Académique Documents

Professionnel Documents

Culture Documents

Silo Pro Catalogue

Transféré par

Sara Ramli0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues19 pagessilo

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentsilo

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues19 pagesSilo Pro Catalogue

Transféré par

Sara Ramlisilo

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 19

os

SILOPRO

GRAIN SYSTEMS

CONTENTS

erie Cale

Hoppersonom sos Spectietions 112

Silo Specifications 1S-16-17-18

‘Awration Systerns& umes

Ce) tal Nhe

SILOPRO's 20.000 m? of plant and office space outfitted with the most modern

engineering and manufacturing technology and equipments available. For

domestic sales with C5I® brand name and for export sales with SILOPRO® brand

name; we have been working to provide the highest Quality service in the market.

In the grain storage market, as a result ef our pursuing work experience and our

not compensation on our fair trade sensibility, our company became to be Tur-

key's one of the biggest silo systems exporter company. All materials used in pro-

duction of silos and equipments are ISO 9001 certified and meet with all Quality

management systems’ requirements.

SILOPRO became specialized on producing silos and its equipments with its

highest technology facilities. Having necessary infrastructure, technology and

enough manpower, was effective on its becoming a challenging position in the

market. Within a short time period, producing and assembling of different ton-

nage and size of steel grain storage silos, handling equipments, base of concrete,

tower platforms and other transporting groups and perfect installing in time are

the basis of our today’s success in total grain systems.

SILOPRO proves its privilege on projection with its specialized research and

development department and quality safety unit. At every stage of production by

using modern machines for the precise manufacturing, engineering staff is per-

forming post-production quality control, quality safety department analyses cus-

tomer requirements and offer them the optimum solutions. Its experienced engi-

neers working on research and development department by using the most

updated computer drawings and techniques,they are preparing developing and

Project designs, drafts, plans, drawings and production specifications

In order to completely fulfil customer needs and to provide them with quality

products, SILOPRO has begun its quality journey. SILOPRO has recognized the nec-

essary factors other than advanced technology. Some of these essential compo-

nents are; investment in the work force and the quality.The objective all along this

Journey has been to accommodate the contemporary needs of the companies and

predict future requirements.

SILOPRO’s main principle Is to move its high success graphics day by day further.

Therefore, We will continue to.offer our-customers the best in production and ser-

vice by our seriousness.

SILOPRO cammetcial grain bins offer many

outstanding strength and durability features,

Wide corrugated steel sheets manufactured

from high strength steel, heavy duty galvanized

steel stiffeners and strong bawrlb roofs are

some of the quality features avaliable Our

complete line of commercial bins are available in

dlameters from 15 feet (4.57 m) to 105 feet (32

Extra-tall sizes are available in all diameters,

Fiat bottom silos are in capacities changing

between 100 Lons and 15,000 tons to store all

kinds of grains such as wheat, com, rice, hean,

soyabean, barley, sunflower and other free-

flowing products,

PRO WALL SHEETS ™

SILOPRO wall sheets areinG-115

(250qr/m*) standaits and %20 heavier

than the G-90 standart metal sheets.

This difference nat enly prolongs the

Ife of the-coating,but also provides

protection against external factors.

‘The 4"wide corrugations on Silopro sidewall sheets create

less resistance and friction toallaw rain to flow more easily,

Silopro sheets are 44" high, o there-are fewer ings, seams and

bolts than bins with 32° sidewall,

“Enjoy The Quality,

Admire The Value ”

SILOPRO wall sheets have

tensile strength in the range

warn 900,000kgf/cmn?

(63,200 Psi) and

1.000.000kaf/cm (70,260 Psi.

These values are our obvious

superiarity against other stlos

in the market.

of il

PRO LADDER SYSTEMS ™ &

PRO REST PLATFORMS ™

SILOPRO ladder and platforms

‘ave produced completely modu

larfrom galvanised sheets. The

holes; drilled to the strip sheet

metals by CNC Punching Machine

gives easiness to bolt assemble

‘Both extemal and internal

ladders can be assembled to the

‘existing holes by using connection

fittings The standart silo external

ladder safety cage system enables

people to reach the roof safely.

An eave platform can be

Installed belaw the manhole for

your convenience when entering

the bin or inspecting the roof.

Access to the roof and the rest

platform to. observe from mane

hole are SILOPRO'S standart

silo accesorties

will work closely with you from the very early stages of

planning your commercial grain storage project

through to the installation stage and beyond,

“Creative Designs,

Pure Quality”

We know that cur obligation does not end when an

Installation is completed. Customer services impor

{ant for us and we will continue-to-wark with you after

yout commercial installation is even completed

: = PRO STIFFENERS ™

re = Asa result of laboratory tests, SILOPRO stiffeners

are in G-115( 350gr/m? } standarts which are %25

stronger against colour casts and oxidation than

G-90 standart stiffeners. Also %60 more protective

than stiffeners produced undet G-90 stondarts

SILOPRO stiffeners thickness from 4mm to mm

are subjected to hot deep galvanising process.

This allows 709-900 gi/m? amount of galvanize

coating to the stiffeners,

SILOPRO stiffeners are designed according ta

standart of (American lion and Stee! Institute (AISI)

*ASTM A683 Grade 0 Steel have minimum

4:57 0ka{/er? (65,000 PSI) tensile strength This

causes a serious superiority against other silo

manufacturersin the market.

PRO BOLTS ™

8,8 quality high strength decromat 500 a SILOPRO stiffeners feature strong

coated bolts are used in alll sheet connection ‘splice joints with large cross sectional

places in order to obtain highest degree of areas, both critical elements of

durability of allSiLOPRO silas.Special caulking is | vertical stiffeners. Splices thicknesses

{sed in all slo body sheets and ipper cone ‘rary from 4mm to Brame according to

connection paints In order to obtain full alr the design.

Imperviousity and full waterproofness.

“ Creative Designs,

Pure Quality ”

ROOF SYSTEMS &

PRO ROOF SYSTEMS ™

‘Bur aim for designing the sila roof with 30° degree

Inclination isto easily flow out the moisture in the silo,

During the ventilation, it also helps the air to flow out easily

SILOPRO-roofs.are produced to be resistant upto a maxi

mum peek load from 15.0001. to 30.0001. During designing.

We consider values as a standart in snow toad <0lbyft and in

Wind load Srp,

Silos between 3.65 mt-12.60 mt diameters have roof

structure supported on asingle stage. This type of roof

structures are sultable to carry loads up-to 907ka (2.0001,

and have resistance against 78 kg/m? (16 psf} alive loads,

In 14.63:mt diameter and above silos. we use CNC bending

twisted double stage beams. This type of roof structures are

suitable to carry loads up to 4,536 kg (14.000lb,) and have

resistances against 122 kam? (25 pst} alive loads.

“ Let Your Grains

Be In SAFE !!! "

SILOPRO roof panels are triangle in shape and bath sides

of the panels are roll formed as 9 90 iin deep trapeze. There

are inspection covers on each silo roof providing entrance in

to the silo when the grain level is above the sidewall access

door

PRO WIND RINGS ™

SILOPRO wind rings mounted on the body of the silo, provide stable structure:

tothe silo during filling and disharge. During the discharge process, silo opposes:

the pressure and stress of the side walls by the help of these rings. Thisallows you

to use your silo with confidence for many years

SILOPRO wind rings can also be used Inthe raof to strength the construction as

used In the sla body sheets. SILOPRO wind rings are mounted on the silos

according to the diameter of the silo, seismic zone and side discharge gates,

PRO FANS ™

SILOPRO carefully prepared the ventilation

products to meet your needs, These products and

systems are fully galvanized, motor efficiency using

the optimal relevance, special designed products,

‘Centrifugal Fans

The air flow of the stared grain can be possible with

‘only proper ventilation equipments. SILOPRO aeration

system equipments prolong the life of your grains with

ventilation naturally and cooled.

SILOPRO ventilation systems are designed to decrease

damage percentage of the grain, level af humidity and rate Ablal Fans

of insects in order to reduce risk of grain spoiling

PRO FLOORS ™

SILQPAG ventilation grids laids cn the venwitation channels of the silo base,

“Through the grid structure and bottom supports, ft has a design to carry thousands of grain

Through the perforated structure, it easily transmit the ait flow inside the grain coming from

the fait, Due to the special design. it prevents the fall of cereal grain in to the channels

SILOPRO entirely produces ventilation grilles with galvanized products not to allow your

‘grains to contact any coated surface.

Mf) 7a

AM

“varlove peor Noor estan

PRO AUGERS ™

SILOPRO slso offers full ine of grain bin Unloading equipment ihcluding unloads, power

stweeps, roof augers, clean sweeps, power heads.and more. When it comes to getting the

rain moving nobady qlves you more options than SiLOPRO,

SILOPRO roof exhausters help

your aeration fans effectively

Control gain spoilage In storage

bins with flat or pitched roots

These high volume fans produce

the effective sweeping action

needed to reduce condensation

of the top of your grain,

For best operation, exhausters

should run continuously white

aeration fans are on, then long

afterwards to assure removal of

humid airfrom the overspace.

PRO VENTS ™

—

SILOPRO roof vents situated

nsilos are manufactured to be

mounted on the roof.Vents that

entirely produced with bolts are

also assembled to the roof with

bolts, Seal elements that are

Used during assemble of the

oof vents, protect #9100 of that

Fegion against rain Water

SILOPRO tof vents’are

designed to carry out the warm

airfrom the silo and during this

process ta prevent any object to

enter inside the sito, 6

iv

PRO PLATFORMS"

PROVENTS™

The alr produced by fans, flow out from

SILOPRO Roof Yents after passing from

Inside the grain,

PRO LADDERS

SILOPRO External Ladders and Cages are

_assembled fram the fleor to raof section.

Provides easy accessto the manhole placed

at the roof,

SILOPRO Resting Platforms are placed

‘under the manhole for safely visual check

Inside the silo,

=m, PRO SHEETS™

Augers provides safety

discharge of the stored

| SILOPRO Wal Sheets are connected

together with high strength bolts to estab-

lish the ring of the silos

PRO AUGERS™

SILOPRO Unloading

grain inside the silo.

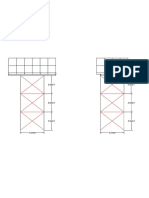

FOUNDATIONS

‘Thetbase of the silo

consist from unloading

auger channel and

aeration channels.

Ci

PRO ACCESS DOORS™

SILOPRO Access Doors ate placed standardly

at the secand ring of the silo, t provides safe

access Inside the silo for cleariing and mainte:

nance operations

PRO SWEEPS™

SILOPRO Sweep Augers

svveeps the final gtain at floor

ofthe silo and transmit to the

unloading auger,

ina humidity region

| mounted around the exterior of the silo

PHO EXHAUST FANS™

SILOPRO Exhaust Fans are placed at the

roof section of the silos and used In special

aeration systems where the silos are placed

PRO WIND RINGS™

ScoeO WME RIgrae racer) Dee |

on the body of the sto and provides ea

stable structure to the sile during

filling and discharge. S|

PRO STIFFENERS & PRO SPLICES™

SILOPRO stiffeners are vertically,

Supporting the body sheets gives more

feslstance against tensile strenghts,

SILOPRO Spliees ate used to connect | l

the stiffeners to each other vertically R

and provide high resistance,

PRO FANS™

The air flow of the stored grain

can be farmed with only proper

ventilation equipments. SILOPRO

Fans profongs the life of the grain /

with natural and cool ventilation.

PRO FLOORS™

SILOPRO Ventilation Grids laids on the

ventilation channels of the silo base.

Through the perforated structure, it

‘easily transmit the air flow inside the

grain coming from the fans.

SILOPRO hopper bottom silos are produced in

range from 5 tonne up te 1.000 tonne,

Generally,it is preferred in continous discharge

status, During unloading, out of energy useand

lower-pperating costs is the main reason to prefer

these type silos. Moreover, this type is a special

preference with the grains that has low angle of

repose For this reason, SILOPRO hopper bottam,

silos are the best solution if you want complete

discharge, self-discharge or low cost disharge in

your system.

SILOPRO also developed special stee! structures,

‘chassis and platforms for hopper bottom silos,

These stee! structures placed in the bottom of the

hoppersila gives height win to the silo. This

prepared combined systems placed on the rail

lines and truck loading paints to fill train vagons

‘and trucks simple and healthy.

Mone

Hes

Haas

Hines

Hiss

Hn6s08

Hpbi

ss

1 045709

HBS

an

a

Teas

acs

Hussaiie

a0

440

aN

oo

tn

3

Hopper sllestower part

bas and 00 degree

aogle an this allows

the iain to low sas

with ts ew fui.

However 49° degr

copsal bottoms are

use or grains

00 dagree conical

battams.re uscd for

fees wet pat eva and

owe uy material,

won

Ea

TTT

un

TAIT

HILT

ToT

MILOT I

ToT

UILO7 Ne

HO

TERE

TORT

HHO

LIC

oa

UCD aes

HG abe

10a

Hos aL

Daal

HED aL

TIGO Lat

Dis

mo

a0

a0

Heda

Toss

PRO-BUCKET ELEVATORS ™

Bucket elevators are-a key component of yaur

rainy handling system na matter the size of your

Grain netage astern,

SILOPRO offers only the: highest quality bucket

elevators with capacities from 5 MT ta 500 MT,

SILOPRO bucket ¢levators incluele-an inspection

aor designed to be Weathertight and make mali

tenance and inspection easier. We have many

Options available for your bucket elevators Sine

capacity, boot and trunk type, and. cup types area

few key considerations

PRO DISTRIBUTORS ™

Keep grain moving where

you want it to ga with precise

contial and long Ife, SILOPRO.

distributors provide trouble

free operation anel rugged

dependability.

Some of the features of

SILOPRO distributors include

dry or wet arain operation,

lust and weather tight

design anda positive locking

deviee.

PRO TOWERS & CATWALKS ™

‘Silety constructions are recommended to be used in complete

grains storage systems These constructions are elevator tokers,

cabvialks and catwalk sipports.Allcan be produced both painted

and galvanised according to customer's request.

SILOPRO offeis a ice Selection Of options wien it comes to the

‘Sctual design of the safety constructions. all structurais are

‘engineered for-vatious heights, wind speeds, and seismic zones The

‘committed design team at SILOPRO wills yau the safety construc-

‘tions that fits your needs and budget.

SSILOPRO-has always been committed tothe long term lie of your

grain bin system, that's why we are proud to offer only the highest:

quality safety constructions that are designed to last

PRO SLIDE GATES ™

Slide gate valves are.generally

used below silo, tank,conveyors and

hoppers,

= SILOPRO sliding gates allows to

contiel the gravitational flow of

anal Site Gate ‘granular materials. Galvanised steel

construction are available for slide

agate valves for wide range of

applications,

ees

= to shut of product onto outs

Gna ether

serial a other discharge pointshandling dry

‘butk materials

PRO CHAIN CONVEYORS ™

SILOPAO chain carveyors are built for longevity and thele

Hexibilty allows application in most qperations. This benetit ct

chain conveyors maine that you ean customize Your graliy

storage system however. No matter hat the siteand needs are

there are plenty of options possible to sult your situation,

SILOPRO allways-design the conveying system that fs right for

you, dlepending on your site, graln being moved. capacities, wea

factors and feeding arrangements

SILOPRO offers only the highest quality chain conveyors vith

apacities from 5 tT to 500 MT.

PRO SCREW CONVEYORS ™

SILOPRO screw conveyors are used for horizontal transfering of gralnsand dusty

materials. Two different spiral sheets are used according to using purpores:Ifitis.only

for transfering, full splals are used. But, If various types of grainsare to be mixed and

transferred in spiral butterfly spiral sheets are used, The transfer perlod of the product

fromyone end to another can be changed bby aljusting the angles of butterfly spiral

sheets,

SILOPRO offers only the highest quality screw conveyors with capacities from 5 NtT

to250 MT.

PRO GRAIN DRYERS ™

SILOPRO diryers are ballttough with the mast modern festures available

for high performance and simplified operation. All of our units feature

G15 galvanized, ribbed, and perforated sidewalls with solid 16-gauge

column dividers every two feet. (Stainless steel perforated outside wall

sheets along with stainless steal nuts, bos and washers are.also available)

SILOPRO offers only the highest quality grain dryers with capacities fram

3 MT to SOMT,

STEEL STRUCTURES

(Our expertise and experiance has grown te all facets of commercial

construction.Our ich history was built around commercial projects,

primarily through the-use of pre-engineered steel buildings Throughout

‘the years we have used steel buildings in a wide array of applications

FLAT BOTTOM Si TIONS

rave eight | vera setgnr| Vetume | arteysase) | Carn (i72) | rece is) | wheat osm

meet | Pree ees] CY, my int) | Capacity cons | Capacity Kans | Capacieviion) | Capacity (on)

srosta | sa Ls 17

wis] sib Bal

‘sroctoon [aan

a

S060 )0-| a

Srceai | aan

Srceaaie | aan

Sheil | nib

sreetaia | a:

Sra 08

SPavvI

Soo =

Pca 23s

SPoeun Bi

3.00016 ie.

Sears | a2 nor

in si

Sos =

S05 2 oe

SPs ne

SHcst Tiss

Sho ba

Semin] art Tae

sro ar

SrmH a

me

ht

mm

9.14

i

us

rT

FINE

Wns

1s

0.05

$F-.cosse | 10s

Srio0s1F

Sri00s1

Shih

©

FLAT BOTTOM SILOS SPECIFICATIONS

Volume | marty ou) | Carmmray | recy | Wrear ney

memet | is (wt He my | Copaciy (een) | Capacity ion) | Capacity tan) | Capacity an

sriove | 1097 z a = se 630

10074 a a se 55 99

cusp | 109 om at me

sport | 19 18s 5 ig

srw | ins 1 aa gs

swore] 10.97 7 2H wr

sre]. 1303 a a

seus} yer ass oo

sro] ge Tes oa

shoot | 1097 se a oa

sree] ier isa uss

ering] 10s i

Tm ia

=

Sm 12001

SP-120010

13710

ps7

SET oa

Smut Li

Sry i se

SPT Do.

SUT x TK

Spits ita

SrasTiih

Shisvii7

STS

635

sriasi

SPe\oa5

sre)

Sasi

SPST

Shas

SP168510

Src as

FLAT BOTTOM Si IFICATIONS

ave tigi | Overall eight | Votume | artevensny | Carn (072) | tee ust)

fo (at n'y | Cupaciey inn) | Capaciy wad | Capacity on)

Monet, | me i] ing Nr,

Tee a ns 7 TR

Ht 1s

if

1

0

Bes

Bs

SE I01019

alta

P2010

Sp-201022

SFOs

SP20ues

Seso410

E1941

Sp. 210017

94 5 x 2 a

oe sais

9s

sp 93

SEAS

SEIS

8

SE es0

See

SP I007

See

SRS

©

(reel eg saariey 12.60) | Cornenz2y | ico .o4) | Wines amy

eee | eee eee ost Capacity (ran) | Capacity (an) | Capcity coy | Capacity tum

SEIS om es

Sh2THIS 20-1 “207

SPIT 2 40

amu.

wet

ah

sue

EE

ei eT =

[ee ete)

[sr |e

sae

EDU Goss ae eat

a2 TE ota

+ SILOPRO Silos ire designed forthe storage of grain and othe fre flowing mateslals

= Specifications and design are subject tochange without notice

= Othe ing heights avalable Insure dlameters

6 6 Compaction factor Isxclu

‘= Typical Grain Dans

hea apprenimately 200 gin’

Cornappreximatly 720 kgm

Fico approuiraaly 620 kg

I TI

EM

‘O:

MM:

fu:

OQ:

J:

Wi:

f

“=

-_

(a

Vous aimerez peut-être aussi

- 60M10 M Stand ModelDocument1 page60M10 M Stand ModelSara RamliPas encore d'évaluation

- Simplified Analytical Model of A Covered Burr-Arch-Truss Timber BridgeDocument10 pagesSimplified Analytical Model of A Covered Burr-Arch-Truss Timber BridgeSara RamliPas encore d'évaluation

- Handbook of Machine FoundationsDocument249 pagesHandbook of Machine FoundationsSara Ramli100% (1)

- CraneDocument100 pagesCraneYati ChanPas encore d'évaluation

- IELTS - Write Right - Retyped by Hội các sĩ tử luyện thi IELTSDocument260 pagesIELTS - Write Right - Retyped by Hội các sĩ tử luyện thi IELTSNguyen Duc Tuan100% (16)

- Alternatives For FirstlyDocument1 pageAlternatives For FirstlyTuğrul ErdoğanPas encore d'évaluation

- IELTS Writing Task 2 Sample Answer Essay: Advertisements & Needs (Real Past IELTS Exam/Test)Document16 pagesIELTS Writing Task 2 Sample Answer Essay: Advertisements & Needs (Real Past IELTS Exam/Test)Sara RamliPas encore d'évaluation

- Abstract André Branco de AlmeidaDocument9 pagesAbstract André Branco de AlmeidaSara RamliPas encore d'évaluation

- 09 Truss Analysis PDFDocument18 pages09 Truss Analysis PDFSara RamliPas encore d'évaluation

- IELTS Writing Task 2 Sample Answer Essay: Advertisements & Needs (Real Past IELTS Exam/Test)Document16 pagesIELTS Writing Task 2 Sample Answer Essay: Advertisements & Needs (Real Past IELTS Exam/Test)Sara RamliPas encore d'évaluation

- Design Data-Conductor ACSR 240 40Document3 pagesDesign Data-Conductor ACSR 240 40Sara RamliPas encore d'évaluation

- CDJ 228 Part Ii 030810Document45 pagesCDJ 228 Part Ii 030810ravi06201Pas encore d'évaluation

- Design Data-Conductor ACSR 240 40Document3 pagesDesign Data-Conductor ACSR 240 40Sara RamliPas encore d'évaluation

- The Catenary PDFDocument5 pagesThe Catenary PDFChandra PrakashPas encore d'évaluation

- Design Data-Conductor ACSR 240 40Document3 pagesDesign Data-Conductor ACSR 240 40Sara RamliPas encore d'évaluation

- Dongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsDocument2 pagesDongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsSara RamliPas encore d'évaluation

- Dongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsDocument3 pagesDongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsSara RamliPas encore d'évaluation

- Template For A Master's ProposalDocument14 pagesTemplate For A Master's ProposaltilahunthmPas encore d'évaluation

- Dongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsDocument2 pagesDongula - Wadi Halfa 220 KV Transmission Line Project: Reference DrawingsSara RamliPas encore d'évaluation

- Full-Scale Experimental Tests On Three Lattice Steel Transmission TowersDocument21 pagesFull-Scale Experimental Tests On Three Lattice Steel Transmission TowersSara RamliPas encore d'évaluation

- CDJ 228 Part Ii 030810Document45 pagesCDJ 228 Part Ii 030810ravi06201Pas encore d'évaluation

- Studies - On The Method of Orthogonal Collocation: I-A One-Point Collocation Method For The Transient Heat Conduction ProblemDocument13 pagesStudies - On The Method of Orthogonal Collocation: I-A One-Point Collocation Method For The Transient Heat Conduction ProblemSara RamliPas encore d'évaluation

- Ipe 120 PDFDocument1 pageIpe 120 PDFSara RamliPas encore d'évaluation

- Church Khartoum Model PDFDocument1 pageChurch Khartoum Model PDFSara RamliPas encore d'évaluation

- Corrugated Steel Bridge and Tunel Solutions 2015 08 06 Finalcopy 150603215514 Lva1 App6892 PDFDocument63 pagesCorrugated Steel Bridge and Tunel Solutions 2015 08 06 Finalcopy 150603215514 Lva1 App6892 PDFSara RamliPas encore d'évaluation

- Corrugated Steel Bridge and Tunel Solutions 2015 08 06 Finalcopy 150603215514 Lva1 App6892 PDFDocument63 pagesCorrugated Steel Bridge and Tunel Solutions 2015 08 06 Finalcopy 150603215514 Lva1 App6892 PDFSara RamliPas encore d'évaluation

- دليلك للايلتس PDFDocument127 pagesدليلك للايلتس PDFHussam100% (4)

- ASte Purlins ML PDFDocument56 pagesASte Purlins ML PDFBenard OmondiPas encore d'évaluation

- EssaysDocument25 pagesEssaysSara RamliPas encore d'évaluation

- Purlins Design GuideDocument44 pagesPurlins Design GuideJonathan GutiérrezPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)