Académique Documents

Professionnel Documents

Culture Documents

Strain Hardening PDF

Transféré par

ebsanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Strain Hardening PDF

Transféré par

ebsanDroits d'auteur :

Formats disponibles

Issue No.

50 February 2013 Updated from Original September 2005 Publication

Strain Hardening

(This issue of Technical Tidbits continues the materials science refresher series on basic concepts of

The hard work of work

material properties.) Previous editions of Technical Tidbits have discussed strain hardening or work

hardening An in-depth hardening, as a means of strengthening a metal prior to its delivery to the customer. The temper of an

discussion of strain alloy is partially determined by the amount of strain hardening it undergoes at the production mill.

hardening in metals. However, strain hardening behavior is not limited to the mill, but occurs any time that the metal is

permanently deformed. It is also a mechanical property that not only determines how a material

strengthens, but how well it forms in a stamping die. This property can be seen in a materials true stress-

strain curve.

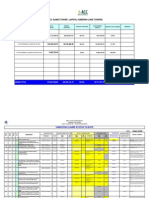

Strain The chart on the left side of Figure 1 shows the engineering and true stress-strain curve for Alloy C17410

copper beryllium strip that has appeared in previous editions of Technical Tidbits. However, there is now a

Hardening third line added in green. This is an approximation of the plastic flow, or strain hardening, behavior of the

material when the stress exceeds the yield strength. Its derivation is described below.

Work

Hardening When one plots the base 10 logarithm of true stress against the base 10 logarithm of true strain, an

interesting thing happens. The majority of the stress-strain curve falls onto two straight lines, as shown in

True Stress the chart on the right side of Figure 1. The first line, shown in blue, represents the elastic portion of the

stress-strain curve, where Hookes law holds and the elastic modulus is constant (i.e., =E ). The second

True Strain line represents the plastic region of the curve where strain hardening occurs. Here, the stress-strain

relationship can be summed up by a power law (i.e. =K n). On the logarithmic scales, this exponential

Strain function is mapped onto a straight line (log = log K + n log ), whose slope is equal to the strain

Hardening hardening exponent (n), and whose intercept with a true strain value of 1 is the strength coefficient (K).

Often, the strain hardening exponent is referred to by its symbol, and is simply called the n value. In the

Exponent (n) case shown in Figure 1, linear regression of the curve in Figure 1 finds that n = 0.0713, Log 10 K = 5.1577,

and therefore K = 143780.5. The equation describing the plastic portion of the curve is thus

Strength =143780.50.0713 psi. The green line in the plot on the left side of figure 1 shows that the power function

Coefficient (K) is a good approximation of the plastic portion of the curve, if one ignores the section in the elastic region.

n Value The strain hardening exponent (n) determines how the metal behaves when it is being formed. Materials

that have higher n values have better formability than those with low n values. As metals work harden,

their remaining capacity for work hardening decreases. This means that high strength tempers of a given

material typically would have lower n values than lower strength tempers of the same alloy. (This is

clearly illustrated by the chart on the right side of Figure 2.) Furthermore, since the yield strength is also

higher, the K value also typically would increase for higher strength tempers. However, since these

coefficients are derived from curve fitting, these trends will not necessarily hold true in reality.

Fit of Strain Hardening Coefficient and Exponent Determination of Strain Hardening Coefficient

140000 6

120000 5

Log (True Stress)

100000 4

True Stress

Elastic Stress

80000 Plastic Stress

True Stress 3 174 HTS

The next issue of 60000

Linear (Plastic Stress)

K*strain^n

Technical Tidbits 2

40000 Engineering Stress log (stress)=n*log(strain)+log(K)

continues the 1

20000 y = 0.0713x + 5.1577

discussion on strain 0

0

hardening. 0 0.05 True Strain 0.1 0.15

-4 -3 -2 -1 0

Log (True Strain)

Figure 1. True Stress-Strain Curve on Linear Scale (Left),

and True Stress-Strain Curve on Logarthmic Scale (Right)

2013 Materion Brush Performance Alloys

Strain Hardening (continued) Recall that cold-rolled tempers of a material are defined by the

amount of strain hardening, or cold work, to which they are subjected after the final anneal. The chart

on the left side of Figure 2 shows the true stress-strain curves for 4 cold-rolled tempers of N03360

nickel beryllium alloy strip plotted on the same set of axes. The elastic moduli of all 4 samples are

equal, but the strain hardening regions are very different. As the temper increases, the yield strength

increases as is evidenced by the progressively higher curves. The amount of elongation decreases with

the temper, as is evidenced by the progressively shorter curves. However, remember that by ASTM

temper definitions 1/4 H temper material is simply annealed strip that has been given 10.9% cold work,

or 0.116 true strain. Furthermore, 1/2 H temper has been given 20.7% cold work and 0.232 true strain,

and H temper has been cold worked 29.4% for 0.347 true strain. If the true stress-strain curves are

replotted with the initial strain taken into consideration, the reasons for the trends in strength and

elongation become obvious. This is graphically shown in the chart on the right of Figure 2. The plastic

portions of the higher strength temper nearly form a continuous curve along the curve for the annealed

temper. The samples shown below are from separate heats, each processed to different ready-to-finish

gauges at the final anneal and different final thicknesses, which accounts for the variation. If they were

identically processed from the same material and just given the different amounts of cold work at the

final step, then the curves would have been expected to line up exactly (barring minor differences due to

Please contact your local

differing thicknesses).

sales representative for

The key points to take away from all this are that a materials capacity to be permanently deformed further information on

depends on the strain hardening exponent. A materials formability is dictated by how it strain hardens strain hardening or other

questions pertaining to

when permanently deformed. Alloys with high strain hardening exponents will tend to form better than

Materion or our products.

materials with low values. Higher strength tempers of a given alloy will have less formability than

lower strength tempers of the same alloy, because some of their capacity for strain hardening has

already been used up in the cold rolling process. This is why formability of strip material decreases

with increasing temper. Also, this is why precipitation hardenable alloys like copper beryllium or nickel

beryllium tend to have better strength to formability ratios than alloys that are strengthened entirely by

cold work, since alloys that are heat treated do not require as much cold work to reach a given strength

level.

800000 N03360 Cold Rolled Nickel Beryllium Strip 800000 N03360 Cold Rolled Nickel Beryllium Strip

Stress-Strain Curves Stress-Strain Curves

700000 700000

360 A Stress

360 1/4 H Stress

600000 600000

360 1/2 H Stress

True Stress (psi)

True Stress (psi)

500000 500000 360 H Stress

400000 400000

Health and Safety

300000 360 A Stress 300000 Handling copper beryllium in

360 1/4 H Stress

200000 200000

solid form poses no special

360 1/2 H Stress

100000 360 H Stress

health risk. Like many

100000

industrial materials, beryllium-

0

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35

0 containing materials may pose a

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

True Strain True Strain health risk if recommended safe

handling practices are not

Figure 2. True Stress-Strain Curves for Alloy 360 NiBe Strip Plotted with All Curves Starting at the Origin followed. Inhalation of airborne

beryllium may cause a serious

(Left), and with All Curves Adjusted for the Strain Imparted by the Cold Working Process (Right). lung disorder in susceptible

individuals. The Occupational

Written by Mike Gedeon of Materion Brush Performance Alloys Customer Technical Service Safety and Health

Department. Mr. Gedeons primary focus is on electronic strip for the telecommunications Administration (OSHA) has set

mandatory limits on

and computer markets with emphasis on Finite Element Analysis (FEA) and material occupational respiratory

selection. exposures. Read and follow the

guidance in the Material Safety

Data Sheet (MSDS) before

working with this material. For

additional information on safe

handling practices or technical

data on copper beryllium,

contact Materion Brush

Materion Brush Performance Alloys Performance Alloys

6070 Parkland Blvd.

Mayfield Heights, OH 44124

(216) 486-4200

(216) 383-4005 Fax

(800) 375-4205 Technical Service

2013 Materion Brush Performance Alloys

Vous aimerez peut-être aussi

- Strain Hardening Exponent-Sep-Oct 2005Document2 pagesStrain Hardening Exponent-Sep-Oct 20056541646Pas encore d'évaluation

- 10 - Fundamentals of Metal Forming (Chapter 14)Document37 pages10 - Fundamentals of Metal Forming (Chapter 14)Taher al suhamiPas encore d'évaluation

- Uji TarikDocument49 pagesUji Tarikberlian pulungPas encore d'évaluation

- 2010 SharmaPK Techandhealthcare MechanicsofmaterialsDocument13 pages2010 SharmaPK Techandhealthcare MechanicsofmaterialsMarcus AffulPas encore d'évaluation

- Fatica Oligociclica PDFDocument116 pagesFatica Oligociclica PDFPaoloPetraglia100% (1)

- הרצאה 7Document44 pagesהרצאה 7api-26922789Pas encore d'évaluation

- Slide 5 Metal Forming IntroDocument72 pagesSlide 5 Metal Forming IntrogunjanPas encore d'évaluation

- Lecture3 SlidesDocument17 pagesLecture3 SlidesRabab AssemPas encore d'évaluation

- Joules X M N X N KX DX KX X D F W: MATE 431 - 2010 HW1 Solution SheetDocument6 pagesJoules X M N X N KX DX KX X D F W: MATE 431 - 2010 HW1 Solution SheetIndra H BasriPas encore d'évaluation

- True Stress-Strain ME 207 - Chapter 3 - P3Document13 pagesTrue Stress-Strain ME 207 - Chapter 3 - P3klausoshoPas encore d'évaluation

- Chapter-1 SOM 2010 - 7Document1 pageChapter-1 SOM 2010 - 7Amit MondalPas encore d'évaluation

- Mechanical Properties of Metals ( ) : Dr. Aneela Wakeel 09-01-2017Document39 pagesMechanical Properties of Metals ( ) : Dr. Aneela Wakeel 09-01-2017Jawad AhmedPas encore d'évaluation

- Strength of Materials 2015 by S K MondalDocument473 pagesStrength of Materials 2015 by S K MondalNitik KumarPas encore d'évaluation

- 02 Drill String DesignDocument99 pages02 Drill String DesignArkhatTompakovPas encore d'évaluation

- Mechanical Properties of Engineering MaterialsDocument48 pagesMechanical Properties of Engineering MaterialsCarlos Andres Pinzon LoaizaPas encore d'évaluation

- Mae 244 7sep05 Tensile and ImpactDocument9 pagesMae 244 7sep05 Tensile and Impactapi-3730129100% (2)

- lmcm2 Aula4Document26 pageslmcm2 Aula4Daryll Escusa100% (1)

- Design and Performance of Bridge Cap Beam/Column Joints Using Headed Reinforcement and Mechanical CouplersDocument92 pagesDesign and Performance of Bridge Cap Beam/Column Joints Using Headed Reinforcement and Mechanical CouplersDiego Leonel Suárez VásquezPas encore d'évaluation

- Tutorial 2 - Stress Strain Tensile TestingDocument28 pagesTutorial 2 - Stress Strain Tensile TestingZadrin TuckerPas encore d'évaluation

- Mechanical Properties of Metals: StrainDocument26 pagesMechanical Properties of Metals: StrainAd Man GeTigPas encore d'évaluation

- Closed-Book Practice-Ch 06 (2016!07!31)Document8 pagesClosed-Book Practice-Ch 06 (2016!07!31)JuanPas encore d'évaluation

- Fracture Mechanics GuideDocument72 pagesFracture Mechanics GuideSrinivas Kumar100% (1)

- Lec-4-Flexural Analysis and Design of BeamnsDocument15 pagesLec-4-Flexural Analysis and Design of BeamnsManoj BalakrishnanPas encore d'évaluation

- Prof. Zahid Ahmad Siddiqi Lec-3-Flexural Analysis and Design of BeamnsDocument15 pagesProf. Zahid Ahmad Siddiqi Lec-3-Flexural Analysis and Design of Beamnsrana100% (1)

- Lab 4 - 332LDocument5 pagesLab 4 - 332LAsem HalawaniPas encore d'évaluation

- Lec-4-Flexural Analysis and Design of BeamnsDocument15 pagesLec-4-Flexural Analysis and Design of BeamnshamzaPas encore d'évaluation

- Lecture 07 Mechanical Properties 2Document20 pagesLecture 07 Mechanical Properties 2antoine demeirePas encore d'évaluation

- Chapter 5Document6 pagesChapter 5tabloid07Pas encore d'évaluation

- Machine Design (Term Paper)Document7 pagesMachine Design (Term Paper)Sajawal KhanPas encore d'évaluation

- Laboratory Experiment # 1: Error! No Text of Specified Style in DocumentDocument8 pagesLaboratory Experiment # 1: Error! No Text of Specified Style in DocumentM Asjid SaeedPas encore d'évaluation

- Review of Stress-Strain Due To Flexure: CE 437/537, Spring 2014 1 / 5Document5 pagesReview of Stress-Strain Due To Flexure: CE 437/537, Spring 2014 1 / 5Hussein MouzannarPas encore d'évaluation

- MECHANICS OF DEFORMABLE BODIESDocument106 pagesMECHANICS OF DEFORMABLE BODIESVinayak PrabhuPas encore d'évaluation

- Critical-State Soil Mechanics For Dummies: Paul W. Mayne, PHD, P.EDocument22 pagesCritical-State Soil Mechanics For Dummies: Paul W. Mayne, PHD, P.ENajihaPas encore d'évaluation

- Structural Details To Increase Ductility of ConnectionsDocument12 pagesStructural Details To Increase Ductility of ConnectionsNicușor SfârleaPas encore d'évaluation

- Strength Ch3Document34 pagesStrength Ch3Aya ShalaboPas encore d'évaluation

- Mechanical Properties 1Document27 pagesMechanical Properties 1Dr.Risalah A MohammedPas encore d'évaluation

- ME 303 (Manufacturing Engineering) - 03 - Material Properties IIDocument46 pagesME 303 (Manufacturing Engineering) - 03 - Material Properties IITt OwnsqqPas encore d'évaluation

- CE 433 Stress-Strain ReviewDocument5 pagesCE 433 Stress-Strain ReviewIhab SorourPas encore d'évaluation

- Stress Strain RelationDocument29 pagesStress Strain RelationZuhair QamarPas encore d'évaluation

- Ch3. Stress and StrainsDocument49 pagesCh3. Stress and StrainsAbimael wendimuPas encore d'évaluation

- Mechanical properties overviewDocument59 pagesMechanical properties overviewNeil BosePas encore d'évaluation

- MECH 321 Practice Problem Set SolutionsDocument4 pagesMECH 321 Practice Problem Set SolutionsMetehan AtagürPas encore d'évaluation

- Cast Steel: True Stress - True Strain Curve: AbstractDocument5 pagesCast Steel: True Stress - True Strain Curve: AbstractAli ErdoganPas encore d'évaluation

- Lecture Notes - Metal Forming PDFDocument68 pagesLecture Notes - Metal Forming PDFIrfan KhanPas encore d'évaluation

- L14 20 T7 9 MOS With SolutionsDocument115 pagesL14 20 T7 9 MOS With SolutionsJithin SreeshanPas encore d'évaluation

- Thermal StressDocument104 pagesThermal Stressmanishtopsecrets100% (1)

- Dynamic Fatigue Life of RubberDocument5 pagesDynamic Fatigue Life of RubberPiet VeermanPas encore d'évaluation

- CSSM For DummiesDocument23 pagesCSSM For DummiesAdrián FernándezPas encore d'évaluation

- CH 06Document34 pagesCH 06Firas Abu talebPas encore d'évaluation

- Fib2014 408 Grammatikou Et Al Full PaperDocument10 pagesFib2014 408 Grammatikou Et Al Full Paperhasan aziziPas encore d'évaluation

- Mechanical Properties of Metals 1201349582254633 4Document26 pagesMechanical Properties of Metals 1201349582254633 4andresr36100% (3)

- Mechanical Properties Guide for MaterialsDocument55 pagesMechanical Properties Guide for MaterialsbinoPas encore d'évaluation

- Plastic AnalysisDocument31 pagesPlastic Analysisgaiagmr100% (1)

- Mechanical Properties of Metals: StrainDocument27 pagesMechanical Properties of Metals: Strainrr pandianPas encore d'évaluation

- Lecture 18 - Mechanical Tesing and AnalysisDocument15 pagesLecture 18 - Mechanical Tesing and AnalysisyonathanPas encore d'évaluation

- Mechanical Science for Technicians: Volume 1D'EverandMechanical Science for Technicians: Volume 1Évaluation : 5 sur 5 étoiles5/5 (1)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresD'EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresÉvaluation : 4 sur 5 étoiles4/5 (1)

- Pendukung pvc2Document1 pagePendukung pvc2ebsanPas encore d'évaluation

- Debris Filter: Water Box KondensorDocument1 pageDebris Filter: Water Box KondensorebsanPas encore d'évaluation

- Key 2Document1 pageKey 2ebsanPas encore d'évaluation

- Jawab 7Document2 pagesJawab 7ebsanPas encore d'évaluation

- Introduction to Cryogenic SystemsDocument1 pageIntroduction to Cryogenic SystemsebsanPas encore d'évaluation

- Bahan 6Document1 pageBahan 6ebsanPas encore d'évaluation

- Bahan 5Document1 pageBahan 5ebsanPas encore d'évaluation

- Key 2Document1 pageKey 2ebsanPas encore d'évaluation

- Jawab 8Document2 pagesJawab 8ebsanPas encore d'évaluation

- Bahan 6Document1 pageBahan 6ebsanPas encore d'évaluation

- Questio SDocument1 pageQuestio SebsanPas encore d'évaluation

- Bagian EksperimentalDocument1 pageBagian EksperimentalebsanPas encore d'évaluation

- Bahan 6Document1 pageBahan 6ebsanPas encore d'évaluation

- Bahan 4Document1 pageBahan 4ebsanPas encore d'évaluation

- Soal 2Document1 pageSoal 2ebsanPas encore d'évaluation

- Tempert Jurnal PDFDocument6 pagesTempert Jurnal PDFebsanPas encore d'évaluation

- Erf TablesDocument0 pageErf TablesRaúl Antonio Morales DomínguezPas encore d'évaluation

- Mmax PL: P 200 N, L 100 MM, and X 2Document3 pagesMmax PL: P 200 N, L 100 MM, and X 2ebsanPas encore d'évaluation

- 1172936614Document1 page1172936614ebsanPas encore d'évaluation

- Erf TablesDocument0 pageErf TablesRaúl Antonio Morales DomínguezPas encore d'évaluation

- Erf TablesDocument0 pageErf TablesRaúl Antonio Morales DomínguezPas encore d'évaluation

- Tugas Pengganti Kuliah Prinsip Korosi Kumpulkan Tugas Ini Di Sesi Kuliah Jam 08 - 10, Sabtu 23 September 2017Document1 pageTugas Pengganti Kuliah Prinsip Korosi Kumpulkan Tugas Ini Di Sesi Kuliah Jam 08 - 10, Sabtu 23 September 2017ebsanPas encore d'évaluation

- Mechanics of Materials IntroductionDocument51 pagesMechanics of Materials IntroductionebsanPas encore d'évaluation

- Erf TablesDocument0 pageErf TablesRaúl Antonio Morales DomínguezPas encore d'évaluation

- Overall M1H: Turbine Cooling Air Fan 1ADocument5 pagesOverall M1H: Turbine Cooling Air Fan 1AebsanPas encore d'évaluation

- Overall M1H: Turbine Cooling Air Fan 1ADocument5 pagesOverall M1H: Turbine Cooling Air Fan 1AebsanPas encore d'évaluation

- Cooling and Heating Load CalculationDocument48 pagesCooling and Heating Load CalculationDaniel YoworldPas encore d'évaluation

- Stone Slope StabilityDocument9 pagesStone Slope Stabilitypakbilal1Pas encore d'évaluation

- Amendment No. 5 July 2019 TO Is 456: 2000 Plain and Reinforced Concrete - Code of PracticeDocument7 pagesAmendment No. 5 July 2019 TO Is 456: 2000 Plain and Reinforced Concrete - Code of Practiceraviteja036Pas encore d'évaluation

- Conversion table of EN - Materials vs. US Materials (assorted by ASTM NoDocument1 pageConversion table of EN - Materials vs. US Materials (assorted by ASTM NoNattapong PongbootPas encore d'évaluation

- SEJIN ProfileDocument42 pagesSEJIN ProfilehungletePas encore d'évaluation

- 40RBW - Catalog - Single SkinDocument12 pages40RBW - Catalog - Single SkinPhuNguyenHoangPas encore d'évaluation

- Helmet Color Code For Construction SitesDocument38 pagesHelmet Color Code For Construction SitesChandrasekhar ChintadaPas encore d'évaluation

- Timber SeasoningDocument3 pagesTimber SeasoningEllz LahCe Gimotea BaluyutPas encore d'évaluation

- Building Inspection Checklist For Fire and General SafetyDocument3 pagesBuilding Inspection Checklist For Fire and General SafetyShayazAhSmdPas encore d'évaluation

- Belt Conveyor Pulley DesignDocument11 pagesBelt Conveyor Pulley Designthakur_raghab100% (1)

- Pipeline Stress Corrosion CrackingDocument7 pagesPipeline Stress Corrosion CrackingWendy AguilarPas encore d'évaluation

- Notes Earthing 23 03 20 PDFDocument11 pagesNotes Earthing 23 03 20 PDFAkhilesh MendonPas encore d'évaluation

- How Motorcycle Exhaust Pipes Are Made & Materials NeededDocument8 pagesHow Motorcycle Exhaust Pipes Are Made & Materials NeededRidzuan JazlanPas encore d'évaluation

- WorkbookDocument37 pagesWorkbookMahmoud AbdelnasserPas encore d'évaluation

- System Air Conditioner: Service ManualDocument405 pagesSystem Air Conditioner: Service ManualHai NamPas encore d'évaluation

- Pa PGD TT 6.6.1.10 Izbor Klima KomoraDocument12 pagesPa PGD TT 6.6.1.10 Izbor Klima KomoraStefan VitezovićPas encore d'évaluation

- Flexej Elaflex Erv G 1116Document2 pagesFlexej Elaflex Erv G 1116victorvikramPas encore d'évaluation

- A7793a A7797aDocument1 pageA7793a A7797aCarlos Rafael Rondon AbreuPas encore d'évaluation

- Soil Liquefaction: A Critical State ApproachDocument7 pagesSoil Liquefaction: A Critical State Approachvisio2004Pas encore d'évaluation

- PetrochemicalsDocument7 pagesPetrochemicalsabuzar mahdiPas encore d'évaluation

- Price List 2018Document48 pagesPrice List 2018B R PAUL FORTINPas encore d'évaluation

- Claim ListDocument52 pagesClaim Listsui1981100% (2)

- 2010 California Historical Building CodeDocument39 pages2010 California Historical Building CodeLaisattrooklai PhisitPas encore d'évaluation

- Model Series S, Din: Sempell Safety ValveDocument17 pagesModel Series S, Din: Sempell Safety ValveKiattisak JaemjunPas encore d'évaluation

- SmartRHEO SeriesDocument2 pagesSmartRHEO Seriesrajesh_rbpPas encore d'évaluation

- 4 Compressors Sample ProblemsDocument5 pages4 Compressors Sample ProblemsDominic Padua Paningbatan100% (1)

- Bohler Catalog 2005Document28 pagesBohler Catalog 2005Claudia MmsPas encore d'évaluation

- Fourier Law of Heat Conduction (Gate60 Short Notes)Document4 pagesFourier Law of Heat Conduction (Gate60 Short Notes)Guru Abhinai Meduri100% (1)

- Corrosion Protection Evaluation of Some Organic Coatings in Water Transmission LinesDocument2 pagesCorrosion Protection Evaluation of Some Organic Coatings in Water Transmission LinesGabo TellezPas encore d'évaluation

- Double Pipe Heat Exchanger - SsDocument72 pagesDouble Pipe Heat Exchanger - SsNathanian100% (2)