Académique Documents

Professionnel Documents

Culture Documents

MDI 165EN - Installing

Transféré par

Raphael LinoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MDI 165EN - Installing

Transféré par

Raphael LinoDroits d'auteur :

Formats disponibles

Installing industrial gear wheels shaft-

mounted gear units, horizontal model

MDI-165-A-EN 20.02.2007

INSTALLING INDUSTRIAL GEAR WHEELS SHAFT MOUNTED GEAR

UNITS, HORIZONTAL MODEL

1. INSTALLING A SHAFT-MOUNTED GEAR UNIT WITH KEY CONNECTION ................... 2

2. INSTALLING A SHAFT-MOUNTED GEAR UNIT WITH SHRINK DISC CONNECTION.... 2

3. REMOVING A SHAFT-MOUNTED GEAR UNIT................................................................. 4

4. INSTALLATION ACCURACY ............................................................................................. 5

4.1 GEAR UNIT INSTALLATION ACCURACY .................................................................................. 5

Moventas Santasalo Oy 1(5)

Installing industrial gear wheels shaft-

mounted gear units, horizontal model

MDI-165-A-EN 20.02.2007

1. INSTALLING A SHAFT-MOUNTED GEAR UNIT WITH KEY CONNECTION

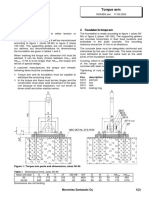

The installation of a shaft-mounted gear unit is done To start the installation, remove the cover (F) of the

using an end plate (A) and the appropriate mounting hollow shaft. Treat the end of the shaft of the

screws (B) (Figure 1). The number and size of machine to be used with anti-corrosive oil or grease,

screws needed in installation can be found in the such as NOCO Fluid, Never-seez, Molykote DX,

dimensional drawing of the unit. Molykote G Rapid 2 plus, Fel-Pro C-670 or

Before installation, check the following: Chesterton 785 when using a key connetion. Lift the

shaft-mounted gear unit to the height of the end of

dimensions of the hollow shaft (C) bore the shaft (D) of the machine being used. Heat the

dimensions of the end of the shaft (D) of the hollow shaft of the shaft-mounted gear unit (C) to

machine being used +60..+70 C, for example with blowtorch. Be careful

not to damage the oil seals. Mount the gear unit on

dimensions of the keyway and the key (E) the shaft using nuts (G), if necessary, tightening them

compatibility of the bores of the end plate (A) against the end plate (A).

with the thread holes at the end of the shaft (D) Finally, remove the mounting screws (B), lock the

shaft (D) to the end plate (A) with the locking screws

(H) and fix the cover (F) in place.

Figure 1. Installing the key connection and installed key connection.

2. INSTALLING A SHAFT-MOUNTED GEAR UNIT WITH SHRINK DISC CONNECTION

The installation of a shaft-mounted gear unit is done Before installation, check the following:

using an end plate (A) and the appropriate mounting

screws (B) (Figure 2). The number and size of

dimensions of the hollow shaft (C) bore

screws needed in installation can be found in the dimensions of the end of the shaft (D) of the

dimensional drawing of the unit. machine being used

compatibility of the bores in the end plate (A)

with the thread holes at the end of the shaft (D)

Moventas Santasalo Oy 2(5)

Installing industrial gear wheels shaft-

mounted gear units, horizontal model

MDI-165-A-EN 20.02.2007

Also read the separate shrink disc connection Lift the shaft-mounted gear unit to the height of the

instructions for information on attaching the shrink end of the shaft (D) of the machine being used.

disc (K). Mount the gear unit on the shaft using nuts (G), if

The hollow shaft (C) bore at the shrink disc end and necessary, tightening them against the end plate (A).

the end of the shaft (D) of the machine to be used Finally, remove the mounting screws (B), lock the

must be carefully cleaned of oil and grease so as to shaft with the shrink disc (K) and fix the cover (F) in

create sufficient friction between the joint surfaces. place (Figures 2 and 3).

You should grease the contact surface at the free

end of the hollow shaft to prevent friction corrosion.

You can use greases listed in section 1 for this

purpose. The cone surfaces of the shrink disc must

also be greased.

Figure 2. Two different applications for installing a shrink disc connection.

Figure 3. Shrink disc connection installed in two different ways.

Moventas Santasalo Oy 3(5)

Installing industrial gear wheels shaft-

mounted gear units, horizontal model

MDI-165-A-EN 20.02.2007

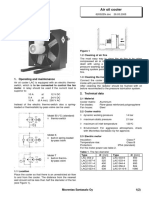

3. REMOVING A SHAFT-MOUNTED GEAR UNIT

First remove the oil from the shaft and lift the cover of You can also use a pressurised-oil cylinder and

the hollow shaft (F). Then fix the hoist to the gear unit appropriate removal tools.

and detach the torque arm. Turn the end plate (A) When removing a shaft-mounted unit with a shrink

into a position where the pull-out screws (M) do not disc joint (K), refer to the separate instructions for the

align with the thread holes in the shaft (D). Remove shrink disc joint.

the gear unit using the pull-out screws (M) and the

.

thread holes in the end plate (A) (Figures 4 and 5).

Figure 4. Removing a key connection.

Figure 5. Removing a shrink disc connection.

Moventas Santasalo Oy 4(5)

Installing industrial gear wheels shaft-

mounted gear units, horizontal model

MDI-165-A-EN 20.02.2007

4. INSTALLATION ACCURACY

4.1 Gear unit installation accuracy

The anchoring base (R) material is nodular cast iron, base and the anchoring rod. There must be two

and it is forbidden to weld it. There must be a gap (S) pivots in the anchoring support.

for transverse movement between the anchoring There is a separate guide for mounting the anchoring

support on the base.

Figure 6. Allowable margins in mounting.

Moventas Santasalo Oy 5(5)

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Awwa Hdpe PDFDocument37 pagesAwwa Hdpe PDFRaphael LinoPas encore d'évaluation

- 5 - Equivalencia de Normas PERNOSDocument1 page5 - Equivalencia de Normas PERNOSRaphael LinoPas encore d'évaluation

- Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationDocument9 pagesLubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationRaphael LinoPas encore d'évaluation

- Assembly Report: Gear Unit: Manuf. Number: DriveDocument1 pageAssembly Report: Gear Unit: Manuf. Number: DriveRaphael LinoPas encore d'évaluation

- Mdi 110en PDFDocument2 pagesMdi 110en PDFRaphael LinoPas encore d'évaluation

- Pressure lubrication unit connectionsDocument2 pagesPressure lubrication unit connectionsRaphael LinoPas encore d'évaluation

- enDocument2 pagesenRaphael LinoPas encore d'évaluation

- L3206en PDFDocument2 pagesL3206en PDFRaphael LinoPas encore d'évaluation

- MDI 120EN - Safety GuideDocument6 pagesMDI 120EN - Safety GuideRaphael LinoPas encore d'évaluation

- Corrosion Protection and StorageDocument3 pagesCorrosion Protection and StorageRaphael LinoPas encore d'évaluation

- Use and Maintenance of Gear UnitDocument4 pagesUse and Maintenance of Gear UnitRaphael LinoPas encore d'évaluation

- Use and Maintenance of Gear UnitDocument4 pagesUse and Maintenance of Gear UnitRaphael LinoPas encore d'évaluation

- MDI 120EN - Safety GuideDocument6 pagesMDI 120EN - Safety GuideRaphael LinoPas encore d'évaluation

- Corrosion Protection and StorageDocument3 pagesCorrosion Protection and StorageRaphael LinoPas encore d'évaluation

- M062210 Part ListDocument4 pagesM062210 Part ListRaphael LinoPas encore d'évaluation

- M062210 Tech SpecDocument1 pageM062210 Tech SpecRaphael LinoPas encore d'évaluation

- M062210 - Manual Cover SheetDocument1 pageM062210 - Manual Cover SheetRaphael LinoPas encore d'évaluation

- Mdi 110enDocument2 pagesMdi 110enRaphael LinoPas encore d'évaluation

- L3206en PDFDocument2 pagesL3206en PDFRaphael LinoPas encore d'évaluation

- L3206ENDocument2 pagesL3206ENRaphael LinoPas encore d'évaluation

- Safety Valve Durgo: 2. Ensure The Valve FunctionsDocument1 pageSafety Valve Durgo: 2. Ensure The Valve FunctionsRaphael LinoPas encore d'évaluation

- 2577910.dimensional DrawingDocument1 page2577910.dimensional DrawingRaphael LinoPas encore d'évaluation

- enDocument2 pagesenRaphael Lino100% (1)

- enDocument1 pageenRaphael LinoPas encore d'évaluation

- enDocument2 pagesenRaphael LinoPas encore d'évaluation

- Astm A105Document1 pageAstm A105Raphael LinoPas encore d'évaluation

- Visual Differential Pressure Indicator: Type FPC V 10 VMDocument1 pageVisual Differential Pressure Indicator: Type FPC V 10 VMRaphael LinoPas encore d'évaluation

- Shaft Driven Pump Operation DirectionsDocument1 pageShaft Driven Pump Operation DirectionsRaphael LinoPas encore d'évaluation

- enDocument2 pagesenRaphael LinoPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Ogl422 Milestone Three Team 11 Intro Training Session For Evergreen MGT Audion Recording Due 2022apr18 8 30 PM PST 11 30pm EstDocument14 pagesOgl422 Milestone Three Team 11 Intro Training Session For Evergreen MGT Audion Recording Due 2022apr18 8 30 PM PST 11 30pm Estapi-624721629Pas encore d'évaluation

- DNT Audit Cash CountDocument2 pagesDNT Audit Cash CountAnonymous Pu7TnbCFC0Pas encore d'évaluation

- Test SessionDocument2 pagesTest SessionMuhammad Fiaz AslamPas encore d'évaluation

- Lesson Plan 2018-2019 Term 1Document205 pagesLesson Plan 2018-2019 Term 1Athlyn DurandPas encore d'évaluation

- Marijuana Grow Basics - Jorge CervantesDocument389 pagesMarijuana Grow Basics - Jorge CervantesHugo Herrera100% (1)

- Ilham Bahasa InggrisDocument12 pagesIlham Bahasa Inggrisilhamwicaksono835Pas encore d'évaluation

- OROLO & W. D. GannDocument56 pagesOROLO & W. D. GannGaurav Garg100% (1)

- Neonatal SepsisDocument87 pagesNeonatal Sepsisyhanne100% (129)

- Nqs PLP E-Newsletter No68Document5 pagesNqs PLP E-Newsletter No68api-243291083Pas encore d'évaluation

- Android Attendance Management SystemDocument54 pagesAndroid Attendance Management Systemskpetks75% (12)

- Global 6000 SystemsDocument157 pagesGlobal 6000 SystemsJosé Rezende100% (1)

- Rubric - Argumentative EssayDocument2 pagesRubric - Argumentative EssayBobPas encore d'évaluation

- Brooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFDocument36 pagesBrooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFlois.guzman538100% (12)

- CH - 3Document3 pagesCH - 3Phantom GamingPas encore d'évaluation

- Ireland in Pre Celtic TimesDocument398 pagesIreland in Pre Celtic TimesGrant MacDonald100% (5)

- Brochure - Truemax Concrete Pump Truck Mounted TP25M4Document16 pagesBrochure - Truemax Concrete Pump Truck Mounted TP25M4RizkiRamadhanPas encore d'évaluation

- SQL 1: Basic Statements: Yufei TaoDocument24 pagesSQL 1: Basic Statements: Yufei TaoHui Ka HoPas encore d'évaluation

- FINAL - Plastic Small Grants NOFO DocumentDocument23 pagesFINAL - Plastic Small Grants NOFO DocumentCarlos Del CastilloPas encore d'évaluation

- OLA CAB MARKET ANALYSIS AND TRENDSDocument55 pagesOLA CAB MARKET ANALYSIS AND TRENDSnitin gadkariPas encore d'évaluation

- No.6 Role-Of-Child-Health-NurseDocument8 pagesNo.6 Role-Of-Child-Health-NursePawan BatthPas encore d'évaluation

- Aircraft ChecksDocument10 pagesAircraft ChecksAshirbad RathaPas encore d'évaluation

- Complete Hemi Sync Gateway Experience ManualDocument43 pagesComplete Hemi Sync Gateway Experience Manualapi-385433292% (92)

- Assessing Eyes NCM 103 ChecklistDocument7 pagesAssessing Eyes NCM 103 ChecklistNicole NipasPas encore d'évaluation

- HU675FE ManualDocument44 pagesHU675FE ManualMar VeroPas encore d'évaluation

- Ipo Exam Revised SyllabusDocument1 pageIpo Exam Revised Syllabusজ্যোতিৰ্ময় বসুমতাৰীPas encore d'évaluation

- 40 Multiple Choice Questions in Basic StatisticsDocument8 pages40 Multiple Choice Questions in Basic StatisticsLevi CorralPas encore d'évaluation

- Av1 OnDocument7 pagesAv1 OnLê Hà Thanh TrúcPas encore d'évaluation

- Seminar #22 Vocabury For Speaking PracticeDocument7 pagesSeminar #22 Vocabury For Speaking PracticeOyun-erdene ErdenebilegPas encore d'évaluation

- Scholars of Hadith Methodology in Dealing With The Two Sahihs: The Criticized Ahadith As A Model. Ammar Ahmad Al-HaririDocument37 pagesScholars of Hadith Methodology in Dealing With The Two Sahihs: The Criticized Ahadith As A Model. Ammar Ahmad Al-HaririSalah KhanPas encore d'évaluation

- January 2013 Igcse Timetable 22-06-2012Document2 pagesJanuary 2013 Igcse Timetable 22-06-2012Rizwanur RahmanPas encore d'évaluation