Académique Documents

Professionnel Documents

Culture Documents

Steel Joist Specification for Libyan Infrastructure Project

Transféré par

wafikmh4Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Steel Joist Specification for Libyan Infrastructure Project

Transféré par

wafikmh4Droits d'auteur :

Formats disponibles

SECTION 05210

STEEL JOISTS

THIS SPECIFICATION SECTION RELATES TO STRUCTURAL ELEMENTS AND SHALL BE EDITED

ONLY BY THE STRUCTURAL ENGINEER OF RECORD FOR THE SPECIFIC PROJECT.

PART 1 - GENERAL

1.01 DESCRIPTION:

A. Provide open web steel joists, long span steel joists and steel joist girders as

indicated and specified.

B. Provide bridging in accordance with the Steel Joist Institute, OSHA requirements

and as indicated and specified.

C. Provide accessories in accordance with Steel Joist Institute requirements.

1.02 RELATED WORK:

(NTS: Select and list specification sections for inserting into this subsection based

on the following:

1. Specification sections that contain products and construction that the reader

might expect to find in this section BUT are specified elsewhere.

2. Specification sections referenced in the body of this section.)

A. Section 03200: Concrete Reinforcement

B. Section 03300: Cast-In-Place Concrete

C. Section 04200: Unit Masonry and Accessories

D. Section 05120: Structural Steel

E. Section 05300: Steel Deck

F. Section 05500: Miscellaneous Metal

(NTS: Use next item only if field painting required. Field painting of joists is

generally not required

G. Section 09941: Field Painting

1.03 REFERENCES:

A. Steel Joist Institute (SJI)

Libya Infrastructure Master Spec 05210-1 20-Nov-08

(NTS: Select the appropriate Steel Joist Institute Reference Specification in the next

paragraph and delete those that do not apply.)

1. Standard Specifications for Open Web Steel Joists, K-Series

2. Standard Specifications for Longspan Steel Joists, LH-Series and Deep

Longspan Steel Joists, DLH-Series

3. Standard Specifications for Joists Girders

4. Recommended Code of Standard Practice for Steel Joists and Joist Girders

5. Technical Digest #9 Handling and Erection of Steel Joists and Joist

Girders

B. American Institute of Steel Construction AISC:

1. AISC Manual of Steel Construction, Allowable Stress Design

2. AISC Code of Standard Practice for Steel Buildings and Bridges

3. AISC Specification for Structural Joints using ASTM A 325 or A 490

Bolts

4. AISC Structural Steel Detailing Manual

C. American Society for Testing and Materials (ASTM) Publications:

1. A 307: Specification for Carbon Steel Bolts and Studs, 60,000 PSI (413.7

MPa) Tensile Strength

2. A 325: Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi

(827/724 MPa) Minimum Tensile Strength

3. A 384: Practice for Safeguarding Against Warpage and Distortion During

Hot-Dip Galvanizing of Steel Assemblies

4. A 385: Practice for Providing High Quality Zinc Coatings (Hot-Dip)

5. A 449: Specification for Quenched and Tempered Steel Bolts and Studs

D. Steel Structures Painting Council (SSPC)

1. Specification 15 Commercial Grade Power Tool Cleaning

E. Occupational Safety and Health Administration (OSHA)

Libya Infrastructure Master Spec 05210-2 20-Nov-08

1. Steel Erection Standard 29 CFR 1926.757

F. Equivalent British/European codes and standards may be used; however, the

equivalency shall be demonstrated and submitted by the Contractor and approved

by the CM/CS.

1.04 SUBMITTALS:

A. Shop Drawings: Submit the following in conformance with Section 01300:

1. Complete and checked shop and erection drawings for all steel joists, joist

girders and components.

a. Indicate standard designations, sizes, spacing and locations of

joists, joists, bridging, connections, attachments and top and

bottom chord extensions.

b. Shop and erection drawings for all steel joists shall be approved by

CM/CS prior to fabrication.

B. Certification, signed and sealed by a Professional Structural Engineer employed

by the joist manufacturer indicating the codes and specifications to which the joist

design conforms and stating that all members, elements and connections are

designed to withstand the specified loads.

C. Qualification test reports bearing witness certification by an independent testing

laboratory for each welder, welding operator and tacker to be employed in the

work.

D. Certificate stating that the surface preparation and painting conforms to SSPC-15.

1. Provide shop coatings proposed by type, brand and manufacturer.

2. Provide product data for determining compatibility of shop coatings with

field coats.

1.05 QUALITY ASSURANCE:

A. Provide in accordance with Section 01400 and as specified.

B. Design joists, girders and connections for the loads, moments and chord forces

indicated on the drawings.

C. Design joists, girders and connections for a net uplift of 20 psf [1.0 kPa] unless

otherwise indicated on the drawings.

Libya Infrastructure Master Spec 05210-3 20-Nov-08

D. Steel joist and joist girder design, manufacture, handling and installation shall

conform to the Steel Joist Institute Standard Specifications and load and weight

tables.

E. Bridging size and installation shall be as prescribed by the Steel Joist Institute.

F. Steel joists and joist girders shall be fabricated by manufacturer who is a member

of Steel Joist Institute.

G. Steel joists and joist girders shall be Steel Joist Institute approved.

H. Welding Qualification and Certification:

1. Each welder, welding operator and tack welder shall be certified by test to

perform type of work required in conformance with the Steel Joist

Institute.

1.06 DELIVERY, STORAGE AND HANDLING:

A. Provide in conformance with Section 01610 and as specified.

B. Storage and handling shall conform to the Steel Joist Institute Technical Digest

#9.

C. Transport, handle and store materials to protect from weather, rusting, corrosion

or other damage.

D. Store joists on substantial timbers and blocking with webs of joists vertical. Cover

and protect from snow, rain and ground splatter

E. Deliver, store and handle in a manner that prevents overstressing, deformation or

damage.

F. Prevent damage to shop coat.

PART 2 - PRODUCTS

2.01 STEEL JOISTS:

A. Fabricate steel joists and joist girders in accordance with the approved shop

drawings and the standard specifications of the Steel Joist Institute.

B. Provide top and bottom chord extensions as indicated or required. Top chord

extensions shall be Type R.

Libya Infrastructure Master Spec 05210-4 20-Nov-08

C. Provide sloped bearing ends where joist or girder slope exceeds per foot [21

mm per meter].

D. Provide bearing lengths in accordance with the Steel Joist Institute unless greater

bearing lengths are indicated on the drawings.

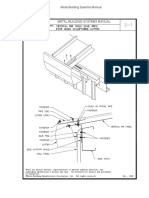

E. Joist Seats

1. Seats for K-Series joists shall be 2 inches [63.5 mm] in depth and shall

extend a minimum of 2 inches [63.5 mm] over steel supports.

2. Seats for LH-Series and DLH-Series joists shall be 5 inches [127 mm] in

depth and shall extend a minimum of 4 inches [100 mm] over steel

supports.

3. Seats for joist girders shall be 7 inches [190.5 mm] in depth and shall

extend a minimum of 6 inches [150 mm] over steel supports.

4. Fabricate with special seats as indicated or required.

F. Provide additional web members at points of application of concentrated loads to

transfer loads to panel points.

2.02 JOIST BRIDGING:

NTS: Insure special bridging requirements are indicated on the drawings.

A. Provide bridging and bridging anchorage in accordance with the Steel Joist

Institute and 29 CFR 1926.757 requirements.

B. Provide cross bridging between the last two joists at the end of a bridging line

such as at end walls or expansion joints.

C. Provide a line of bridging near each of the first bottom chord panel points for

joists subjected to uplift.

D. Provide bridging to brace the top chord of joists supporting standing seam roofing

under gravity loads.

E. Additional bridging shall be provided as required and where indicated on the

drawings

F. Manufacturer of joists shall furnish bridging and bridging anchorage.

2.03 CONNECTIONS:

A. Provide bolted connections using ASTM A325 bolts.

Libya Infrastructure Master Spec 05210-5 20-Nov-08

B. Provide welded connections in conformance with the Steel Joist Institute.

2.04 SHOP PAINTING:

A. Provide manufacturers standard SSPC-15 (gray) shop coat primer.

PART 3 - EXECUTION

3.01 PREPARATION:

A. Coordinate placement of anchorages in concrete and masonry construction for

securing bearing plates, angles and bridging anchors.

B. Verify that completed construction is ready for and will support steel joist and

joist girder placement.

C. Notify the CM/CS if discrepancies are found. Do not proceed or install joists and

joist girders in areas of discrepancy until those discrepancies have been fully

resolved to the satisfaction of the CM/CS.

3.02 JOISTS:

A. Steel joist erection shall comply with 29 CFR 1926.757.

B. Install in accordance with the Steel Joist Institute specifications, manufacturers

printed instruction and as indicated and specified.

C. Install in straight parallel lines at spacing indicated within a tolerance of 1/4-in. [6

mm] plus or minus.

D. Secure by welding to steel support beams or steel plates.

E. Do not apply loads to joists until secured in place and bridging is installed and

anchored at its ends.

F. Do not use damaged joists. Replacement joists shall be furnished at Contractors

expense.

3.03 BRIDGING:

A. Bridging and bridging anchorage shall be provided in accordance with the Steel

Joist Institute recommendations and 29 CFR 1926.757 requirements.

3.04 FIELD BOLTED CONNECTIONS:

Libya Infrastructure Master Spec 05210-6 20-Nov-08

A. Provide bolted connections between joist and columns which are not braced in at

least two directions by structural steel members.

3.05 FIELD WELDING:

A. Field welding shall be performed in accordance with the American Welding

Society, the Steel Joist Institute and the approved shop drawings.

B. Workmanship and techniques for welded construction shall conform to the

requirements of the Steel Joist Institute and as indicated or specified.

C. No field welding will be permitted unless indicated on CM/CS approved shop

drawings.

3.06 SHOP PAINTING:

A. Remove looses scale, rust or other foreign materials from fabricated joists, joist

girders and accessories.

B. Apply one coat of the manufacturers standard shop coat.

(NTS: Include the next item if field painting is required.)

3.07 FIELD PAINTING:

A. Provide field painting in accordance with Section 09941.

3.08 CONTRACT CLOSEOUT:

A. Provide in accordance with Section 01700.

END OF SECTION

Libya Infrastructure Master Spec 05210-7 20-Nov-08

Vous aimerez peut-être aussi

- AISC DESIGN GUIDE eXCERPTDocument3 pagesAISC DESIGN GUIDE eXCERPTMike2322Pas encore d'évaluation

- Design Flexural Strength of Steel Beams GuideDocument54 pagesDesign Flexural Strength of Steel Beams GuideFer Rivas NietoPas encore d'évaluation

- Ec - 1110 2 6066Document540 pagesEc - 1110 2 6066path967Pas encore d'évaluation

- SDI - COSP2014 - Code of Standard PracticeDocument18 pagesSDI - COSP2014 - Code of Standard PracticeAlonso Aguilar SalasPas encore d'évaluation

- Verco Floor Deck Catalog VF4 03-2012 PDFDocument100 pagesVerco Floor Deck Catalog VF4 03-2012 PDFFerdie TolosaPas encore d'évaluation

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Ahmad Badsha QuadriPas encore d'évaluation

- Stability Requirements: EM 1110-2-2100 1 Dec 05Document20 pagesStability Requirements: EM 1110-2-2100 1 Dec 05Edson HuertaPas encore d'évaluation

- Inspection Checklist for Masonry ConstructionDocument3 pagesInspection Checklist for Masonry Constructionrmm99rmm99Pas encore d'évaluation

- Steel Erection 6512Document63 pagesSteel Erection 6512brenstagPas encore d'évaluation

- C & Zed Purlins Design Manual and Catalogue BC783d01Document31 pagesC & Zed Purlins Design Manual and Catalogue BC783d01GnabBangPas encore d'évaluation

- Checking Punching Shear Strength with Finite Element ModelsDocument1 pageChecking Punching Shear Strength with Finite Element ModelsDaniyal AhmadPas encore d'évaluation

- Detailing StandardsDocument31 pagesDetailing StandardsJovito EdillonPas encore d'évaluation

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocument12 pagesThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelPas encore d'évaluation

- 04E83326B1B9406B9D2130DE77817D12Document717 pages04E83326B1B9406B9D2130DE77817D12chemikas8389Pas encore d'évaluation

- Design Criteria For RCCDocument7 pagesDesign Criteria For RCCAtifkhan132Pas encore d'évaluation

- Standard Details Public Works ConstructionDocument207 pagesStandard Details Public Works Constructionnido77Pas encore d'évaluation

- Canam Steel DeckDocument168 pagesCanam Steel DeckAnonymous 8hx6hKN3Pas encore d'évaluation

- Welding Process Description PDFDocument31 pagesWelding Process Description PDFcentaury2013Pas encore d'évaluation

- BIA - Steel Lintel DesignDocument7 pagesBIA - Steel Lintel Designgpax42Pas encore d'évaluation

- Quality Assured Steel Bridge Fabrication and Erection: September 2008Document23 pagesQuality Assured Steel Bridge Fabrication and Erection: September 2008amir0% (1)

- SSE Retaining - Wall - ACI Sheet v1.02Document1 pageSSE Retaining - Wall - ACI Sheet v1.02SES DESIGNPas encore d'évaluation

- Basics of Post-Installed Rebar Connections DesignDocument34 pagesBasics of Post-Installed Rebar Connections Designjrobert123321Pas encore d'évaluation

- Software Verification: AISC-360-10 Example 001Document9 pagesSoftware Verification: AISC-360-10 Example 001Davico HernandezPas encore d'évaluation

- Short Column: P F ' F A, and The Total Cross Section Area of The Steel RebarDocument2 pagesShort Column: P F ' F A, and The Total Cross Section Area of The Steel Rebaraditya2053Pas encore d'évaluation

- Steel JoistDocument2 pagesSteel JoistWilliam Greco100% (1)

- Esr 3814Document49 pagesEsr 3814Fahim IslamPas encore d'évaluation

- Construction Plans for Teterboro Landing Retail ProjectDocument11 pagesConstruction Plans for Teterboro Landing Retail Projectmadina1386Pas encore d'évaluation

- Joist Design GuideDocument1 pageJoist Design Guidealexkirokos0% (1)

- Schedule 40 PipeDocument2 pagesSchedule 40 Piperasnowmah2012Pas encore d'évaluation

- SWD-CSA-A23.3-04 Shear Wall Design ManualDocument82 pagesSWD-CSA-A23.3-04 Shear Wall Design ManualYohan LimPas encore d'évaluation

- LAB Design Procedure: 1. Decide The Type of Slab According To Aspect Ratio of Long and Short Side LengthsDocument20 pagesLAB Design Procedure: 1. Decide The Type of Slab According To Aspect Ratio of Long and Short Side Lengthsmollikamin100% (1)

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignnoneofyourbusineesPas encore d'évaluation

- Section Properties and General Stress AnalysisDocument7 pagesSection Properties and General Stress AnalysiscengizPas encore d'évaluation

- Metal Fencing SpecificationsDocument6 pagesMetal Fencing Specificationsyamanta_rajPas encore d'évaluation

- Design of Nailed N Glued Plywd GussetsDocument36 pagesDesign of Nailed N Glued Plywd Gussetsboon1961Pas encore d'évaluation

- Basic guide to steel structures in civil engineeringDocument25 pagesBasic guide to steel structures in civil engineeringJun Crisostomo100% (1)

- Imp Design GuideDocument32 pagesImp Design GuideRahulPas encore d'évaluation

- AD302 Tightening of Ordinary BoltsDocument2 pagesAD302 Tightening of Ordinary Boltsikirby77Pas encore d'évaluation

- "Weldgrp" - Weld Group Analysis ProgramDocument16 pages"Weldgrp" - Weld Group Analysis ProgramMario BertiPas encore d'évaluation

- ACI-350 P-M Interaction 2.1Document27 pagesACI-350 P-M Interaction 2.1Franklyn P. GenovePas encore d'évaluation

- ROOFDECK.xlsDocument9 pagesROOFDECK.xlsamachmouchiPas encore d'évaluation

- Detailed Composite Beam Design AISCDocument20 pagesDetailed Composite Beam Design AISCRaveendra Babu CherukuriPas encore d'évaluation

- Research Report On Single Plate Shear Connections: North Carolina State UniversityDocument51 pagesResearch Report On Single Plate Shear Connections: North Carolina State UniversityHarshaVeeragandhamPas encore d'évaluation

- Notes On Design of Steel Parking Structures IncludDocument42 pagesNotes On Design of Steel Parking Structures IncludSudhakar KrishnamurthyPas encore d'évaluation

- ACI 318M-11 Slab Punching StressDocument9 pagesACI 318M-11 Slab Punching StressIsprotec IngenieriaPas encore d'évaluation

- Cali Marine Oil Terminal Engineering and Maintenance Eskijian Paper - 2ADocument10 pagesCali Marine Oil Terminal Engineering and Maintenance Eskijian Paper - 2AvuongPas encore d'évaluation

- Column JacketingDocument3 pagesColumn Jacketinganonymousupldr666100% (1)

- M.K.Trading & M.K.Trading & M.K.Trading & M.K.Trading & Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.CDocument3 pagesM.K.Trading & M.K.Trading & M.K.Trading & M.K.Trading & Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.Ccheligp1981Pas encore d'évaluation

- Pip Ars13120pre Engineered Metal Building SpecificationDocument26 pagesPip Ars13120pre Engineered Metal Building SpecificationloukmanPas encore d'évaluation

- Structural Design Plan Review Checklist for Beverly Hills Building ProjectDocument14 pagesStructural Design Plan Review Checklist for Beverly Hills Building ProjectOmer HayatPas encore d'évaluation

- TEK 03-04C Bracing CMU Walls Under ConstructionDocument12 pagesTEK 03-04C Bracing CMU Walls Under ConstructionAdam JonesPas encore d'évaluation

- Roof Details Section 2.pdf MBMADocument31 pagesRoof Details Section 2.pdf MBMASilvanaPas encore d'évaluation

- Curb DetailsDocument1 pageCurb Detailsapi-241363936Pas encore d'évaluation

- Gusset Plate Evaluation Guide PDFDocument201 pagesGusset Plate Evaluation Guide PDFadrian55dumitruPas encore d'évaluation

- Post-Installed Rebar Connection BasicsDocument69 pagesPost-Installed Rebar Connection BasicsJeevan ShendrePas encore d'évaluation

- DE010 of-053123-1.0-P-Vulcraft Joist and Deck Plans - Datum ReviewedDocument9 pagesDE010 of-053123-1.0-P-Vulcraft Joist and Deck Plans - Datum ReviewedAzeemuddin Gulam MohammedPas encore d'évaluation

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4Pas encore d'évaluation

- Division 5Document15 pagesDivision 5hari banggaPas encore d'évaluation

- Pre-Fabricated Bridge - MSTDocument12 pagesPre-Fabricated Bridge - MSTwafikmh4Pas encore d'évaluation

- Particle Size Distribution AnalysisDocument3 pagesParticle Size Distribution Analysiswafikmh4Pas encore d'évaluation

- BH#1#3888 LL&PLBH#13888, BH#13888, BH#13888 LM ChartReportDocument1 pageBH#1#3888 LL&PLBH#13888, BH#13888, BH#13888 LM ChartReportwafikmh4Pas encore d'évaluation

- Location NameDocument1 pageLocation Namewafikmh4Pas encore d'évaluation

- TOC Vol.1 Part 6Document1 pageTOC Vol.1 Part 6wafikmh4Pas encore d'évaluation

- Annex A PDFDocument4 pagesAnnex A PDFwafikmh4Pas encore d'évaluation

- C 000a PDFDocument1 pageC 000a PDFwafikmh4Pas encore d'évaluation

- Sieve BH#1 & BH#2 3881Document7 pagesSieve BH#1 & BH#2 3881wafikmh4Pas encore d'évaluation

- Proctor TP - 1 3881Document1 pageProctor TP - 1 3881wafikmh4Pas encore d'évaluation

- Shear Box Test ASTM D3080: R e Sults Summa RyDocument2 pagesShear Box Test ASTM D3080: R e Sults Summa Rywafikmh4Pas encore d'évaluation

- LL&PL BH#1 & BH#2 3881Document2 pagesLL&PL BH#1 & BH#2 3881wafikmh4Pas encore d'évaluation

- NTS: The Following Two Paragraphs Should Be Deleted For Smaller ProjectsDocument18 pagesNTS: The Following Two Paragraphs Should Be Deleted For Smaller Projectswafikmh4Pas encore d'évaluation

- LightingDocument13 pagesLightingwafikmh4Pas encore d'évaluation

- Earth Pressures Against and Stability of Retaining - StructuresDocument200 pagesEarth Pressures Against and Stability of Retaining - StructuresIon PusculitaPas encore d'évaluation

- C 014 PDFDocument1 pageC 014 PDFwafikmh4Pas encore d'évaluation

- Verification of Strength (Sample)Document9 pagesVerification of Strength (Sample)Giri WakshanPas encore d'évaluation

- Design Calculations in GeotechnicsDocument139 pagesDesign Calculations in Geotechnicsgmazzucco100% (8)

- 06 EC2WS Frank Geotechnics PDFDocument55 pages06 EC2WS Frank Geotechnics PDFLuigiForgerone100% (1)

- Design Calculations in GeotechnicsDocument139 pagesDesign Calculations in Geotechnicsgmazzucco100% (8)

- NTS: The Following Two Paragraphs Should Be Deleted For Smaller ProjectsDocument18 pagesNTS: The Following Two Paragraphs Should Be Deleted For Smaller Projectswafikmh4Pas encore d'évaluation

- Electrical Design CriteriaDocument27 pagesElectrical Design Criteriawafikmh4Pas encore d'évaluation

- Design Criteria For Infrastructure Projects - Rev 03 - Nov 2010Document456 pagesDesign Criteria For Infrastructure Projects - Rev 03 - Nov 2010wafikmh4100% (2)

- Design Criteria For Infrastructure ProjectsDocument7 pagesDesign Criteria For Infrastructure Projectswafikmh4Pas encore d'évaluation

- Quality ManualDocument114 pagesQuality ManualPanneer SelvamPas encore d'évaluation

- Design Criteria For Infrastructure ProjectsDocument7 pagesDesign Criteria For Infrastructure Projectswafikmh4Pas encore d'évaluation

- Guidelines For Master SpecificationsDocument2 pagesGuidelines For Master Specificationswafikmh4Pas encore d'évaluation

- TOC Vol.1 Part 4Document1 pageTOC Vol.1 Part 4wafikmh4Pas encore d'évaluation

- PavementDocument38 pagesPavementwafikmh4Pas encore d'évaluation

- Guidelines For Master SpecificationsDocument2 pagesGuidelines For Master Specificationswafikmh4Pas encore d'évaluation

- SP 007Document51 pagesSP 007Obak PrithibiPas encore d'évaluation

- Health and Safety PlanDocument11 pagesHealth and Safety Planwafikmh4Pas encore d'évaluation

- SHAPING MACHINE SETUP GUIDEDocument10 pagesSHAPING MACHINE SETUP GUIDEsifuszPas encore d'évaluation

- "Uaht" Brake CylindersDocument8 pages"Uaht" Brake CylindersArmando RodriguezPas encore d'évaluation

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts List Southwest 8490-25alew Fluid End For Lewco Wh-2214Document12 pagesSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts List Southwest 8490-25alew Fluid End For Lewco Wh-2214Alejandro AlejandrePas encore d'évaluation

- ASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150Document1 pageASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150rabzihPas encore d'évaluation

- Mechanical Hand ValvesDocument70 pagesMechanical Hand ValvesruiloupaPas encore d'évaluation

- Mechanical Properties For Stainless Steel FastenersDocument3 pagesMechanical Properties For Stainless Steel FastenersGonzalo MazaPas encore d'évaluation

- SXL Rudder Carrier Bearings IntroductionDocument4 pagesSXL Rudder Carrier Bearings IntroductionAndrea NaranjoPas encore d'évaluation

- Specs PeDocument8 pagesSpecs PeKhairilMunawarPas encore d'évaluation

- BT4000 PartsDocument117 pagesBT4000 PartsPilaquinga DiegoPas encore d'évaluation

- TB 990178Document4 pagesTB 990178Salvador ReyesPas encore d'évaluation

- Catalogue Anglais (Nouveau)Document24 pagesCatalogue Anglais (Nouveau)Lai HuynhPas encore d'évaluation

- Neoporte BrochureDocument32 pagesNeoporte Brochurejanaaab5068Pas encore d'évaluation

- Grinnell Figure 772 Grooved Rigid CouplingDocument4 pagesGrinnell Figure 772 Grooved Rigid CouplingJuanPas encore d'évaluation

- UMSxDocument2 pagesUMSxjuan yenquePas encore d'évaluation

- Manual Reductor Falk 465A3-CR de Faja 105Document4 pagesManual Reductor Falk 465A3-CR de Faja 105jhonatan100% (1)

- Flinger Disc: Operating ManualDocument8 pagesFlinger Disc: Operating ManualKaiser46Li206Pas encore d'évaluation

- Manual Skoda Octavia - Gearbox m5 02KDocument116 pagesManual Skoda Octavia - Gearbox m5 02KCornea Horatiu Sebastian100% (5)

- INDUSTRIAL TRAINING PresentationDocument31 pagesINDUSTRIAL TRAINING Presentationjatin uppalPas encore d'évaluation

- Unloading Relief ValvesDocument6 pagesUnloading Relief ValvesStar SealPas encore d'évaluation

- 6601 Pull Type Combine IntroductionDocument4 pages6601 Pull Type Combine IntroductionNelson Andrade VelasquezPas encore d'évaluation

- Graco Husky 2150 Diaphragm Pump Manual: ALUMINUM, STAINLESS, AND DUCTILE IRONDocument34 pagesGraco Husky 2150 Diaphragm Pump Manual: ALUMINUM, STAINLESS, AND DUCTILE IRONMROstop.com100% (1)

- Design and Compliance Control of A Robotic Gripper For Orange HarvestingDocument5 pagesDesign and Compliance Control of A Robotic Gripper For Orange HarvestingLeonardoGrandiniAdamiPas encore d'évaluation

- Installation Method for Smoke Curtain SystemDocument13 pagesInstallation Method for Smoke Curtain SystemJuwe PkdoPas encore d'évaluation

- Slun-N: Swing Lift Up MechanismDocument1 pageSlun-N: Swing Lift Up MechanismSarinPas encore d'évaluation

- Fastener Design: Bolts and Nuts Bolts NutsDocument13 pagesFastener Design: Bolts and Nuts Bolts NutsAdam PrasetyaPas encore d'évaluation

- Power Generation Corporation 1 Thermal Power Project Management Board 3Document2 pagesPower Generation Corporation 1 Thermal Power Project Management Board 3mameniqPas encore d'évaluation

- Installation Instructions Dresser Wayne Dispenser Sumps - GenericDocument5 pagesInstallation Instructions Dresser Wayne Dispenser Sumps - GenericCamilo CorreaPas encore d'évaluation

- Breathers: Threaded Adapters For Creating Tank BreathersDocument11 pagesBreathers: Threaded Adapters For Creating Tank BreathersAmjedPas encore d'évaluation

- 50 Pies 00065 - BBDocument6 pages50 Pies 00065 - BBbsnegi111Pas encore d'évaluation

- Helical PilesDocument51 pagesHelical Pilesmateus45680% (5)