Académique Documents

Professionnel Documents

Culture Documents

Fisher TAD-9415 PDF

Transféré par

jose44450 évaluation0% ont trouvé ce document utile (0 vote)

16 vues70 pagesTitre original

Fisher_TAD-9415.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

16 vues70 pagesFisher TAD-9415 PDF

Transféré par

jose4445Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 70

T ae °

FILE NO.

SERVICE MANUAL

Contents

Specitication

Operating the Reset Switch

Laser Beam Safety Precaution

Handling the Pickup

Before Repairing the CD Player

Disassembly

Adjustment Mechanism

Standard Maintenance

Lead Wire Attachment

System Connection

Description of Operation .

low Chart of Operation

Service Mode (CD)

Service Mode (Tuner & Ano)

2D Adjustment. :

Tape Deck Adjustment

Tape Dock Torque & Replacement

Tuner Adjustment

Exploded View (Cabinet)

Exploded View (Chassis)

Parts List

Parts List (CD Mechanism)

Exploded View (CD Base Mechanisrn)

“This Service manual consists of "TAD-341

RLEFLESSSSSREVSROLNmNMa=

(us)

Digital High-Fidelity System

with REM-9415 Wireless Remote Control

PRODUCT CODE No.

129 438 00

Exploded View (CD Rotary Mechanism)

Exploded View (Tape Mechanism). .

Parts List (Tape Mechanism)

Trouble Shooting Guide

Display Block

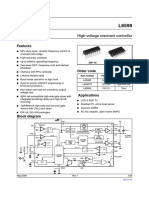

IC Block Diagram

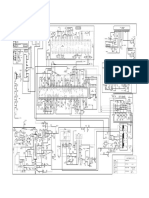

Schematic Diagram (Tuner)

Wiring Connection

‘Schematic Diagram (CD Main)

‘Wiring Diagram (CD Main)

Schematic Diagram (CD Mechanism)

‘Wiring Diagram (CO Mechanism)

‘Schematic Diagram (Deck)

Wiring Diagram (Deck)

‘Schematic Diagram (Front)

Wiring Diagram (Front)

Schematic Diagram (Pre Ampifor)

‘Wiring Diagram (Tuner & Pro Amplifier).

‘Schematic Diagram (Main Ampificr)

Wiring Diagram (Main Ampitier)

IC Voltage Tablo of CD

55

58

87

58

65

2

4

78.

B

80

82

Bs

86

98

90

92

94

96

98

100

REFERENCE No. SM580319

SPECIFICATIONS:

‘TAD-9415 MAIN UNIT

Amplifier section

Continuous minimum sine wave RMS power output per channel

at 8 ohms from 40 Hz to 20 kHz with no more than 0.9% total

harmonic distortion 100 Watts.

BASS control + 10:dB (100 Hz)

Troble control + 10:dB (10 kHz)

Dynamic bass = 10d ( 100 Hz)

Input sensitivity and impedance

PHONO 3.0 mV /47 kohims

VIDEO (Audio) 300 mV / 47 kohms

Outputs impedance

‘SPEAKERS (Nominal)

PHONES (Nominal)

Tuner section

(em)

Frequency range

Bohms

8-32 ohms

87.5 - 107.9 MHz (200 kHz steps)

Usable sensitivity 12.2 481 (MONO)

(am)

Frequency range 520 - 1,710 kHz (10 kHz stops)

Sensitivity 500 -V/m (AM Loop Antenna)

Cassette deck section

‘Track system

Frequency response

Signal to noise ratio

‘Wow and flutter

Fast forward /

rewind timetapprox.)

4-track, 2-channel stereo

60 - 12,500 Hz (Normal tape)

52 dB

0.18 % (WAMS)

110 sec. (C-60)

IMPORTANT INFORMATION

CD changer section

Type « 24-dise Bi-Directional,

Radial Transport

‘Channols 2-channel stereo

‘Sampling frequency ... 44.1 kHz

Pickup Optical $-boam,

‘semiconductor laser

Frequency response ... 20 Hz - 20 kHz

Signal to noise ratio 95 dB

Wow and flutter Below measurable limits

General

Power requirements... AC: 120 V+ 10%, 60 He

Power consumption 15 Watts

Dimensions(approx.) .-. 16.5"(W)x17.2"(H)x 15.7")

Weightiapprox.) 386 lbs.

REM-9415 WIRELESS REMOTE CONTROLLER

Power requirements 3VDC - Twa "AA" batteries

Dimensions(approx.) 4.5"(W)x6.6"(H)x0.7"(D)

Weight(approx.) 17 02. (without battorios)

Because its products are subject to continuous improvement, FISHER reserves the right to modify product designs and spec-

fications without notice and without incurring any obligation.

OPERATING THE RESET SWITCH $+

This unit is provided with a rosot switch on the rear panel. The reset switch serves to initialize the microprocessor in the unit

Which controls the CD-CHANGER, TUNER, TAPE-DECK and AMPLIFIER section. If tho unit is to be serviced or key input is

‘not acknowledged even when the CD, TUNER, TAPE DECK and etc. operation buttons are pressed, press the RESET switch

‘and initialize the microprocessor following the step below.

»

2)

Disconnect the AC power cord from the power outlet.

Keep the RESET switch depressed for 60 seconds.

(The backed up electrolytic capacitor

keeping the RESET switch depress.)

Reconnect the AC power cord to the power outlet.

3)

4)

operations, and check their operation,

Press the CD-CHANGER, TUNER, TAPE-DECK and ote.

discharged by

LASER BEAM SAFETY PRECAUTIONS (CD)

‘Do not look direcly al the laser beam coming from the pickup or allow it to stike against your fingers, skin, ete

Do not apply power if there is a broken part in the laser output section of the pick-up.

TNVISIBLE LASER RADIATION EXPOSURE TO BEAM IS DANGEROUS CLASS 1 LASER PRODUCT

‘QUTPUTPOWER: 0.6 mW MAX

WAVELENGTH : 790 nm

This unit is made and tested to meet exacting safety

standards. tmeets ULand FCC requirements andcomplies

with safety performance standards of he U.S. Department

of Health and Human Services.

CAUTION - USE OF CONTROLS OR ADJUSTMENTS

OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZ-

ARDOUS RADIATION EXPOSURE.

FCC INFORMATION

For CD player section:

This device complies with Part 15 of the FCC Rules.

‘Operation is subject to the following two conditions:

7I8S0 ASSEN ST, CHATSWORTH

aU, 3911

(1) This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

HANDLING THE PICK-UP (€D) A

1. Shipping and storage cautions

'. The pick-up must be stored ia a conductive bag until

immeciately prior tits use,

b, Do not crop itor subject to impacts.

2. Repair cautions

’a. When handling the pick-up, be careful not to give it

undue force or shock by your hands. Otherwise the

pick-up may malfunction or the PCB may be cracked.

bb. The pick-up which has been minutely adjusted before

shipment as one part. Never touch and move the

adjusting points and setscrows of the pick-up unless

‘otherwise described in the item of adjustment to avoid

damage.

c. Astrong magnet is used in the pick-up.

Do not bring a magnet or other magnetized object near

twit

4. Cleaning the lens

* If dust gets on the lens, clean it away by using an air

brush such as used for a camera lens,

* The lens is held in place by a spring,

IW the center of the lens is dirty, carefully clean it

Using cotton swab moistened with isopropylalcohol.

Since special coating is made on the surface of the

lens which is made of plastics, do not use other kind

of alcohol and cleaning fluid to prevent damage 0

the lens. Also, be careful not to bend the lens spring

when cleaning

BEFORE REPAIRING THE CD CHANGER -—$HJJHY,[XT~S-_

1. Preparations

‘a, Many ICs, LSI and the Pick-up (laser diode) are used

in the compact disc player, These components are

sonsitive to static electricity, and might be damaged

by static electricity or high voltage, so particular care

should be taken regarding this point.

. Many precision components and the lens are used in

the pick-up.

Never attempt to make ropairs, or to store parts,

where the temperature or humicity is high, where

magnetism is strong, or where there is much dust.

2. Notes regarding repairs

a. Be sure to first disconnect the power plug before

attempting to replace any component.

b. All tools, instruments, etc., used for measuring must

bbe grounded.

Grounding can be accomplished by using a

conductive metal sheet on the work bench.

. To prevent AV leakage of the soldering iron, ground.

its metal part

d. Repair personnel must be grounded.

DISASSEMBLY.

Disassembly and Reassembly Instructions

Remove all compact discs (CDs).

Unplug the AC power cord from the wall outlet (AC outlo!).

It lead wires are disconnected, be sure to reconnect them

afterward as they were,

|. Removing the Cabinet

1) Remove the nine screws © securing both sides and rear

ofthe cabinet.

2) Pull outward slightly on both sides of the cabinet and lit

it off in the direction indicated by the arrow @.

2, Removing the Amplifier Block

1) Remove the knob ©.

2) Remove the two screws © fixing the speakers switch

‘and headphone socket P. W. Board.

3) Unplug the connectors @ from the CD block, etc.

4) Remove the four screws

5) Lift out the ampitier block in the direction indicated by

the arrow

DISASSEMBLY:

3. Removing the CD Block

1) Romove the three serews @ securing the cabinet bottom and CD rear panel.

2) Remove the CD rear pane! in the direction indicated by the arrow @.

3) Unplug the connectors @ from the front pan.

4) Remove the two screws © securing the cabinet bottom and front panel.

'5) Remove the front panel in the direction indicated by the arrow

+ Shutter setting

‘With the shutter door closed (), move the shutter gear in the direction indicated by arrow (l) and push the front panel

in the direction indicated by arrow (ll). This will cause the spring and shutter door to engage at point @.

4, Removing the Cassette Deck Mechanism

1) Open the both cassette lids © by the EJECT buttons.

2) Remove the six screws @.

3) Lift out the deck mechanism in the direction indicated

bby the arrow ©.

DISASSEMBLY (CD)

[If the CDs cannot be removed]

5. Procedure for removing CDs from the disc table (turntable)

1) Remove the screw D holding the sub-op lid in place

2) Remove the sub-top lid inthe direction indicated by arrow ©)

3) CDs can now be removed through the space created by removing the sub-tp ld

4) I the disc table wll not turn, perform stops (1) and (2) of the gear salting procedure described below. This will allow

the disc-iabo to be moved.

(1) As shown in the detail drawing at right, tun the cam gear for front loading in the direction indicated by the arrow so

4 that it and the tip gear move to a position where they do not engage each other.

(2) As shown in the detail drawing at left, turn the cam gear for play loading in the direction indicated by tho arrow so

that it and the stip gear move to a position where they do not engage each other.

To perform gear setting steps (1) nd (2), either move the motor drive systems by hand or apply DO 3 to the appro-

priate motor terminals to activate them. When applying DG 3 V to operate the motors, make sure to disconnect the

motor lead wires before applying voltage. The motor drive circuitry could be damaged it the motor lead wires are not

disconnected firs.

SUB TOP-LID

su OBA

o1S¢-TAGLE

SUP GEAR

FOR PLAY LOADING FOR FRONT LOADING

6. Procedure for removing CDs from the base mechanism

1) As shown in the diagram, unchuck GOs that are chucked by turning the chucking gear inthe dlection indicated by the

arrow.

i ‘To turn the chucking gear in stop 1), either move the chucking motor drive system by hand or apply DG 9 V to the mo-

i tor terminals to activate it. When applying DC 3 V to operate the motor, make sure to disconnect the motor load wires

before applying voltage. The motor drive circuitry could be damaged if the motor lead wires are not disconnected first.

2) Once the CD is unchucked, move it from inside the base mechanism to the disc-tablo.

To move the CD in step 2), ether move the play loading motor drive system by hand or apply DG 3 V to the motor te.

mminals to activate it, When applying DC 8V to operate the motor, make sure to disconnect the motor lead wires before ~

applying voltage. The motor drive circuitry could be damaged ifthe motor lead wires are not disconnected firs.

3) CDs in the csc table can now be removed using the method described in section 1

se

DISASSEMBLY (CD)

BASE (PICKUP)

MECHANISM PART

7, Removing the top lid from the mechanism

1) Flemove the three screws @ securing the base mechanism to the support bracket.

2) Remove the two screws © holding the support bracket in place.

3) Remove the support bracket in the direction indicated by arrow @.

4) Remove the six screws @ holding the top lid in place.

5) Remove spring ©.

6) Unplug the four connectors © from the top lid.

7) Unplug the four connectors @ from the mechanism chassis.

£8) Remove the top lid,

OISt-TABLE PART

(TURNTABLE)

DISASSEMBLY (CD)

8. Removing the disc-table

1) Remove washer D.

2) Remove the two screws @ holding the sensor assy

in place.

3) Remove the disc-table in the direction indicated by

arrow ®,

‘When replacing the disc table, perform gear setting

steps (1) and (2) bolow to facilitate easy remounting.

(1) Turn the cam gear for front loading to move the

front loading slide as far as it will go in the direc

tion of arrow @.

@) Turn the cam gear for play loading to move the

play loading slide as far as it will go in the direc-

tion of arrow ©.

9, Removing the base (pickup) mechanism

1) Remove the screw @) holding the base mechanism

in place.

2) Remove the screw @ holding the base mechanism

in place.

3) Remove the base mechanism in the direction indi-

cated by arcow ®.

Contirm end eater

completely inserted

Tranging and securing

17 ane She ead wires,

ADJUSTMENT MECHANISM (CD)

Procedure for Mounting Main Mechanism Parts

1. Top tid Ns @

sauce

BANE tan

exrensnye [oP suze sgease

[REFERENCE FIGURE

a

| site MOTOR

2. Disctable (turntable)

1) Turn the cam gear for front loading to move the front loading slide as far

2) Tum the cam gear for play loading to move the play loading slide as far as it will o in the direction of arrow @.

3) As shown in detail drawing @, align the oval shaped hole in the tray turn gear (indicated by *) with the center of the

tray turn pulley.

4) Line up hole number 23 on the disc table with the round hole In the tray turn gear, after setting it es described in stop

4). Then fit the dise table over the chassis shalt (boss) in the direction indicated by arrow ©)

‘When aligning hole number 23 on the disc table with the hole in the tray turn gear, a cortain amount of skill is required.

“The task can be made easier by inserting a Philips screwdriver or the like through the two holes and then fiting the dis

tablo over the chassis shaft (boss).

+ Semew oRIvER:

ore than gon

ete IRIS Sm

ADJUSTMENT MECHANISM (CD).

3. Front loading portion

Front oaoine sue @p

ERONT LOROING

chi Ge

ERONT LOADING.

SLIP GEAR

4. Play loading portion

cewe

-@

PLAY LOADING a7 @

ADJUSTMENT MECHANISM (CD):

5. Front loading and disctable motor

LOADING SLIDE SWITCH woh —= 2

Chall

REFERENCE FIGURE

ADJUSTMENT MECHANISM (CD).

7. Replacing the pickup

Shaft mounting/removal

1) Insert th shaft from section ® of the front ofthe chassis, pass i through the pickup and fit the tip into the groove at

section ®.

2) Push the shat in further so that its tip stops at section ®. Then secure it in place using stopper wing @

When mounting or removing the shalt, be careful not to lose stopper wing ®.

Mounting the sled gear

1) To mount the sled goar, move the pickup as far as it will go in the direction indicated by the arow

2) Push slightly on point © on the inside of the pickup gear when mounting the sled gear

‘Apply Fegrease G-4748,

on shaded portion of the shaft

° oO

‘Top and Bottom) (Around the shat

D ® (ie Siakete”)_ (Around the shat)

PIRI ocaR

pa ==>

A '

A qj SLED GEAR

¢ U

T ie, a

ply F-orease

mew 111) Seg Bie

UL °

alt reo

OHS THES

T |S

CHASSIS ‘STOPPER WING

sear]

8, Sled and spindle motor of base mechanism

SPINDLE SLED

MOTOR MOTOR

2s

83mm.

SLED

MOTOR

REFERENCE FIGURE

ee

STANDARD MAINTENANCE (CD)—2#£-_———_—_

Applying grease and grease point

1. Front panel 2. Play loading roller

3. Shutter portion 4, Disctable portion

= 12-

STANDARD MAINTENANCE (CD).

6. Disc driver portion

lone ato tS i

DISC STOP SENSOR PCB.

6. Front loading portion

eniy geese 30,

Lae

wissen

‘ound the boss for ger.

STANDARD MAINTENANCE (CD).

7. Play loading portion

9 @

at LOADING :

T

swans

Aca ta

NG

‘SEAR

ua on

‘8, Chucking driver portion

‘guuextns onave

e evar Gear

stipe

cuucning,

onive SUDE,

moans

‘switOT PLB

‘only Me=grase ESOL

ihe ra

STANDARD MAINTENANCE (CD)

8. Chucking bracket portion

ey

Apply MC-grease EM-50.

on shaded portion.

Eompitelyinsete

into chassi.

Aoply Mc-grease €M-5.

‘round the shatt

11, Sled Driver portion

‘apply Fegrease 6-478,

(on shaded portion of the shaft

°

Top and bettors) (Around the sha

(RR BERIT) _Atound the shat)

PICKUP GEAR

Apply F-grease

GeA74B on shaded

Portion

10. Chucking lever portion

©,

Ley

Pu

cuuckins.

BRCKET

‘opty Mc-grease EM-50L

Apply MC-grease EM-5OL

fon shaded portion

YES | s1801=0N

‘Shutter motor rotation stop.

i

Front loading motor turn to the CW.

Ghucking motor rotation stop.

vo

Play loading motor turn to the OCW.

YES | sig05=ON

NO

Yes | s1e04=0Nn

TBGEs the play sensor 1 turnon 7

YES | p1836=0N

Timer set at 0.5 seconds,

Yes

Front joading motor rotation stop,

i

Disc-table turn to the right.

Timer sot at 0.5 seconds.

ee!

Is the timer over ?

Yes.

TMi spec)

YES | si07:

Play loading motor rotation stop.

T Dise-table position detact counter reset

Does the DISC No. 24 deteat 7.

ves

‘Chucking motor tuen to the CW.

Disc-table speed reduction.

Does the DISC No, t detect 7

Yes

Diso-table rotation stop.

y

End

‘Shutter motor turn to the close.

- 2 -

FLOW CHART OF OPERATION

2. Eject the Disc in base mechanism

‘Start

ruc OFF |

(Chucking motor tu to the COW.

Ei Sein ot nT

a

YES | sigo1=0N

Chucking motor rotation stop.

T

O1SC LOADED TO OISG-TABLE HAS BEEN BEGUN

Play __Cenrestra net ‘motor turn to the COW.

ms

YES | stao4=

[DISC LOADED TO OISC-TABLE roses

{oes the play sensor 1 tumnon

eeeaeeaeeann eee

Disc-table turn to the left.

[>>| thigh speeay

oes the disc-tablo position:

detect completed 7

NO

‘Shutter motor turn to the open.

Does the shutter

open completed 2

‘Shuiter motor rotation stop.

Front loading motor turn to the COW.

98 the front sensor 2° 3-4-7

Timer set at 0-5 soconds.

pI

Is the timer over ?

Play loading motor rotation stop.

I

(Chucking motor tuen to the OW.

Yes [ s1a02=0Nn

Chucking motor rotation stop.

NO turnoff ?

yes

Front loading motor rotation stop.

Timer set at 10 seconds.

U

= 23 -

FLOW CHART OF OPERATION?

Does the front sensor 2 ~ 7

turnon ?

YES

190 ~ 01895=All ON °

Does the front sensor 2 or 3

tunon ?

“Timor set at 10 seconds.

NO

YES | 01890 or 01831 = OFF

Is the timer over ?

YES

Hoes the front sensor 5 or 6

tunon?

1633 or D1894= OFF

Is the timer over ?

Yes

‘Shutter motor turn to the close.

3

‘When pull out the dise by fingers, completed the

eject. Yes

After pull out the disc, not insert the disc in 10

sec.>Yes

: When push on the disc by fingers>Yes

: When pull out the disc in 10 sec.~>Yes

OFF

(Chucking motor rotation stop.

|

Ges the play sensor 1 tunon

= 25 -

FLOW CHART OF OPERATION

4. Insert the disc to the appointment position from the frontend

Start

YES [Lert ROTATION

is the rotate quantity 1 2

Yes

No

NO. RIGHT ROTATION

©: Detect the rotate destination as to compare between the

now position and the appointment position.

Is the rotate quantity 1?

YES

Disc-table turn to the left.

Disc-table tuin to the right,

tow specs)

as

tow speed)

oo

Dise-table turn to the lft

Disc-table tum to the right.

T 0h soot

_J (hich speed)

Does the disc-table position

dotect completed 2

No

‘Shutter motor turn to the open.

—| o|2] ~}or] |] o0}ro}

: 13: Error Indications during the mechanism mode

“Time indicator part (seconds) ‘Shutter engage owitch ($1730)

Bc

> : Releases the key checking mode and returns the set to the normal mode.

TABLE 1 : Corresponding buttons and displays in the button checking mode

FM123. AUTO“ STEREO

swi2 Vireo FM MONO

AMW TOIT MEE ch At

2. Tuner operation mode

1) Enter this mode by pressing the DYNAMIC BASS button during the service mode entry state

2) Once in the tuner service mode, press the DYNAMIC BASS butlon to perform the following operations.

(1) Auto station select begins in the down direction, staring from the frequency three steps above the current reception

frequency.

(2)When a broadcast is received, operation (3) is performed i ts frequency is the same as the starting frequency. If itis,

a different frequency, auto station select operation in the down direction stops. If no broadcast strong enough to-be

received are encountered, auto station select operation continues.

{@)Auto station select begins in the up direction, starting from the frequency three steps below the starting frequency.

{(§) Auto station select operation stops if a broadcast is recoived. If no broadcasts strong enough to be received are en-

‘countered, auto station select operation continues _ gq _

3) This made is released when the power is turned off.

JUSTMENT-

| Adjustment

have presented explanations regarding compact

r handling, notes prior to repair, handling the pick-

sassembly of the unit. Be sure to carefully read

uctions before making any adjustments.

ons for Adjustments

instruments, tools an

ise. ny)

yscope : SS5711 (10MHz or dual phenomenon)

smory scope : DSS6521 (Storage scope)

a voltmeter (Input impedance 1M ohm or more)

ter

ok ow

tee

ortPa

O0%p F $100k Oscito-Seape

16

BAND PASS FILTER

(4) AF Oscillator (40042, 300mV RMS)

Frequency Counter (SMH2 ; or moro)

{6)Screw drivers (no motallc) for adjustments

(7)Band Pass Filtor

(8)AC Voltage Meter

‘The adjustments can be using the equipment produced by other manufactures provided that the performance of

that equipment corresponds to that of the abow

Use a 10 : 1 probe for observing signals on the os

Test disc is subject change without notice,

set up

SVRI1t at its inital position of adjustment controls

1 in figure of right side.

ications (Service mode entry)

any service mode, frst simultaneously press. the

4 ENTER CATEGORY-SUB buttons, This access-

vice mode entry state. Now press one of the but-

x @ Service mode. AS the service mode entry

scontinued after Isecond elapses, the system wil enter

ode only ifthe next button is pressed within 1 second

ng Balance (SVR11)

ne test disc

ct the oscilloscope to TE(Tracking Error) and

ge Center) in test pin

this mode by pressing the PLAY/PAUSE button

the service mode entry state. (Service mode =

ng Balance Adjustment mode = See service

1g the PLAY / PAUSE button.

SVR11 so that the TE signal waveform on the os

ope is vertically symmetrical relative to VC. (See

of right side)

playing pressing the MEMORY button turn on

cking balance adjust state, for playing press the

/ PAUSE button (tacking servo off state).

the STOP button to exit this made and return to

mal mode,

ut the test disc

listed models.

lloscope and storage scope.

svri1

INITIAL SET

(MECHANICAL CENTER)

aL ongs

If this adjustment is imperfect, become run away the sled

motor (Pickup sending motor). inferior playat

~ 36 -

CD ADJUSTMENT:

4. Focus Gain Confirmation

41, Connect the storage scope to F.E : Focus Error (Test- 4, Set the output of AF oscillator to 400Hz, 0.5V rms and

pin) through the Band pass filter. (See BPF Figure) Connect to pin 24 (IG101) through the resistor : 100k

2. Tum on the power of the unit. ohms.

3, Playback the test dis. ». Confiem so that the voltage of the F.E signal waveform

fon the storage scope is 0.5V p-p23dB by through

BPF.

‘lf this CONFIRMATION is imperfect, become weak the mechanical shock, inferior playability, and can not playback the Disc

AF OSCILLATOR MAIN CO POB: OSCILLOSCOPE or STORAGE SCOPE

100 BANO PASS FILTER

00H2 us ion

ov me PIN26 FE

ve |

5. Tracking Gain Confirmation

1. Connect the storage scope to T.E : Tracking Error (Test

pin) through the Band pass fer. (See BPF Figure)

2. Tum on the power of the unit.

3. playback the test disc.

4, Set the output of AF oscillator to 400Hz, 0.5V rms and

Connect to pin 14 (IC101) through resistor 58k ohms.

8. Confirm so that the voltage of T.E signal waveform on

the storage scope is 0.5V p-p:+3d8 by through BPF,

If this CONFIRMATION is imperfect, become weak the mechanical shock, inferior playability, and can not playback the Disc.

[AF OSCILLATOR MAIN CO PCB. OSCILLOSCOPE or STORAGE SCOPE

sk BAND PASS FILTER

oe) cro

o.5V ms PI's TE

oT

ea

i

ADJUSTMENT OF TAPE DECK

1. Azimuth Adjustment

‘# Bo sure to clean the heads before attempting to make any adjustment

‘® Bo sure both channels (1 and 2) are the same level (Using a dual-channel oscilloscope),

‘© Be sure both cannel's waveform are same for the phase matching,

«© After completion ofthe adjustment, use the threadiock (TB-1401B) to secure the azimuth adjustment screws.

(DECK 1

4. Load a test tape (VTT-738 et

2. Prass the PLAY button. (norm

3. Use a + tip screwdriver

azimuth adjustment so that the left ani

are maximized at the same phase during normal

back.

(@)DECK 2

1, Repeat procedure for deck 2.

2. Tape Speed Adjustment

REPLACEMENT OF TAPE DECK MECHANISM

4, Torque Measurements

rer | spceo | eck |testtaPe] svr | TAPE COUNTER REMARKS

+ | Normal | DECK 2995 ~ 3005 Hz | Memorize the tape speed on counter. Confirm

oor | SVRS01 that the spood of DECK 2 is in -40 ~ 70 Hz

2 | Normal | DECK 2 ~40~70H2 | against DECK 1

Notes: 1. For making adjustment of step 1, set the DECK 2 mechanism is record made with C-60 blank cassette tape.

2, Adjustment should be made at the ending portion of the tape.

+3. Confirm the indication of the tape speed for 2 second atter adjustment has been made and adjusting driver has

been removed from SVR on the TAPE DECK AMPLIFIER P. C. Boavd.

4, For adjustment, use the screwdriver with isolated tip from grip

5. For high speed check, short the test points (HIGH-SPEED) to chassis ground on the Tape Deck Amy

Board, (Test Tape is MTT-111N) and confirm that the speed of DECK 2 is in -40 ~ 70 He against DECK 1

vrgo1 CN305

TAPE SPEED J 2

BIAS FREQUENCY

ADJUSTMENT

-38-

TEM TAKE-UP TORQUE BACK TENSION TAPE TENSION

a PLAY = TW PLAY :TW- Driving power cassette:

F.FWD/REW : TW-2291 REW:Torque Gage Tw.2412

PLAY 30 ~ 60 grcm 20 ~ 45 rom > 60g

FFWO 55 ~ 120 grom =

REW 55 ~ 120 grom =

5. Replacement of Head

REC/PLAY HEAD

Re0

oe

veuow

eanti|| PLAY HEAD

| ”

6 Replacement of Motor and Belt

=39-

Use a plas

| TUNER ADJUSTMENT.

adjustment

|| © Agjust the intermediate frequency of AM and FIM to the frequency of ceramic fer.

1. AM BAND ‘Antonna : IRE Loop, M SG RF Level : Open Voltage dB

aa Tuning input Condition ‘Output Con: Standards

toms | Frequency [Measure Taput_| Measure

Digit

1 | cover voi,

2. | TRACKING AM Sc oe | aaa

1s00K2 ANT | Oscitosoope

a | STATION | oops AM SG Loo’ 2 P22) | ovreg

DOTECTION (e108,v) ANT TP23(e)

Note : I rotate SVR29(AM SD) after FM alignment, align SVR22(FM SD) again.

‘Antenna : 30008 Balanced, 75 - 300 ohm Pad

(-5 6B), SG AF Lovel: Open Voltage 6B

Iso w Exr(STEREO)|

2. FM BAND ‘Modulation : kHz, Dev. : MONO: +75kHz / STEREO- + 67.5kHz(Main) - + 6.75kH2(Piot)

sop| te [pee a omens

‘ COVER [Tiov.omHe ~ volimetor

TRACKING FM SG

ae ee ee ee

GTECTION (8408 .N) TERMINAL TP2a(E)

ru aa | _ vn

‘STEREO

8 |sensmuiry|

9e.aMHe

FM SG (7208) | FM ANT

[Soto EXT(STEREO)| TERMINAL

3. Parts location

“Tuner Mado : AUTO STEREO

|AM LOOP ANT.

TH

oo

EXPLODED VIEW (CABINET)

OTAPE DECK

MECHANISM,

T=SGISTNISP

-a-

EXPLODED VIEW (CHASSIS)

Ref. No.

B

® x

AASSY ANTENA, LOOP, AM 6 x

a LABEL, FUSE

REMOTE CONTROLLER (REM-9415)

Ref. No.| Part No eseition ELECTRICAL PARTS

fef.No.] Part No. ‘Deserption

a8

Br

5-735 CO CHANGER MECHANISM

PM-DADRCH/SP

614 263 3472

4 263 3465

614 248 9086

514 248 6438

ots 269 6371

CHASSIS. FIXING PARTS.

Ref. No. Ref. No.

a Yor “SHS CRBINET

yo eS

y03 S-TPG BIN

INT CASSETTE REAR SOCKET

=43-

PARTS LIST- PARTS LIST-

Ref. Wo. No, Ref. No.[ Part No. Des Ref No.| Part No. Description Ref. Wo.| Port No. Description

Yoo Wo6 060% | SCREW S-TFG BIN 70 9265 | ROUNT-E,TCO aa ae Te DTCs 2 DiooE Testa

PHONO GHD 814 220 3651 | SHEET.LCD Gear | 405 TR 2Sk1015-GR or DIODE 185176

vos 411 008 0402 | WASHER OUT TW 3, 814 257 2867 | HOLDER, NOUNT-E, FUNCTION LED oa ae TR 28A730-K 310s | 407 007 9008 | oroDe axaos,

Yoo 1 108 9704 |wASHER Z ax10x eweet | 614 263 7005 | assv,counectoR-s,9P, ce 408 TR ESAGOB-FESPA ari 55133

vor 411 021 6406 | scREW s-1P6 BIN’ 3x8, FRONT-TUNER czeaz | 408 rR TaNI207-1P4 or tssi76

ANP REAR SOCKET nese | 614 263 7029 | aSSY,CONNECTOR-S, 13°, ne 405 D106 E GHA

08 411 021 6408 | ScReW S-TP6 BIN 5x8, FRONT-PREAME aa 208 o 188138

BOTTON-CO REAR cnzes | 614 263 6902 | assy,counecToR-s, ap, Seoor | ous SWITCH, TACT, POER 7 yf ASsi76

ma 411 024 6408 | ScAEW s-TPG OIH 3x8, FRONT -PREAP s2eoz | 614 SWITCH, TACT, TAPE 03107 | 407 007 sa0e | or00e cuaot

FRONT-BRACKET cnzes | 614 036 4011 | socKeT,2P,70 Leo LAP seeps | 614 SUITCH TACT CO ee £55133

viz 414 o2t 6406 | scReW S-TP6 BIN 3x8, cass | 614 263 7012 | assy counécroR-s, 10P, seeos | 614 SVITCH, TACT, TONER or 188176

BOTTON-BRACKET FRONT -PREAME szeos | 614 SNITCH, TACT, PHONO 3108 uso

v3 411 o2t 3603 | scReW S-1P6 BIN sx10,cean |] n2601 | 407 138 4700 | PHOTO DIODE sPS-420-1, sens | 614 SVITCH TACT VIDEO ee 185133

vi 411 020 9902 | SCREW S-1P6 BRZ+FLG 3x8, REWOCON(TR) RECIEVE Senor | aus ce

BOTTOM-CO MECHA 2621 | 408 020 9708 | LED SLZ-1518-01-AB, POWER seve | 614 pain

v5 41 021 6408 | SCREW S-TPG BTN 3x8, 2622 | 408 020 7908 | LED sLz-0308-20-A8, TAPE esi |e a

CD REAR-CHASSIS 2823 | 408 020 7908 | LeD sLz-9368-20-A8,c0 see | 614 or

v8 411 o2t 6405 | SCREW S-1P6 BIN 3x8, 02624 | 408 020 7908 | LED stZ-0568-20-AB, TUNER ea eas : Test | aoa 25 Te TASieaH

CD PwB-8OTTON 02628 | 408 020 7908 | LED SLZ-9588-20-AB, PHONO sees | 614 SWITCH, TACT.PS Lseot | 614 212 1023 | TeaNs, osc, 5Kuz

v7 411 o2t 3107 | ScReW S-1P6 BIN 2.6x8, 2eze_ | 408 020 7908 | LED stz-9368-20-AB, VIDEO s20is | 614 220-8870 | suITCH TACT. Ps tarot | 648 oo# oseo [1upucton, im 9

Co Pwe-RONT 92627 | 408 020 7609 | LED Siz~s368-20-aB, BASS szeis | 614 220 5870 | SWITCH, TACT,P3 30 645, TNOUCTOR, 1H 3

v8 414 o2t 6405 | scReW S-1P6 tN axs,tamp Pwo || n2528 | 408 020 7809 | LED SLZ-3368-20-A8, MUTE s2e17 | 614 220 5870 oaioi | 40s Tm 2SA733-T-R

v9 411 21 6408 | SCREW S-1P6 BTN 3x8, 264i | 407 007 9904 | oL00e Guson s2618 | 614 220 5870 or 405, TR 25A733-K

CHASSIS-AMP_PwB or 407 012 4408 | oTOoE 185133 sze1e | 614 220 5870 a 408 TH 25Ai015-6R

veo 411 021 6405 | SCREW 5-TPG BIN 3x8, or 407 012 8809 | bYooE 185178 Seezo | 614 220 5870 ost | Aas th mutzoz

HEAT StHK-BRACKET or 407 £83 6109 | OFODE 1ssit9-o41 52608 | 614 246 7138 on 408 TR BALAGH

va 411 021 6405 | SCREW 5-TPG BIN 3x8, 2642 | 407 007 8904 | DYODE Guaot yaaor | 614 003 4303 ee 405, TR oTcsaes

‘AMP PNB-BRACKET or 407 012 4408 | oro0e 185133 veavz | 614 003 4363 sis | 405 TR 2scz001-x

vee 411 o2t 6408 | ScREW 5-TPG BIN 3x8, or 407 012 8809 | orooe 185176 yaaos | 614 003 6768 ea 408 Th 2scztz0-¥

TU PWB-BRACKET or 407 183 6109 | DIODE 185119-041 x2eot | 614 215 5561 | RESONATOR, CERAMIC, 3P, otomuz |] qs104 | 405 Tm RNIZIL

vas 411 021 6405 | SCREW 5-TPG BIW 3x8, bas4s | 407 06% 6508 | zeweR DIODE Gzss.7Y ea 408 TR BAIAAZ

ORACKET-CHASSIS or 407 083 5808 | ZENER DIODE WTZ4.78 or 408, Te orciaTs

vs 411 021 6405 | SCREW 5-TPG BIN 3x8, basse | 407 007 9904 | or00e uaos 105 | a08 TR wuiz02z

(CHASSIS-FRONT BRACKET or 407 012 440s | r0De 185133 Se ne 208 Th BAIAMM

v8 411 021 9804 | SCREW S-TPG BIN 4x8, or 407 012 8800 | DIODE 18si76 Ref. No.| Part No. Description or ae TR DTCLiNES

BRACKET-CHASSIS( TRANS) or DIODE 155119-04 Te G14 250 G27E | ASSY, PWBLANP(N.5.PY os10s | 405 TR Ru2202

v8 411 021 6405 | SCREW 5-TPG BIN 3x8, 264s DYODE GuAoT cuss | 614 038 4921 | sockéT, 2,10 FRONT or 408, Th BAA

DECK MECHA-FRONT or DIODE 18533 pi2si | 614 240 1101 LAMP, 12V GoMA or 405, TR DTALIAES

ver 411 021 6405 | screw 5-196 BW 3x8, PosrsToR || or DIODE 185176 ptzsz | 614 240 1101 | LAMP, 12v Goma 3601 | 408 TR 25ca4sn-P

28 411 074 0603 | SCREW TPG PANSFLG 3416, or DIODE 185119-041 ca “08 Th 28CO48A-K

PONER IC-HEAT SINK e281 1 w3822202-052FP ca 408 Th 28C1815-6R

ves ‘411 021 9604 | SCREW S-TPG BIM 4x8, 140s. 16 Las4sos ‘TAPE DECK AMPLIFIER P. W. BOARD ASSY ossoz | 405 Tm 25¢1627-Y

‘TRANSFORNER L2eot FILTER, 100UH,REPPLE CANCEL ga7o1 | 40s Th 2sci7aas-S

ys0 411 o2t 6405 | SCREW S-T#G BIN 3x8, e026 LCO(LIQUID CRYSTAL DISPLAY) Ref. No.[ Part No. Description ne ae Th aseeresc

SPEAKER SW-H,P SOCKET geet TR Rwi204 73 Tia 280 TEE | ASST, PHB, DECK ANP(W.S.PY oo faa TRISSCOTAESE

vst 4x1 021 3107 | ScREW 5-16 BIN 2.6x8, or TR BALL casos | 403 058 9900 oLYESTER 0.018U K SOV or ae irajesczaesien

BRACKET -ECABUTTON or ra oreiaaes c3eos | 403 062 1105 POLYESTER 0.047U M_50V cree tack Th awtzoe

vse 411 028 2908 | SCREW 5-TPG PAW 2x4, Q2s22 TR RNiz08 casos | 403 058 1102 | roLvester 100° x ov ea ae Reker

DECK-BRACKET or Ta BAILaN cso | 614 017 2166 pLUG,9P,TO TUNER/AE-ANP or nad BICLIHES

v3 411 028 2005 | SCREW S-TPG Paw 2x4, or TR orcisses cnaoz | 614 017 2126 TO TUNER/PRE-AMP cava tase

REC, SPRINGPLATE 2623 Ta ANIZ04 caos | 614 017 2677 TO WECHANISN swiTcH || Oe a Th 2ozraeee

v8 ant o2t 6405 | scnew 5-196 81N 3x8, DECK PCB || or TR BALLAM tvaoe | 614 020 ose2| socKér.de,o MEcHantsw woron || or 408 Th 2502786-F

1 021 6408 | SCREW 5-17 ; or 405 000 6104 | 78 oTCsaAEs 34, or 408 014 8209 | TR 25cz45e-cR

ee eo wEcin READ FIX Gases | tae oot oaos | anszon Sia O16 eave |pLuc,ahyrésr om erase Ib atetesttocel| a ance

¥36 ant o2t 3107 | Screw S-196 BIN 2.6x8, or 405 078 3005 | 78 BALLAM 614 017 2530 | PLUG,2P,70 STOP swITcH te Pastoral conn lta anna

‘MP FRONT PCB or 405 000 0104 | 72 oTCIAaes 614 017 2653 | PLUG, 4P,T0 PLAY HEAD or ostono| atna|| TRioreiiies

vs? 411 021 6405 | SCREW S-TG BIN 3x8, 2628 | 405 001 0408 | 78 RNiZ08 614 017 2677 | PLUG, 6P.70 P/R & E HEAD fesuoart | tacit santonas||isuiven’arine n7e)

{co LAN PCB or 405.078 3005 | TR BALLAM 407 007 9808 | vroDe reson |) Sora] sno] 7e01||leorumimerentexta)

38 411 024 3708 | SCREW S-TPG PaN+FLG 2x6, or 406 000 6104 | Te OTCLAdeS 407 012 4406 | DIODE

Dece-BRACKET 2626 | 405 001 0408 | Te Rwiz08 407 012 $809 | or0De

vs9 412 003 1708 | Scaew,SPEctALM,cD ooo sw || or 405 078 3008 | TR BALLAN 407 007 9908 | prope STOP SWITCH P. W. BOARD ASSY

or 408 000 6104 | 18 OTCisses 407 012 4408 | D100 =

2827 | 405 067 0800 | 18 RN2207 407 012 5809 | Dro0e Ref.wo.[ Part No. SR

or 405.078 2404 | TR BNIAMP 407 007 9908 | or00e 74 B14 265 5555 [ASST PHB,

Sonne eos ae or 408 000 0904 | 72 oTATLAYS. 407 012 4408 | or00e este 017 2539 | PLUG,2P,70 TAPE DECK ANP

Ref. No.[ Part Wo. Description 2628 | 408 001 0408 | TR Rw1208 407 012 8809 | D100 sao01 | 614 203 7911 | swrTcH, STOP

ha Bia 259, 6206 | ASST, FRONT (WSF) or 408 076 3008 | Ta BALLIN 407 007 9804 | 0100

-44~ -a5-

Vous aimerez peut-être aussi

- Philips 21PT263A77B - Chassis PV4.0 PDFDocument5 pagesPhilips 21PT263A77B - Chassis PV4.0 PDFjose4445Pas encore d'évaluation

- PHILIPS 21PT263 25PT463 Chassis PV4.0AA PDFDocument22 pagesPHILIPS 21PT263 25PT463 Chassis PV4.0AA PDFjose4445Pas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Service Philips 2005Document73 pagesService Philips 2005canario92Pas encore d'évaluation

- Manual Usuario 8M63S PDFDocument23 pagesManual Usuario 8M63S PDFjose4445Pas encore d'évaluation

- Hitachi CDH-21GM2 - Chasis - JYM-510 PDFDocument1 pageHitachi CDH-21GM2 - Chasis - JYM-510 PDFjose4445Pas encore d'évaluation

- H-905F Stereo PDFDocument1 pageH-905F Stereo PDFjose4445Pas encore d'évaluation

- Chasis 3Y18Document1 pageChasis 3Y18Ernesto SuarezPas encore d'évaluation

- L12M3.1++PFL3508 3518 4508 5508 7008 8008 PDFDocument128 pagesL12M3.1++PFL3508 3518 4508 5508 7008 8008 PDFRofo201550% (2)

- RCA - 40SMARTR30 - Manual Service PDFDocument60 pagesRCA - 40SMARTR30 - Manual Service PDFjose4445Pas encore d'évaluation

- RCA L32S9500 Manual Service PDFDocument20 pagesRCA L32S9500 Manual Service PDFjose4445Pas encore d'évaluation

- Diagrama BGH+BLE3215D+Chasis+MSD6308RTDocument15 pagesDiagrama BGH+BLE3215D+Chasis+MSD6308RTOscar David Mamani33% (3)

- PHILIPS PDP Ch. LC4.41E AADocument107 pagesPHILIPS PDP Ch. LC4.41E AAlj41Pas encore d'évaluation

- L6599 PDFDocument36 pagesL6599 PDFjose4445Pas encore d'évaluation

- IPE18T24X (40-PBE49D-PWD2LG) - Fuente TV NOBLEX DI49X6500 - Sin Valores PDFDocument3 pagesIPE18T24X (40-PBE49D-PWD2LG) - Fuente TV NOBLEX DI49X6500 - Sin Valores PDFjose444567% (3)

- Surface Mount Silicon Zener Diode: SOD-323 Plastic PackageDocument4 pagesSurface Mount Silicon Zener Diode: SOD-323 Plastic Packagejose4445Pas encore d'évaluation

- BGH - BLE3213RT - Chasis MSD1328 - Manual ServiceDocument38 pagesBGH - BLE3213RT - Chasis MSD1328 - Manual Servicejose4445Pas encore d'évaluation

- AOC - L32W431 - Manual ServiceDocument107 pagesAOC - L32W431 - Manual Servicejose4445Pas encore d'évaluation

- LCD Television Service Manual: MTK5655EPDJDocument55 pagesLCD Television Service Manual: MTK5655EPDJyoregistradoPas encore d'évaluation

- MFL68606401 32LF550D-DD Da NewDocument74 pagesMFL68606401 32LF550D-DD Da NewAndres Alegria100% (2)

- Philips - TPM14.2L-LA ENDocument98 pagesPhilips - TPM14.2L-LA ENjose4445100% (1)

- CV59SH-ASM - Placa Main - Service ManualDocument55 pagesCV59SH-ASM - Placa Main - Service Manualjose4445Pas encore d'évaluation

- Samsung LN19A330J1D N45CDocument58 pagesSamsung LN19A330J1D N45Cjose4445Pas encore d'évaluation

- LG 22LN41xx - Chassis LM91MDocument33 pagesLG 22LN41xx - Chassis LM91MDebasisRay100% (1)

- Samsung 732n Plus 932b Plus 932n Plus CH Ls17pea Ls19peb Ls19pea PDFDocument83 pagesSamsung 732n Plus 932b Plus 932n Plus CH Ls17pea Ls19peb Ls19pea PDFRafael Enrique MoyejaPas encore d'évaluation

- Sony Audio HCD-GZR88D - GZR99DDocument110 pagesSony Audio HCD-GZR88D - GZR99Djose4445100% (2)

- Samsung+CS29B850F18XSV+ +KSDB P CB1M RDocument63 pagesSamsung+CS29B850F18XSV+ +KSDB P CB1M Rjose4445100% (1)

- PHILIPS - 21GX1565 - Chasis Anubis SCCDocument22 pagesPHILIPS - 21GX1565 - Chasis Anubis SCCjose4445Pas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)