Académique Documents

Professionnel Documents

Culture Documents

Micropla PDF

Transféré par

Charles JacobTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Micropla PDF

Transféré par

Charles JacobDroits d'auteur :

Formats disponibles

MICROPLASMA ARC WELDING DOES THE UNUSUAL

There has been much written about the advantages and disadvantages of plasma welding.

Plasma Arc Welding (PAW) is usually compared to Gas Tungsten Are Welding (GTAW).

Below are a list of examples why plasma welding works in the real world.

1. Brass Welding and Copper Tin Coated Wire Welding

One advantage of PAW over GTAW is the protected electrode. When welding materials such

as brass or tin coated wires that have a high concentration of zinc, the brass material out gasses

during welding. The out gassing of zinc would contaminate the tungsten electrode during

GTAW welding and drastically shorten the life of tungsten electrode. Shortened electrode life

decreases production time. With PAW, the electrode is protected by a nozzle.Tungsten

electrode life is much longer and production is higher. Plasma welding is used in welding

brass truck radiators and tinned plated electrical connections.

2. Teflon Coated Medical Guide Wire Welding.

Another advantage of PAW over GTAW is pulsing. There are PAW power supplies on the

market that can pulse up to lO,OOOHz. Pulsing when welding teflon coated medical guide wires

can be used to have the arc stay on a high amperage for 10% of the pulse time and 90% on the

low pulse time. The high pulse burns the teflon and cleans the wire and the low pulse does the

welding of the wires. Pulsing in the case of brass welding produces welds that are cleaner and

they have less porosity. Also pulsing stiffens the arc and enhances the column shape of the arc.

3. Thermos Bottles Made of Stainless Steel.

PAW stand off arc distance is not critical like GTAW. The stand off arc distance can vary

from 0.040" to 0.060" and the PAW will still produce good welds. A good example is butt

fusion edge welds of stainless steel. A well known customer that manufacturers stainless steel

thermos bottles was having problems welding the bottles with GTAW because of runout and

mismatch of the parts. See drawing

below.

Stand off arc distance is the distance from the weld nozzle to the work. In GTAW welding the

stand off arc distance must be very consistent. If the distance is not consistent the voltage to

the welding torch changes and there is then a drastic change in heat input to the part (either

higher or lower). PAW is very forgiving of part variation. Also when edges are mismatched

the PAW equipment will still weld. A GTAW arc will want to jump either to one edge or the

other. A PAW arc goes where you aim it. You can also have tooling and chill damping closer

to die weld joint and the PAW arc will go where it is aimed. The GTAW arc will go usually to

the tooling. Another application where PAW is used is the welding of medical guide wires

with a Teflon coating.

4. Welding of Fine Wire Mesh.

Low amperage arc welding and non transferred arc welding PAW can be used to weld very

fine wire mesh used in the fiber and paper industries. An arc can be started at O.O5 amps. In

GTAW welding the arc start, because of a high frequency burst will destroy many small parts.

Also the plasma can be modified to weld using a non transferred arc which is a arc established

inside the plasma torch. This technique is used when an arc of 0.05 amps would be so high it

would destroy the material. Because plasma arc welding does not have the high frequency arc

burst it can be used easily used with robots and automated equipment.

Vous aimerez peut-être aussi

- Plasma Arc Welding (Paw)Document13 pagesPlasma Arc Welding (Paw)Nurul AduraPas encore d'évaluation

- 18 Equipment For Plasma WeldingDocument3 pages18 Equipment For Plasma Weldingprasetyo ilhamPas encore d'évaluation

- On Plasma Arc WeldingDocument13 pagesOn Plasma Arc WeldingDUKEPas encore d'évaluation

- Research Paper On Plasma Arc WeldingDocument4 pagesResearch Paper On Plasma Arc Weldingnydohavihup2100% (1)

- Submerged Arc Welding (Saw)Document26 pagesSubmerged Arc Welding (Saw)Kurt1905Pas encore d'évaluation

- Plasma Arc Welding Process Guide: PAW vs GTAWDocument1 pagePlasma Arc Welding Process Guide: PAW vs GTAWMuhammed RazeemPas encore d'évaluation

- Welding MachineDocument3 pagesWelding MachinetuanPas encore d'évaluation

- Plasma Arc WeldingDocument24 pagesPlasma Arc Weldingroy_subham_subrataPas encore d'évaluation

- Job Knowledge 17Document4 pagesJob Knowledge 17Mehmet SoysalPas encore d'évaluation

- Plasma Arc Welding - Job Knowledge 7Document2 pagesPlasma Arc Welding - Job Knowledge 7tuanPas encore d'évaluation

- CWI Module 3Document2 pagesCWI Module 3Basil M. Ikhleif100% (1)

- Effect of Process Parameters of Micro-Plasma Arc Welding On Morphology and Quality in Stainless Steel Edge Joint WeldsDocument8 pagesEffect of Process Parameters of Micro-Plasma Arc Welding On Morphology and Quality in Stainless Steel Edge Joint WeldsCharles JacobPas encore d'évaluation

- TIG Welding Process GuideDocument29 pagesTIG Welding Process GuidezahidPas encore d'évaluation

- Chapter 1 - ProcessesDocument6 pagesChapter 1 - ProcessesAnonymous dh6DITPas encore d'évaluation

- 12 Tig WeldingDocument8 pages12 Tig WeldingSampath KumarPas encore d'évaluation

- GMAW Welding VariablesDocument16 pagesGMAW Welding VariablesrobinfanshawePas encore d'évaluation

- Micro Plasma Arc WeldingDocument5 pagesMicro Plasma Arc WeldingJigar ChaudharyPas encore d'évaluation

- (PAW) Plasma Arc WeldingDocument11 pages(PAW) Plasma Arc WeldingSyahir ZufayriPas encore d'évaluation

- Presentation FCAWDocument27 pagesPresentation FCAWEvan Jared L. GalvezPas encore d'évaluation

- Welding EngineeringDocument338 pagesWelding EngineeringMuhammed Sulfeek100% (3)

- Tungsten Electrode Selection GuideDocument7 pagesTungsten Electrode Selection Guidemimi_chan_17Pas encore d'évaluation

- Plasma Arc WeldingDocument4 pagesPlasma Arc WeldingMinePas encore d'évaluation

- Plasma Arc Welding and MachiningDocument8 pagesPlasma Arc Welding and MachiningVinayak ShegarPas encore d'évaluation

- TIGBook Chpt4Document12 pagesTIGBook Chpt4luyckxjPas encore d'évaluation

- WELDING QUESTIONS AND ANSWERSDocument6 pagesWELDING QUESTIONS AND ANSWERSengrzia76Pas encore d'évaluation

- Welding Term PaperDocument26 pagesWelding Term PaperBiswajit SenPas encore d'évaluation

- 14250A ch9 PDFDocument147 pages14250A ch9 PDFAyush VermaPas encore d'évaluation

- Gas Tungsten Arc WeldingDocument2 pagesGas Tungsten Arc WeldingVenkatesh NatlaPas encore d'évaluation

- IMOA Shop Sheet 105Document2 pagesIMOA Shop Sheet 105liamcsPas encore d'évaluation

- Flux Cored Arc WeldingDocument5 pagesFlux Cored Arc WeldingPatrick DominguezPas encore d'évaluation

- Welding Processe1Document3 pagesWelding Processe1Balaji SrinivasanPas encore d'évaluation

- Aws Gtaw Study GuideDocument2 pagesAws Gtaw Study GuideTouil HoussemPas encore d'évaluation

- WeldingDocument93 pagesWeldingPradeepPas encore d'évaluation

- Welding ProcessDocument29 pagesWelding ProcessKoon AnuPas encore d'évaluation

- Gmaw PDFDocument34 pagesGmaw PDFGnanasekaran MPas encore d'évaluation

- Best Practices For TIG Welding 1Document6 pagesBest Practices For TIG Welding 1Orlando1949Pas encore d'évaluation

- Set-Up Welding EquipmentsDocument37 pagesSet-Up Welding EquipmentsEvan Jared L. GalvezPas encore d'évaluation

- Gas Tungsten Arc WeldingDocument2 pagesGas Tungsten Arc WeldingSteranskoPas encore d'évaluation

- Sheet Metal Welding-Tips PDFDocument5 pagesSheet Metal Welding-Tips PDFMphilipTPas encore d'évaluation

- Submerged Arc Welding Metal Inert Gas Welding Tungsten Inert Gas Welding Oxy-Acetylene Gas WeldingDocument42 pagesSubmerged Arc Welding Metal Inert Gas Welding Tungsten Inert Gas Welding Oxy-Acetylene Gas WeldingRaj singhPas encore d'évaluation

- Welding ParametersDocument11 pagesWelding Parametershuze_nedian100% (1)

- A Beginner's Guide To TIG WeldingDocument5 pagesA Beginner's Guide To TIG WeldingKalaimugilan ArunPas encore d'évaluation

- Welding NPTEL Lecturers - Part4Document30 pagesWelding NPTEL Lecturers - Part4Sai ChaithanyaPas encore d'évaluation

- TIG Welding GuideDocument39 pagesTIG Welding GuideSaptarshi PalPas encore d'évaluation

- TIG Welding Seminar ReportDocument13 pagesTIG Welding Seminar ReportRahul ShawPas encore d'évaluation

- Aluminium GMAW WeldingDocument34 pagesAluminium GMAW Weldingcentaury2013Pas encore d'évaluation

- WeldingDocument71 pagesWeldingg4gohar100% (2)

- Gas Tungsten Arc WeldingDocument2 pagesGas Tungsten Arc WeldingIGNACIO MADRINAN BORREROPas encore d'évaluation

- GTAW Guide: Gas Tungsten Arc Welding Process OverviewDocument147 pagesGTAW Guide: Gas Tungsten Arc Welding Process Overviewjcarlos7411Pas encore d'évaluation

- Welding MP-IDocument28 pagesWelding MP-IPIYUSH SHARMAPas encore d'évaluation

- PHD Thesis Topics in WeldingDocument5 pagesPHD Thesis Topics in Weldingjennawelchhartford100% (2)

- GTAWDocument61 pagesGTAWIela TeoPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Soldering Electronic Components 2nd EditionD'EverandSoldering Electronic Components 2nd EditionÉvaluation : 3 sur 5 étoiles3/5 (2)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesD'EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesPas encore d'évaluation

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsD'EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- RL 396 17 StateDocument7 pagesRL 396 17 StateCharles JacobPas encore d'évaluation

- 00 ContentsDocument56 pages00 ContentsCharles JacobPas encore d'évaluation

- About The Knowledge TestDocument4 pagesAbout The Knowledge TestCharles JacobPas encore d'évaluation

- Lilawati or A Treatise On ArithmeticDocument233 pagesLilawati or A Treatise On Arithmeticsatish kumarPas encore d'évaluation

- Hare-Clarke Controversy Over Invention of Improved Gas BlowpipeDocument6 pagesHare-Clarke Controversy Over Invention of Improved Gas BlowpipeCharles JacobPas encore d'évaluation

- Weldingguide ENGDocument518 pagesWeldingguide ENGBoris Kozjan0% (1)

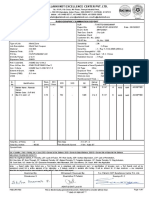

- Pallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportDocument1 pagePallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportCharles JacobPas encore d'évaluation

- !indx PipDocument18 pages!indx PipCharles JacobPas encore d'évaluation

- THE ALL-NEW XL666 BrochureDocument15 pagesTHE ALL-NEW XL666 BrochureCharles JacobPas encore d'évaluation

- Henri Sainte-Claire DevilleDocument8 pagesHenri Sainte-Claire DevilleCharles JacobPas encore d'évaluation

- Use of N2 Gas For Purging in GTAW of SSDocument4 pagesUse of N2 Gas For Purging in GTAW of SSrondulf goPas encore d'évaluation

- ED57 Big Blue 400 Pro EnglsihDocument8 pagesED57 Big Blue 400 Pro EnglsihCharles JacobPas encore d'évaluation

- 2020 Price List: Certification ProgramsDocument2 pages2020 Price List: Certification ProgramsCharles JacobPas encore d'évaluation

- Pipe FitterDocument4 pagesPipe FitterVasanth SubbiahPas encore d'évaluation

- Minimum Requirements For The Education, Examination and QualificationDocument34 pagesMinimum Requirements For The Education, Examination and QualificationАнтон ХруцкийPas encore d'évaluation

- Web Work PDFDocument39 pagesWeb Work PDFCharles JacobPas encore d'évaluation

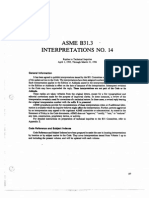

- ASME B31.3 Interpretations No. 14: General Information BeenDocument10 pagesASME B31.3 Interpretations No. 14: General Information Beenchuck_sbPas encore d'évaluation

- Team-BHP PDI Checklist PDFDocument3 pagesTeam-BHP PDI Checklist PDFCharles JacobPas encore d'évaluation

- Question Paper and Answer Key: Mathematics (MA)Document25 pagesQuestion Paper and Answer Key: Mathematics (MA)Charles JacobPas encore d'évaluation

- Quantitative AptitudeDocument2 pagesQuantitative AptitudeSivakumar MPas encore d'évaluation

- Indian Railway Catering and Tourism Corportion Limited Retiring Room VOUCHER (IRCTCDocument2 pagesIndian Railway Catering and Tourism Corportion Limited Retiring Room VOUCHER (IRCTCCharles JacobPas encore d'évaluation

- Metallurgical Engineering SyllabusDocument2 pagesMetallurgical Engineering Syllabusrahul44311gmailcomPas encore d'évaluation

- Code of ConductDocument1 pageCode of Conductangeloflight179Pas encore d'évaluation

- Indian Railway Catering and Tourism Corportion Limited Retiring Room VOUCHER (IRCTCDocument2 pagesIndian Railway Catering and Tourism Corportion Limited Retiring Room VOUCHER (IRCTCCharles JacobPas encore d'évaluation

- ExhibitorList 2018Document68 pagesExhibitorList 2018Charles JacobPas encore d'évaluation

- EnveloperyDocument11 pagesEnveloperyCharles JacobPas encore d'évaluation

- Excon 2019 - Visitor RegistrationDocument2 pagesExcon 2019 - Visitor RegistrationCharles JacobPas encore d'évaluation

- 820 PDFDocument19 pages820 PDFCharles JacobPas encore d'évaluation

- Wit T 2008PVDocument6 pagesWit T 2008PVCharles JacobPas encore d'évaluation

- ISO Welder Qualification ExaminersDocument5 pagesISO Welder Qualification ExaminerskaelcorbettPas encore d'évaluation

- Jig and Fixture Design Manual - Erik K. Hendriksen - 3709Document2 243 pagesJig and Fixture Design Manual - Erik K. Hendriksen - 3709Jason Rogers86% (14)

- Drywall Manual 2017 - FinishingDocument15 pagesDrywall Manual 2017 - Finishingomar100% (1)

- Casting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006Document56 pagesCasting Processes: ME 4210: Manufacturing Processes and Engineering Prof. J.S. Colton © GIT 2006anand_lmlPas encore d'évaluation

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFDocument2 pagesISO 1302 DIN 4768 Comparison of Surface Roughness Values Stainless Steel T PDFWega Wahyu100% (2)

- Joint Efficiency TutorialDocument47 pagesJoint Efficiency TutorialJignesh ShahPas encore d'évaluation

- Division 05 - Metals: Structural SpecificationDocument19 pagesDivision 05 - Metals: Structural SpecificationFranklyn GenovePas encore d'évaluation

- 11kv and LV Pin InsulatorsDocument1 page11kv and LV Pin InsulatorsMosa Elnaid ElnaidPas encore d'évaluation

- 1-Architect Material AnalysisDocument25 pages1-Architect Material Analysisk.o.m channel (kmeng)Pas encore d'évaluation

- Normazione: Aluminium - and Zinc-Lamellar Base Anti-Corrosion Coating For Ferrous Material PartsDocument15 pagesNormazione: Aluminium - and Zinc-Lamellar Base Anti-Corrosion Coating For Ferrous Material Partserkin gulerPas encore d'évaluation

- JJ104 Workshop Technology Chapter8 Oxy-Acetylene Welding 1Document24 pagesJJ104 Workshop Technology Chapter8 Oxy-Acetylene Welding 1Ah Tiang100% (3)

- Low Temperature Corossion (Molten Salt Corossion) in Black Liquor Recovery BoilersDocument108 pagesLow Temperature Corossion (Molten Salt Corossion) in Black Liquor Recovery BoilersSIL PROJECTSPas encore d'évaluation

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamPas encore d'évaluation

- Steel Suppliers in Doha - Qatar Business and Directory Listings PDFDocument3 pagesSteel Suppliers in Doha - Qatar Business and Directory Listings PDFuzairmetallurgistPas encore d'évaluation

- 5.4 ESW and EGW Processes: AWS D1.1/D1.1M:2015 Clause 5. FabricationDocument1 page5.4 ESW and EGW Processes: AWS D1.1/D1.1M:2015 Clause 5. FabricationRohit KamblePas encore d'évaluation

- Ebook Design Guidlines For Injection MoldingDocument20 pagesEbook Design Guidlines For Injection MoldingAnonymous tQhtrPbPas encore d'évaluation

- Bob Hunt Sheeting WingDocument36 pagesBob Hunt Sheeting WingHeman Lee100% (2)

- Ws MetalworkDocument4 pagesWs MetalworkNicolae James Patre SanchezPas encore d'évaluation

- MS HSD Bs-Vi SpecsDocument3 pagesMS HSD Bs-Vi SpecsKusunuru SandeepPas encore d'évaluation

- PDF Chapter 1 MEC 218 Welding Overview Student ResourceDocument9 pagesPDF Chapter 1 MEC 218 Welding Overview Student ResourceShamsudeen Abubakar SodangiPas encore d'évaluation

- Classification of CokeDocument2 pagesClassification of CokeSUKANTA DALAIPas encore d'évaluation

- MT Form Asme PDFDocument1 pageMT Form Asme PDFTrung Tinh HoPas encore d'évaluation

- Casting DefectDocument25 pagesCasting Defectravikataria02Pas encore d'évaluation

- Primacore MW 71Document2 pagesPrimacore MW 71rjan7pePas encore d'évaluation

- Company Reference List - 2013 PDFDocument13 pagesCompany Reference List - 2013 PDFMuhamad FajriPas encore d'évaluation

- SG1400M BrochureDocument2 pagesSG1400M BrochureValentina VelascoPas encore d'évaluation

- CIRCULAR CLARIFIERDocument3 pagesCIRCULAR CLARIFIERChristine FernandezPas encore d'évaluation

- Form Qw-482 Format For Welding Procedure Specification (WPS) (See QW-200,1, Section Ix, ASME Boiler and Pressure Vessel Code)Document4 pagesForm Qw-482 Format For Welding Procedure Specification (WPS) (See QW-200,1, Section Ix, ASME Boiler and Pressure Vessel Code)Rajkumar ArikumarPas encore d'évaluation

- Imidazoles: Contact UsDocument2 pagesImidazoles: Contact Usian lesterPas encore d'évaluation

- SP7021M00U18 000 A PDFDocument3 pagesSP7021M00U18 000 A PDFPedro Casimiro GámizPas encore d'évaluation

- 6328 Stoody Hardbanding Manual 62-1216Document12 pages6328 Stoody Hardbanding Manual 62-1216Cesar ObesoPas encore d'évaluation