Académique Documents

Professionnel Documents

Culture Documents

Spec Raceways, Boxes & Fittings PDF

Transféré par

Herman DamanikDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Spec Raceways, Boxes & Fittings PDF

Transféré par

Herman DamanikDroits d'auteur :

Formats disponibles

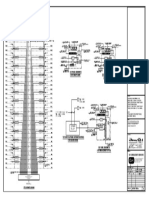

SECTION 16130

RACEWAYS, BOXES AND FITTINGS

DEWAN Building - UAQ Electrical Specifications

Block 1, Sector 8 Plot 6, Al Khor 1, UAE Section 16130: Raceways, boxes and fittings

RACEWAYS, BOXES AND FITTINGS

TABLE OF CONTENT

PART 1 - GENERAL

PART 2 - PRODUCTS AND SYSTEMS

2.1 CONDUITS AND ACCESSORIES

PART 3 - FIELD AND INSTALLATION WORK

3.1 CONDUIT AND WIREWAYS GENERALLY

3.2 RACEWAY APPLICATIONS AND INSTALLATIONS GENERALLY

3.3 PVC CONDUITS

3.4 EMBEDDED CONDUITS

3.5 EXPOSED CONDUITS

VOLUME II Part 3 Page No. 2 of 7

DEWAN Building - UAQ Electrical Specifications

Block 1, Sector 8 Plot 6, Al Khor 1, UAE Section 16130: Raceways, boxes and fittings

RACEWAYS, BOXES AND FITTINGS

PART 1 - GENERAL

1.1 ELECTRICAL WORK GENERALLY: is to be in accordance with the requirements

of Section 16000 of the Specification.

1.2 DESCRIPTION OF WORK: raceways including conduits, wireways and related

installations and accessories necessary to support and protect cables, feeders,

branch circuit wiring and wiring of low current systems, communications and signal

cables.

1.3 REGULATIONS AND STANDARDS: conduits, wireways, cables trays and fittings

are to be designed, constructed and installed to give safe installation and reliable

mechanical protection for wires and cables in accordance with the Regulations.

Standards of products are to be as specified.

1.4 TECHNICAL DATA: submit data for approval including, but not limited to, the

following:

A. Manufacturers catalogues with specifications of raceways including conduits,

trunking etc. and related accessories.

B. Samples of each type of raceway and accessory.

1.5 SHOP AND CONSTRUCTION DRAWINGS: submit drawings for approval including,

but not limited to, the followings:

A. Exact routing of conduits, trunking etc. With indication of boxes, accessories and

expansion joints, size of conduits and boxes

B. Typical assembly details of installation of trunking, trays etc.

C. Construction details of pull boxes.

D. Typical installation details including connection of conduits to metal enclosure.

Connections of flexible conduits, vapour-tight installations in cold rooms, liquid tight

flexible metallic outdoors etc. and earthing connections.

E. Spare parts of quantity not less than 10% of the total system quantities shall be

provided by the contractor to the owner after handing over.

PART 2 - PRODUCTS AND SYSTEMS

2.1 CONDUITS AND ACCESSORIES

A. RIGID & FLEXIBLE METAL CONDUIT

1. FLEXIBLE METAL CONDUIT: steel, cold rolled and annealed, non-threaded type,

formed from continuous length of helically wound and interlocked strip steel, with

fused zinc coating on inside and outside.

2. RIGID METAL CONDUIT: Black enameled or hot dipped galvanized, L= 3m,

screwed on both ends to applicable European Standards.

VOLUME II Part 3 Page No. 3 of 7

DEWAN Building - UAQ Electrical Specifications

Block 1, Sector 8 Plot 6, Al Khor 1, UAE Section 16130: Raceways, boxes and fittings

3. LIQUID-TIGHT FLEXIBLE METALLIC CONDUIT: is to have PVC jacket extruded

over core.

4. FITTINGS GENERALLY: thread less, hinged clamp type, hot dipped

galvanized or cadmium plated malleable cast iron. Fittings used in corrosive

atmospheres are to be specially treated.

5. STRAIGHT CONNECTORS: one piece body, female type, hot dipped

galvanized or cadmium plated malleable cast iron. Fittings used in corrosive

atmospheres are to be specially treated.

6. ANGLE CONNECTORS: of 45 or 90 degree and terminal connectors are to be

as specified for straight connectors, except that body is to be two-piece with

removable upper section.

B. RIGID HEAVY GAUGE PVC CONDUIT

1. MATERIAL: rigid un-plasticized, could form a bend with PVC accessories,

polyvinyl chloride with high impact and high temperature resistance, flame

retardant, non hygroscopic and non- porous, compressive strength 1250 N, IK 10

(20 Joules) to CEE 26, EN 50086, DIN 49026 or other equal and approved

standards conforming to IEC 423.

2. FITTINGS GENERALLY: unbreakable, non-flammable, self-extinguishing,

moulded plastic.

3. ASSEMBLY: conduits, boxes and accessories are to be assembled by cementing,

using manufacturers recommended products and appropriate connectors or spouts

are available use smooth bore male PVC bushes and sockets.

C. FLEXIBLE HEAVY GAUGE PVC CONDUIT

1. MATERIAL: flame retardant, heat resistant, non-hygroscopic PVC, high

resistance to impact, plain non corrugated construction.

PART 3 - FIELD AND INSTALLATION WORK

3.1 CONDUIT AND WIREWAYS GENERALLY

A. USE: unless otherwise specifically indicated all light and power circuits,

communications, signal and low current systems wiring are to be drawn inside

conduits or wireways up to the various electric power consuming equipment as

shown on the Drawings. Separate conduit and wireways installations are to be

used for LV cables/wires normal lighting and power circuits, emergency lighting

and power circuits and communication, signal and other low current systems

wiring and carrying 40% spare space.

B. BOXES: junction, pull and splice boxes of ample capacity (with 30% spare at least)

are to be provided as indicated or required. Boxes are to remain permanently

accessible. Minimum outlet, junction, or pull box depth to be 50mm clear.

C. TOOLS AND ACCESSORIES: for forming and installing conduit and wire way

systems are to be purpose made for the particular application and used in

accordance with manufacturers instructions.

VOLUME II Part 3 Page No. 4 of 7

DEWAN Building - UAQ Electrical Specifications

Block 1, Sector 8 Plot 6, Al Khor 1, UAE Section 16130: Raceways, boxes and fittings

D. FIXING: conduits and wire way installations are to be concealed as much as

possible.

E. SIZES: Unless otherwise specified conduits and wireways sizes, not shown on the

Drawings, are to be selected in accordance with the tables on design drawings

and in relation to the number and size of conductors. Minimum size of conduit

for all applications is to be 20 mm diameter with minimum thickness of 1.8mm,

unless otherwise shown on the Drawings.

F. MECHANICAL CONTINUITY: conduits and wireways are to be effectively joined

together )special cement) and connected to electrical boxes, fittings and cabinets

(threaded glands) to provide firm mechanical assembly. Earthing jumpers are to be

installed on steel conduits where required to ensure effective electrical continuity

irrespective of whether a protective earth conductor is required or not.

3.2 RACEWAY APPLICATIONS AND INSTALLATIONS GENERALLY

A. RIGID HEAVY GAUGE PVC CONDUIT: unless otherwise specified or mentioned on

drawings or contradictory to local AUTHORITY codes; is to be used generally in

underground, in screed, in duct banks and surface installation for lighting, power and

light current circuits.

B. FLEXIBLE HEAVY GAUGE PVC CONDUIT: is to be used for lighting, power and

light current circuits in under tiles and walls installation and for connection to fixtures

installed in false ceiling, unless otherwise specified or mentioned on the drawings or

contradictory to local AUTHORITY codes.

C. FLEXIBLE STEEL CONDUIT: is to be used, in the technical rooms (except pumps

rooms), for connection vibrating and non-rigidly fixed equipment, lighting fixtures and

where requested by BS 7671 and local AUTHORITY codes.

D. FLEXIBLE LIQUID-TIGHT STEEL CONDUIT: is to be used, in the pumps rooms, for

connection vibrating and non-rigidly fixed equipment, lighting fixtures and where

requested by BS 7671 and local AUTHORITY codes.

E. RIGID STEEL CONDUIT: is to be used for exposed installations in technical

areas (except pumps rooms) and where requested by BS 7671 and local

AUTHORITY codes.

F. RIGID STEEL PVC COATED CONDUIT: is to be used for exposed installations in the

pumps rooms, boiler room and technical rooms which involve water handling and

where requested by BS 7671 and local AUTHORITY codes.

G. EXPOSURE TO DAMAGE: conduit considered being subject to undue risk of

damage by shock or corrosion is to be brought to the attention of the Engineer.

H. CROSSINGS: conduits are not to cross pipe shafts, vents or openings.

I. CLEARANCES: install conduits at least 150 mm clear of and preferably above pipes

of other non-electrical services.

J. SLEEVES: obtain approval for positioning sleeves where conduits pass through

reinforced concrete. Additional openings may be allowed in finished slabs but

are to be drilled and not broken. Fix sleeves rigidly to maintain position and

alignment during construction work.

VOLUME II Part 3 Page No. 5 of 7

DEWAN Building - UAQ Electrical Specifications

Block 1, Sector 8 Plot 6, Al Khor 1, UAE Section 16130: Raceways, boxes and fittings

K. EXPANSION FITTINGS: provide in each conduit run over 30 mm in length and at

crossing of expansion joint in structure.

L. WATERPROOF CONSTRUCTION: conduits are not to cross waterproof

construction unless permitted by the Engineer. Specially designed and approved

fittings are to be used.

M. MAKE GOOD all holes for conduits passing through walls, floors and ceilings with

cement or similar fire-resisting material to full thickness.

N. BENDS: conduit runs between outlet, fitting and fitting or outlet and fitting are

not to contain more than the equivalent of 2 quarter bends (180 degree total).

O. BENDING is to be made without damaging conduit or tubing and without

reducing internal diameter. Methods of field bending are to be approved.

P. CUT ENDS are to be reamed to remove burrs and sharp edges.

Q. CONDUITS ENTERING COLD STORES are to be made vapor tight, so that vapor

from outside cannot enter conduit.

R. DRAINING: arrange conduits so that condensed moisture can drain to screwed plug

at lowest point.

S. BEFORE WIRING, conduits are to be swabbed through. Do not draw cables into any

section of system until conduit and draw boxes are fixed in position.

T. CAPPING: conduits are to be properly capped until wiring conductors are drawn in.

U. CONDUITS AND FITTINGS INSTALLED OUTDOORS are to be watertight and

highly resistant to corrosion. Use appropriate fittings, threaded and hubbed

boxes, gaskets with screw on covers and the like.

V. TERMINATIONS: do not terminate or fasten rigid conduits to motor frame or base.

W. LENGTH AND RADIUS OF FLEXIBLE CONDUIT used for motors and vibrating

equipment is to permit bending of feeder cables without damage to conductor or

insulation.

X. FLEXIBLE CONDUIT FOR SLIDE RAIL MOUNTED MOTOR is to have sufficient

slack to allow for movement of motor over entire slide rail length.

Y. PULLING WIRE: install 3 mm galvanized stranded steel wire or equivalent strength

cord with wooden blocks fastened at ends, in empty service conduits (power, low

current and signal).

Z. STANDARD ELBOWS are to be used for conduit sizes equal or greater than 20mm.

AA. TAGS: fit to conduits entering or leaving floors, walls or ceilings for identification of

conduit and circuits. Tags are also to be placed at suitable intervals throughout the

systems. Tags shall be approved by the engineer and have their durability at

least equal to those used for power feeders.

3.3 PVC CONDUITS

A. COUPLING OF CONDUIT and/ or termination into spouted fittings is to be made

watertight and permanent using special cement.

VOLUME II Part 3 Page No. 6 of 7

DEWAN Building - UAQ Electrical Specifications

Block 1, Sector 8 Plot 6, Al Khor 1, UAE Section 16130: Raceways, boxes and fittings

B. TERMINATION: connect conduits terminating in switchgear, panel boards, trunking,

adaptable boxes or non-spouted enclosures etc, with smooth bore male PVC bushes

and sockets.

C. ENDS OF CONDUIT end conduit fittings are to be cleaned and jointed using

PVC cement recommended by manufacturer.

D. SEMI-PERMANENT ADHESIVE: use in joints requiring expansion couplers.

3.4 EMBEDDED CONDUITS

A. CONDUITS IN CONCRETE SLABS: place conduits parallel to main reinforcing steel.

B. CONDUITS IN PARTITIONS OR SIDE WALLS: horizontal or cross runs are to be

avoided.

C. PULL-BOXES are not to be used. If unavoidable, pull-boxes may be approved if

located inconspicuously.

D. CONDUITS IN FLOOR OF BEDS ON GRADE: encase in concrete, minimum

thickness 50 mm or to thickness allowed by architectural detail.

E. PVC CONDUITS IN REINFORCED CONCRETE STRUCTURES are generally to be

installed after placing reinforcement and before concreting, if protected against

damage, or are to be placed in grooves in formed in the concrete, if approved.

3.5 EXPOSED CONDUITS

A. CONDUITS ON WALLS: run neatly, horizontally or vertically.

B. SUPPORTS: use approved clamps, hangers or clips fastened by machine screws to

expansion sleeves in inserts or to lead anchors.

C. SPACING OF CLAMPS OR CLIPS for supporting steel conduits is not to be greater

than:

Conduit Size Maximum Spacing of Supports

mm (inches) meters

20 (3/4) 1.5 m

25 (1) 1.5 m

32-38 (1-1/4-1-1/2) 2m

D. SPACING OF CLAMPS OR CLIPS for supporting PVC conduits is not to be greater

than.

Conduit Size Maximum Spacing of Supports

mm (inches) meters

20 (3/4) 0.50

25-50 (1-2) 0.50

63-75 (2-1/2-3) 0.75

E. BENDS AND FITTINGS: firmly fasten conduit at each side of bends and within 900

mm of each outlet box, junction box, cabinet or fitting.

F. OUTLETS: do not run more than one conduit to any surface wall outlet. Install

junction box on home run near to ceiling level and tap-off vertical conduit to outlet

box below.

VOLUME II Part 3 Page No. 7 of 7

Vous aimerez peut-être aussi

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- 16139-Cable TraysDocument4 pages16139-Cable TraysNATHANPas encore d'évaluation

- 16126Document13 pages16126uddinnadeemPas encore d'évaluation

- DEWA Instrumentation Cable SpecsDocument12 pagesDEWA Instrumentation Cable SpecsFlavioPas encore d'évaluation

- MDB Specs PDFDocument9 pagesMDB Specs PDFAbdElrahman AhmedPas encore d'évaluation

- GroundingDocument6 pagesGroundinguddinnadeemPas encore d'évaluation

- Standard Electrical SpecificationDocument9 pagesStandard Electrical SpecificationmatshonaPas encore d'évaluation

- Station: NTPC Simhadri BHEL REF NO: PS-DC-186-500-Ntpc Ref No: Sim/1/Ts/ / Sheet 1 of 2Document2 pagesStation: NTPC Simhadri BHEL REF NO: PS-DC-186-500-Ntpc Ref No: Sim/1/Ts/ / Sheet 1 of 2lrpatraPas encore d'évaluation

- Electrical Specs MusandaDocument95 pagesElectrical Specs MusandaEngr.bilalPas encore d'évaluation

- Installation MCC Room, E&I Rooms, and Battery RoomDocument9 pagesInstallation MCC Room, E&I Rooms, and Battery RoomDario WicaksonoPas encore d'évaluation

- Unofficial Copy - SDCS03 PDFDocument29 pagesUnofficial Copy - SDCS03 PDFmusleh19Pas encore d'évaluation

- Nec Cable Bending RadiusDocument3 pagesNec Cable Bending Radiusact_rahul53Pas encore d'évaluation

- Fewa SpecificationsDocument28 pagesFewa SpecificationsAnonymous GdZqtY88ZRPas encore d'évaluation

- 11 KV RMU-Tech. Spec PDFDocument23 pages11 KV RMU-Tech. Spec PDFMohsin ElgondiPas encore d'évaluation

- Maintenance Handbook On Earthing & Surge Protection For S&T InstallationsDocument48 pagesMaintenance Handbook On Earthing & Surge Protection For S&T InstallationsHendrias Ari Sujarwo100% (3)

- SECTION 16120 Conductors and Cables Rev 0Document49 pagesSECTION 16120 Conductors and Cables Rev 0Ahmed HashimPas encore d'évaluation

- 4-Technical Specs - LVDocument29 pages4-Technical Specs - LVtauqeer544gmailcomPas encore d'évaluation

- Specification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqDocument9 pagesSpecification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqAhmed JaPas encore d'évaluation

- Sa3-Ps2, Main Pump House Scale Below Ground Earthing - Location of Lugs Layout, Sections and DetailsDocument1 pageSa3-Ps2, Main Pump House Scale Below Ground Earthing - Location of Lugs Layout, Sections and DetailssartajPas encore d'évaluation

- Symbols of Transmission Lines: (Electrical Distribution)Document2 pagesSymbols of Transmission Lines: (Electrical Distribution)mhs madiunPas encore d'évaluation

- Sizing of Earth CablesDocument1 pageSizing of Earth CablesLilet P. DalisayPas encore d'évaluation

- Underground Cable Installation ManualDocument45 pagesUnderground Cable Installation Manualwasi baigPas encore d'évaluation

- Fewa ReqDocument12 pagesFewa ReqMoin AhmedPas encore d'évaluation

- General Notes Specs PDFDocument2 pagesGeneral Notes Specs PDFZaul tatingPas encore d'évaluation

- Technial Specification of Panel .Wiring, SwitchgearDocument19 pagesTechnial Specification of Panel .Wiring, SwitchgearkiroPas encore d'évaluation

- QCS-2010 Section 21 Part 21 Lightning ProtectionDocument4 pagesQCS-2010 Section 21 Part 21 Lightning Protectionbryanpastor106Pas encore d'évaluation

- Android Based Electrical Appliance ControlDocument5 pagesAndroid Based Electrical Appliance Controlharrysingh100% (1)

- Electrical Unpriced BOQ-23 07 2019Document13 pagesElectrical Unpriced BOQ-23 07 2019Mitesh KhandwalaPas encore d'évaluation

- Derating FactorsDocument2 pagesDerating FactorsBaSem GaMalPas encore d'évaluation

- S-AAA-CAB-ACC-LV-S&I (Rev.0-2019)Document10 pagesS-AAA-CAB-ACC-LV-S&I (Rev.0-2019)Wael AlmassriPas encore d'évaluation

- EP-MS-P4-S3-085 - 11kV Heat Shrinkable Joints - (KM Material Spec)Document8 pagesEP-MS-P4-S3-085 - 11kV Heat Shrinkable Joints - (KM Material Spec)dimaomarPas encore d'évaluation

- Addc NotesDocument18 pagesAddc NotesIranna BiradarPas encore d'évaluation

- External Electrical Boq R2Document15 pagesExternal Electrical Boq R2mudassir mPas encore d'évaluation

- 400kV DEWA ClearancesDocument1 page400kV DEWA ClearancesJayabalan R KPas encore d'évaluation

- Tes T 111 02R0 PDFDocument35 pagesTes T 111 02R0 PDFMohammad Abo AliPas encore d'évaluation

- Karnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemDocument4 pagesKarnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemJahangir Alam100% (1)

- TDC & Specification of CSS&RMU - RevisedDocument31 pagesTDC & Specification of CSS&RMU - RevisedShatrughna SamalPas encore d'évaluation

- Specification SCADADocument9 pagesSpecification SCADAkamarajin100% (1)

- bdb001380008 - 000 Grounding PDFDocument40 pagesbdb001380008 - 000 Grounding PDFJayce PinedaPas encore d'évaluation

- Himel Catalogue 161019100832 PDFDocument507 pagesHimel Catalogue 161019100832 PDFMohamed Habib Elmi0% (1)

- 38 TMSS 05 R0Document0 page38 TMSS 05 R0renjithas2005Pas encore d'évaluation

- 16453-Grounding & Bonding Telecommunication SystemDocument6 pages16453-Grounding & Bonding Telecommunication SystemuddinnadeemPas encore d'évaluation

- Quality Control Procedure For HVDocument9 pagesQuality Control Procedure For HVVIKRAM DESAIPas encore d'évaluation

- Qcs 2010 Section 10 Part 2 Telemetry SCADADocument29 pagesQcs 2010 Section 10 Part 2 Telemetry SCADAbryanpastor106Pas encore d'évaluation

- Basic Electrical Requirment KSADocument10 pagesBasic Electrical Requirment KSAfarooq929Pas encore d'évaluation

- Method Statement For Conduits WiringDocument8 pagesMethod Statement For Conduits WiringÖmeralp SakPas encore d'évaluation

- Specification of Lightning Protection Based On BSEN 62305Document8 pagesSpecification of Lightning Protection Based On BSEN 62305Ayman SaberPas encore d'évaluation

- Elv Panel Schematic (For Tenant'S Unit) Elv Panel Schematic (For Gym Room)Document1 pageElv Panel Schematic (For Tenant'S Unit) Elv Panel Schematic (For Gym Room)sana ullah100% (1)

- SECTION 16450 Grounding Part 1 - GeneralDocument8 pagesSECTION 16450 Grounding Part 1 - Generalno namePas encore d'évaluation

- Method Statement - Elect. Jerry ShellDocument5 pagesMethod Statement - Elect. Jerry ShellnayumPas encore d'évaluation

- RAMS For Installation and Testing of Access Control SystemDocument22 pagesRAMS For Installation and Testing of Access Control SystemAnandu AshokanPas encore d'évaluation

- Mos T&C EarthingDocument20 pagesMos T&C EarthingAhanaf TahmidPas encore d'évaluation

- Video Intercom Solution and Cabling SpecificationsDocument20 pagesVideo Intercom Solution and Cabling SpecificationsSaid GedeonPas encore d'évaluation

- Electrical Drawings Checklist UpdatedDocument23 pagesElectrical Drawings Checklist UpdatedEng-Al Raie SaadPas encore d'évaluation

- Electrical SpecificationsDocument7 pagesElectrical SpecificationsSaad AkramPas encore d'évaluation

- Section 16110-RacewaysDocument5 pagesSection 16110-RacewayskdpmansiPas encore d'évaluation

- Spec Wiring DevicesDocument10 pagesSpec Wiring DevicesDolyPas encore d'évaluation

- SECTION 16450 Grounding Part 1 - GeneralDocument5 pagesSECTION 16450 Grounding Part 1 - GeneraljosemartinpenatorresPas encore d'évaluation

- Low-Voltage Electrical Power Conductors and Cables PDFDocument9 pagesLow-Voltage Electrical Power Conductors and Cables PDFJairo WilchesPas encore d'évaluation

- INST241 Sec4Document145 pagesINST241 Sec4Herman DamanikPas encore d'évaluation

- INST232 Sec1Document99 pagesINST232 Sec1Herman DamanikPas encore d'évaluation

- INST241 Sec3Document141 pagesINST241 Sec3Herman DamanikPas encore d'évaluation

- INST241 Sec2Document156 pagesINST241 Sec2Herman DamanikPas encore d'évaluation

- Kron Reduction - Open ElectricalDocument2 pagesKron Reduction - Open ElectricalHerman DamanikPas encore d'évaluation

- Dq0 Transform - Open ElectricalDocument5 pagesDq0 Transform - Open ElectricalHerman DamanikPas encore d'évaluation

- Infinite Bus - Open Electrical PDFDocument2 pagesInfinite Bus - Open Electrical PDFHerman DamanikPas encore d'évaluation

- Coil - Open ElectricalDocument3 pagesCoil - Open ElectricalHerman DamanikPas encore d'évaluation

- Anatomy of A Short Circuit - Open ElectricalDocument5 pagesAnatomy of A Short Circuit - Open ElectricalHerman DamanikPas encore d'évaluation

- Simple Power Flow Example - Open ElectricalDocument3 pagesSimple Power Flow Example - Open ElectricalHerman DamanikPas encore d'évaluation

- Diode Laser Hair Service ManualDocument23 pagesDiode Laser Hair Service ManualInfo Ventura MedtechPas encore d'évaluation

- Dwyer Photohelic DigitalDocument1 pageDwyer Photohelic DigitalHaryo AntyoPas encore d'évaluation

- Winch Safety TrainingDocument27 pagesWinch Safety Trainingaymenmoataz100% (1)

- Screw Removal BrochureDocument12 pagesScrew Removal BrochureAnselmo PrecybiloviczPas encore d'évaluation

- Eos 7d Mark II Af Guide Cusa 9-2014Document17 pagesEos 7d Mark II Af Guide Cusa 9-2014b127204Pas encore d'évaluation

- Battery Charge Lester ElectricalDocument8 pagesBattery Charge Lester ElectricaldungnvbsPas encore d'évaluation

- Plastic Cameras MDocument12 pagesPlastic Cameras Msonic youtherPas encore d'évaluation

- 900-DSII Hydraulic Systems Oil-Flow DiagramDocument32 pages900-DSII Hydraulic Systems Oil-Flow DiagramHdmq Parts100% (2)

- GURPS - Shadowrun Equipment - 3rd PartyDocument17 pagesGURPS - Shadowrun Equipment - 3rd PartyLloyd CalvinPas encore d'évaluation

- P c900 PDFDocument504 pagesP c900 PDFPhôtôKhanhPas encore d'évaluation

- Viking Airtech Pte LTDDocument12 pagesViking Airtech Pte LTDWee WeePas encore d'évaluation

- SOP 1 Forklift OperationDocument4 pagesSOP 1 Forklift OperationDoxi HDPas encore d'évaluation

- Fenwalnet 6000Document4 pagesFenwalnet 6000Andrew PanjaitanPas encore d'évaluation

- Use and Function of ToolsDocument19 pagesUse and Function of ToolsEmmerPas encore d'évaluation

- JHA No D0011 "Rust/Paint Chipping": Job Hazard Analysis and Tool Box Discussion FormDocument3 pagesJHA No D0011 "Rust/Paint Chipping": Job Hazard Analysis and Tool Box Discussion Formtjeng syuwenPas encore d'évaluation

- Spare Parts List: Figure B-1 Upper Cover AssyDocument11 pagesSpare Parts List: Figure B-1 Upper Cover AssySunny SinghPas encore d'évaluation

- PST Hand Out NewDocument49 pagesPST Hand Out NewBhargav Krsna GayanPas encore d'évaluation

- Features:: Advanced Protection TechnologiesDocument2 pagesFeatures:: Advanced Protection Technologiesdnps2011Pas encore d'évaluation

- PIP048 DataSht FlangeRepairRing-2Document1 pagePIP048 DataSht FlangeRepairRing-2Juan VillarroelPas encore d'évaluation

- Sample OphhhhhDocument2 pagesSample OphhhhhNathan DrakePas encore d'évaluation

- Ins PT005Document1 pageIns PT005faisal hajjPas encore d'évaluation

- Evolium Rns / BSS: Evolium A9100 MBS Outdoor Installation ManualDocument84 pagesEvolium Rns / BSS: Evolium A9100 MBS Outdoor Installation Manualdvvdvv100% (1)

- Brake Circuit Diagram: Path Chassis IDDocument4 pagesBrake Circuit Diagram: Path Chassis IDMinn Thet NaingPas encore d'évaluation

- Manual de Partes Generador - C33 D5TDocument40 pagesManual de Partes Generador - C33 D5TDany_Wally100% (1)

- H8C DatasheetDocument5 pagesH8C DatasheetJavier Quiroga de la RozaPas encore d'évaluation

- Ciao 6-1850 User Manual EnglishDocument8 pagesCiao 6-1850 User Manual EnglishMMF PLUSPas encore d'évaluation

- Despieze y Repuestos de Refrigerador Kitchen Aid KBLS22KWMS6Document13 pagesDespieze y Repuestos de Refrigerador Kitchen Aid KBLS22KWMS6Obi DoninelliPas encore d'évaluation

- Fire Detection and Alarm System QCDD Form (Record of Completion)Document3 pagesFire Detection and Alarm System QCDD Form (Record of Completion)Ronie PaduaPas encore d'évaluation

- Catalog Midea v5 X Series VRF Systemsvqc PDFDocument45 pagesCatalog Midea v5 X Series VRF Systemsvqc PDFQuốc CườngPas encore d'évaluation

- All Photocopiers Error Codes & RemediesDocument74 pagesAll Photocopiers Error Codes & RemediesAmit SharmaPas encore d'évaluation

- A Place of My Own: The Architecture of DaydreamsD'EverandA Place of My Own: The Architecture of DaydreamsÉvaluation : 4 sur 5 étoiles4/5 (242)

- Sustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsD'EverandSustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsPas encore d'évaluation

- Civil Engineer's Handbook of Professional PracticeD'EverandCivil Engineer's Handbook of Professional PracticeÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Real Life: Construction Management Guide from A-ZD'EverandReal Life: Construction Management Guide from A-ZÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Even More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsD'EverandEven More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsPas encore d'évaluation

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AD'EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&APas encore d'évaluation

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedD'EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialD'EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialPas encore d'évaluation

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationD'EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettÉvaluation : 4 sur 5 étoiles4/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsD'EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyD'EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyÉvaluation : 4 sur 5 étoiles4/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionD'EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Piping Engineering Leadership for Process Plant ProjectsD'EverandPiping Engineering Leadership for Process Plant ProjectsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessD'EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessÉvaluation : 5 sur 5 étoiles5/5 (3)

- Estimating Construction Profitably: Developing a System for Residential EstimatingD'EverandEstimating Construction Profitably: Developing a System for Residential EstimatingPas encore d'évaluation

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesD'EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesPas encore d'évaluation

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsD'EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Fire Protection Engineering in Building DesignD'EverandFire Protection Engineering in Building DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Building Construction Technology: A Useful Guide - Part 1D'EverandBuilding Construction Technology: A Useful Guide - Part 1Évaluation : 4 sur 5 étoiles4/5 (3)

- The Homeowner's DIY Guide to Electrical WiringD'EverandThe Homeowner's DIY Guide to Electrical WiringÉvaluation : 5 sur 5 étoiles5/5 (2)

- EMOTIONAL EATING: How To Stop Emotional Eating Naturally And Live A Better LifeD'EverandEMOTIONAL EATING: How To Stop Emotional Eating Naturally And Live A Better LifeÉvaluation : 4 sur 5 étoiles4/5 (14)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideD'Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyD'EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyÉvaluation : 4 sur 5 étoiles4/5 (1)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesD'EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesPas encore d'évaluation