Académique Documents

Professionnel Documents

Culture Documents

Specification For Carbon Steel Forgings, For General-Purpose Piping

Transféré par

Mauricio Esteban Fernandez RamirezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Specification For Carbon Steel Forgings, For General-Purpose Piping

Transféré par

Mauricio Esteban Fernandez RamirezDroits d'auteur :

Formats disponibles

SPECIFICATION FOR CARBON STEEL FORGINGS,

FOR GENERAL-PURPOSE PIPING

SA-181 /SA-181M

(Identical with ASTM Specification A 181 /A 181M-95b except for editorial differences in paras. 7.3.2 and 12.6.)

1. Scope A 751 Test Methods, Practices, and Terminology for

1.1 This specification covers nonstandard as-forged Chemical Analysis of Steel Products

fittings, valve components, and parts for general service. A 788 Specification for Steel Forgings, General Require-

Forgings made to this specification are limited to a maxi- ments

mum weight of 10 000 lb [4540 kg]. Larger forgings may E 165 Test Methods for Liquid Penetrant Inspection

be ordered to Specification A 266. Method

E 709 Guide for Magnetic Particle Examination

1.2 Two grades of material are covered, designated

as Classes 60 and 70, respectively, and are classified in 2.2 ASME Boiler and Pressure Vessel Code:

accordance with their chemical composition and mechan- Section IX, Welding Qualifications

ical properties as specified in 5.1 and 6.1. Section VIII, Pressure Vessels, Div. 1

1.3 Class 60 was formerly designated Grade I and

2.3 Military Standard:

Class 70 was formerly designated Grade II.

MIL-STD-163 Steel Mill Products, Preparation for Ship-

1.4 This specification is expressed in both inch-pound ment and Storage

units and SI units. However, unless the order specifies

the applicable M specification designation (SI units), 2.4 AIAG Standard:

the material shall be furnished to inch-pound units. AIAG B-5 02.00 Primary Metals Identification Tag

Application Standard

1.5 The values stated in either inch-pound units or

SI units are to be regarded as standard. Within the text,

the SI units are shown in brackets. The values stated in

each system are not exact equivalents; therefore, each 3. Ordering Information

system must be used independently of the other. Combin- 3.1 It is the purchasers responsibility to specify in

ing values from the two systems may result in noncon- the purchase order all ordering information necessary to

formance with the specification. purchase the needed material. Examples of such informa-

tion include but are not limited to the following:

2. Referenced Documents 3.1.1 Quantity,

2.1 ASTM Standards:

3.1.2 Dimensions (Tolerances and surface finishes

A 266 Specification for Forgings, Carbon Steel, for Pres-

should be included),

sure Vessel Components

A 275 /A 275M Test Method for Magnetic Particle Exam- 3.1.3 Specification number (The year date should

ination of Steel Forgings be included) and class,

A 370 Test Methods and Definitions for Mechanical Test-

3.1.4 Supplementary requirements, and

ing of Steel Products

A 700 Practices for Packaging, Marking, and Loading 3.1.5 Additional requirements (See 4.6, 12.2, 10,

Methods for Steel Products for Domestic Shipment 12.7, 17.2, 18.1, 18.2, and 11.1).

247

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

SA-181 /SA-181M 2004 SECTION II

4. Materials and Manufacture The chemical composition thus determined shall conform

4.1 The steel shall be made by the open-hearth, basic- to Table 1 within the permissible variations of Table 2.

oxygen, or electric-furnace process and shall be fully 5.2.2 Test Methods, Practices, and Terminology A

killed. 751 shall apply.

4.2 A sufficient discard shall be made from source

material to secure freedom from injurious piping and 6. Mechanical Properties

undue segregation.

6.1 The material shall conform to the requirements

4.3 The material shall be forged as close as practicable as to tensile properties prescribed in Table 3.

to the specified shape and size.

6.2 Testing shall be performed in accordance with

4.4 Except for flanges of all types, hollow, cylindri- Test Methods and Definitions A 370.

cally shaped parts may be machined from hot-rolled or

forged bar, provided that the axial length of the part is

approximately parallel to the metal flow lines of the stock. 7. Workmanship, Finish, and Appearance

Other parts, excluding flanges of all types, up to and 7.1 The forgings shall be free of injurious imperfec-

including NPS 4 may be machined from hot-rolled or tions as defined below and shall have a workmanlike

forged bar. Elbows, return bends, tees, and header tees finish. At the discretion of the inspector representing the

shall not be machined directly from bar stock. purchaser, finished forgings shall be subject to rejection

if surface imperfections acceptable under 7.3 are not scat-

4.5 Except as permitted in 4.4, the finished product tered but appear over a large area in excess of what is

shall be a forging as defined in the Terminology section considered a workmanlike finish.

(exclusively) of Specification A 788.

7.2 Depth of Injurious Imperfections Selected typi-

4.6 When specified in the order, the manufacturer cal linear and other typical surface imperfections shall

shall submit for approval of the purchaser a sketch show- be explored for depth. When the depth encroaches on the

ing the shape of the rough forging before machining. minimum wall thickness of the finished forging, such

4.7 Forgings shall be protected against sudden or too imperfections shall be considered injurious.

rapid cooling from the rolling or forging while passing 7.3 Machining or Grinding Imperfections Not Classi-

through the critical range. fied as Injurious Surface imperfections not classified

4.8 Heat treatment is neither required nor prohibited, as injurious shall be treated as follows:

but when applied, heat treatment shall consist of temper- 7.3.1 Forgings showing seams, laps, tears, or slivers

ing, annealing, normalizing, or normalizing and tem- not deeper than 5% of the nominal wall thickness or 116

pering. in. [1.6 mm], whichever is less, need not have these

imperfections removed. If the imperfections require

removal, they shall be removed by machining or grinding.

5. Chemical Composition

7.3.2 Mechanical marks or abrasions and pits shall

5.1 Cast or Heat Analysis An analysis of each cast be acceptable without grinding or machining provided

or heat shall be made by the manufacturer to determine the depth does not exceed the limitations set forth in

the percentages of the elements specified in Table 1. The 7.2 and if not deeper than 116 in. [1.6 mm]. If such

analysis shall be made from a test sample taken preferably imperfections are deeper than 116 in. [1.6 mm] but do

during the pouring of the cast or heat. The chemical not encroach on the minimum wall thickness of the forg-

composition thus determined shall conform to the require- ing they shall be removed by grinding to sound metal.

ments in Table 1.

7.3.3 When imperfections have been removed by

5.2 Product Analysis: grinding or machining, the outside dimension at the point

5.2.1 The purchaser may make a product analysis of grinding or machining may be reduced by the amount

on forgings supplied to this specification by any of the removed. Should it be impracticable to secure a direct

commonly accepted methods that will positively identify measurement, the wall thickness at the point of grinding,

the material. Samples for analysis may be taken from or at imperfections not required to be removed, shall be

midway between center and surface of solid forgings, determined by deducting the amount removed by grind-

midway between inner and outer surfaces of hollow forg- ing, from the nominal finished wall thickness of the forg-

ings, midway between center and surface of full-size ing, and the remainder shall not be less than the minimum

prolongations, or from broken mechanical test specimens. specified or required wall thickness.

248

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

PART A FERROUS MATERIAL SPECIFICATIONS SA-181 /SA-181M

8. Number of Tests 12.2 Prior approval of the purchaser shall be required

8.1 One tension test shall be made from each heat. to weld repair special parts made to the purchasers

requirements.

8.2 If any test specimen is defectively machined, it

may be discarded and another specimen substituted. 12.3 The welding procedure and welders shall be

qualified in accordance with Section IX of the ASME

Boiler and Pressure Vessel Code.

9. Retests

9.1 When one or more representative test specimens 12.4 The composition of the weld deposits shall be

do not conform to specification requirements for the tested similar to the base metal and in accordance with the

characteristic, only a single retest for each nonconforming procedure qualification for the applicable material. Weld-

characteristic may be performed to establish product ing shall be accomplished with a weld procedure designed

acceptability. Retests shall be performed on twice the to produce low hydrogen in the weldment. Short-circuit

number of representative specimens that were originally gas metal arc welding is permissible only with the

nonconforming. When any retest specimen does not con- approval of the purchaser.

form to specification requirements for the characteristic 12.5 Unacceptable imperfections shall be removed by

in question, the lot represented by that specimen shall be mechanical means or thermal cutting or gouging methods.

rejected, heat-treated or reheat-treated in accordance with Cavities prepared for welding shall be examined by one

4.8, and tested in accordance with Sections 6, 8, and 10. of the following methods to verify removal of the imper-

fection:

10. Test Specimens 12.5.1 Magnetic particle examination in accor-

10.1 The tension test specimens shall be machined dance with Test Method A 275 or Guide E 709.

to the form and dimensions of the standard 2 in. [50 mm] 12.5.2 Liquid penetrant examination in accordance

gage length tension test specimen shown in Fig. 4 of with Test Method E 165.

Test Methods and Definitions A 370, except as specified

in 10.2. 12.6 Weld repaired area(s) shall be blended uniformly

to the base metal and shall be examined by the same

10.2 In the case of small sections which will not

method used for 12.5.

permit the taking of standard test specimen specified in

10.1, the tension test specimen shall be as large as feasible 12.7 Repair by welding shall neither exceed 10% of

and its dimensions shall be proportional to those shown the surface area of the part, nor 3313% of the wall thick-

in Fig. 4 of Test Methods and Definitions A 370. The ness of the finished product at the location of repair,

gage length for measuring elongation shall be four times without prior approval of the purchaser.

the diameter of the specimen.

10.3 For the purpose of determining conformance to

Table 3, specimens shall be obtained from the production 13. Marking of Forgings

forgings, or from separately forged test blanks prepared 13.1 Identification marks consisting of the manufac-

from the stock used to make the finished product. Such turers symbol or name (Note), designation of service

test blanks shall receive approximately the same working rating, Specification number, grade, and size shall be

as the finished product. legibly forged or stamped on each forging, and in such

a position as not to injure the usefulness of the forgings.

The specification number marked on the forgings need

11. Reports of Testing not include specification year of issue and revision letter.

11.1 Upon request of the purchaser in the contract or

order, a report of the test results and chemical analyses NOTE For purposes of identification marking, the manufacturer is

considered the organization that certifies the piping component was

shall be furnished. The specification designation included

manufactured, sampled, and tested in accordance with this specification

on reports of testing shall include year of issue and revi- and the results have been determined to meet the requirements of this

sion letter, if any. specification.

13.2 Bar Coding In addition to the requirements

12. Repair by Welding in 13.1, bar coding is acceptable as a supplementary

12.1 Repair welding, by the manufacturer, is permissi- identification method. The purchaser may specify in the

ble for parts made to dimensional standards such as those order a specific bar coding system to be used. The bar

of ANSI or equivalent standards. coding system, if applied at the discretion of the supplier,

249

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

SA-181 /SA-181M 2004 SECTION II

should be consistent with one of the published industry 17. Packaging, Marking, and Loading for

standards for bar coding. If used on small parts, the bar Shipment

code may be applied to the box or a substantially 17.1 Packaging, marking, and loading for shipment

applied tag. shall be in accordance with Practices A 700.

17.2 When specified in the contract or order, and for

14. Inspection direct procurement by or direct shipment to the govern-

ment, when level A is specified, preservation, packaging,

14.1 The manufacturer shall afford the purchasers

and packing shall be in accordance with the Level A

inspector all reasonable facilities necessary to satisfy him

requirements of MIL-STD-163.

that the material is being produced and furnished in accor-

dance with this specification. Mill inspection by the pur-

chaser shall not interfere unnecessarily with the

18. Certificate of Compliance

manufacturers operations. All tests and inspections shall

be made at the place of manufacture, unless otherwise 18.1 When specified in the purchase order or contract,

agreed to. a producers or suppliers certification shall be furnished

to the purchaser that the material was manufactured, sam-

pled, tested, and inspected in accordance with this speci-

15. Rejection fication and has been found to meet the requirements.

The specification designation included on certificates of

15.1 Each forging that develops injurious defects dur-

compliance shall include year of issue and revision letter,

ing shop working or application shall be rejected and the

if any.

manufacturer notified.

18.2 When specified in the purchase order or contract,

a report of the test results shall be furnished.

16. Rehearing

16.1 Samples representing material rejected by the

purchaser shall be preserved until disposition of the claim 19. Keywords

has been agreed upon between the manufacturer and the 19.1 pipe fittings; steel; piping applications; pressure

purchaser. containing parts; steel forgings; carbon; steel valves

250

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

PART A FERROUS MATERIAL SPECIFICATIONS SA-181 /SA-181M

TABLE 1

CHEMICAL REQUIREMENTS

Composition, %

Element Classes 60 and 70

Carbon, max 0.35

Manganese, max 1.10 A

Phosphorus, max 0.05

Silicon, max 0.100.35

Sulfur, max 0.05

A

Manganese may be increased to 1.35% max provided the car-

bon is reduced 0.01% for each 0.06% increase in manganese over

the limit shown in the table.

TABLE 2

PERMISSIBLE VARIATIONS IN PRODUCT ANALYSIS

--`,,```,,,,````-`-`,,`,,`,`,,`---

Permissible Variations over the Maximum Limit or Under the Minimum Limit, %

Over 200 to 400 in.2 Over 400 to 800 in.2 Over 800 to 1600 in.2

200 in.2 [1290 cm2] [1290 to 2580 cm2] [2580 to 5160 cm2] [5160 to 10 320 Over 1600 in.2

and under incl incl cm2] [10 320 cm2]

Manganese

Up to and including 0.90 0.04 0.05 0.06 0.07 0.08

0.91 and over 0.06 0.07 0.08 0.08 0.09

Phosphorus 0.008 0.010 0.010 0.015 0.015

Sulfur 0.010 0.010 0.010 0.015 0.015

Silicon 0.03 0.04 0.04 0.05 0.06

NOTE 1 Product cross-sectional area (taken at right angles to the axis of the original ingot or billet) is defined as either:

(a) maximum cross-sectional area of rough machined forging (excluding boring),

(b) maximum cross-sectional area of the unmachined forging, or

(c) maximum cross-sectional area of the billet, bloom or slab.

TABLE 3

TENSILE REQUIREMENTS

Class 60 Class 70

Tensile strength, min, ksi [MPa] 60 [415] 70 [485]

Yield strength, A min, ksi [MPa] 30 [205] 36 [250]

Elongation in 2 in. [50 mm], min, % 22 18

Reduction of area, min, % 35 24

A

Determined by either the 0.2% offset method or the 0.5%

extension-under-load method.

251

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

SA-181 /SA-181M 2004 SECTION II

SUPPLEMENTARY REQUIREMENTS

S1. Carbon Equivalent S1.2 Determine the carbon equivalent (CE) as

follows:

S1.1 The maximum carbon equivalent based on heat

analysis shall be as follows: CE p Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

S1.3 A lower maximum carbon equivalent may be

Maximum Carbon Equivalent Value

agreed upon between the supplier and the purchaser.

Maximum Section Thickness Maximum Section Thickness

Class Less Than or Equal to 2 in. Greater Than 2 in. S1.4 When this Supplementary Requirement is

60 0.45 0.46 invoked, all elements in the carbon equivalent formula

70 0.47 0.48 shall be analyzed and the amounts reported.

252

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

Vous aimerez peut-être aussi

- Specification For Carbon Steel Forgings, For General-Purpose PipingDocument4 pagesSpecification For Carbon Steel Forgings, For General-Purpose PipingezequieltoniPas encore d'évaluation

- Asme Section Ii A-2 Sa-905Document6 pagesAsme Section Ii A-2 Sa-905Anonymous GhPzn1xPas encore d'évaluation

- A 181 - A 181M - 00 Qte4ms0wmaDocument3 pagesA 181 - A 181M - 00 Qte4ms0wmafadjarPas encore d'évaluation

- Carbon Steel Forgings For Pressure Vessel ComponentsDocument4 pagesCarbon Steel Forgings For Pressure Vessel ComponentsRishabh AroraPas encore d'évaluation

- Asme Section Ii A-2 Sa-836 Sa-836mDocument4 pagesAsme Section Ii A-2 Sa-836 Sa-836mdavid perezPas encore d'évaluation

- Steel Wire, Oil-Tempered For Mechanical SpringsDocument4 pagesSteel Wire, Oil-Tempered For Mechanical SpringsJerry BeanPas encore d'évaluation

- Astm A181-2001 PDFDocument3 pagesAstm A181-2001 PDFMohammed TariqPas encore d'évaluation

- A395x PDFDocument8 pagesA395x PDFrohit kumarPas encore d'évaluation

- ASTM A227 A227M - 06 Steel Spring WireDocument4 pagesASTM A227 A227M - 06 Steel Spring WireLesley EsparzaPas encore d'évaluation

- ASME Secc II A SA-727M Specif For Forgings Carbon Steel ForDocument6 pagesASME Secc II A SA-727M Specif For Forgings Carbon Steel ForEduardo ArrietaPas encore d'évaluation

- ASTM A 487 (Impeller) PDFDocument6 pagesASTM A 487 (Impeller) PDFnugrohowiwitPas encore d'évaluation

- Astm 401Document4 pagesAstm 401JOSEPH REFUERZOPas encore d'évaluation

- Astm 401 PDFDocument4 pagesAstm 401 PDFJOSEPH REFUERZOPas encore d'évaluation

- Sa 420Document10 pagesSa 420Widya widyaPas encore d'évaluation

- Specification For Carbon Steel Forgings For Pressure Vessel ComponentsDocument6 pagesSpecification For Carbon Steel Forgings For Pressure Vessel Componentsmr.aghelPas encore d'évaluation

- Asme Section Ii A-2 Sa-727 Sa-727mDocument6 pagesAsme Section Ii A-2 Sa-727 Sa-727mdavid perezPas encore d'évaluation

- SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKDocument10 pagesSAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKFerry SiegersPas encore d'évaluation

- A 181 Â " A 181M Â " 01 - QTE4MS9BMTGXTQDocument3 pagesA 181 Â " A 181M Â " 01 - QTE4MS9BMTGXTQhans ccPas encore d'évaluation

- A 181 - A 181M - 01 Qte4ms9bmtgxtqDocument3 pagesA 181 - A 181M - 01 Qte4ms9bmtgxtqfadjarPas encore d'évaluation

- Steel Wire, Modified Chromium Vanadium Valve Spring Quality: Standard Specification ForDocument4 pagesSteel Wire, Modified Chromium Vanadium Valve Spring Quality: Standard Specification ForDouglasPas encore d'évaluation

- Sa 350Document12 pagesSa 350ismaelarchilacastilloPas encore d'évaluation

- Asme Section Ii A-2 Sa-675 Sa-675mDocument6 pagesAsme Section Ii A-2 Sa-675 Sa-675mdavid perezPas encore d'évaluation

- Asme Section Ii A-2 Sa-995Document4 pagesAsme Section Ii A-2 Sa-995Anonymous GhPzn1xPas encore d'évaluation

- Astm A 27 PDFDocument4 pagesAstm A 27 PDFmvalenzuelatPas encore d'évaluation

- Astm A 401 - A 401M - 03 - Qtqwms9bndaxtqDocument4 pagesAstm A 401 - A 401M - 03 - Qtqwms9bndaxtqEjat IS100% (1)

- Carbon Steel Forgings, For General-Purpose PipingDocument3 pagesCarbon Steel Forgings, For General-Purpose PipingedwinbadajosPas encore d'évaluation

- Astm A227Document4 pagesAstm A227Luis Eduardo PlazasPas encore d'évaluation

- ASTM-A227 Spring SteelDocument4 pagesASTM-A227 Spring SteelLalo CastañedaPas encore d'évaluation

- High-Strength Low-Alloy Structural Steel Plate With Low Carbon and Restricted Sulfur For Improved Weldability, Formability, and ToughnessDocument3 pagesHigh-Strength Low-Alloy Structural Steel Plate With Low Carbon and Restricted Sulfur For Improved Weldability, Formability, and ToughnessDiegoPas encore d'évaluation

- Sa 351Document7 pagesSa 351Pavul RajPas encore d'évaluation

- A27-A27m Standard Specification For Steel Castings, Carbon, For General ApplicationDocument4 pagesA27-A27m Standard Specification For Steel Castings, Carbon, For General Applicationarmando0212-1Pas encore d'évaluation

- ASTM - A 27 - Standard Specification For Steel Castings, Carb PDFDocument4 pagesASTM - A 27 - Standard Specification For Steel Castings, Carb PDFMohamed RizkPas encore d'évaluation

- Asme Section Ii A Sa-181 Sa-181mDocument4 pagesAsme Section Ii A Sa-181 Sa-181mksd2Pas encore d'évaluation

- A 395 - A 395M - 99 QTM5NS9BMZK1TQDocument8 pagesA 395 - A 395M - 99 QTM5NS9BMZK1TQserkandmPas encore d'évaluation

- ASTM A 706 Standard Specification For Low-Alloy Steel Deformed and Plain Bars For Concrete ReinforcementDocument5 pagesASTM A 706 Standard Specification For Low-Alloy Steel Deformed and Plain Bars For Concrete ReinforcementRyan LasacaPas encore d'évaluation

- A 877 - A877mDocument4 pagesA 877 - A877mAon HemmatadPas encore d'évaluation

- A230A230M-05 (2011) E1 Standard Specification For Steel Wire, Oil-Tempered Carbon Valve Spring QualityDocument4 pagesA230A230M-05 (2011) E1 Standard Specification For Steel Wire, Oil-Tempered Carbon Valve Spring Qualitytjt4779Pas encore d'évaluation

- Steel Wire, Pressure Vessel Winding: Standard Specification ForDocument3 pagesSteel Wire, Pressure Vessel Winding: Standard Specification ForDouglasPas encore d'évaluation

- Astm A 27 PDFDocument4 pagesAstm A 27 PDFRyan LasacaPas encore d'évaluation

- Astm-A707 CS As LTS PDFDocument5 pagesAstm-A707 CS As LTS PDFGoutam Kumar DebPas encore d'évaluation

- A 266 - A 266M - 03 Qti2ni0wmw - PDFDocument4 pagesA 266 - A 266M - 03 Qti2ni0wmw - PDFCristian CanavidesPas encore d'évaluation

- Chromium-Vanadium Alloy Steel Spring Wire: Standard Specification ForDocument4 pagesChromium-Vanadium Alloy Steel Spring Wire: Standard Specification ForHoem ITPas encore d'évaluation

- Steel Wire, Cold-Drawn For Mechanical SpringsDocument4 pagesSteel Wire, Cold-Drawn For Mechanical SpringsARAVIND PATILPas encore d'évaluation

- A705A705MDocument7 pagesA705A705MAnderson TadeuPas encore d'évaluation

- Sa 453Document10 pagesSa 453Widya widyaPas encore d'évaluation

- Standard ASTM A 470-01Document6 pagesStandard ASTM A 470-01Dumitru PascuPas encore d'évaluation

- Steel Castings Suitable For Pressure ServiceDocument6 pagesSteel Castings Suitable For Pressure ServiceJerry BeanPas encore d'évaluation

- Astm A 227 A227m 2006Document4 pagesAstm A 227 A227m 2006Aadhya engineering ServicesPas encore d'évaluation

- Compendio Normas de AceroDocument10 pagesCompendio Normas de AceroBIELDELPas encore d'évaluation

- A878A878M-05 (2011) Standard Specification For Steel Wire, Modified Chromium Vanadium Valve Spring QualityDocument4 pagesA878A878M-05 (2011) Standard Specification For Steel Wire, Modified Chromium Vanadium Valve Spring Qualitytjt4779Pas encore d'évaluation

- Steel Castings, Carbon, For General ApplicationDocument4 pagesSteel Castings, Carbon, For General Applicationsandeep acharPas encore d'évaluation

- A859A859M-04 (Reapproved 2014) PDFDocument5 pagesA859A859M-04 (Reapproved 2014) PDFHadi HowaidaPas encore d'évaluation

- Steel Wire, Oil-Tempered Carbon Valve Spring Quality: Standard Specification ForDocument4 pagesSteel Wire, Oil-Tempered Carbon Valve Spring Quality: Standard Specification ForErick ERICKPas encore d'évaluation

- Astm A395-1999 (2018)Document8 pagesAstm A395-1999 (2018)senthil selvarajPas encore d'évaluation

- Astm A266x 2021Document5 pagesAstm A266x 2021amitPas encore d'évaluation

- Astm 487Document6 pagesAstm 487JOSEPH REFUERZOPas encore d'évaluation

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Brittle Fracture in Steel StructuresD'EverandBrittle Fracture in Steel StructuresG.M. BoydPas encore d'évaluation

- (Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodDocument4 pages(Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodMauricio Esteban Fernandez RamirezPas encore d'évaluation

- 3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 K Gh6HswlhpeuhghDocument4 pages3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 K Gh6HswlhpeuhghMauricio Esteban Fernandez RamirezPas encore d'évaluation

- 7hfqrorjtdgh) Deulfdflyq 3ureohpdv KrudvDocument5 pages7hfqrorjtdgh) Deulfdflyq 3ureohpdv KrudvMauricio Esteban Fernandez RamirezPas encore d'évaluation

- 3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 K Gh6HswlhpeuhghDocument3 pages3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 K Gh6HswlhpeuhghMauricio Esteban Fernandez RamirezPas encore d'évaluation

- (Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodDocument4 pages(Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodMauricio Esteban Fernandez RamirezPas encore d'évaluation

- (Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodDocument4 pages(Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodMauricio Esteban Fernandez RamirezPas encore d'évaluation

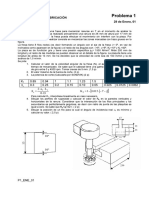

- 3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 KP GH (QhurDocument3 pages3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 KP GH (QhurMauricio Esteban Fernandez RamirezPas encore d'évaluation

- Cuaderno 2Document10 pagesCuaderno 2Mauricio Esteban Fernandez RamirezPas encore d'évaluation

- F I / D I D I U UDocument4 pagesF I / D I D I U UMauricio Esteban Fernandez RamirezPas encore d'évaluation

- XsxsDocument6 pagesXsxsMauricio Esteban Fernandez RamirezPas encore d'évaluation

- Specification For Carbon Steel Forgings For Piping ApplicationsDocument10 pagesSpecification For Carbon Steel Forgings For Piping ApplicationsMauricio Esteban Fernandez RamirezPas encore d'évaluation

- 7hfqrorjtdvgh) Deulfdflyq 3ureohpd: 7lhpsrgxudflyqk 6hswlhpeuhghDocument3 pages7hfqrorjtdvgh) Deulfdflyq 3ureohpd: 7lhpsrgxudflyqk 6hswlhpeuhghMauricio Esteban Fernandez RamirezPas encore d'évaluation

- 7hfqrorjtdvgh) Deulfdflyq 3ureohpd: 7Lhpsrk GH) HeuhurDocument4 pages7hfqrorjtdvgh) Deulfdflyq 3ureohpd: 7Lhpsrk GH) HeuhurMauricio Esteban Fernandez RamirezPas encore d'évaluation

- Diurno1trans PDFDocument10 pagesDiurno1trans PDFMauricio Esteban Fernandez RamirezPas encore d'évaluation

- Cuaderno 1Document10 pagesCuaderno 1Mauricio Esteban Fernandez RamirezPas encore d'évaluation

- Specification For Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes Nps 16 and Over)Document6 pagesSpecification For Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes Nps 16 and Over)Mauricio Esteban Fernandez RamirezPas encore d'évaluation

- Specification For Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater TubesDocument6 pagesSpecification For Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater TubesMauricio Esteban Fernandez RamirezPas encore d'évaluation

- Index: Acoustic Emission Examination of Fiber-Reinforced Plastic Vessels, Article 11Document7 pagesIndex: Acoustic Emission Examination of Fiber-Reinforced Plastic Vessels, Article 11Mauricio Esteban Fernandez RamirezPas encore d'évaluation

- Specification For Seamless Medium-Carbon Steel Boiler and Superheater TubesDocument4 pagesSpecification For Seamless Medium-Carbon Steel Boiler and Superheater TubesMauricio Esteban Fernandez RamirezPas encore d'évaluation

- Specification For Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-Finished, General Requirements ForDocument26 pagesSpecification For Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-Finished, General Requirements ForMauricio Esteban Fernandez RamirezPas encore d'évaluation

- Ayudantía Diseño - 20171011231336Document3 pagesAyudantía Diseño - 20171011231336Mauricio Esteban Fernandez RamirezPas encore d'évaluation

- Specification For Carbon Structural Steel: SA-36 /SA-36MDocument6 pagesSpecification For Carbon Structural Steel: SA-36 /SA-36MMauricio Esteban Fernandez RamirezPas encore d'évaluation

- CELLSDocument21 pagesCELLSPhia LhiceraPas encore d'évaluation

- Reduced Complexity Decision Feedback Equalizer For Supporting High Mobility in WimaxDocument5 pagesReduced Complexity Decision Feedback Equalizer For Supporting High Mobility in Wimaxjoy0302Pas encore d'évaluation

- Excel FunctionsDocument13 pagesExcel Functionsfhlim2069Pas encore d'évaluation

- Spiking Into Aqueous Samples: Standard Guide ForDocument6 pagesSpiking Into Aqueous Samples: Standard Guide Formohdhafizmdali100% (1)

- Chap. 49 Modes: 3. Modes On Regular Triangular DrumDocument9 pagesChap. 49 Modes: 3. Modes On Regular Triangular DrumfudogPas encore d'évaluation

- Strike RiskDocument4 pagesStrike RiskAdilson Leite ProençaPas encore d'évaluation

- CR EstimateDocument307 pagesCR EstimateGani AnosaPas encore d'évaluation

- KTM Tokamak Project. Present and Future Activity: January 2008Document9 pagesKTM Tokamak Project. Present and Future Activity: January 2008AB XEROXPas encore d'évaluation

- Inductive Sensor For Temperature Measurement in Induction Heating Applications PDFDocument8 pagesInductive Sensor For Temperature Measurement in Induction Heating Applications PDFNjabulo XoloPas encore d'évaluation

- DTP German Volume Training StyleDocument37 pagesDTP German Volume Training StyleRyan Pan100% (1)

- Brochure Cementindustrie PfeifferDocument24 pagesBrochure Cementindustrie Pfeifferdoxa maria0% (1)

- The Effects of GeoGebra Software On Pre-Service Mathematics Teachers' Attitudes and Views Toward Proof and ProvingDocument22 pagesThe Effects of GeoGebra Software On Pre-Service Mathematics Teachers' Attitudes and Views Toward Proof and ProvingLidra Ety Syahfitri Harahap lidraety.2022Pas encore d'évaluation

- KW Kwh/YrDocument3 pagesKW Kwh/YrHaris BaigPas encore d'évaluation

- DISTANCE MEASUREMENT - Problem Solving With Theory and Objective Type QuestionsDocument40 pagesDISTANCE MEASUREMENT - Problem Solving With Theory and Objective Type QuestionsSakuntala Uteebrirova100% (2)

- Homework # 4:: Hazard Analysis, Groundmotion, Response Spectrum and Nonlinear ResponseDocument2 pagesHomework # 4:: Hazard Analysis, Groundmotion, Response Spectrum and Nonlinear ResponseAbhinavPas encore d'évaluation

- Basic Concepts in Biostatistics 1-1Document36 pagesBasic Concepts in Biostatistics 1-1Teslim RajiPas encore d'évaluation

- 4-DatAdvantage Advanced Installation For Microsoft Platforms 8.6 - M365 PatchDocument158 pages4-DatAdvantage Advanced Installation For Microsoft Platforms 8.6 - M365 PatchyaritzaPas encore d'évaluation

- BB Conduction-and-ConvectionDocument13 pagesBB Conduction-and-ConvectionRamon LlonaPas encore d'évaluation

- Unit QuestionsDocument155 pagesUnit QuestionsSanya KhanPas encore d'évaluation

- Onion Ring Magic SquareDocument8 pagesOnion Ring Magic SquareMJ Foust100% (2)

- Juniper SRX Quickstart-12.1r3Document455 pagesJuniper SRX Quickstart-12.1r3Pichai Ng-arnpairojhPas encore d'évaluation

- Fatique Lecture NotesDocument41 pagesFatique Lecture NotesMarcel SilvaPas encore d'évaluation

- COE Test 06 Code A JEE Main 2024 XII 09 10 2023answer KeyDocument1 pageCOE Test 06 Code A JEE Main 2024 XII 09 10 2023answer KeyaebagnedhPas encore d'évaluation

- Warrick 26m Control de Nivel AuxiliarDocument3 pagesWarrick 26m Control de Nivel AuxiliarCarlos WayPas encore d'évaluation

- W12 1321 01 ADocument19 pagesW12 1321 01 ALucy SimmondsPas encore d'évaluation

- Force Plates: Pressure TransducerDocument9 pagesForce Plates: Pressure Transduceramit_pt021Pas encore d'évaluation

- Latex ProjectDocument3 pagesLatex ProjectPrincess MiroPas encore d'évaluation

- Switchgear and Protection May 2022Document1 pageSwitchgear and Protection May 2022Sanapala RAJENDRA PRASADPas encore d'évaluation

- Metoda Securiti Pada DNP3 ProtokolDocument16 pagesMetoda Securiti Pada DNP3 ProtokolDeny AriefPas encore d'évaluation

- Effects of The Cone and Edge On The Acoustic Characteristics Ofa Cone LoudspeakerDocument13 pagesEffects of The Cone and Edge On The Acoustic Characteristics Ofa Cone LoudspeakerJavierPas encore d'évaluation