Académique Documents

Professionnel Documents

Culture Documents

2 Foverview

Transféré par

suryakanta padhiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2 Foverview

Transféré par

suryakanta padhiDroits d'auteur :

Formats disponibles

2F

Performance Testing of Shipping Containers for LTL 2

0

Shipment, National Motor Freight Classification Item 180 1

0

ISTA 2 Series ISTA, Distributing Confidence, Worldwide™

Partial

Simulation ISTA 2 Series tests are a combination of basic test elements from ISTA 1 Series (Non-Simulation Integrity Performance Testing)

Performance and advanced test elements from ISTA 3 Series (General Simulation Performance Testing).

Test • They challenge the capability of the package and product to withstand transport hazards, but

Procedure • They only simulate some actual transport hazards, and

• They do not necessarily comply with carrier packaging regulations.

When properly applied, ISTA procedures will provide tangible benefits of:

• Shortened packaged development time and confidence in product launch

• Protection of products and profits with reduced damage and product loss

VERSION • Economically balanced distribution costs

DATE • Customer satisfaction and continued business.

Last

TECHNICAL There are three sections: Overview, Testing and Report

Change: • Overview provides the general knowledge required before going into the testing laboratory and

JANUARY • Testing presents the specific instructions to do the testing in the laboratory and

2010 • Report indicates what data shall be recorded to submit a test report to ISTA.

Two systems of weights and measures are presented in ISTA test procedures. They are the English system (Inch-Pound) and the

Last

international system SI (Metric). Inch-Pound units are shown first with Metric units in brackets, except in some tables where they

EDITORIAL

are shown separately.

Change:

JANUARY • Either system may be used as the unit of measure (standard units), but

2010 • The standard units chosen shall be used consistently throughout the procedure.

• Units are converted to two significant figures and

Adopted: • Not exact equivalents.

JULY 2007

VERY IMPORTANT:

The entire document shall be read and understood before proceeding with a test.

For complete

listing of NOTE:

Procedure National Motor Freight Classification (NMFC) Item 180 is copyrighted by the National Motor Freight Traffic Association, Inc.

Changes and (NMFTA) and its inclusion in Procedure 2F is with expressed permission of the NMFTA. To be certified under National Motor

Version Dates Freight Classification (NMFC) Item 180, the testing laboratory must register with the National Classification Committee (NCC). Test

go to reports must be submitted to the NCC’s Packaging Engineer with the required information as specified in the NMFC. Successful

www.ista.org completion of ISTA Procedure 2F will not imply automatic approval or certification under NMFC Item 180.

OVERVIEW OF PROCEDURE 2F

Preface Test Procedure 2F is a partial simulation test for individual packaged-products, including palletized loads.

• It provides an alternative to: The National Motor Freight Classification Test Shipment Permit Program (Item 689): other NMFC

packaging Rules except those relating to drums, pails and bags; and numbered Packages in the NMFC.

• It can be used to qualify as passing NCC/LTL ITEM 180 for NMFC Certification

• It can be used to evaluate the performance of a packaged-product.

• It can be used to compare relative performance of package and product design alternatives.

• It should be considered for the evaluation of packaged-products intended for Less-than-Truck Load shipment.

• The package and product are considered together and not separately.

• Some conditions of transit, such as moisture, pressure or unusual handling, may not be covered.

Other ISTA Procedures may be appropriate for different conditions or to meet different objectives.

Refer to Guidelines for Selecting and Using ISTA Procedures and Projects for additional information.

ISTA 2F 2007 - Page 1 of 26

© 2010 International Safe Transit Association. All rights Reserved.

2F OVERVIEW OF PROCEDURE 2F

Scope Test Procedure 2F covers testing of individual packaged-products, including palletized loads, except for drums, pails and bags,

when prepared for Less-than-Truck Load (LTL) shipment.

It is recommended for solving chronic damage problems and for providing an acceptable assurance level of packaging for articles

of great value. In order to qualify as authorized methods of packaging under Procedure 2F and NCC Item 180, shipping

containers, including palletized loads, must be preshipment tested and successfully pass the following prescribed performance test

requirements and meet the acceptance criteria as indicated.

Shippers will be required to perform the specified minimum test as often as necessary to maintain a satisfactory performance level

of the packaged article (see Test Report section). Multiple test specimens are recommended when available.

Shippers will be required to perform the specified minimum tests as often as necessary to maintain a satisfactory performance

level of the packaged article. Multiple test specimens are recommended when available and all specimens tested must pass.

This Rule does not purport to address all of the safety issues, if any, associated with its use. It is the responsibility of the user

of this Rule to establish appropriate safety and health practices and to determine the applicability of regulatory limitations or

requirements prior to use.

Product Damage The shipper shall determine the following prior to testing:

Tolerance and • what constitutes damage to the product and

Degradation • what damage tolerance level is allowable, if any, and

Allowance • the correct methodology to determine product condition at the conclusion of the test and

• the acceptable package condition at the conclusion of the test.

For additional information on this determination process refer to Guidelines for Selecting and Using ISTA Procedures and

Projects.

Samples Samples should be the untested actual package and product, but if one or both are not available, the substitutes shall be as

identical as possible to actual items.

Number of samples required:

• One sample is required for the tests in this procedure.

Replicate Testing Recommended:

To permit an adequate determination of representative performance of the packaged-product, ISTA:

• Requires the procedure to be performed one time, but

• Recommends performing the procedure five or more times using new samples with each test.

NOTE:

Packages that have already been subjected to the rigors of transportation cannot be assumed to represent standard

conditions. In order to insure testing in perfect condition, products and packages shipped to certified laboratories for testing

must be:

• over-packaged for shipment to the laboratory or

• repackaged in new packaging at the laboratory.

ISTA 2F 2007 - Page 2 of 26

© 2010 International Safe Transit Association. All rights Reserved.

2F OVERVIEW OF PROCEDURE 2F

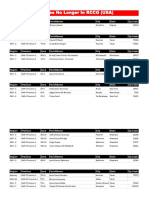

Test Sequence The tests sequence will vary depending upon the configuration of the package or package system. The tests shall be performed on

each test sample in the sequence indicated in one of the corresponding tables below:

Table 1: An individual container weighing less than 200 lb (91 kg) with no skid or pallet attached and not part of a unitized load

Table 2: An individual container weighing 200 lb (91 kg) or more with no skid or pallet attached and not part of a unitized load

Table 3: An individual container with definite skid or pallet whether integral or external

Table 4: A palletized load made up of multiple numbers of containers or Unitized loads of bulk configuration

Table 1 An individual container weighing less than 200 lb (91 kg) with no skid or pallet attached and

not part of a unitized load

Sequence

Test Category Test Type Test Level For ISTA Certification

Number

1 Atmospheric Temperature and Humidity Ambient Optional

Preconditioning

TEST BLOCK 1

2 Atmospheric Controlled Temperature 23°C (73°F) @ 50% RH Required

Conditioning and Humidity

Minimum 24 hr for Paper-

TEST BLOCK 1 Based Packaging

All Others: Min. 12 hrs

3 Vibration Under Random Vibration Calculated Test Load Required

Dynamic Load with a Top Load Overall Gr m s level of 0.52 (Alternative sequence

TEST BLOCK 2 allowed: you may select to

conduct Sequence 4 and 5

in lieu of 3)

4 Compression Machine Apply and Release Calculated Test Force Required

TEST BLOCK 3 (Alternative allowed)

Constant Load

5 Vibration Fixed Displacement 1 in (25mm) peak to peak Required

TEST BLOCK 4 or at a frequency to be (Alternative allowed)

TEST BLOCK 5 determined

Random Overall Gr m s level of 0.52

6 Shock Drop Height varies with Required

TEST BLOCK 6 packaged-product weight

ISTA 2F 2007 - Page 3 of 26

© 2010 International Safe Transit Association. All rights Reserved.

2F OVERVIEW OF PROCEDURE 2F

Test Sequence An individual container weighing 200 lbs. or more with no skid or pallet attached and not part

Table 2

of a unitized load

Sequence

Test Category Test Type Test Level For ISTA Certification

Number

1 Atmospheric Temperature and Humidity Ambient Optional

Preconditioning

TEST BLOCK 1

2 Atmospheric Controlled Temperature 23°C (73°F) @ 50% RH Required

Conditioning and Humidity Minimum 24 hr for Paper-

Based Packaging

TEST BLOCK 1

All Others: Min. 12 hrs

3 Vibration Under Random Vibration Calculated Test Load Required

Dynamic Load with a Top Load Overall Gr m s level of 0.52 (Alternative sequence

TEST BLOCK 2 allowed: you may select to

conduct Sequence 4 and 5

in lieu of 3)

4 Compression Machine Apply and Release Calculated Test Force Required

TEST BLOCK 3 (Alternative allowed)

Constant Load

5 Vibration Fixed Displacement 1 in (25mm) peak to peak Required

TEST BLOCK 4 or at a frequency to be (Alternative allowed)

TEST BLOCK 5 determined

Random Overall Gr m s level of 0.52

6 Shock Drop Drop height of 6.0 in Required

(Alternative methods (150 mm)

allowed – select one

test type) Incline Impact (Conbur) Impact Velocity 5.75 ft/sec

TEST BLOCK 6 or (1.75 m/s)

TEST BLOCK 7 Horizontal Impact Impact Velocity 5.75 ft/sec

(1.75 m/s)

7 Shock Rotational Edge and Drop height of 6.0 in Required

TEST BLOCK 9 Corner Drop (150 mm)

ISTA 2F 2007 - Page 4 of 26

© 2010 International Safe Transit Association. All rights Reserved.

2F OVERVIEW OF PROCEDURE 2F

Test Sequence An individual container with definite skid or pallet whether integral or external

Table 3

Sequence

Test Category Test Type Test Level For ISTA Certification

Number

1 Atmospheric Temperature and Humidity Ambient Optional

Preconditioning

TEST BLOCK 1

2 Atmospheric Controlled Temperature 23°C (73°F) @ 50% RH Required

Conditioning and Humidity Minimum 24 hrs for Paper-

Based Packaging

TEST BLOCK 1

All Others: Min. 12 hrs

3 Vibration Under Random Vibration with a Calculated Test Load Required

Dynamic Load Top Load Overall Gr m s level of 0.52 (Alternative sequence

TEST BLOCK 2 allowed: you may select to

conduct Sequence 4 and 5

in lieu of 3)

4 Compression Machine Apply and Release Calculated Test Force Required

TEST BLOCK 3 (Alternative allowed)

Constant Load

5 Vibration Fixed Displacement 1 in (25mm) peak to peak Required

TEST BLOCK 4 or at a frequency to be (Alternative allowed)

TEST BLOCK 5 determined

Random Overall Gr m s level of 0.52

6 Shock Rotational Flat Drop Height varies with Required

TEST BLOCK 10 packaged-product weight

7 Shock Incline Impact (Conbur) Impact Velocity 4.0 ft/sec Required

(Alternative methods (1.2 m/s)

allowed – select one

test type) Horizontal Impact Impact Velocity 4.0 ft/sec

TEST BLOCK 11 (1.2 m/s)

ISTA 2F 2007 - Page 5 of 26

© 2010 International Safe Transit Association. All rights Reserved.

2F OVERVIEW OF PROCEDURE 2F

Test Sequence A palletized load made up of multiple numbers of containers or Unitized loads of bulk

Table 4

configuration

Sequence

Test Category Test Type Test Level For ISTA Certification

Number

1 Atmospheric Temperature and Humidity Ambient Optional

Preconditioning

TEST BLOCK 1

2 Atmospheric Controlled Temperature 23°C (73°F) @ 50% RH Required

Conditioning and Humidity Minimum 24 hr for Paper-

Based Packaging

TEST BLOCK 1

All Others: Min. 12 hrs

3 Vibration Under Random Vibration with a Calculated Test Load Required

Dynamic Load Top Load Overall Gr m s level of 0.52 (Alternative sequence

TEST BLOCK 2 allowed: you may select to

conduct Sequence 4 and 5

in lieu of 3)

4 Compression Machine Apply and Release Calculated Test Force Required

TEST BLOCK 3 (Alternative allowed)

Constant Load

5 Vibration Fixed Displacement 1 in (25mm) peak to peak Required

TEST BLOCK 4 or at a frequency to be (Alternative allowed)

TEST BLOCK 5 determined

Random Overall Gr m s level of 0.52

6 Shock Rotational Flat Drop Height varies with Required

TEST BLOCK 10 packaged-product weight

7 Shock Incline Impact (Conbur) Impact Velocity 4.0 ft/sec Required

(Alternative methods (1.2 m/s)

allowed – select one

test type) Horizontal Impact Impact Velocity 4.0 ft/sec Required

TEST BLOCK 11 (1.2 m/s)

8 Shock Fork Truck Course Course as described Required

(Alternative methods

allowed – select one

test type) Fixed Displacement Synchronous 30° Out-of-

TEST BLOCK 12 Phase motion

or

TEST BLOCK 13

ISTA 2F 2007 - Page 6 of 26

© 2010 International Safe Transit Association. All rights Reserved.

2F EQUIPMENT REQUIRED FOR PROCEDURE 2F

Equipment Atmospheric Conditioning:

Required

• Chamber and Control apparatus complying with the apparatus section of ASTM D 4332.

Atmospheric

Conditioning • Humidity recording apparatus complying with the apparatus section of ASTM D 4332.

• Temperature recording apparatus complying with the apparatus section of ASTM D 4332.

Equipment The following equipment is required for the Compression Test:

Required

Compression

Type of Compression Test Equipment In compliance with the apparatus section of:

Apply and Release Test Compression test system ASTM D 642

“Fixed-Platen Testing Machine” requirements

Constant Load Compression test system ASTM 4577

or Dead Weight

CAUTION:

When using a dead weights and a load spreader use extreme care to prevent injury.

Equipment The following alternatives are acceptable for the equipment required for the Vibration Test:

Required

Random Vibration Test:

Vibration

• Random Vibration Test System complying with the apparatus section of ASTM D 4728.

Fixed Displacement Vibration Test:

• Vibration Test System with a 1 in (25 mm) fixed or controlled displacement complying with Method A1 or A2 of the apparatus

section of ASTM D 999. Rotary or vertical linear motion of the platform is acceptable.

• The unitized load test requires non-synchronous motion from a vibration Test System with 1 in (25 mm) fixed displacement

complying with Method A2 of the apparatus section of ASTM D 999.

• Metal shim 0.06 in (1.5 mm), thick approximately 2 in (50 mm) wide and at a convenient length.

• Tachometer or suitable indicator for determining vibration frequency in cycles per second (Hz) or cycles per minute (CPM).

• Automatic timer or stopwatch.

NOTE:

For tall or unstable shipping units, random or vertical-linear vibration may be preferred.

Equipment NOTE:

Required This vibration under dynamic load test requirement is:

Vibration • a performance test, but not

Under • a predictor of warehouse stacking capability.

Dynamic

Load Top-Load simulates assorted freight on top of a floor loaded shipping unit in a 108 in (2.7 m) trailer at 10 lb/ft3 (160 kg/m3)

The Top-Load apparatus container(s) shall be (see Figure 1 on next page)

• One, two or four separate loading systems and

• Larger than the test specimen, but

• Shall not overhang the specimen by more than 1.5 in (38 mm) and

• Shall distribute the calculated Top-Load (TL) evenly over the test specimen.

To determine if more than one Top-Load apparatus is required, follow the instructions below:

If the packaged-product

top surface exceeds

18 in (0.46 m) in… Then there shall be…

only one dimension two Top-Load apparatus of equal size and weight along the long edge

both dimensions four Top-Load apparatus of equal size and weight

Continued on next page

ISTA 2F 2007 - Page 7 of 26

© 2010 International Safe Transit Association. All rights Reserved.

2F EQUIPMENT REQUIRED FOR PROCEDURE 2F

Equipment Continued from previous page

Required

Vibration The Top-Load container(s) shall have the following specifications:

Under • Corrugated trays or HSC-style containers of doublewall construction having a corrugated medium maximum basis weight of

Dynamic 33 lb (15 kg) and

Load • a plywood sheet with a minimum thickness of ½” 0.5 in (13 mm) resting inside the container on the complete area of the

Continued bottom inner flaps of the container and

• a block of lead or sand contained in plastic bag(s) evenly distributed over the bottom surface of the container to complete the

required calculated load [sand weighs approximately 110 lb/ft 3 pcf (50 kg/m3)]

Dead Load

Divided into 4 equal parts

11 in.

16 in. 9 in.

20 in.

Test

Specimen

Example,

oversize

requiring that

Dead Load be

divided into 4

20 in. equal parts

30 in.

Figure 1. Example of Concentrated Top Load on Test Specimen for Random Vibration Test. Test Specimen shown in example

measures 30 in x 20 in x 20 in, larger than 18 in (.46 m) in 2 dimensions, requiring that the Top Load be divided into 4 equal parts.

CAUTION:

When using a Top-Load apparatus use extreme care to prevent injury.

A restraining device or devices shall be used with the vibration test system to:

• prevent the Top-Load from moving off the package being tested and

• prevent the test specimen from moving off the platform and

• maintain test orientation of the stack, but

• the device or devices shall not restrict the vertical motion of the test specimen during the test.

ISTA 2F 2007 - Page 8 of 26

© 2010 International Safe Transit Association. All rights Reserved.

2F EQUIPMENT REQUIRED FOR PROCEDURE 2F

Equipment The following alternatives are acceptable for the equipment required for the Shock Test:

Required

Shock

Type of Shock Test Type of Equipment In compliance with the apparatus section of …

Drop Test Free fall drop tester ASTM D 5276

Alternative Incline Test Incline impact tester (Conbur) ASTM D 880

Alternative Horizontal Test Horizontal impact test system ASTM D 4003

Rotational Edge Test ASTM D 6179

Fork Truck ASTM D 6055

Fork Truck Course

Equipment Fork Truck Course

Required The fork truck test course should include at least

Fork Truck • One (1) right angle turn on a rigid flat surface representative of carrier terminals and warehouses.

Obstacle • An Obstacle, a modified 2 in x 6 in board with long edge beveled full height at 45 degrees (see Figure 2) placed on the

Course course in a position where both lift truck wheels on one side must pass over it during each handling sequence, and

• A second modified 2 in x 6 in board shall be placed on the course after the right angle turn in such a position that both lift

truck wheels on the opposite side must pass over it during each handling sequence.

1.5"

45° 45°

5.5"

Figure 2 Obstacle

ISTA 2F 2007 - Page 9 of 26

© 2010 International Safe Transit Association. All rights Reserved.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Module 3 Bearing CapacityDocument20 pagesModule 3 Bearing Capacitysuryakanta padhiPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Well Foundation FinalDocument21 pagesWell Foundation FinalSwapnil KurhePas encore d'évaluation

- Module 3 Bearing CapacityDocument20 pagesModule 3 Bearing Capacitysuryakanta padhiPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Analysis of Single and Group of Piles Subjected To Lateral Load Using Finite Element MethodDocument6 pagesAnalysis of Single and Group of Piles Subjected To Lateral Load Using Finite Element Methodsuryakanta padhiPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Usace Backfill For Subsurface StructuresDocument60 pagesUsace Backfill For Subsurface Structuressuryakanta padhiPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Bearing Capacity of SoilsDocument1 pageBearing Capacity of Soilssuryakanta padhiPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Modulus of Subgrade ReactionDocument41 pagesModulus of Subgrade Reactionsuryakanta padhi100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Settlement and Consolidation, 1-25-00Document5 pagesSettlement and Consolidation, 1-25-00seljak_veseljakPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Modulus of Subgrade ReactionDocument41 pagesModulus of Subgrade Reactionsuryakanta padhi100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- FPSCDocument15 pagesFPSCBABER SULTANPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- 123456Document4 pages123456Lance EsquivarPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Rebecca Young Vs CADocument3 pagesRebecca Young Vs CAJay RibsPas encore d'évaluation

- Chain of CommandDocument6 pagesChain of CommandDale NaughtonPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- W 26728Document42 pagesW 26728Sebastián MoraPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Research Report On Energy Sector in GujaratDocument48 pagesResearch Report On Energy Sector in Gujaratratilal12Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Wonderland Audition PacketDocument5 pagesWonderland Audition PacketBritt Boyd100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Rele A Gas BuchholtsDocument18 pagesRele A Gas BuchholtsMarco GiraldoPas encore d'évaluation

- Churches That Have Left RCCG 0722 PDFDocument2 pagesChurches That Have Left RCCG 0722 PDFKadiri JohnPas encore d'évaluation

- Contoh RPH Ts 25 Engish (Ppki)Document1 pageContoh RPH Ts 25 Engish (Ppki)muhariz78Pas encore d'évaluation

- Sample Behavioral Interview QuestionsDocument3 pagesSample Behavioral Interview QuestionssanthoshvPas encore d'évaluation

- Polymeric Nanoparticles - Recent Development in Synthesis and Application-2016Document19 pagesPolymeric Nanoparticles - Recent Development in Synthesis and Application-2016alex robayoPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Torah Hebreo PaleoDocument306 pagesTorah Hebreo PaleocamiloPas encore d'évaluation

- Diane Mediano CareerinfographicDocument1 pageDiane Mediano Careerinfographicapi-344393975Pas encore d'évaluation

- 9francisco Gutierrez Et Al. v. Juan CarpioDocument4 pages9francisco Gutierrez Et Al. v. Juan Carpiosensya na pogi langPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- 1 Introduction To PPSTDocument52 pages1 Introduction To PPSTpanabo central elem sch.Pas encore d'évaluation

- Harbin Institute of TechnologyDocument7 pagesHarbin Institute of TechnologyWei LeePas encore d'évaluation

- ListeningDocument2 pagesListeningAndresharo23Pas encore d'évaluation

- 37 Sample Resolutions Very Useful, Indian Companies Act, 1956Document38 pages37 Sample Resolutions Very Useful, Indian Companies Act, 1956CA Vaibhav Maheshwari70% (23)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Concept of HalalDocument3 pagesConcept of HalalakPas encore d'évaluation

- Effect of Added Sodium Sulphate On Colour Strength and Dye Fixation of Digital Printed Cellulosic FabricsDocument21 pagesEffect of Added Sodium Sulphate On Colour Strength and Dye Fixation of Digital Printed Cellulosic FabricsSumaiya AltafPas encore d'évaluation

- PCI Bank V CA, G.R. No. 121413, January 29, 2001Document10 pagesPCI Bank V CA, G.R. No. 121413, January 29, 2001ademarPas encore d'évaluation

- Proposed) Declaration of Factual Innocence Under Penal Code Section 851.8 and OrderDocument4 pagesProposed) Declaration of Factual Innocence Under Penal Code Section 851.8 and OrderBobby Dearfield100% (1)

- W2-Prepares Feasible and Practical BudgetDocument15 pagesW2-Prepares Feasible and Practical Budgetalfredo pintoPas encore d'évaluation

- Module 1 Facilitator's Guide - Assessing Information NeedsDocument62 pagesModule 1 Facilitator's Guide - Assessing Information NeedsadkittipongPas encore d'évaluation

- Aero - 2013q2 Apu On DemandDocument32 pagesAero - 2013q2 Apu On DemandIvan MilosevicPas encore d'évaluation

- HTTP Parameter PollutionDocument45 pagesHTTP Parameter PollutionSpyDr ByTePas encore d'évaluation

- SEW Products OverviewDocument24 pagesSEW Products OverviewSerdar Aksoy100% (1)

- Weill Cornell Medicine International Tax QuestionaireDocument2 pagesWeill Cornell Medicine International Tax QuestionaireboxeritoPas encore d'évaluation

- Custom Belt Buckles: Custom Brass Belt Buckles - Hand Made in The USA - Lifetime Guarantee of QualityDocument1 pageCustom Belt Buckles: Custom Brass Belt Buckles - Hand Made in The USA - Lifetime Guarantee of QualityAndrew HunterPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)