Académique Documents

Professionnel Documents

Culture Documents

Determining Spline Misalignment Capabilities-NovemberDecember 1995 PDF

Transféré par

j_moellersTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Determining Spline Misalignment Capabilities-NovemberDecember 1995 PDF

Transféré par

j_moellersDroits d'auteur :

Formats disponibles

Determining Spline

M tsa Ii-gnment '.Canabili

e

_apa_ 1 mes e

Richard 'T. IFriedman

Intred uct ion

Introducing backlash into. pline couplings has

been common practice in order to provide for

component eccentric and angular misalignment,

The method presented here is believed to be exact

for splines with even numbers of teeth and

approximate for those with odd numbers of teeth.

This method i based on the reduction of the max-

imum effective tooth thickne to achieve the nec-

essary clearance. Other methods. such as tooth

Fig . - Inner and outer tooth pro'liles. crowning. are also effective.

Tooth Thickness and Its Re'larionship

to Misalignment apabm&y

II.i lmportant to understand what feature of

the spline provides the rnisalignrnentcapability,

Tbe approach presented here focuses on the sp!ine

tooth and space width that is perpendicular ro the

direction of misalignment. As shown in the fol-

lowing set of figures, this et of teeth is the geom-

etry that controls the mi alignment.

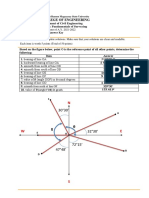

F:ig. I shows the inner and outer tooth profiles of

Fig. 2 - Tooth profiles where effective tooth thickness measured at Ute pilCh diameter a 16-loolh. 24/48-pitch, 30 0

pressure angle, fillet

bas been reduced bJ .o.ms"

root, side-fit spline at maximum material condi-

tions. In this slate. no allowance for misatignment

exists. The effective eooth thickness of the external

spline (inner profile), can be reduced during manu-

tacturing to provide clearance (see Fig. 2).

Direction of Misalignment

In Fig. 2. the e lema! spline has been reduced.

In shaping or hobbing, this is accomplished by

increasing the feed of a standard culler. In this

illustration. the effective tooth taickness mellftrecl

- Tooth Contact Point at the pitch diameter has been reduced by .015".

111e resulting clearance allow the pline center-

Fig, 3 - TIL spline center has moved ..0065", and contaet occurs on the tooth per-

lines to be offset to provide for component mi -

pendicular 10 Ih alignment 111i appears in Fig. 3. where an enlarged.

section has been howa for clarity, ote jhar the

Upper Border Created by amount the spline center moved is .(1065" [(Tooth

Internal Spline Space Width Thickness Rcc.iuclionl2) '. cos30ol. Whell the spline

loath ill Fig. 3 is rotated 30 about. the shaft center-

line, tile normal 10 the involute profile at the pitch

diameter is ill the misalignment direction. AI Ihat

point, the profile of the internal and external splines

are colineaz This is the limiting geometry, and it is

Lower Border Created by

cornpen ated for by the above trigonometric rela-

Internal Spline Space Width

tionship 10 the horizontal tooth position.

To calculate the allowable misalignment

Fig. " - Cross section of onelooth 'on the external spl in e and one

internal splln " (angular and eccentric), it is necess ary 1.0 consider

,36 (lEAR TECHNOLOGY

- (5 - 2 ClOSfJ HK sinfJ + 2 cosP lanA HK' cos8- 2 cosP GZ' tanA - 2, cosp GHJ

ll=----------------~--~--~--~--~~~-------------------

- ts + 2 cos/3' GZ 'lartA + 2' cosf3. GH + 2 cos/3 /iK si1l8- 2 cos/3' -in" '. L~ - 2 cos/3' tanA 11K c058+ 2 cos/3 1.rUlAcesa- L\J

12=------------------------------------~--~--~--~~~----------------------------------

(- cos{3. cos8- cosfJ tanA' ~in9)

Fig. S - Equations to rind the tooth thickness required h~, lip I, and lip' 2 crheria,

one 'tooth on the external spline and one space

width on the internal pline, The set is perpeedic-

ularto the direction of misalignment. Viewing a

cro s section of (hi from the side in Fig. 4, one

can see the tooth of the external. pline as well as

the borders of the internal spline space width. The

values for the space width and tooth thickness at

the pitch diameter are used in the calculations.

Coupling

In the example shown in Fig. 6, we shall con-

sider the external spline on the end of a pump

shaft and theiruernal spline on the end of a molar

shaft. Tile pump piVOLSarnund polru H. while 'the

motor pivots around point Z. Point Z i off et ver-

tically by distance #G and horizontally by dis- Fig. 6,- Diagram for II ,cliret'l coupling.

tance GZ. Distance HK describes the pline length The. e equations can be rearranged to find the

beyond pivot point H. and Ls is the pline length. loath thickness required bythe lip I and tip 2 cri-

The length of the motor's spline teeth must be suf- teria. The smaller value for tooththickness must

ficient to ensure engagement with the pump's be chosen (see Fig. 5).

spline. Tile pump angular misalignment is angle By making the appropriate substitutions, 'the

(J'. and the motor's angular misalignment is angle following expressions are derived for tile tooth

(3. The intercepts bl , b2 and b3 for contact at Tip thickness al tip .1and lip 2.

I and Tip 2 are calculated. but di lances bl-b2 a = 2 cosfJ GI-I

and h2-b3 axe probably not equal 10 one another. b = 2 cosfJ flK sin6

The formulas using t 1 the required tooth thiclmess (' = 2 co fJ lanA' HK', coB

to meet the geometric constraints that evolve [mill =

d 2 cosf3 GZ 'lanA.

'lip I contact with a space width are as follows: e == .cosfJ cos 6' - casp .' LanA. sin e

r'" 180 - P f= 2 co. fJ in8 Ls

HK. casuLl - -II,

. IX' ;;;;,

np in8

g ; 2. cosfJ - lanA cose' Ls

2 tl = - (s - b+ c - d - 01

tip.. .1Y = HK sinf +.!!.

2 cos8

r2 = - (5 + d + a + h - (- c + g)

bl = tip IY - tanA . tip IX e

b2 = - GZ tanA - GH 'TIle fixed angular displacement of the geome-

s = 2 (b2 - b 1)0 co .f3 try force con ideration of both t 1 and 12 as inde-

The additional formulas using t2 as the pendent elutions. The spline toorh thicknesi thai

'required tooth thickne to meet the geometric will fit within space width s i the smaller of these

construirus thai evolve from lip 2 contact wiLh a two values. A second set of equations must be

. pace width s are derived in the arne manner for contact at rip 3 and

Y= 180 -,B lip 4. All permutations of fJ and 8 must be tried

10 evaluate the smallc 'I tooth thickness.

lip 2X = (HK - L:I) 0 cos 9 +!1. sine

2 The final result should be multiplied by the Richard T.

lip 2Y = (HK - Ls) . in8 - t2. cos6

cosine of the pre urc angle as shown in Fig. 3 to fri,edman

2 obtain the required tooth Ihickness.Q IS a principal em:irlfN

.dlll Nichols )lin'raft

b2 = - GZ [anA - GH

Je'll Us Wha1. VOII Think ...If vou found this article of Di"ilitm of Parker

h3:::: tip 2Y -lanA tip 2X interest and/or useful, please circle R'e'aderService Ilanlliji/l Corporation,

s = 2 (b2 - b3) co.fJ 0 Num'ber A-11M. Wa/lham. MA.

NOV E "'8E RIDE CE M 8 E'R 1995 :31

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Integrating Wind Turbine With Energy StorageDocument22 pagesIntegrating Wind Turbine With Energy Storagej_moellersPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- MetalTek 2011 Rev Official Fisher Leave Behind PDFDocument120 pagesMetalTek 2011 Rev Official Fisher Leave Behind PDFj_moellersPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Compressed Air GuidelinesDocument7 pagesCompressed Air Guidelinesj_moellersPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- wndw3 Ebook PDFDocument520 pageswndw3 Ebook PDFj_moellersPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- ENERGY and STRUCTURE - A Theory of Social Power by Richard Newbold AdamsDocument366 pagesENERGY and STRUCTURE - A Theory of Social Power by Richard Newbold Adamsj_moellers100% (1)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Bell Cantilever 200 300 Manual PDFDocument20 pagesBell Cantilever 200 300 Manual PDFj_moellersPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- 13xtipsandtricks 160421165227Document34 pages13xtipsandtricks 160421165227j_moellersPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- MetalTek 2011 Rev Official Fisher Leave Behind PDFDocument120 pagesMetalTek 2011 Rev Official Fisher Leave Behind PDFj_moellersPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A Natural History of Destruction - SEBALD PDFDocument12 pagesA Natural History of Destruction - SEBALD PDFj_moellers100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Janni NCKDocument7 pagesJanni NCKmanuelPas encore d'évaluation

- ENERGY and STRUCTURE - A Theory of Social Power by Richard Newbold AdamsDocument366 pagesENERGY and STRUCTURE - A Theory of Social Power by Richard Newbold Adamsj_moellers100% (1)

- ENERGY and STRUCTURE - A Theory of Social Power by Richard Newbold Adams PDFDocument366 pagesENERGY and STRUCTURE - A Theory of Social Power by Richard Newbold Adams PDFj_moellersPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Chapter 11 Special Pumping UnitsDocument28 pagesChapter 11 Special Pumping Unitsj_moellersPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Manual J University PDFDocument27 pagesManual J University PDFj_moellersPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Chapter 10 Lineshaft Turbine Operating ConditionsDocument18 pagesChapter 10 Lineshaft Turbine Operating Conditionsj_moellersPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Chapter 11 Special Pumping UnitsDocument28 pagesChapter 11 Special Pumping Unitsj_moellersPas encore d'évaluation

- Chapter 10 Lineshaft Turbine Operating ConditionsDocument18 pagesChapter 10 Lineshaft Turbine Operating Conditionsj_moellersPas encore d'évaluation

- Solar Module Vs Thermoelectric Final SubmittedDocument13 pagesSolar Module Vs Thermoelectric Final Submittedj_moellersPas encore d'évaluation

- Chapter 9 Normal Operating Conditions-End Suction and Split Case Centrifugal PumpsDocument42 pagesChapter 9 Normal Operating Conditions-End Suction and Split Case Centrifugal Pumpsj_moellersPas encore d'évaluation

- Chapter 9 Normal Operating Conditions-End Suction and Split Case Centrifugal PumpsDocument42 pagesChapter 9 Normal Operating Conditions-End Suction and Split Case Centrifugal Pumpsj_moellersPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Chapter 6 Selection and Replacement of Mechanical SealsDocument28 pagesChapter 6 Selection and Replacement of Mechanical Sealsj_moellersPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Chapter 7 Pump Piping SystemDocument32 pagesChapter 7 Pump Piping Systemj_moellersPas encore d'évaluation

- Chapter 2 Centrifugal Pump TypesDocument30 pagesChapter 2 Centrifugal Pump Typesj_moellersPas encore d'évaluation

- Chapter 8 Pump HydraulicsDocument62 pagesChapter 8 Pump Hydraulicsj_moellersPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Chapter 3 Centrifugal Pump ComponentsDocument62 pagesChapter 3 Centrifugal Pump Componentsj_moellersPas encore d'évaluation

- Pumps & Pumping-CompleteDocument433 pagesPumps & Pumping-Completej_moellers89% (9)

- Chapter 7 Pump Piping SystemDocument32 pagesChapter 7 Pump Piping Systemj_moellersPas encore d'évaluation

- Chapter 1 Centrifugal Pump TheoryDocument26 pagesChapter 1 Centrifugal Pump Theoryj_moellersPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- ManagingGalvanicCorrosion 14027Document18 pagesManagingGalvanicCorrosion 14027j_moellersPas encore d'évaluation

- Associated and Compound Angles (SN Dey Xi)Document5 pagesAssociated and Compound Angles (SN Dey Xi)sadafmurtaza231Pas encore d'évaluation

- Geometery PDFDocument27 pagesGeometery PDFSaugat KarPas encore d'évaluation

- Triangles Proofs KEYDocument8 pagesTriangles Proofs KEYZeeshan Jahangir0% (1)

- Pythagorean Theorem Guided NotesDocument3 pagesPythagorean Theorem Guided NotesDavid CollierPas encore d'évaluation

- Triangle Properties Graphic OrganizerDocument3 pagesTriangle Properties Graphic OrganizerJuanita GreenePas encore d'évaluation

- Intersection and Resection - Docx GRP 555555Document5 pagesIntersection and Resection - Docx GRP 555555Priyanshu PathakPas encore d'évaluation

- 20094em3 Exercise 22Document2 pages20094em3 Exercise 22api-25895802Pas encore d'évaluation

- MATH GR9 QTR4-M2 24pagesDocument24 pagesMATH GR9 QTR4-M2 24pageschrxtine hernandoPas encore d'évaluation

- Chapter 1Document25 pagesChapter 1Noor Faizah ZohardinPas encore d'évaluation

- CE 214 Quiz 2 Answer KeyDocument2 pagesCE 214 Quiz 2 Answer KeyJerome M JaldoPas encore d'évaluation

- Table Primitives UsuellesDocument1 pageTable Primitives UsuellesBlake LyPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Goemtryننفرد بنشر الشيت الأفضل للأول الإعدادى لغات ترم أول 2014Document10 pagesGoemtryننفرد بنشر الشيت الأفضل للأول الإعدادى لغات ترم أول 2014deyaa1000000Pas encore d'évaluation

- CSEC-Maths-2023-pdfDocument41 pagesCSEC-Maths-2023-pdfsharmaramdahin6Pas encore d'évaluation

- Formula - by B B Susheel KumarDocument14 pagesFormula - by B B Susheel KumarB B Susheel KumarPas encore d'évaluation

- Math 20-1 Formula SheetDocument2 pagesMath 20-1 Formula SheetTayson PretePas encore d'évaluation

- KL 1 RussianCircularSlideRuleDocument2 pagesKL 1 RussianCircularSlideRuleEl RuloPas encore d'évaluation

- Activity Sheet-Theorems On Inscribed AnglesDocument6 pagesActivity Sheet-Theorems On Inscribed AnglesBecky May SajoPas encore d'évaluation

- Séries de Olimpíadas de Matemática - Volume 10 - Resolvendo Problemas em Geometria - 1° Edição de 2018 em Inglês - Hang e WangDocument370 pagesSéries de Olimpíadas de Matemática - Volume 10 - Resolvendo Problemas em Geometria - 1° Edição de 2018 em Inglês - Hang e WangIGOR LYNCOLN DA SILVA SABREUPas encore d'évaluation

- Trigonometric Equations PDFDocument34 pagesTrigonometric Equations PDFSanjay Gupta100% (1)

- Straight Lines - 01 - NewDocument15 pagesStraight Lines - 01 - NewMadhav MaheshwariPas encore d'évaluation

- AnswersDocument44 pagesAnswersStephaniePas encore d'évaluation

- AcesDocument3 pagesAcesJay TabagoPas encore d'évaluation

- Angles 160924221626Document29 pagesAngles 160924221626Haroon Khan DurraniPas encore d'évaluation

- CSEC Math Specimen Solutions TitleDocument16 pagesCSEC Math Specimen Solutions Titleanilbajnath100% (1)

- Hobson's Trigonometry 4th - Ed B WDocument414 pagesHobson's Trigonometry 4th - Ed B WJust Barry100% (5)

- Preliminaries: 0.1 Concepts ReviewDocument62 pagesPreliminaries: 0.1 Concepts Reviewdiego7yangariPas encore d'évaluation

- Geometry m2 Topic e Lesson 27 Teacher PDFDocument10 pagesGeometry m2 Topic e Lesson 27 Teacher PDFJamie BaczewskiPas encore d'évaluation

- GRE Geometry - by Greenlight Test PrepDocument193 pagesGRE Geometry - by Greenlight Test PrepRamuPas encore d'évaluation

- Geometry Tutor - Worksheet 3 - Complimentary and Supplementary AnglesDocument17 pagesGeometry Tutor - Worksheet 3 - Complimentary and Supplementary AnglesCydrick P DescalzoPas encore d'évaluation

- (DownSub - Com) (1280x720) Geometry Course - Online Course For Studying Geometry The Great Courses Plus - mp4Document32 pages(DownSub - Com) (1280x720) Geometry Course - Online Course For Studying Geometry The Great Courses Plus - mp4Sylvia Al-AmaPas encore d'évaluation

- LIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionD'EverandLIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionÉvaluation : 4 sur 5 étoiles4/5 (402)

- Why We Die: The New Science of Aging and the Quest for ImmortalityD'EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Outlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisD'EverandOutlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisÉvaluation : 4 sur 5 étoiles4/5 (1)

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedD'EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedÉvaluation : 5 sur 5 étoiles5/5 (78)

- The Age of Magical Overthinking: Notes on Modern IrrationalityD'EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityÉvaluation : 4 sur 5 étoiles4/5 (13)