Documents

Loctite 577™: Technical Data Sheet

Transféré par

Cristian SerbovTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Loctite 577™: Technical Data Sheet

Transféré par

Cristian SerbovDroits d'auteur :

Formats disponibles

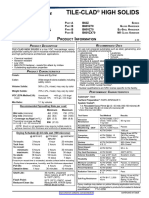

Technical Data Sheet

LOCTITE 577

(TDS for the new formulation of LOCTITE 577) August-2016

PRODUCT DESCRIPTION approval. Please contact your local Technical Service Center

LOCTITE 577 provides the following product for more information and clarification.

characteristics:

Technology Acrylic EN 751-1

Chemical Type Dimethacrylate ester Sealing materials for metallic threaded joints in contact

Appearance (uncured) Yellow pasteLMS with 1st, 2nd, and 3rd family gases and hot water; Part 1:

Fluorescence Positive under UV lightLMS Anaerobic jointing compounds. LOCTITE 577 has been

Components One component - tested and conforms to EN 751-1 for a class H compound and

requires no mixing carries the DVGW certification.

Viscosity High, thixotropic

Cure Anaerobic

Secondary Cure Activator TYPICAL PROPERTIES OF UNCURED MATERIAL

Application Thread sealing Specific Gravity @ 25 C 1.1

Strength Medium

Viscosity, Brookfield - RVT, 25 C, mPas (cP):

Spindle 6, speed 2.5 rpm 70,000 to 130,000LMS

Spindle 6, speed 20 rpm 16,000 to 33,000LMS

This Technical Data Sheet is valid for LOCTITE 577

manufactured from the dates outlined in the

Flash Point - See SDS

"Manufacturing Date Reference" section

TYPICAL CURING PERFORMANCE

LOCTITE 577 is designed for the locking and sealing of

metal threaded pipes and fittings. Particularly suitable for use

Cure Speed vs. Substrate

on stainless steel without the need for surface activation. The The rate of cure will depend on the substrate used. The graph

product cures when confined in the absence of air between below shows the breakaway strength developed with time on

close fitting metal surfaces and prevents loosening and M10 steel nuts and bolts compared to different materials and

leakage from shock and vibration. The thixotropic nature of tested according to ISO 10964.

LOCTITE 577 reduces the migration of liquid product after

application to the substrate. LOCTITE 577 provides robust 100

% of Full Strength on Steel

curing performance. It not only works on active metals (e.g. Steel

brass, copper) but also on passive substrates such as stainless 75

steel and plated surfaces. The product offers gap performance Brass

to 0.25 mm (0.01 in), high temperature performance and ate

ichrom

contamination tolerance. It cures in the presence of minor 50 Zinc d

surface contaminations from various oils, such as cutting,

lubrication, anti-corrosion and protection fluids and cleaners 25

containing surfactants and corrosion inhibitors.

Stainless steel

NSF International 0

1min 5min 30min 1h 3h 6h 24h 72h 168h

Registered to NSF Category P1 for use as a sealant where Cure Time

there is no possibilty of food contact in and around food

processing areas. Note: This is a regional approval. Please

contact your local Technical Service Center for more Cure Speed vs. Bond Gap

information and clarification. The rate of cure will depend on the bondline gap. Gaps in

threaded fasteners depends on thread type, quality and size.

The following graph shows shear strength developed with time

Approved by the Australian Gas Association Certificate

on steel pins and collars at different controlled gaps and tested

number 4787 Class III rated working pressure 2000 kPa,

according to ISO 10123.

working temperature -10 to 135C. Note: This is a regional

TDS LOCTITE 577, August-2016

% of Full Strength on Steel 100 TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties:

0.05 mm

Specific Heat, kJ/(kgK) 2.0

75 0.15 mm Tensile Strength, ISO 37 N/mm 1.3

(psi) (190)

Tensile Modulus, ISO 37 N/mm 168

50 (psi) (24,350)

0.25 mm

25 TYPICAL PERFORMANCE OF CURED MATERIAL

Adhesive Properties

After 24 hours @ 22 C

0

Breakaway Torque, ISO 10964:

1min 5min 30min 1h 3h 6h 24h 72h 168h

Cure Time M10 steel nuts and bolts Nm 33

(lb.in.) (295)

M10 brass nuts and bolts Nm 23

Cure Speed vs. Temperature (lb.in.) (205)

The rate of cure will depend on the temperature. The graph M10 zinc dichromate nuts and bolts Nm 20

below shows the breakaway strength developed with time at (lb.in.) (175)

different temperatures on M10 steel nuts and bolts and tested M10 stainless steel nuts and bolts Nm 15

according to ISO 10964. (lb.in.) (135)

M10 zinc phosphate nuts and bolts Nm 30

(lb.in.) (265)

150

% of Full Strength on Steel

M6 steel nuts and bolts Nm 7

(lb.in.) (62)

125

5 C M16 steel nuts and bolts Nm 69

22 C (lb.in.) (615)

100

3/8 x 16 steel nuts (grade 2) and bolts Nm 33

(grade 5) (lb.in.) (295)

75

40 C

50 Prevail Torque, ISO 10964:

M10 steel nuts and bolts Nm 2.5

25 (lb.in.) (22)

M10 brass nuts and bolts Nm 1.3

0 (lb.in.) (12)

1min 5min 30min 1h 3h 6h 24h 72h 168h M10 zinc dichromate nuts and bolts Nm 3.7

Cure Time (lb.in.) (33)

M10 stainless steel nuts and bolts Nm 1.9

(lb.in.) (17)

Cure Speed vs. Activator

M10 zinc phosphate nuts and bolts Nm 1.8

Where cure speed is unacceptably long, or large gaps are (lb.in.) (16)

present, applying activator to the surface will improve cure

M6 steel nuts and bolts Nm 0.7

speed. The graph below shows the breakaway strength (lb.in.) (6.2)

developed with time on M10 zinc dichromate steel nuts and M16 steel nuts and bolts Nm 7.5

bolts using Activator SF 7471 and SF 7649 and tested (lb.in.) (66)

according to ISO 10964. 3/8 x 16 steel nuts (grade 2) and bolts Nm 3.8

(grade 5) (lb.in.) (34)

100

% of Full Strength on Steel

Breakloose Torque, ISO 10964, Pre-torqued to 5 Nm:

M10 steel nuts and bolts Nm 27

75 (lb.in.) (240)

No activator Max. Prevail Torque, ISO 10964, Pre-torqued to 5 Nm:

50 F 7091 M10 steel nuts and bolts Nm 2.0

Activator S (lb.in.) (18)

SF 7471

Activator

25

Activator SF 7649 Compressive Shear Strength, ISO 10123:

Steel pins and collars N/mm 5LMS

0

1min 5min 30min 1h 3h 6h 24h 72h 168h (psi) (725)

Cure Time After 1 week @ 22 C

Breakloose Torque, ISO 10964, Pre-torqued to 5 Nm:

M10 zinc phosphate nuts and bolts Nm 30

(lb.in.) (265)

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE 577, August-2016

TYPICAL ENVIRONMENTAL RESISTANCE This product is not recommended for use in pure oxygen

Cured for 1 week @ 22 C and/or oxygen rich systems and should not be selected as

Breakloose Torque, ISO 10964, Pre-torqued to 5 Nm: a sealant for chlorine or other strong oxidizing materials.

M10 zinc phosphate steel nuts and bolts For safe handling information on this product, consult the

Safety Data Sheet (SDS).

Where aqueous washing systems are used to clean the

Hot Strength surfaces before bonding, it is important to check for

Tested at temperature compatibility of the washing solution with the adhesive. In

100

some cases these aqueous washes can affect the cure and

performance of the adhesive.

This product is not normally recommended for use on plastics

% Strength @ 22 C

75 (particularly thermoplastic materials where stress cracking of

the plastic could result). Users are recommended to confirm

compatibility of the product with such substrates.

50

Directions for use:

For Assembly

25 1. For best results, clean all surfaces (external and internal)

with a LOCTITE cleaning solvent and allow to dry.

0

2. If the material is an inactive metal or the cure speed is

0 20 40 60 80 100 120 140 160 180 too slow, spray with LOCTITE SF 7471 or LOCTITE

Temperature, C SF 7649 and allow to dry.

3. Apply a 360 bead of product to the leading threads of

Cold Strength the male fitting, leaving the first thread free. Force the

This product has been tested to -75C (-100 F). This product material into the threads to thoroughly fill the voids. For

may work below this temperature, but has not been tested. bigger threads and voids, adjust product amount

accordingly and apply a 360 bead of product on the

Heat Aging female threads also.

Aged at temperature indicated and tested @ 22 C 4. Using compliant practices, assemble and wrench tighten

150 fittings in accordance with manufacturers

recommendations.

% Initial Strength @ 22 C

120 C

125 5. Properly tightened fittings will seal instantly to moderate

pressures. For maximum pressure resistance and

100 150 C solvent resistance allow the product to cure a minimum of

180 C 24 hours.

75

For Disassembly

50 1. Remove with standard hand tools.

2. Where hand tools do not work because of excessive

25 engagement length or large diameters (over 1"), apply

localized heat to approximately 250 C (480F).

0 Disassemble while hot.

0 200 400 600 800 1000

Exposure Time, hours For Cleanup

1. Cured product can be removed with a combination of

Chemical/Solvent Resistance soaking in a LOCTITE solvent and mechanical

Aged under conditions indicated and tested @ 22 C.

abrasion such as a wire brush.

% of initial strength

Environment C 100 h 500 h 1000 h

Loctite Material SpecificationLMS

Acetone 22 95 65 70 LMS dated November-30, 2015. Test reports for each batch

DEF (AdBlue ) 22 125 125 130 are available for the indicated properties. LMS test reports

Brake Fluid (DOT 4) 22 115 115 120 include selected QC test parameters considered appropriate to

specifications for customer use. Additionally, comprehensive

Ethanol 22 110 90 90 controls are in place to assure product quality and

Motor oil 125 120 130 135 consistency. Special customer specification requirements may

(5W30 -Synthetic) be coordinated through Henkel Quality.

Unleaded Petrol 22 115 105 105

Storage

Water/glycol 50/50 87 105 95 90

Store product in the unopened container in a dry location.

B100 Bio-Diesel 22 105 115 115 Storage information may be indicated on the product container

E85 Ethanol fuel 22 100 90 90 labeling.

Optimal Storage: 8 C to 21 C. Storage below 8 C or

greater than 28 C can adversely affect product properties.

Material removed from containers may be contaminated during

GENERAL INFORMATION

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE 577, August-2016

use. Do not return product to the original container. Henkel In case products are delivered by Henkel Corporation, Resin Technology

Group, Inc., or Henkel Canada Corporation, the following disclaimer is

Corporation cannot assume responsibility for product which applicable:

has been contaminated or stored under conditions other than The data contained herein are furnished for information only and are believed to

those previously indicated. If additional information is required, be reliable. We cannot assume responsibility for the results obtained by others

please contact your local Technical Service Center or over whose methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production methods mentioned

Customer Service Representative. herein and to adopt such precautions as may be advisable for the protection of

property and of persons against any hazards that may be involved in the handling

Manufacturing Date Reference and use thereof. In light of the foregoing, Henkel Corporation specifically

This Technical Data Sheet is valid for LOCTITE 577 disclaims all warranties expressed or implied, including warranties of

merchantability or fitness for a particular purpose, arising from sale or use

manufactured from the dates below: of Henkel Corporations products. Henkel Corporation specifically

disclaims any liability for consequential or incidental damages of any kind,

Made in: First manufacturing date: including lost profits. The discussion herein of various processes or

EU February 2016 compositions is not to be interpreted as representation that they are free from

domination of patents owned by others or as a license under any Henkel

India May 2016 Corporation patents that may cover such processes or compositions. We

China May 2016 recommend that each prospective user test his proposed application before

repetitive use, using this data as a guide. This product may be covered by one or

more United States or foreign patents or patent applications.

Conversions Trademark usage

(C x 1.8) + 32 = F Except as otherwise noted, all trademarks in this document are trademarks of

kV/mm x 25.4 = V/mil Henkel Corporation in the U.S. and elsewhere. denotes a trademark

mm / 25.4 = inches registered in the U.S. Patent and Trademark Office.

m / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in Reference 1.3

N/mm x 145 = psi

MPa x 145 = psi

Nm x 8.851 = lbin

Nm x 0.738 = lbft

Nmm x 0.142 = ozin

mPas = cP

Note:

The information provided in this Technical Data Sheet (TDS) including the

recommendations for use and application of the product are based on our

knowledge and experience of the product as at the date of this TDS. The product

can have a variety of different applications as well as differing application and

working conditions in your environment that are beyond our control. Henkel is,

therefore, not liable for the suitability of our product for the production processes

and conditions in respect of which you use them, as well as the intended

applications and results. We strongly recommend that you carry out your own

prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

except if otherwise explicitly agreed and except in relation to death or personal

injury caused by our negligence and any liability under any applicable mandatory

product liability law.

In case products are delivered by Henkel Belgium NV, Henkel Electronic

Materials NV, Henkel Nederland BV, Henkel Technologies France SAS and

Henkel France SA please additionally note the following:

In case Henkel would be nevertheless held liable, on whatever legal ground,

Henkels liability will in no event exceed the amount of the concerned delivery.

In case products are delivered by Henkel Colombiana, S.A.S. the following

disclaimer is applicable:

The information provided in this Technical Data Sheet (TDS) including the

recommendations for use and application of the product are based on our

knowledge and experience of the product as at the date of this TDS. Henkel is,

therefore, not liable for the suitability of our product for the production processes

and conditions in respect of which you use them, as well as the intended

applications and results. We strongly recommend that you carry out your own

prior trials to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or any other

written or oral recommendation(s) regarding the concerned product is excluded,

except if otherwise explicitly agreed and except in relation to death or personal

injury caused by our negligence and any liability under any applicable mandatory

product liability law.

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

Vous aimerez peut-être aussi

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- Loctite 577 en UsDocument4 pagesLoctite 577 en Uschittaranjan routPas encore d'évaluation

- Loctite 638™: Technical Data SheetDocument4 pagesLoctite 638™: Technical Data SheetChinmoy BaruahPas encore d'évaluation

- Loctite 680Document4 pagesLoctite 680A DamiánPas encore d'évaluation

- Loctite 515™: Technical Data SheetDocument4 pagesLoctite 515™: Technical Data SheetNelson OsbornnePas encore d'évaluation

- LOCTITE 680 - UpgradeDocument4 pagesLOCTITE 680 - UpgradeChinmoy BaruahPas encore d'évaluation

- Loctite 271Document3 pagesLoctite 271ydwihatmanto123Pas encore d'évaluation

- Loctite 648™: Technical Data SheetDocument4 pagesLoctite 648™: Technical Data SheetEriksonPas encore d'évaluation

- Loctite-577 Thread SealantDocument4 pagesLoctite-577 Thread SealantqcselvaPas encore d'évaluation

- Loctite 648™: Technical Data SheetDocument4 pagesLoctite 648™: Technical Data SheetBahim BahimanPas encore d'évaluation

- Henkel - Loctite AA 331 - TDS PDFDocument4 pagesHenkel - Loctite AA 331 - TDS PDFDang Ngoc Tuong ViPas encore d'évaluation

- Loctite Fixmaster Metal Magic Steel™: Technical Data SheetDocument3 pagesLoctite Fixmaster Metal Magic Steel™: Technical Data SheetHamzaNoumanPas encore d'évaluation

- Loctite EA 9466™: Product Description Typical Curing Performance Fixture TimeDocument4 pagesLoctite EA 9466™: Product Description Typical Curing Performance Fixture TimeVesna NikolicPas encore d'évaluation

- LOctite SI 5900Document3 pagesLOctite SI 5900Giovanni HernandezPas encore d'évaluation

- 5570 WhiteDocument2 pages5570 WhitesasidharkanthetiPas encore d'évaluation

- 248-ENDocument4 pages248-ENPaulo BertoPas encore d'évaluation

- Loctite SI 5900: Technical Data SheetDocument3 pagesLoctite SI 5900: Technical Data SheetSanthosh Kumar RavichandranPas encore d'évaluation

- Loctite 567™: Technical Data SheetDocument3 pagesLoctite 567™: Technical Data SheetManikanta Sai KumarPas encore d'évaluation

- Loctite MR 2000™: Technical Data SheetDocument3 pagesLoctite MR 2000™: Technical Data Sheetروشان فاطمة روشانPas encore d'évaluation

- Loctite Aa V5004-EnDocument4 pagesLoctite Aa V5004-EnDan AyalaPas encore d'évaluation

- 5660 enDocument3 pages5660 enסטניסלב טלשבסקיPas encore d'évaluation

- Loctite SI 5060™: Product DescriptionDocument3 pagesLoctite SI 5060™: Product DescriptionSanthosh Kumar RavichandranPas encore d'évaluation

- DION IMPACT 9102 SeriesDocument5 pagesDION IMPACT 9102 SeriesLENEEVERSONPas encore d'évaluation

- LOCTITEDocument2 pagesLOCTITEHrPas encore d'évaluation

- SP Eng NLGI 1,2,3 2012 OctDocument3 pagesSP Eng NLGI 1,2,3 2012 OctundraazolbayarPas encore d'évaluation

- Zalac 002Document4 pagesZalac 002Stevie Herman TDPas encore d'évaluation

- Zalac 002Document3 pagesZalac 002Tarık DikbasanPas encore d'évaluation

- Si 596 Red-EnDocument3 pagesSi 596 Red-EnkabiriscPas encore d'évaluation

- Loctite 510™: Technical Data SheetDocument4 pagesLoctite 510™: Technical Data SheetYasser RezkPas encore d'évaluation

- Loctite 515 and 518 Tech. SheetDocument6 pagesLoctite 515 and 518 Tech. Sheetveronica aldridgePas encore d'évaluation

- Cepsa Arga SyntDocument1 pageCepsa Arga SyntRamonPas encore d'évaluation

- Loctite 573 - Tech - Info - Sheet - ENDocument3 pagesLoctite 573 - Tech - Info - Sheet - ENChristopherPas encore d'évaluation

- Aa 3295-En PDFDocument3 pagesAa 3295-En PDFDan AyalaPas encore d'évaluation

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechPas encore d'évaluation

- LOCTITE SI 5927 RED en - GLDocument2 pagesLOCTITE SI 5927 RED en - GLOmer IkhlasPas encore d'évaluation

- Ea 3463 enDocument3 pagesEa 3463 enasistengerenciasigsPas encore d'évaluation

- Loctitie Fix Master Ea 3463-Na-EnDocument3 pagesLoctitie Fix Master Ea 3463-Na-EnImran KhanPas encore d'évaluation

- Grasa biodegradable skf LGGB 2Document2 pagesGrasa biodegradable skf LGGB 2ALANPas encore d'évaluation

- Ea 3463 New-EnDocument2 pagesEa 3463 New-EnRonald Mario Quiroz SerratePas encore d'évaluation

- Specseal LC Endothermic Firestop Sealant: ApplicationsDocument2 pagesSpecseal LC Endothermic Firestop Sealant: ApplicationsKarim TarekPas encore d'évaluation

- Loctite EA 9464: Product DescriptionDocument3 pagesLoctite EA 9464: Product DescriptionehsanPas encore d'évaluation

- Loctite EA E-120HP: Product Description MixedDocument3 pagesLoctite EA E-120HP: Product Description MixedRavi ModyPas encore d'évaluation

- MOLYKOTE BR2 Plus Grease 80-3104A-01Document2 pagesMOLYKOTE BR2 Plus Grease 80-3104A-01Sophia RosePas encore d'évaluation

- Si 5970-EnDocument4 pagesSi 5970-EnphairyPas encore d'évaluation

- Si 5699-EnDocument3 pagesSi 5699-EnWahyu Riz AmblakadarrPas encore d'évaluation

- LT8209 Thread Sealant Upgrade SS Thread FHRPDFDocument2 pagesLT8209 Thread Sealant Upgrade SS Thread FHRPDFjuanmanuel13.diazPas encore d'évaluation

- Loctite 515™: Technical Data SheetDocument3 pagesLoctite 515™: Technical Data SheetVincent EsperanzaPas encore d'évaluation

- 242 en PDFDocument4 pages242 en PDFCamilo EspinosąPas encore d'évaluation

- 587 enDocument2 pages587 enabhayundalePas encore d'évaluation

- Molykote G-2003Document2 pagesMolykote G-2003Luz Angela GuerreroPas encore d'évaluation

- Loctite 5699 - enDocument3 pagesLoctite 5699 - enRider OaklandPas encore d'évaluation

- Graxa SKF - 2Document2 pagesGraxa SKF - 2rodrigomessiasPas encore d'évaluation

- Loctite 545: Product Description Technology Cure Speed vs. TemperatureDocument3 pagesLoctite 545: Product Description Technology Cure Speed vs. TemperatureAndrew LorzanoPas encore d'évaluation

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1Pas encore d'évaluation

- Loctite Ea 3478 - Carga MetalicaDocument3 pagesLoctite Ea 3478 - Carga Metalicafrancisca ferrerPas encore d'évaluation

- Loctite 460™: Technical Data SheetDocument3 pagesLoctite 460™: Technical Data Sheetdantewow1Pas encore d'évaluation

- Loctite 2432: Technical Data SheetDocument2 pagesLoctite 2432: Technical Data SheetFabio ParceroPas encore d'évaluation

- Steel PuttyDocument1 pageSteel PuttySiva SubramaniPas encore d'évaluation

- 190017-EN - Explosive Charge BonderDocument2 pages190017-EN - Explosive Charge BonderdatkoloPas encore d'évaluation

- Loctite 268 en UsDocument3 pagesLoctite 268 en UsmtrikPas encore d'évaluation

- ROCOL Maintenance BrochureDocument48 pagesROCOL Maintenance Brochurejeancon100% (1)

- (20200922) Theo Doi AW RFQ 1-5Document29 pages(20200922) Theo Doi AW RFQ 1-5Tuấn PhạmPas encore d'évaluation

- Galvanizedsteel PDFDocument23 pagesGalvanizedsteel PDFKok Wai100% (1)

- An Introduction To Condensers and Auxilary Equipment For Steam Power Plants R1Document34 pagesAn Introduction To Condensers and Auxilary Equipment For Steam Power Plants R1jenixson tamondongPas encore d'évaluation

- Interzinc 22Document4 pagesInterzinc 22dexterisPas encore d'évaluation

- MarineDocument6 pagesMarinesmg26thmayPas encore d'évaluation

- Bunsen Burner Gas Design and InstallationDocument10 pagesBunsen Burner Gas Design and InstallationRaulSaavedra50% (2)

- Audi A2 - Body. Construction and FunctionDocument64 pagesAudi A2 - Body. Construction and Functionspy2o100% (2)

- History of Materials: Building Materials Used For Construction, Properties and ApplicationDocument17 pagesHistory of Materials: Building Materials Used For Construction, Properties and ApplicationPau AbesPas encore d'évaluation

- Quantitative Colorimetric Determination of Ni2+ Metal Ions Using Conventional and Smart Phone Digital-Imaging MethodsDocument4 pagesQuantitative Colorimetric Determination of Ni2+ Metal Ions Using Conventional and Smart Phone Digital-Imaging MethodsShowlay ShowmanPas encore d'évaluation

- Cy6152 QBDocument10 pagesCy6152 QBYuvanManiPas encore d'évaluation

- Norris Steel Sucker Rods GuideDocument2 pagesNorris Steel Sucker Rods GuidelapinPas encore d'évaluation

- Cooling Tower Institute Win 10 JournalDocument92 pagesCooling Tower Institute Win 10 JournalprakashPas encore d'évaluation

- Design and Acceptability of a Universal Concrete SpacerDocument74 pagesDesign and Acceptability of a Universal Concrete SpacerJohn Aries Almelor SarzaPas encore d'évaluation

- WJ 2013 05Document128 pagesWJ 2013 05Matija BušićPas encore d'évaluation

- Nor R3Document29 pagesNor R3grsPas encore d'évaluation

- Metals-And-Acid-Learning-Mat Mark SchemeDocument2 pagesMetals-And-Acid-Learning-Mat Mark SchemeIva ZdravkovicPas encore d'évaluation

- Rugged Cast Iron Manual Valve Actuators IP67 SealedDocument10 pagesRugged Cast Iron Manual Valve Actuators IP67 SealedPeter RhoadsPas encore d'évaluation

- Solarwaterheatingsystems-Codeofpractice I: Indian StandardDocument14 pagesSolarwaterheatingsystems-Codeofpractice I: Indian StandardAbinashBeheraPas encore d'évaluation

- Chemrite Ferrogard 110Document2 pagesChemrite Ferrogard 110ICPL-RWPPas encore d'évaluation

- One City’s Wastewater is Another City’s Water SupplyDocument51 pagesOne City’s Wastewater is Another City’s Water SupplyDia' M. T. Ghanem100% (2)

- Scientific Glass EquipmentDocument28 pagesScientific Glass EquipmentJuan P RuizPas encore d'évaluation

- Naval ShipsDocument100 pagesNaval ShipsSaravana KumarPas encore d'évaluation

- DZR Fixed Orifice Commissioning Valve (FODRV) - ISO 228 Parallel Thread, With Regulation, Isolation and Flow Measurement FunctionsDocument7 pagesDZR Fixed Orifice Commissioning Valve (FODRV) - ISO 228 Parallel Thread, With Regulation, Isolation and Flow Measurement FunctionsMd EtPas encore d'évaluation

- Corrosion Aspects of A Nuclear Power Plant: Chemical LabDocument19 pagesCorrosion Aspects of A Nuclear Power Plant: Chemical LabSourav BasakPas encore d'évaluation

- Offshore Structural DesignDocument36 pagesOffshore Structural Designmesserklinge100% (1)

- Pneumsys Presentation Nov23Document38 pagesPneumsys Presentation Nov23rahulmadhviPas encore d'évaluation

- Ballast Tank Corrosion ProtectionDocument13 pagesBallast Tank Corrosion Protectionnima100% (1)

- Surface Engineering & Advanced Coatings SIG Final ReportDocument44 pagesSurface Engineering & Advanced Coatings SIG Final ReportMadan Pal SainiPas encore d'évaluation

- Materials System Specification: 34-SAMSS-010 03 October 2019 Quality Requirements For Pressure Retaining InstrumentsDocument10 pagesMaterials System Specification: 34-SAMSS-010 03 October 2019 Quality Requirements For Pressure Retaining Instrumentsseeralan balakrishnanPas encore d'évaluation