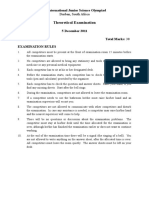

Académique Documents

Professionnel Documents

Culture Documents

Reflux in A Gas Dehydration Plant

Transféré par

ghasem_726990287Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Reflux in A Gas Dehydration Plant

Transféré par

ghasem_726990287Droits d'auteur :

Formats disponibles

Reflux in a gas dehydration plant

Gas dehydration by adsorbent processes may lead to the damaging

regeneration reflux phenomenon during adsorbent regeneration

SAJAD MIRIAN and HOSSEIN ANISI Nitel Pars Co (Fateh Group)

XIANG YU Hengye Chemical Co

SEPEHR SADIGHI Research Institute of Petroleum Industry

D

ehydration of natural gas adsorbent is repeatedly used in used are reduced. Therefore, the

entails the removal of cycles by carrying out these total cycle time is usually

water that is associated two steps. When a regeneration designed such that at the end of

with natural gases in vapour step is carried out through the adsorption a short time is

form. The natural gas industry reduction of the total pressure, available for appropriate regen-

has recognised that dehydra- the process is called pressure eration of the adsorbent. Hence,

tion is necessary to ensure swing adsorption (PSA). the inlet section of the adsorp-

smooth operation of gas trans- Temperature swing adsorption tion bed is faced immediately

mission lines. This (TSA) is another technique with a high temperature from

pretreatment prevents the used for regenerating a bed of the start of the regeneration

formation of gas hydrates and adsorbent that is loaded with without any heating ramp.

reduces corrosion. The three the targeted impurity gas. This Heating up the adsorber with-

major methods of dehydration technology began commercially out using a heating ramp causes

are direct cooling, adsorption in the 1960s and continues a strong temperature difference

and absorption. Adsorption- today for drying continuous air in the bed. So, at the bottom,

based processes for separation and natural gas as well as the molecular sieve is very hot

of multi-component gaseous other purification applications and desorbs the adsorbed water

mixtures are becoming increas- such as carbon dioxide strip- while the top layers are still at

ingly popular. The new ping from air. TSA exploits the adsorption (low) temperature.

generation of synthetic and capacity of certain adsorbent Therefore, water desorbed in

more selective adsorbents materials, such as activated the bottom layer condenses in

developed in recent years has alumina, silica gel and zeolites, the top layer. This phenomenon

enabled adsorption-based tech- to adsorb gases at moderate is called refluxing or retro-con-

nology to compete successfully temperatures (40C, 100F) and densation. A schematic diagram

with traditional gas separation later release them when the of an adsorber with regenera-

techniques. temperature rises above 120C tion refluxing is shown in Figure

Any adsorption-based sepa- (250F). 1. To prevent this catastrophic

ration process requires two Natural gas treating units phenomenon, a good molecular

essential steps: adsorption using molecular sieves and TSA sieve formulation (binder and

during which one or more technology are usually opti- zeolite) or improvement in the

components are preferentially mised by manipulating both the regeneration condition is inevi-

adsorbed/separated; and adsorption and the regeneration tably required.

regeneration during which time. By reducing the adsorp- In this article, modelling of

these components are removed tion time, both the vessel size the regeneration reflux

from the adsorbent bed. The and the amount of adsorbent phenomenon during regenera-

www.digitalrefining.com/article/1001030 PTQ Q4 2014 1

tion is performed and the tion mode for removing the

effects of it on the adsorption residual water. At once, that

process are reviewed. bed which has completed the

Recommendations to prevent regeneration step is replaced.

this phenomenon in a commer- During the regeneration

cial scale dehydration unit (as process, a regenerative gas

a case study) are presented. Solid caked layer stream is passed through a

of adsorbent and

salt fused together heater where it is heated to

Process description approximately 270C. This hot

The purpose of a natural gas Effective gas passes upwards through

bed diameter

dehydration package is to the offline saturated dryer

reduce the water content of the Original heating the molecular sieves.

natural gas to avoid freezing bed diameter As the sieves are heated up,

and hydrate formation in the adsorbed water begins to

pipeline. In order to utilise desorb and is carried away by

natural gas for urban consump- the hot gas. The operating

tion, the water dew point conditions of the target adsorp-

should be reduced to below tion and regeneration processes

-10C, accomplished by using a and specifications of their feeds

molecular sieve adsorption unit Figure 1 Schematic of a bed faced are shown in Table 1 and Table

which adsorbs water from the with regeneration reflux 2, respectively.

inlet gas.

To perform such a process, are in adsorption and one in Mathematical modelling

water saturated natural gas regeneration. The feed stream of regeneration

from the upstream unit is sent is split into three identical A computational fluid dynamic

to the molecular sieve dehydra- streams, each of which passes modelling technique was used

tion plant where the gas stream downward through one of the to model the momentum, heat

passes through a separator to beds that are in adsorption content and mass transfer of

retain any free water carry- mode (see Figure 2). fluid through porous media,

over from the upstream Dry gas streams leaving the and also to investigate the

facilities. It is then routed to adsorption beds are joined and refluxing phenomenon in the

the molecular sieve dryers. A passed through a filter to retain regeneration process studied.

dehydration package consists any solid particles coming from To solve these set of equations,

of four dryers loaded with a the dryers. Finally, dry and commercial software (Comsol

special type of molecular sieve filtered gas is sent to the Multiphysics Ver. 4.2) was

4A; at any time three dryers municipal gas station via a

transmission pipeline. Feed and regeneration gas

Each adsorption cycle takes compositions

Adsorption Regeneration

mode mode

eight hours. After that, the

dryer is switched to regenera- Components Adsorption Regeneration

Methane, wt% 72.95 73.1

Ethane, wt% 8.13 8.14

Adsorption and regeneration Propane, wt% 4.1 4.11

operating conditions i-Butane, wt% 1.22 1.22

n-Butane, wt% 1.56 1.56

i-Pentane, wt% 0.00 0.00

n-Pentane, wt% 0.140 0.141

Specifications Value

n-Hexane, wt% 1.73 1.73

Adsorption temperature, C 47

n-Heptane, wt% 0.1897 0.19

Adsorption pressure, kPa 9101

n-Octane, wt% 0.1622 0.1625

Adsorption mass flow, kg/h 2.409e+05

n-Nonane, wt% 0.0337 0.0338

Regeneration temperature, C 270

CO2, wt% 3.79 3.8

Regeneration pressure, kPa 7929

Nitrogen, wt% 4.57 4.58

Regeneration mass flow, kg/h 4.751e+04

H2O, wt% 0.1573 0.000

Figure 2 Schematic diagram of the

dehydration unit studied Table 1 Table 2

2 PTQ Q4 2014 www.digitalrefining.com/article/1001030

employed that utilises the finite

element method to discretise

6500

partial differential equations to Temperature, K

6000 543.15

ordinary differential equations

5500

and finally solve them. The 5000

following assumptions are 4500 500

considered during the mathe- 4000

Regeneration reflux

zone

matical procedure: 3500 450

To reduce computation time, 3000

2D axisymmetric mode is 2500

assumed 2000 400

The gaseous phase is an ideal 1500

Desorption

gas 1000 zone 350

Entrance and exit effects are 500 Starts at 120C-140C

negligible 0 320.14

There is no slip condition 4000 3000 2000 1000 0 1000 2000

near the dryer wall.

Figure 3 Temperature distribution during the regeneration process

Governing equations

Mathematical modelling of the the dynamic viscosity of the Results and discussions

target regeneration process is fluid; (m2) is the permeability Figure 3 shows the temperature

obtained by coupling a set of tensor of the porous medium; distribution of the adsorption

general equations (including F (kg/m4) is Forchheimer bed at an early stage in the

continuity, momentum, energy drag option; F (kg/m2s2) is the regeneration process. As is

and mass balances), and influence of gravity and other apparent in this figure, a high

particular equations such as volume forces; (Cp)eq is the regeneration gas temperature

physical properties, adsorption equivalent volumetric heat (without enough ramp-up)

and desorption isotherms and capacity at constant pressure; T leads to a large temperature

equation of state as follows: (K) is the bed temperature; Cp gradient along the bed, and

is the fluid heat capacity at creates reflux at the early

Continuity equation: constant pressure; keq is the stages of the regeneration

equivalent thermal conductiv- cycle.

+ ( u ) = Qbr

t ity (a scalar or a tensor if the At these operating conditions,

Momentum equation: thermal conductivity is aniso- due to the high pressure of the

regeneration gas, high moisture

u u 2

( + (u ) ) = [ PI + (u + (u)T ) ( u) I ] ( + f u + Qbr )u + F concentration and a large

p t p p 3 p kbr

temperature gradient are inevi-

Energy equation: tropic); Q is the heat source (or table. For the design case, the

T sink); c is the concentration of licensor charged a molecular

( C p ) eq + C p u T = (keq T ) + Q

t the species (mol/m3); D is the sieve with enough strength

diffusion coefficient (m2/s), against reflux which could work

Mass equation: and R is the reaction rate more than four years without

ci expression for the species any malfunction. But for the

+ .( Di ci ) + u ci = Ri

t (mol/m3s). Furthermore, the next loading, a regular molecu-

major particular equations are lar sieve, manufactured by

In these equations, (kg/m3) the Langmuir adsorption another company, could not

is the density of the fluid; t (s) isotherm and ideal gas law. withstand those conditions. It

is the time; u (m/s) is the The proposed equations in 2D was observed that, only three

velocity vector; Qbr (kg/m3s) is axisymmetric mode have been months from the start of run,

the mass source or mass sink; solved using the required the loaded molecular sieve was

p is the porosity of bed; P (Pa) initial and boundary ruined due to the reflux

is the pressure; (kg/ms) is conditions. phenomenon. It also increased

www.digitalrefining.com/article/1001030 PTQ Q4 2014 3

phenomenon with the follow-

Recommendations and consequences to prevent reflux phenomena

ing malfunctions:

High pressure regeneration

Recommendation Consequence gas

1 Decreasing the regeneration gas pressure Needs compressor

Higher operating cost High moisture concentrations

2 Regeneration gas temperature ramp-up Hot oil system modification (if applicable) Large temperature gradients

Higher regeneration cycle time High degree of solubility of

Adsorption cycle time limitation

3 Layer of activated alumina at the top of the bed This approach may minimise the rolling boil binder materials in water

but cannot fix the problem. Based on Figure 3, Choosing an inappropriate

the reflux happens through the bed because of

a high temperature gradient, so it can only flow direction in adsorption

reduce the reflux. We can consider it and regeneration.

a modification.

4 Change the heating gas flow direction from the This is costly. Co-current regeneration

top to the bottom of the bed requires more gas for stripping the Recommendations and

bed completely. consequences

The downward flow pushes heavy liquid

contaminants, and possibly increases fouling The recommendations proposed

rate. in Table 3 can decrease the

5 Try to reduce the heat loss through the top of This can only reduce temperature gradient

the bed by adding extra insulation and even between the top and bottom of the vessel.

reflux phenomena which are

installing a steam tracer reviewed in brief for the target

6 Reverse all flows Bed fluidisation (lifting) gas dehydration unit.

7 Using a special molecular sieve The bed can possibly operate without any

problem. According to recommenda-

tion 7 in Table 3, a special

Table 3 molecular sieve 4A (with high

resistance against reflux

the pressure drop of the dryers. remaining pellets or beads phenomena), manufactured by

Therefore, it can be concluded together to form a solid mass. Shanghai Hengye Chemical

that the molecular sieve, espe- This solid mass, formed in an Co., was loaded into the target

cially the binder and additives, annulus shape with a centre dryers about one year ago. To

should be made of appropriate opening of less than one foot, date, the dehydration unit has

raw materials to be capable of did not allow gas to pass shown a good performance

resisting the reflux phenomenon through, and consequently and no malfunction has been

and preventing operational reduced the effective diameter observed.

malfunctions. of the bed (see Figure 1).

As Figure 3 shows, for our Therefore, boiling water Acknowledgment

case study liquid water moved destroyed the molecular sieve We would like to express our great

downward until it encountered such that the severity of the appreciation to Mr F Noorbakhsh and

Mr M A Fatemi for their valuable and

the heating zone. At this point, operating conditions should be

constructive suggestions during the

boiling water created a reflux greatly reduced to extend the

planning and development of this

which ground the molecular replacement period of the research work. We would also like to

sieve into a powder. Since adsorbent. The regeneration thank Nitel Pars Company, a subsidiary of

certain components of the reflux showed some undesira- Fateh Group, for technical assistance and

binder were somewhat soluble ble effects on the adsorption financial support.

in boiling water, the molecular process which can be summa-

sieve subsequently became a rised as follows: Further reading

wet cake (mud) which was then Molecular sieve particle 1 Agarwal A, Advanced Strategies

baked by the rising hot gas. break-up for Optimal Design and Operation of

These soluble components Increasing pressure drop Pressure Swing Adsorption Processes,

Ph.D. Thesis, Carnegie Mellon University,

could ion exchange with the Gas channelling

2010.

zeolite and/or combine with Premature water breakthrough

2 Serbezov A, Sotirchos S V, Particle-bed

anions in water to form solid which all lead to poor adsorber model for multi-component adsorption-

salts (Na2CO3, CaCO3, MgCO3, performance. based separations: application to pressure

NaNO3, and so on). These solid As a consequence, these swing adsorption, Chemical Engineering

salts could then paste the effects increased the reflux Science, 54, 1999, 5647-5666.

4 PTQ Q4 2014 www.digitalrefining.com/article/1001030

3 Dabrowski A, Adsorption from theory Modeling of Transport Phenomena in Sepehr Sadighi is Assistant Professor

to practice, Advances in Colloid and Porous Media, Kluwer Academic Publisher, with the Catalysis Research Division of

Interface Science, 93, 2001, 135-224. 1990. Research Institute of Petroleum Industry

4 Meyer P B Chr, Hydrothermal (RIPI), Tehran, Iran. He holds a PhD in

damaging of molecular sieve and how Sajad Mirian is a Project Manager in the chemical engineering.

to prevent it, paper presented at the Gas Adsorbents Department of Nitel Pars Co., Email: Sadighis @ripi.ir

Processors Association Europe, Feb 2003, Tehran, Iran. He holds a MSc in chemical

Paris. engineering.

5 T W J Crittenden B, Adsorption Email: ms002@nitelpars.com.

Technology & Design, Heinemann Hossein Anisi is an Adsorbent Expert

Publication, 1998. in the Adsorbents Department of Nitel

6 Nield D, Bejan A, Convection in Porous Pars Co. He holds a BSc in chemical Links

Media, 3rd ed., Springer, 2006. engineering.

7 Le Bars M, Worster M G, Interfacial Email: ms003@nitelpars.com More articles from the following

conditions between a pure fluid and a categories:

porous medium: implications for binary Xiang Yu is an Application Engineer of Corrosion/Fouling Control

alloy solidification, J. of Fluid Mechanics, Hengye Chemical Co., Shanghai, China. Gas Processing/Treatment

550, 2006, 149-173. He holds a BSc in chemical engineering. Mass Transfer & Separation

8 Bear J, Bachmat Y, Introduction to Email: hyms@foxmail.com

www.digitalrefining.com/article/1001030 PTQ Q4 2014 5

Vous aimerez peut-être aussi

- Detailed Engineering Design PhaseDocument8 pagesDetailed Engineering Design Phaserenjithv_494% (18)

- 2018CTSS PackagerGuideDocument4 pages2018CTSS PackagerGuideMadhana GopalPas encore d'évaluation

- Vestamid L Polyamide 12 - EvonikDocument12 pagesVestamid L Polyamide 12 - EvonikHaryo Armono100% (1)

- Drying of AirDocument5 pagesDrying of AirHalima LAARARIPas encore d'évaluation

- Role of DSS in RefineryDocument24 pagesRole of DSS in Refineryramadoss_alwar7307100% (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingD'EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingÉvaluation : 5 sur 5 étoiles5/5 (3)

- Process Design Manual LurgiDocument25 pagesProcess Design Manual LurgiMarcelo Peretti91% (11)

- Front End Engineering Design (FEED) ScheduleDocument1 pageFront End Engineering Design (FEED) ScheduleVinh Do Thanh100% (1)

- Banana Peel Shoe PolishDocument11 pagesBanana Peel Shoe PolishGMae Lim100% (4)

- Adsorption 2Document76 pagesAdsorption 2Shangeetha Tangaraj0% (1)

- Achieving Zero Liquid Discharge in SAGD Heavy Oil RecoveryDocument6 pagesAchieving Zero Liquid Discharge in SAGD Heavy Oil RecoveryLuqmanPas encore d'évaluation

- RadioisotopesDocument28 pagesRadioisotopessivagurunathan.P100% (3)

- Natural Gas Dehydration by Molecular SievesDocument16 pagesNatural Gas Dehydration by Molecular SievesSneha PatelPas encore d'évaluation

- Process Insight:: Selecting The Best Solvent For Gas TreatingDocument1 pageProcess Insight:: Selecting The Best Solvent For Gas Treatingghasem_726990287100% (1)

- MdeaDocument2 pagesMdeaVera MarsellaPas encore d'évaluation

- MdeaDocument2 pagesMdeaVera MarsellaPas encore d'évaluation

- 20080639Document9 pages20080639ghasem_726990287Pas encore d'évaluation

- Practical Considerations For The Design of Adsorbent BedsDocument10 pagesPractical Considerations For The Design of Adsorbent BedsMariam AsgharPas encore d'évaluation

- (VESBO) Catalog en 100317Document55 pages(VESBO) Catalog en 100317AnhNguyen100% (1)

- 6 Microbial ControlDocument36 pages6 Microbial ControlGladish RindraPas encore d'évaluation

- Chloroplast, PPTDocument21 pagesChloroplast, PPTSuchitra Sk88% (8)

- UOP Integration of Membranes For CO2 Removal Tech Paper PDFDocument15 pagesUOP Integration of Membranes For CO2 Removal Tech Paper PDFghasem_726990287Pas encore d'évaluation

- Cost Effective Integrated Gas Plant Design Sulfinol MDocument2 pagesCost Effective Integrated Gas Plant Design Sulfinol Mamirho3ein100% (1)

- Cryomax Jan2016Document8 pagesCryomax Jan2016arielPas encore d'évaluation

- Reverse Osmosis Treatment of Drinking WaterD'EverandReverse Osmosis Treatment of Drinking WaterÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Spectroscopy Primer AnswersDocument13 pagesSpectroscopy Primer AnswersjayshreePas encore d'évaluation

- AMMONIA Syn Gas Drying With Z4-01Document4 pagesAMMONIA Syn Gas Drying With Z4-01raghu4594Pas encore d'évaluation

- Recycle PTQDocument6 pagesRecycle PTQremsorPas encore d'évaluation

- Gas Drying EquipmentDocument6 pagesGas Drying EquipmentJustin Paul CongePas encore d'évaluation

- The Sorbead Quick Cycle Process - LRGCC 2007Document13 pagesThe Sorbead Quick Cycle Process - LRGCC 2007aavianiacPas encore d'évaluation

- Chapter 4 Solid BedDocument25 pagesChapter 4 Solid BedTaha Azab MouridPas encore d'évaluation

- Heat transfer analysis of silica-gel-water adsorption refrigeration systemDocument5 pagesHeat transfer analysis of silica-gel-water adsorption refrigeration systememre_bozkurtPas encore d'évaluation

- Chapter 4 Solid BedDocument27 pagesChapter 4 Solid BedTaha Azab MouridPas encore d'évaluation

- Ion Exchange: Application of Ion Exchanger Water SofteningDocument7 pagesIon Exchange: Application of Ion Exchanger Water SofteningListo A4Pas encore d'évaluation

- Iptc 11497 MS PDocument4 pagesIptc 11497 MS PRalf JonesPas encore d'évaluation

- Modeling and Simulation of Six-Bed Cyclic Adsorption Process Using in Mercaptan Removal From Natural Gas: Non-Isothermal and Non-Adiabatic ConditionsDocument12 pagesModeling and Simulation of Six-Bed Cyclic Adsorption Process Using in Mercaptan Removal From Natural Gas: Non-Isothermal and Non-Adiabatic ConditionsHassane AmadouPas encore d'évaluation

- Natural Gas DehydrationDocument12 pagesNatural Gas DehydrationSagar DadhichPas encore d'évaluation

- Dsorption Efrigeration: Ahmed Rezk, Ahmed Elsayed, Saad Mahmoud, and Raya AL-DadahDocument59 pagesDsorption Efrigeration: Ahmed Rezk, Ahmed Elsayed, Saad Mahmoud, and Raya AL-DadahTechnoKittyKittyPas encore d'évaluation

- Solid Desiccant DehydrationDocument5 pagesSolid Desiccant Dehydrationca_minoPas encore d'évaluation

- Mto 2 Ala FinalDocument27 pagesMto 2 Ala FinalAxit PatelPas encore d'évaluation

- Mto 2 Ala FinalDocument27 pagesMto 2 Ala FinalAxit PatelPas encore d'évaluation

- Condensate Recovery by Reverse OsmosisDocument8 pagesCondensate Recovery by Reverse OsmosisIsbel CedilloPas encore d'évaluation

- Research Article: Design of Batch Distillation Columns Using Short-Cut Method at Constant RefluxDocument15 pagesResearch Article: Design of Batch Distillation Columns Using Short-Cut Method at Constant RefluxSanthosh RockPas encore d'évaluation

- Chemical Cleaning and FoulingDocument4 pagesChemical Cleaning and FoulingoswaldoPas encore d'évaluation

- KC30 4 0937Document12 pagesKC30 4 0937kingking21177Pas encore d'évaluation

- Reactors1 31Document2 pagesReactors1 31Mourad kharbachPas encore d'évaluation

- Chapter 1 Introduction: 1.1 Stripping MethodDocument5 pagesChapter 1 Introduction: 1.1 Stripping MethodBishal LamichhanePas encore d'évaluation

- ProductionDocument35 pagesProductionVageeshPas encore d'évaluation

- 1996 CASALE HEtraysDocument10 pages1996 CASALE HEtraysFatima KazmiPas encore d'évaluation

- Adsorption Isotherms of Terpene Mixtures in Supercritical Carbon DioxideDocument15 pagesAdsorption Isotherms of Terpene Mixtures in Supercritical Carbon DioxideJosé Manuel PeñaPas encore d'évaluation

- NR 2013032814130358Document7 pagesNR 2013032814130358Venkatesh RYPas encore d'évaluation

- Anaerobic Processes: Rate Systems. Thus One Can Have A Low-Rate, Suspended-Growth Anaerobic System WhichDocument6 pagesAnaerobic Processes: Rate Systems. Thus One Can Have A Low-Rate, Suspended-Growth Anaerobic System Whichnickao123Pas encore d'évaluation

- Textile Effluent TreatmentDocument16 pagesTextile Effluent TreatmentnesamaniconstructionsPas encore d'évaluation

- Chapter 2Document71 pagesChapter 2Zemariyam BizuayehuPas encore d'évaluation

- The Art of Countercurrent RegenerationDocument5 pagesThe Art of Countercurrent RegenerationtoroheraPas encore d'évaluation

- Natural Gas ProcessingDocument24 pagesNatural Gas ProcessingMuhammad Shariq KhanPas encore d'évaluation

- R. Albion, S. - World&apos S First SAGD Facility Using Evaporators, Drum Boilers, and ZDocument7 pagesR. Albion, S. - World&apos S First SAGD Facility Using Evaporators, Drum Boilers, and ZLuqmanPas encore d'évaluation

- Alpha 5Document1 pageAlpha 5irenellemedallaPas encore d'évaluation

- Recrystallization Process Upgrades Rock and Solar SaltsDocument17 pagesRecrystallization Process Upgrades Rock and Solar SaltsVirgil CenariuPas encore d'évaluation

- UOP NGL Recovery Treater Optimization For Water Mercaptan Removal Case StudyDocument11 pagesUOP NGL Recovery Treater Optimization For Water Mercaptan Removal Case Studyeko handoyoPas encore d'évaluation

- 200810PSD CeuDocument13 pages200810PSD Ceuedward sabedraPas encore d'évaluation

- Lin 2001Document8 pagesLin 2001Navid AhadiPas encore d'évaluation

- Spe 71460 MS PDFDocument11 pagesSpe 71460 MS PDFLeonela PantojaPas encore d'évaluation

- Siemens Zimpro - Wet Air OxidationDocument8 pagesSiemens Zimpro - Wet Air OxidationGorden DryginPas encore d'évaluation

- Solar/waste Heat Driven Two-Stage Adsorption Chiller: The PrototypeDocument9 pagesSolar/waste Heat Driven Two-Stage Adsorption Chiller: The PrototypeDeyvisPas encore d'évaluation

- 1 s2.0 S2214157X1630185X MainDocument10 pages1 s2.0 S2214157X1630185X MaindandiPas encore d'évaluation

- Experimental Evaluation of A Solid Desiccant System Integrated With Cross Flow Maisotsenko Cycle Evaporative CoolerDocument12 pagesExperimental Evaluation of A Solid Desiccant System Integrated With Cross Flow Maisotsenko Cycle Evaporative CoolerkashifPas encore d'évaluation

- Energy Saving by Purge Gas Recovery UnitDocument20 pagesEnergy Saving by Purge Gas Recovery UnitFerdian AziziPas encore d'évaluation

- Toe To Heal Air Injection - THAIDocument5 pagesToe To Heal Air Injection - THAIAnthon100% (2)

- Processes For Degassing R4i1 enDocument4 pagesProcesses For Degassing R4i1 enwongpengchiong7205Pas encore d'évaluation

- NFL PPTDocument46 pagesNFL PPTvipin6kumar-718654Pas encore d'évaluation

- Comparative Process Study of Biomass Gas PDFDocument6 pagesComparative Process Study of Biomass Gas PDFhmpackingPas encore d'évaluation

- J Apenergy 2016 07 037Document11 pagesJ Apenergy 2016 07 037MichelPas encore d'évaluation

- Separation and Purification Technology: Omid Taheri Qazvini, Shohreh FatemiDocument16 pagesSeparation and Purification Technology: Omid Taheri Qazvini, Shohreh FatemidoufethiPas encore d'évaluation

- Strategies for improving gas treatment with regenerable adsorbentsDocument8 pagesStrategies for improving gas treatment with regenerable adsorbentsamitPas encore d'évaluation

- Desiccants PDFDocument9 pagesDesiccants PDFjesus_manrique2753Pas encore d'évaluation

- Pam and TMDDocument13 pagesPam and TMDPoojit PopliPas encore d'évaluation

- SVUSRC - Volume 3 - Issue 1 - Pages 49-63Document15 pagesSVUSRC - Volume 3 - Issue 1 - Pages 49-63omarrgb97Pas encore d'évaluation

- Scientific American Supplement, No. 446, July 19, 1884D'EverandScientific American Supplement, No. 446, July 19, 1884Pas encore d'évaluation

- Intermediate Pressure: 8 - Temperature Total Compressor PowerDocument1 pageIntermediate Pressure: 8 - Temperature Total Compressor Powerghasem_726990287Pas encore d'évaluation

- Chemicals Ethylene OxideDocument2 pagesChemicals Ethylene OxideEliana TorresPas encore d'évaluation

- Claus Sulphur Recovery OptionsDocument6 pagesClaus Sulphur Recovery Optionsghasem_726990287Pas encore d'évaluation

- Coke FormationDocument10 pagesCoke Formationghasem_726990287Pas encore d'évaluation

- Improve Steam Turbine EfficiencyDocument10 pagesImprove Steam Turbine EfficiencyAmar SolankiPas encore d'évaluation

- 2008 3 12 Faessler eDocument4 pages2008 3 12 Faessler eSayyidah TanjungPas encore d'évaluation

- Compare The Different Options For NGL Recovery From Natural GASDocument21 pagesCompare The Different Options For NGL Recovery From Natural GASRashveenaPas encore d'évaluation

- Mitigating Coke Formation Hydrocarbon Engineering July2014 PDFDocument3 pagesMitigating Coke Formation Hydrocarbon Engineering July2014 PDFghasem_726990287Pas encore d'évaluation

- Choosing A Selective Hydrogenation SystemDocument9 pagesChoosing A Selective Hydrogenation Systemghasem_726990287Pas encore d'évaluation

- Kish Gas Field: General SpecificationsDocument1 pageKish Gas Field: General Specificationsghasem_726990287Pas encore d'évaluation

- 173772738Document2 pages173772738ghasem_726990287Pas encore d'évaluation

- Choose The Right Cooling Tower Chemicals - Power EngineeringDocument11 pagesChoose The Right Cooling Tower Chemicals - Power Engineeringghasem_726990287Pas encore d'évaluation

- 173772738Document2 pages173772738ghasem_726990287Pas encore d'évaluation

- Flare Safe PDFDocument19 pagesFlare Safe PDFghasem_7269902870% (1)

- US8282709B2Document24 pagesUS8282709B2ghasem_726990287Pas encore d'évaluation

- Power Engineering Jul 1998 102, 7 Proquest CentralDocument5 pagesPower Engineering Jul 1998 102, 7 Proquest Centralghasem_726990287Pas encore d'évaluation

- Contactor Vol - 10 No - 7 (Sensible Temperature Profiles)Document2 pagesContactor Vol - 10 No - 7 (Sensible Temperature Profiles)ghasem_726990287Pas encore d'évaluation

- Attachment No.2 CECA Technical Proposal Unit 104ADocument2 pagesAttachment No.2 CECA Technical Proposal Unit 104Aghasem_726990287Pas encore d'évaluation

- Review of Essential Oils from Annonaceae PlantsDocument13 pagesReview of Essential Oils from Annonaceae PlantsroxanaPas encore d'évaluation

- Alpha ProfileDocument2 pagesAlpha ProfileGovind SinghPas encore d'évaluation

- Avantor Chemical Price List 2019-2020-J.T.BAKERDocument54 pagesAvantor Chemical Price List 2019-2020-J.T.BAKERVikki PatelPas encore d'évaluation

- Limites condenatorios aceite en MeritorDocument4 pagesLimites condenatorios aceite en MeritorJavier H Durán ValeroPas encore d'évaluation

- II - ITP - Defect Work FabricationDocument5 pagesII - ITP - Defect Work Fabricationmohd as shahiddin jafriPas encore d'évaluation

- Mineral NutritionDocument23 pagesMineral NutritionRahul KumarPas encore d'évaluation

- 1 Auxilliary Equipment - US PricingDocument132 pages1 Auxilliary Equipment - US PricingOscar EspitiaPas encore d'évaluation

- Wolter Jetfan Broschuere English 2017 PDFDocument15 pagesWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânPas encore d'évaluation

- Kimo Kigaz 200 Combustion Gas Analyzer DatasheetDocument4 pagesKimo Kigaz 200 Combustion Gas Analyzer DatasheetayannathompsoneqsPas encore d'évaluation

- ANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleDocument12 pagesANSWER A. Diesel Cycle Has Lower Efficiency Than Otto CycleParmeshwarPaulPas encore d'évaluation

- Spontaneous Combustion ConversionDocument68 pagesSpontaneous Combustion ConversionRizwan Ullah BaigPas encore d'évaluation

- Atracurium BesylateDocument4 pagesAtracurium BesylateStill DollPas encore d'évaluation

- 20b. Global S CycleDocument15 pages20b. Global S CyclerossydaPas encore d'évaluation

- Ti OSO4Document4 pagesTi OSO4Liz AfanadorPas encore d'évaluation

- FuelsDocument22 pagesFuelsADITYA GAURPas encore d'évaluation

- MCQ IjsoDocument20 pagesMCQ IjsommhabgPas encore d'évaluation

- 11th Chemistry EM - Public Exam 2022 - Model Question Paper - English Medium PDF DownloadDocument3 pages11th Chemistry EM - Public Exam 2022 - Model Question Paper - English Medium PDF DownloadAshwini Shankar KumarPas encore d'évaluation

- Chemistry SBA7 ReportDocument6 pagesChemistry SBA7 ReportSam ChanPas encore d'évaluation

- Profile Prince Decoware Furniture HandlesDocument54 pagesProfile Prince Decoware Furniture HandlesRushabh ShahPas encore d'évaluation

- Flashing CalculationsDocument8 pagesFlashing CalculationsjcmarabouPas encore d'évaluation

- Hydrogen BondsDocument2 pagesHydrogen BondsJohnPas encore d'évaluation

- Dust Collection Design and Maintenance GuideDocument36 pagesDust Collection Design and Maintenance GuideMadan YadavPas encore d'évaluation