Académique Documents

Professionnel Documents

Culture Documents

Technical Note TM008 Low Reactancias PDF

Transféré par

Joseph PinTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Note TM008 Low Reactancias PDF

Transféré par

Joseph PinDroits d'auteur :

Formats disponibles

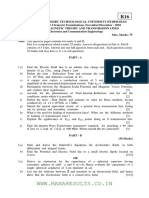

Technical note

Starting methods for AC motors

Reducing electrical and mechanical stress at start-up Star-Delta (Y/D) starting

The starting current of an AC motor can vary from 3 to 7 Most low voltage motors can be connected to run at either

times the nominal current.This is because a large amount of 400 V with delta connection or at 690 V with star connection.

energy is required to magnetise the motor enough to over- This flexibility can also be used to start the motor with a lower

come the inertia the system has at standstill. The high current voltage. Star/delta connection gives a low starting current

drawn from the network can cause problems such as volt- of only about one-third of that during direct-on-line starting,

age drop, high transients and, in some cases, uncontrolled although this also reduces the starting torque to about 25%.

shutdown. High starting current also causes great mechanical The motor is started with Y-connection and accelerated as far

stress on the motors rotor bars and windings, and can affect as possible, then switched to D-connection. This method can

the driven equipment and the foundations. Several starting only be used with induction motors delta connected for the

methods exist, all aiming to reduce these stresses. supply voltage.

UN

The load, the motor and the supply network determine Ist

the most appropriate starting method. When selecting and U N = Rated net voltage

dimensioning the starting equipment and any protective M

devices, the following factors must be taken into account: Ist = Start current at full voltage

The voltage drop in the supply network when starting

the motor Reactor start

The required load torque during start By connecting a coil with an iron core (a reactor) in series

The required starting time with the motor during start, the starting current is limited in

proportion with the voltage. However, this also means a sub-

Direct-on-line (DOL) start stantial (quadratic) reduction in the available starting torque.

Direct on line starting is suitable for stable supplies and The advantage of this method is its low cost in comparison

mechanically stiff and well-dimensioned shaft systems. It is with other methods.

the simplest, cheapest and most common starting method. UN U N = Rated net voltage

Starting equipment for small motors that do not start and IstR

Ist = Start current at full voltage

stop frequently is simple, often consisting of a hand operated

motor protection circuit breaker. Larger motors and motors M IstR = Start current at red. voltag

that start and stop frequently, or have some kind of control XM

system, normally use a direct-on-line starter which can XM = Motor reactance

XR

consist of a contactor plus overload protection, such as XR = Reactor reactance

a thermal relay.

UN IstR 2

(X ) (I )T

UN

IstR = TstR =

Ist M

+ XR st

st

U N = Rated net voltage

Ist = Start current at full voltage

M

Auto transformer start Soft starters are less costly than frequency converters but like

The effect of auto transformer start is similar to that of reac- frequency converters, they may inject harmonic currents into

tor start. Using a transformer to limit the voltage reduces the the grid, disrupting other processes.

starting current and the torque, but less so than the reactor UN

start. The method is more expensive than reactor start. U N = Rated net voltage

IstR

UN UN = Rated net voltage

IstR = Start current at red. voltage

IstR

Ist = Start current at full voltage

U M = Motor voltage

IstR = Start current at red. voltage

UM UM

M UM = Motor voltage M

TM008 EN Rev C 12 2010

Frequency converter start

UM 2 IstR

IstR = (U )IN

st

TstR = ( I )T

st

st

Although a frequency converter is designed for continuous

feeding of motors, it can also be used for start-up only. The

frequency converter enables low starting current because the

Capacitor start motor can produce rated torque at rated current from zero to

By storing the power required for magnetisation in capacitor full speed. As the price of frequency converters continues to

banks, it is possible to start with full starting torque without drop, they are increasingly being used in applications where

disturbing the network. To avoid over-compensation, the soft starters would previously have been used. However in

capacitor bank must be uncoupled after start-up. The dis- most cases they are still more expensive than soft starters,

advantages of this method are the high cost, and the large and like these, they inject harmonic currents into the network.

space requirement of the capacitor banks. UN

XN UN UN = Rated net voltage U N = Rated net voltage

IstR

IstR IstR = Start current w/capacitor

IstR = Start current at red. voltage

XN = Net reactance

XM

UM U M = Motor voltage

M XC = Capacitor bank reactance

M

XC XM = Motor short circuit reactance

XC XM Rheostat starting

Rheostat starting can only be used with slip ring motors.

UN XC + XM

IstR = TstR = Tst On these motors, the resistance of the rotor circuits can be

XC XM XC XM

N(

3 X +

XC + XM ) XN+

XC + XM

increased with an external resistor. This method is usually

chosen when the supply net is weak and the required starting

torque and moment of inertia are very high. By switching in

Soft starters the additional resistances in steps, normally 4 to 7 steps, the

Soft starters are based on semiconductors, which, via a desired acceleration torque can be obtained. The normal DOL

power circuit and a control circuit, initially reduces the motor starting equipment also required.

voltage, resulting in lower motor torque. During the starting UN

process, the soft starter progressively increases the motor IstR U N = Rated net voltage

voltage so that the motor becomes strong enough to acceler-

ate the load to rated speed without causing torque or current UM IstR = Start current at red. voltage

M

peaks. Soft starters can also be used to control the stopping

UM = Motor voltage

of a process.

Copyright 2010 ABB. All Rights Reserved

We reserve the right to make technical changes or modify the contents of this

document without prior notice. No part of this publication may be reproduced

or transmitted in any form or by means, electronic, mechanical, photocopying,

recording or otherwise without prior written permission of ABB.

For more information please contact:

www.abb.com/motors&generators

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Strama PaperDocument28 pagesStrama PaperHiezll Wynn R. Rivera100% (1)

- Substation Equipment's & One Line DiagramDocument10 pagesSubstation Equipment's & One Line DiagramMr Hassan RazaPas encore d'évaluation

- AC Machinery Fundamentals ExplainedDocument38 pagesAC Machinery Fundamentals ExplainedDicky Andra Irawan100% (1)

- Steel Frame Wall Systems Installation GuideDocument48 pagesSteel Frame Wall Systems Installation Guide陳宗煌Pas encore d'évaluation

- Urbanscape Green Roof Systems GuideDocument2 pagesUrbanscape Green Roof Systems GuidePaola ZorrillaPas encore d'évaluation

- MEP 283 Lecture NotesDocument57 pagesMEP 283 Lecture NotesPkay TandohPas encore d'évaluation

- Amte 126 MidtermsDocument4 pagesAmte 126 MidtermsJan Patrick VelosoPas encore d'évaluation

- Honeywell SF340 Manual de UsuarioDocument1 pageHoneywell SF340 Manual de UsuarioIntersistem Fermax sacPas encore d'évaluation

- Dam Outlet Works: 3.1 Introduction To Dam Out LetsDocument17 pagesDam Outlet Works: 3.1 Introduction To Dam Out LetsNatty Tesfaye100% (1)

- DraftDocument53 pagesDraftJack SparrowPas encore d'évaluation

- Kingman Spyder 2008 Electra With Eye ManualDocument35 pagesKingman Spyder 2008 Electra With Eye Manualshizim1Pas encore d'évaluation

- BLHeli - 32 Manual ARM Rev32.x PDFDocument10 pagesBLHeli - 32 Manual ARM Rev32.x PDFaniket5941Pas encore d'évaluation

- Cyberscape Gamma - VRF Installation - Ralgo Industries Inc. - 45-62742 - 3ppDocument441 pagesCyberscape Gamma - VRF Installation - Ralgo Industries Inc. - 45-62742 - 3ppeltonjohnevangelistaPas encore d'évaluation

- Rolling Mill Shutdown Report Aug-Sept 2022Document3 pagesRolling Mill Shutdown Report Aug-Sept 2022ravi kumarPas encore d'évaluation

- An Active-Clamp Push-Pull Converter For Battery Sourcing ApplicationsDocument9 pagesAn Active-Clamp Push-Pull Converter For Battery Sourcing ApplicationsYury KrivtsovPas encore d'évaluation

- SPP368Document5 pagesSPP368Amanda KaizerPas encore d'évaluation

- Template Tutor Sk016 (Terkini)Document6 pagesTemplate Tutor Sk016 (Terkini)cikgu_aminPas encore d'évaluation

- Castell Switchgear Applications GuideDocument20 pagesCastell Switchgear Applications GuideAnonymous w63sFQiQPas encore d'évaluation

- Business Ethics Question PaperDocument27 pagesBusiness Ethics Question PaperPoonamlims100% (1)

- Utse - Metathesis and SyllabusDocument6 pagesUtse - Metathesis and SyllabusutpannaPas encore d'évaluation

- Sandvik DP1500: Surface Top Hammer DrillsDocument3 pagesSandvik DP1500: Surface Top Hammer DrillsRoynino Martinez ventura100% (1)

- EMT and Transmission Lines ReviewDocument2 pagesEMT and Transmission Lines Reviewrupesh guptaPas encore d'évaluation

- GliolDocument1 pageGliolCaballeroGiovanniPas encore d'évaluation

- Chapter 12Document10 pagesChapter 12Mary IdrusPas encore d'évaluation

- FICCI India Office Repurposed To Scaleup ReportDocument17 pagesFICCI India Office Repurposed To Scaleup ReportRitesh KurarPas encore d'évaluation

- Compressible Flow + Fanno Lines For Different Mass FluxesDocument135 pagesCompressible Flow + Fanno Lines For Different Mass Fluxesmyself_riteshPas encore d'évaluation

- Case Study Plant Harris Non Chemical DechlorinationDocument1 pageCase Study Plant Harris Non Chemical DechlorinationIrfan OmercausevicPas encore d'évaluation

- Bosch Filtertype Smokemeter EFAW65B PDFDocument4 pagesBosch Filtertype Smokemeter EFAW65B PDFMuhammad JawadPas encore d'évaluation

- NuFlo Gas TurbineDocument4 pagesNuFlo Gas TurbineANIKRADPas encore d'évaluation

- Recloser COOPER POWER SYSTEMSDocument28 pagesRecloser COOPER POWER SYSTEMSValentina ArthurPas encore d'évaluation