Académique Documents

Professionnel Documents

Culture Documents

Installation Instructions for Khafagi Venturi Flumes

Transféré par

IvanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Installation Instructions for Khafagi Venturi Flumes

Transféré par

IvanDroits d'auteur :

Formats disponibles

Installation Instructions

Khafagi venturi flumes

L

b

ha

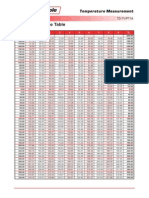

Note! It is very important for the overall measuring h a[m] 1

accuracy to comply with the installation

instructions on the next page. 200mm

160mm

General At free flow, only the level ha is measured. 120mm

The location of the sensor is important and

must be carried out as illustrated below. It is

important to have a laminar flow (horizontal 0,1

streaming calm water with no whirls) at the

outlet and inlet from the flume, and the outlet

must be unobstructed.

The flume must extend upstream at least ten

times the width of the inlet section of the

flume. On the outlet side the only demand is 0,01

that the water should run freely. 0,1 1 10 100 1000

3

Q [m /h]

The flow is calculated from the following

formula: Q/h diagram for the Khafagi Venturi

Q = 6278 x b x ha1,5 + 328 x ha2,5 flumes, the height ha is shown as a

function of the flow Q.

where:

Q= flow in [m3/h]

b= width in the flume in [m]

ha = level

L = distance to sensor = 3 - 4 x ha max

H= height of the flume

Specifications Size QMIN QMAX HMAX Weight

5 inch 120 mm 35 m3/h 125 mm 18.6 kg

5 inch 120 mm Contact 120 m3/h 273 mm 28.5 kg

6 inch 160 mm MJK 150 m3/h 267 mm 38.9 kg

8 inch 200 mm 200 m3/h 281 mm 54.0 kg

8 inch 200 mm 450 m3/h 467 mm 76.0 kg

Material AISI 316

pH range 3 - 10 pH

MJK Automation A/S

KHAF0400GB As our products are developed continuously,

we reserve the right to make any changes without prior notice.

Byageren 7

DK-2850 Nrum

Denmark

Tel.: (+45) 45 56 06 56

Fax: (+45) 45 56 06 46

mjk@mjk.dk

www.mjk.dk

Installation instructions

Instructions

Mounting of the flume The flume is designed to be moulded into concrete. Concrete with a low content of water

should be used - a plasticizer can be mixed in.

1 Position the flume correctly in relation to the flow direction. Observe the flow direction as

indicated with an arrow at the inlet. See also the dimensional illustration below.

2 Fix the flume in the shuttering and make sure it is precisely leveled in both directions.

Levelled both laterally and longitudinally!

3 Cover inlet and outlet with plywood board or similar and put a piece of wood inside the

flume to support its sides.

4 Fill concrete into the shuttering until it lies a little higher than the bottom of the flume and

vibrate, so that the concrete becomes well distributed under the flume.

NB! Let the concrete harden before filling the sides of the shuttering, so the flume will be

firmly secured in the concrete.

5 Fill both sides with concrete. Do not vibrate the concrete at the sides of the flume!

6 A 10 mm elastic infill along both sides of the flume is recommended to prevent water

penetration and possible frost fracture.

Sensor distance 7 Mount the sensor bracket so that the sensor will be located at a distance L from the

flume throat as explained on the front page.

Dimensions

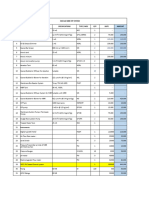

Size A B C D E

5 inch 150 120 300 1050 400

5 inch 300 120 300 1050 400

6 inch 300 160 400 1400 500

8 inch 320 200 500 1750 600

8 inch 520 200 500 1750 600

All measurements in mm

MJK Automation A/S

2 Byageren 7

DK-2850 Nrum

Denmark

Tel.: (+45) 45 56 06 56

Fax: (+45) 45 56 06 46

mjk@mjk.dk

www.mjk.dk

Vous aimerez peut-être aussi

- Guiffre V MaxwellDocument40 pagesGuiffre V MaxwellTechno Fog91% (32)

- Borehole Friction Assessment and Application To Oilfield Casing DDocument279 pagesBorehole Friction Assessment and Application To Oilfield Casing DAntónio Pedro TavaresPas encore d'évaluation

- Flow Measurement - Khafagi VenturiDocument8 pagesFlow Measurement - Khafagi VenturiNguyen Phuc PhamPas encore d'évaluation

- PT100 TableDocument2 pagesPT100 TableEdgar LopesPas encore d'évaluation

- 166-31590 Manual BaylorDocument54 pages166-31590 Manual BaylorJairo Peña100% (5)

- Vibration AnalysisDocument12 pagesVibration AnalysistheealokPas encore d'évaluation

- Zama Walbro Carburetor Theory and DiagramsDocument12 pagesZama Walbro Carburetor Theory and Diagramsrzawa77100% (2)

- Caterpillar CatAVR V2 3Document23 pagesCaterpillar CatAVR V2 3IvanPas encore d'évaluation

- Chapter 18 FiltrationDocument18 pagesChapter 18 FiltrationGMDGMD11Pas encore d'évaluation

- Digi-Drive Operating InstructionsDocument48 pagesDigi-Drive Operating InstructionsIvan100% (1)

- Water Treatment Plant Operation: Coagulation and FiltrationDocument27 pagesWater Treatment Plant Operation: Coagulation and FiltrationmsinsignePas encore d'évaluation

- SBRDocument44 pagesSBRNavneet Singh67% (3)

- PWM Power Inverter 250 To 5000 WattDocument17 pagesPWM Power Inverter 250 To 5000 WattMolay Karmakar100% (1)

- Memcor UF Product Data Sheet CPII MemRackDocument2 pagesMemcor UF Product Data Sheet CPII MemRackDio MiPas encore d'évaluation

- 14 - Hydraulic Design of Urban Drainage Systems PDFDocument45 pages14 - Hydraulic Design of Urban Drainage Systems PDFDeprizon SyamsunurPas encore d'évaluation

- 2014 Berghof Membrane TechnologyDocument53 pages2014 Berghof Membrane TechnologyVictor DominguezPas encore d'évaluation

- Fabm2 q2 Module 4 TaxationDocument17 pagesFabm2 q2 Module 4 TaxationLady HaraPas encore d'évaluation

- L6 Activated Sludge SystemDocument38 pagesL6 Activated Sludge SystemNurul Aliza100% (2)

- Gas Chromatography - COLIN F. POOLE 2012 PDFDocument743 pagesGas Chromatography - COLIN F. POOLE 2012 PDFVo Manh Tien100% (1)

- Activated Sludge Process Design - Calculation, Example With ProcedureDocument13 pagesActivated Sludge Process Design - Calculation, Example With ProcedureTosca MachimbiraPas encore d'évaluation

- Flow Chart of Kitchen Wastewater Reuse System Using KUBOTA Submerged Membrane UnitDocument1 pageFlow Chart of Kitchen Wastewater Reuse System Using KUBOTA Submerged Membrane UnitmutazsalihPas encore d'évaluation

- BAYLOR 7040 166-54238 Rev FDocument68 pagesBAYLOR 7040 166-54238 Rev FPablo Galvez Rodriguez100% (3)

- Compressor House Unit-3Document199 pagesCompressor House Unit-3Priyanka BasuPas encore d'évaluation

- Ecoprocesstm SBR Design NotesDocument3 pagesEcoprocesstm SBR Design NotesTrilok ChandraPas encore d'évaluation

- Planning, Design, Installation Operation and Maintenance ofDocument40 pagesPlanning, Design, Installation Operation and Maintenance ofSaiteja PanyamPas encore d'évaluation

- Simple Activated Sludge Design With Septic Tank 3000Document4 pagesSimple Activated Sludge Design With Septic Tank 3000AlyannaKatePalasPas encore d'évaluation

- Activated Sludge Waste Water Treatment Calculations - S.I. UnitsDocument2 pagesActivated Sludge Waste Water Treatment Calculations - S.I. Unitsnsr2t100% (1)

- Fs-Bio-010-Mbr A20160202Document25 pagesFs-Bio-010-Mbr A20160202GREENLAB ECL TECHPas encore d'évaluation

- Arid Zone Hydrology - SchoellerDocument123 pagesArid Zone Hydrology - Schoellerhashmath01Pas encore d'évaluation

- 20130503132937Document19 pages20130503132937Wendy0% (1)

- GESTAR 2014 User's Manual Installation RequirementsDocument556 pagesGESTAR 2014 User's Manual Installation RequirementsReRersPas encore d'évaluation

- KUBOTA Submerged Membrane Unit Optional Parts: Lifting Tool Guide SetDocument1 pageKUBOTA Submerged Membrane Unit Optional Parts: Lifting Tool Guide SetmutazsalihPas encore d'évaluation

- VISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSDocument8 pagesVISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSFrancisco TipanPas encore d'évaluation

- MBR Design SheetDocument9 pagesMBR Design SheetVenkatesh SivaramanPas encore d'évaluation

- Design & Sizing WWTPDocument30 pagesDesign & Sizing WWTPRavishankar APas encore d'évaluation

- Machine Tools Cutting FluidsDocument133 pagesMachine Tools Cutting FluidsDamodara MadhukarPas encore d'évaluation

- Parshall Flumes Manual (1960) PDFDocument61 pagesParshall Flumes Manual (1960) PDFBenjamín Andres Lagos BerriosPas encore d'évaluation

- Water Reuse For Irrigation-Agriculture Landscapes and TurfGrassDocument19 pagesWater Reuse For Irrigation-Agriculture Landscapes and TurfGrassAntónio OliveiraPas encore d'évaluation

- Robinson1987fermat and The Principle of Least Time PDFDocument4 pagesRobinson1987fermat and The Principle of Least Time PDFarun rajaramPas encore d'évaluation

- Reece Irrigation PlannerDocument6 pagesReece Irrigation PlannerHenry BettisonPas encore d'évaluation

- Aqwise New Integrated Solutions BrochureDocument8 pagesAqwise New Integrated Solutions BrochureNguyen Bao NguyenPas encore d'évaluation

- Considerations on Using Airlift Pumps in Sewage TreatmentDocument7 pagesConsiderations on Using Airlift Pumps in Sewage TreatmentvladmmuresanPas encore d'évaluation

- Dwarf Boas of The Caribbean PDFDocument5 pagesDwarf Boas of The Caribbean PDFJohn GamesbyPas encore d'évaluation

- Self-Aerated Flow On Corps of Engineers SpillwaysDocument112 pagesSelf-Aerated Flow On Corps of Engineers SpillwaysdjajadjajaPas encore d'évaluation

- Friction Factor CalculationsDocument2 pagesFriction Factor CalculationsHu Hin AngPas encore d'évaluation

- MBBR enDocument4 pagesMBBR enRoland LumpasPas encore d'évaluation

- Fab Reactor 2Document5 pagesFab Reactor 2Yasmeen Sana SaadiPas encore d'évaluation

- MBBR Design CalculationDocument5 pagesMBBR Design CalculationPANDIARAJ KARUPPATHEVARPas encore d'évaluation

- Lesson 17 - Activated SludgeDocument8 pagesLesson 17 - Activated SludgeShane RodriguezPas encore d'évaluation

- Topology Rules and Validation in ArcGISDocument25 pagesTopology Rules and Validation in ArcGISCristina CristeaPas encore d'évaluation

- EWT Carrousel Systems: UNR SeriesDocument8 pagesEWT Carrousel Systems: UNR SeriesKhang TrầnPas encore d'évaluation

- Step-by-step guide to designing Parshall flumesDocument29 pagesStep-by-step guide to designing Parshall flumesCarlos AlviarezPas encore d'évaluation

- Trickling Filter and Trickling Filter-Suspended Growth Process Design and OperationDocument19 pagesTrickling Filter and Trickling Filter-Suspended Growth Process Design and OperationMichał KisielewskiPas encore d'évaluation

- Drinking Water Treatment Residuals - A Review of Recent UsesDocument12 pagesDrinking Water Treatment Residuals - A Review of Recent Usesgabriel oliveiraPas encore d'évaluation

- Flow in Conduits: Fluid Mechanics, Spring Term 2009Document44 pagesFlow in Conduits: Fluid Mechanics, Spring Term 2009Remoremo RemoPas encore d'évaluation

- Standard Step Method (STMDocument8 pagesStandard Step Method (STMtonka1406Pas encore d'évaluation

- MBBR Product Information MaterialsDocument2 pagesMBBR Product Information MaterialsAvinash kandharePas encore d'évaluation

- Nomenclature and Positioning of Mixers in Non-Aerated TanksDocument6 pagesNomenclature and Positioning of Mixers in Non-Aerated TanksYash SPas encore d'évaluation

- AWW December 2017Document68 pagesAWW December 2017prabal rayPas encore d'évaluation

- Teknofanghi Monoscrew Pump - CatalougeDocument4 pagesTeknofanghi Monoscrew Pump - CatalougeKarim ShamashergyPas encore d'évaluation

- Surface Water Treatment Operations Plan TemplateDocument8 pagesSurface Water Treatment Operations Plan TemplateSkid RowPas encore d'évaluation

- Présentation SWMMDocument16 pagesPrésentation SWMMAnonymous 7obx8JKPas encore d'évaluation

- WeirDocument12 pagesWeirBabylyn Austria100% (1)

- Collection and Distribution of Water 4.1 Types of IntakeDocument71 pagesCollection and Distribution of Water 4.1 Types of IntakenimcanPas encore d'évaluation

- Grey Water Recycling & ReuseDocument21 pagesGrey Water Recycling & Reuseven1959100% (1)

- Wastewater Treatment Plants (WWTP) : General Flow Diagram For The Wastewater Treatment PlantDocument12 pagesWastewater Treatment Plants (WWTP) : General Flow Diagram For The Wastewater Treatment PlantAhmed AmediPas encore d'évaluation

- Environmental Engg - Water TreatmentDocument14 pagesEnvironmental Engg - Water TreatmenthitkcivilPas encore d'évaluation

- Lecture 5 - FiltrationDocument90 pagesLecture 5 - FiltrationChuah Chong YangPas encore d'évaluation

- Calculos Torre de AireacionDocument8 pagesCalculos Torre de AireacionMonica Alexandra Rueda RamirezPas encore d'évaluation

- Combined & Separate Sewer SystemsDocument9 pagesCombined & Separate Sewer SystemsKhairylle JuanPas encore d'évaluation

- 9 Wet Weather FreakonomicsDocument58 pages9 Wet Weather FreakonomicsRJN Group, Inc.Pas encore d'évaluation

- M13 - L17 Grit ChamberDocument6 pagesM13 - L17 Grit ChamberBerliana Cahya Ningtias0% (1)

- Bab IX OrificeDocument40 pagesBab IX OrificeDark Specialist DPas encore d'évaluation

- cANAL PARSHALL CATALOGODocument2 pagescANAL PARSHALL CATALOGOJuan AlejandroPas encore d'évaluation

- Endress y Hausser Flow MeasureDocument8 pagesEndress y Hausser Flow MeasureAlicia ArellanoPas encore d'évaluation

- Hitachi L100M AC DrivesDocument23 pagesHitachi L100M AC DrivesIvanPas encore d'évaluation

- CROSCO DC 752 Man 1Document82 pagesCROSCO DC 752 Man 1IvanPas encore d'évaluation

- Sices GC 250 ManualDocument4 pagesSices GC 250 ManualIvan50% (2)

- CROSCO DC 752 Man 1Document82 pagesCROSCO DC 752 Man 1IvanPas encore d'évaluation

- Pumpe Za Termicka Ulja - Thermic Oil PumpsDocument2 pagesPumpe Za Termicka Ulja - Thermic Oil PumpsIvanPas encore d'évaluation

- Mini/Microsim To Nanosim Cutting GuideDocument1 pageMini/Microsim To Nanosim Cutting GuideJeff JjPas encore d'évaluation

- Hitachi L100M AC DrivesDocument23 pagesHitachi L100M AC DrivesIvanPas encore d'évaluation

- ZM 33064Document5 pagesZM 33064IvanPas encore d'évaluation

- Primjer PCF8591PDocument2 pagesPrimjer PCF8591PIvanPas encore d'évaluation

- Mjerni TraficiDocument9 pagesMjerni TraficiIvanPas encore d'évaluation

- Primjer PCF8591PDocument2 pagesPrimjer PCF8591PIvanPas encore d'évaluation

- Tablice TežinaDocument84 pagesTablice TežinaAmanda BrownPas encore d'évaluation

- EPGDocument24 pagesEPGIvanPas encore d'évaluation

- RPM BascomDocument2 pagesRPM BascomIvanPas encore d'évaluation

- Sr4a FilesDocument43 pagesSr4a FilesdjibtapzPas encore d'évaluation

- Primjer 1Document3 pagesPrimjer 1IvanPas encore d'évaluation

- Tablice TežinaDocument84 pagesTablice TežinaAmanda BrownPas encore d'évaluation

- Alpha Phi Omega National Service Fraternity Strategic PlanDocument1 pageAlpha Phi Omega National Service Fraternity Strategic Planlafay3ttePas encore d'évaluation

- The Quantum Gravity LagrangianDocument3 pagesThe Quantum Gravity LagrangianNige Cook100% (2)

- Culinary Nutrition BasicsDocument28 pagesCulinary Nutrition BasicsLIDYAPas encore d'évaluation

- Primary Homework Help Food ChainsDocument7 pagesPrimary Homework Help Food Chainsafnaxdxtloexll100% (1)

- Data Validation and Verification - BBC BitsizeDocument56 pagesData Validation and Verification - BBC BitsizeluciferothegoatPas encore d'évaluation

- Trabajo de Investigación FormativaDocument75 pagesTrabajo de Investigación Formativalucio RPas encore d'évaluation

- Online Music QuizDocument3 pagesOnline Music QuizGiang VõPas encore d'évaluation

- Marketing of Agriculture InputsDocument18 pagesMarketing of Agriculture InputsChanakyaPas encore d'évaluation

- IS 2848 - Specition For PRT SensorDocument25 pagesIS 2848 - Specition For PRT SensorDiptee PatingePas encore d'évaluation

- Operation Manual TempoLink 551986 enDocument12 pagesOperation Manual TempoLink 551986 enBryan AndradePas encore d'évaluation

- Mehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Document294 pagesMehdi Semati - Media, Culture and Society in Iran - Living With Globalization and The Islamic State (Iranian Studies)Alexandra KoehlerPas encore d'évaluation

- Rpo 1Document496 pagesRpo 1Sean PrescottPas encore d'évaluation

- Insert BondingDocument14 pagesInsert BondingHelpful HandPas encore d'évaluation

- Galley cleaning hazards and controlsDocument9 pagesGalley cleaning hazards and controlsRosalie RosalesPas encore d'évaluation

- Lignan & NeolignanDocument12 pagesLignan & NeolignanUle UlePas encore d'évaluation

- Project Final Report: Crop BreedingDocument16 pagesProject Final Report: Crop BreedingAniket PatilPas encore d'évaluation

- Study Quran Online - The Online Quran Teaching Academy UK - QutorDocument9 pagesStudy Quran Online - The Online Quran Teaching Academy UK - QutorQutor co ukPas encore d'évaluation

- Thinking and Acting Outside The BoxDocument36 pagesThinking and Acting Outside The BoxMariecris GatlabayanPas encore d'évaluation

- Data Sheet FC SIDocument2 pagesData Sheet FC SIAndrea AtzeniPas encore d'évaluation

- Classification of Methods of MeasurementsDocument60 pagesClassification of Methods of MeasurementsVenkat Krishna100% (2)

- Value Chain AnalysisDocument4 pagesValue Chain AnalysisnidamahPas encore d'évaluation

- EE114-1 Homework 2: Building Electrical SystemsDocument2 pagesEE114-1 Homework 2: Building Electrical SystemsGuiaSanchezPas encore d'évaluation

- (V) 2020-Using Extensive Reading in Improving Reading Speed and Level of Reading Comprehension of StudentsDocument7 pages(V) 2020-Using Extensive Reading in Improving Reading Speed and Level of Reading Comprehension of StudentsMEYTA RAHMATUL AZKIYAPas encore d'évaluation