Académique Documents

Professionnel Documents

Culture Documents

Manutencao Accuflex

Transféré par

Davis GarciaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Manutencao Accuflex

Transféré par

Davis GarciaDroits d'auteur :

Formats disponibles

Preventive Maintenance

...................................

2

.....

Overview

Introduction This chapter contains recommended preventive maintenance (PM) procedures for the

AccuFlex printer. Itemized logs for the PM procedures are included, organized both by

frequency of performance and by major assembly.

In this chapter This chapter is divided into eight sections.

For information on See Section

Before You Begin A

Preventive Maintenance Itemized Logs B

Preventive Maintenance - Daily C

Preventive Maintenance - Weekly D

Preventive Maintenance - Monthly E

Preventive Maintenance - Semi-Annual F

Preventive Maintenance - Annual G

Troubleshooting Charts H

Accuflex Preventive Maintenance Guide 2-1

PREVENTIVE MAINTENANCE

2 Overview

Section A: Before You Begin

...................................

Overview

Introduction This section contains information that must be read before performing preventive

maintenance procedures.

Cleaning Work The following describes the importance of a clean work surface.

Surfaces

Solder paste residue on the worktable and adjacent components reduces print

quality.

Cleanliness of internal working surfaces is critical for printing accuracy.

The primary purpose of this manual is to provide instructions for inspecting,

cleaning and lubricating those parts of the printer that if neglected, will reduce

print quality and/or reduce machine longevity.

Consult local HAZMAT codes and MSDS sheets on the appropriate use, storage,

and disposal of suggested cleaning solutions within your facility.

Read and comply with the warnings and cautions given with each PM routine for

your own safety and the safety of the printer.

Ordering Speedline Some procedures may require Speedline replacement parts. Review each procedure

Replacement Parts before beginning work on the printer and determine if replacement parts are required.

Replacement parts can be ordered from Speedline Global Service Group by calling

1-800-737-8110.

For help identifying replacement parts, refer to the Accuflex Drawings Guide.

This volume provides illustrated parts breakdowns (IPBs) and corresponding parts

lists for each of the major printer assemblies.

The parts list identifies part numbers, part descriptions, and the quantity of parts

used in each assembly.

Refer to the Accuflex Repair Guide for a list of available parts contained in the

various spares kits. If you dont have the spare, contact Speedline Global Service

Group at 1-800-737-8110.

2-2 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Overview

Section B: Preventive Maintenance Itemized Logs

...................................

Overview

Introduction The following tables are an itemized log of PM procedures to be performed on a

scheduled basis. Copy the (blank) original logs and use copies for recording PM

procedures as they are done.

It is strongly recommended that the initialed and dated PM log sheets be retained in a

separate PM log book for future reference.

Daily (Operator) Machine operator performs these procedures daily or at 3,000 cycles.

Assembly Completed Date

(Initial)

Remove paste and debris from machine

Clean top cover and monitor screen

Inform technician if stencil wiper paper or solvent

need replenishment.

Inform technician of any problems

Check stencil cleaner paper tension

Verify wiper plenum pressure. Adjust regulator

Daily (Technician) Technician performs these procedures daily or at 3,000 cycles.

Assembly Completed Date

(Initial)

Discuss any machine problems with operator

Check / replace stencil cleaner paper

Check / replace solvent

Check / replace automatic paste dispenser, if

installed

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Overview

Weekly (Technician) Technician performs these procedures weekly or at 21,000 cycles.

Assembly Completed Date

(Initial)

Complete daily action items.

Visually check conveyor belts and board foil clamps

Clean top and bottom edges of board supports

Clean camera top and bottom prism lenses

Check squeegee condition

Clean individual board supports. Clean pickup heads

(auto tooling option)

Clean all electromechanical faces

Check solvent tank for leaks

Check wiper / plenum blade and solvent tube for

paste deposits

Inspect solvent tube

Weekly Squeegee Technician performs these procedures weekly or at 21,000 cycles.

Maintenance

(Technician)

Assembly Completed Date

(Initial)

Check Squeegee blade contact with stencil.

Adjust polyurethane squeegees, if installed

2-4 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Overview

Monthly Perform these procedures monthly or at 80,000 cycles.

(Technician)

Assembly Completed Date

(Initial)

Perform weekly maintenance

Wipe print carriage bearings with oil

Wipe stencil cleaner and camera guide rails with oil

Inspect stencil wiper plenum, solvent tubes, hoses,

and solvent bar

Semi-Annually Perform these procedures semi-annually or at 480,000 cycles.

(Technician)

Assembly Completed Date

(Initial)

Re-grease Camera X Ball Screw

Replace vacuum pump filter

Annually Perform these procedures or at 960,000 cycles.

(Technician)

Assembly Completed Date

(Initial)

Re-grease the camera rack and pinion

Re-grease the printhead carriage bearings

Re-grease the stencil cleaner bearings

Re-grease the table rising bearings

Re-grease the camera carriage

Check squeegee drive belts

Check and grease rising table actuator shaft

Check conveyor belts

Check squeegee bearing movement

Replace hood gas struts

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Overview

Section C: Preventive Maintenance - Daily

...................................

Overview

Introduction This section contains inspection and cleaning procedures to be performed daily or

every 3,000 cycles, whichever occurs first.

Poison

Warning. Solder paste and other printing medium contain lead and are

hazardous to your health and the environment. Always wear protective gloves

and safety goggles when handling printing medium and make sure you properly

dispose of all waste material according to manufacturers instructions. Failure to

comply could result in personal injury and/or damage to the environment.

Chemical Hazard

Caution. Solvent may cause severe burns. Always wear protective gloves and

safety glasses when handling solvent, and be careful not to spill the solvent

when filling the solvent tank. Review solvents Material Safety Data Sheet before

use. Failure to comply may result in personal injury.

Safety Glasses

Caution. Wear protective safety glasses when handling solvent. Solvent can

cause burns to the skin and can damage plastic and painted surfaces.

Safety Gloves

Caution. Wear protective gloves when handling solvent. Solvent can cause

burns to the skin and can damage plastic and painted surfaces.

In this Section This section contains the following topics.

Topic See Page

Operator 7

Technician 8

2-6 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Operator

Operator

Introduction The machine operator will perform these functions on a daily basis.

Estimated 5 minutes

Completion Time

Tools, Equipment, The following is needed to perform daily maintenance:

and Materials

Rubber gloves

Speedline-approved solvent

Clean lint-free cloths

Protective goggles

Operator Actions The following table lists operator daily maintenance action items.

Step Action

1 Remove any paste or debris from the machine, paying special attention

to the table area.

2 Clean the top cover and monitor screen. The paint and acrylic surfaces

of the machine covers will tolerate most cleaning agents. However, do

not use solvents.

3 Inform technician if stencil wiper paper or solvent need replenishment.

4 Inform technician of any machine operation problems.

5 Check the stencil cleaner paper tension.

6 Verify that the wiper plenum pressure gauge reads the value 25 -35 PSI

(1.7 bars/170kPa - 2.4 bars.240kPa). Adjust the regulator pressure, if

necessary.

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Technician

Technician

Introduction The technician will perform these functions on a daily basis.

Estimated 5 - 20 minutes

Completion Time

Tools, Equipment, The following is needed to perform daily maintenance:

and Materials

Rubber gloves

Speedline-approved solvent

Clean lint-free cloths

Protective goggles

Technician Actions The following table lists technician daily maintenance action items.

Step Action

1 Discuss any machine operation problems with the operator.

2 Check and replace the stencil cleaner paper, if necessary.

A visual check of the wiper paper roll will show when the roll needs

replacing.

Cleaning Cloth

UP5121

2-8 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Technician

Step Action

3 Check and replace the stencil cleaning solvent as necessary. Stencil

cleaning solvent is stored in a container located at the rear of the

machine. Unscrew the top of the container to check the level or

replenish the liquid.

Viewed from back of Printer

Stencil Cleaning Fluid

UP5122

4 If you have an automatic paste dispenser, replace the cartridge as

necessary.

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Overview

Section D: Preventive Maintenance - Weekly

...................................

Overview

Introduction This section contains inspection and cleaning procedures to be performed weekly or

every 21,000 cycles, whichever occurs first.

Tools, Equipment, The following is needed to perform weekly maintenance:

and Materials

Clean lint-free cloths

Cotton swabs

Speedline-approved solvent

Protective goggles

Rubber gloves

Inspection mirror and flashlight

In this Section This section contains the following topics.

Topic See Page

Technician 11

Squeegee Maintenance 13

2-10 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Technician

Technician

Introduction In addition to the daily maintenance, the technician must perform the weekly

procedures in this section.

Procedure This table lists the technicians weekly action items.

Step Action

1 Complete the daily action items.

2 Visually check conveyor belts and board foil clamps.

Clamp Foil Assembly

Conveyor

Board Support

UP5123

3 Clean the top and bottom edges of the board supports shown in Step 2.

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Technician

Step Action

4 Clean camera top and bottom prism lenses using a non-abrasive clean

cloth or cotton swab and an appropriate solvent, such as isopropyl

alcohol.

Camera viewed from right side of printer

Top Lens

Lifting Pistons

Bottom Lens

UP5124

5 Check the condition of the squeegees.

6 Clean the individual board supports using isopropyl alcohol and a lint-

free cloth. If you have the automatic tooling option, clean the pickup

heads, lifting pistons and carousel slots.

7 Clean all electromechanical faces, such as the stencil cleaner - camera

carriage connection, using isopropyl alcohol.

8 Check the solvent tank for possible leaks.

9 Check the wiper/plenum blade and solvent tube for paste deposits.

Clean using a cloth and Speedline-approved solvent.

10 Inspect the solvent tube for signs of wear or damage. If replacement is

necessary, contact Speedline Customer Service.

2-12 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Squeegee Maintenance

Squeegee Maintenance

Introduction The squeegee pushes paste through the stencil. The squeegee angle of attack

causes the paste to form a wave-like action in front of the squeegee. The condition of

the squeegee is important in obtaining a uniform deposit over the print area.

Estimated 5 minutes

Completion Time

Poison

Warning. Solder paste and other printing medium contain lead and are

hazardous to your health and the environment. Always wear protective gloves

and safety goggles when handling printing medium and make sure you properly

dispose of all waste material according to manufacturers instructions. Failure to

comply could result in personal injury and/or damage to the environment.

Procedure Perform the following squeegee maintenance on a weekly basis.

Step Action

1 Check that the squeegee blade makes good contact with the stencil

throughout its length. Present the work edge to a table surface or other

suitable flat surface and inspect for any gaps.

2 Adjusting the squeegee mounting screws will cause a polyurethane

squeegee blade to deform and this adjustment can correct local

outages. Replace blades that cannot be made usable in this way.

Metal blades are made to fine tolerances and usually present an

extremely straight edge. No adjustment is needed. Replace blades

when gaps or wear occurs.

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Overview

Section E: Preventive Maintenance - Monthly

...................................

Overview

Introduction This section contains inspection and cleaning procedures to be performed monthly or

every 80,000 cycles, whichever occurs first.

Tools, Equipment, The following is needed to perform monthly maintenance:

and Materials

Clean lint-free cloth

Speedline-approved solvent

Protective goggles

Rubber gloves

Light machine oil

In this Section This section contains the following topics.

Topic See Page

Technician 15

2-14 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Technician

Technician

Introduction The technician will perform these operations on a monthly basis.

Estimated 5 - 15 minutes

Completion Time

Procedure Perform the following:

Step Action

1 Perform weekly maintenance.

2 Wipe the print carriage bearings with a lint-free cloth and light machine

oil.

Left Print Carriage Bearing Right Print Carriage Bearing

UP5125

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Technician

Step Action

3 Wipe the stencil cleaner/camera guide rails with a lint-free cloth and

light machine oil.

Stencil Cleaner

Camera Gantry

Stencil Cleaner and

Camera Gantry utilize

the same Guide Rails

Guide Rail Guide Rail

UP5126

2-16 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Technician

Step Action

4 Wipe front cover gas struts the with a lint-free cloth and light machine

oil. These struts are accessible by raising the front cover.

Table Rising Table Rising

Rail Rail

Viewed from Lower Left Rear Viewed from Lower Right Rear

looking towards back of Printer looking towards back of Printer

UP5127

5 Inspect the stencil wiper plenum, solvent tubes, hoses, and solvent bar.

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Overview

Section F: Preventive Maintenance - Semi-Annual

...................................

Overview

Introduction This section contains inspection and cleaning procedures to be performed semi-

annually or every 480,000 cycles, whichever occurs first. Perform these procedures

in addition to the monthly preventive maintenance action items.

Tools, Equipment, The following is needed to perform semi-annual preventive maintenance:

and Materials

Protective goggles

light machine oil

In this Section This section contains the following topics.

Topic See Page

Re-grease the Camera X Ball Screw 19

Semi Annual Stencil Cleaner Maintenance 20

2-18 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Re-grease the Camera X Ball Screw

Re-grease the Camera X Ball Screw

Procedure Re-grease the camera X ball screw as follows:

Step Action

1 Remove the camera drive cover.

2 Remove the camera drive block cover.

3 Locate the lubrication hole in the top of the drive nut assembly.

Using a lithium based grease gun (with grease such as Castrol LMX),

pump grease into the lubrication hole.

Lubrication Hole

Viewed from Front of Printer UP5128

4 Replace the covers.

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Semi Annual Stencil Cleaner Maintenance

Semi Annual Stencil Cleaner Maintenance

Procedure Replace the vacuum pump filter as follows:

Step Action

1 Open the rear printer door.

2 Locate the two glass filter jars attached to the vacuum motors.

3 Unscrew the jars slowly, one at a time, to release any residual air

pressure.

4 Remove the filter.

5 Position a new filter and secure it with the base plate.

6 Screw the jar securely to the top of the assembly.

7 Close the printer door.

2-20 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Overview

Section G: Preventive Maintenance - Annual

...................................

Overview

Introduction This section contains inspection and cleaning procedures to be performed annually or

every 960,000 cycles, whichever occurs first. Perform these preventive maintenance

steps in addition to the semi-annual action items.

Tools, Equipment, The following is needed to perform the annual preventive maintenance:

and Materials

Clean lint-free cloth

Speedline-approved solvent

Protective goggles

Rubber gloves

In this section This section contains the following topics.

Topic See Page

Annual Preventive Maintenance 22

Hand Crush Hazard

Caution. Before performing maintenance procedures, you may need to

reposition printer components to gain better access. Stay clear as components

move. Failure to comply may result in personal injury.

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Annual Preventive Maintenance

Annual Preventive Maintenance

Procedure Perform these maintenance steps annually:

Step Action

1 Re-grease the camera rack and pinion.

2 Re-grease the printhead carriage bearings with a lithium-based grease,

such as Castrol LMX.

3 Re-grease the stencil cleaner bearings with the lithium-based grease.

4 Re-grease the table rising bearings with the lithium-based grease.

5 Re-grease the camera carriage with the lithium-based grease.

6 Check the condition and tightness of the squeegee drive belts.

7 Check and grease the rising table actuator shaft.

Viewed from

Rear Left side

Rising Table

Actuator Shaft

UP5129

8 Check the condition of the conveyor belts. Replace if necessary.

ATTENTION

Edges of the board clamping foils are sharp. Keep hands

clear. Apply foil safety covers before manually adjusting

the rails, setting up, cleaning, or servicing the printer.

Exercise caution when cleaning foils and rails.

2-22 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

Annual Preventive Maintenance

Step Action

9 Check to see that the squeegees move down easily on their bearings

against their springs. Replace the bearings and springs if necessary.

10 Replace the hood gas struts yearly, or earlier if they exhibit wear.

ATTENTION

A falling hood can cause injury.

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Overview

Section H: Troubleshooting Charts

...................................

Overview

Introduction This section contains various charts to aid in troubleshooting your Accuflex printer.

In this section The following is covered.

Topic See Page

AccuFlex Motor List 25

Z Amplifier Troubleshooting Chart 26

AccuFlex Signal LEDs 27

2-24 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

AccuFlex Motor List

AccuFlex Motor List

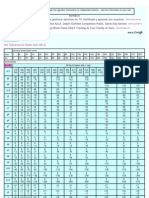

Motor Motor Description No./ Motor Part Standard/ Crate Card Comments

machine No. Option Controllin

g Motor

M3 Speed enhanced Z motor 1 P7719 Hi Speed X3-Feed X77 - Pac Sci Amp/

Option Controller controls

motor

M3 Standard Z motor 1 1008242 Standard X3-Feed X14 Amp

18M1, Center transport belt 2 1006961-1 Standard X3-Feed

18M2 motor 1006961-2

18M1, Center transport belt 2 1008606-1 Triple track X3-Feed 1008606-7 is spare

18M2 motor 1008606-2 option

18M4, Left buffer transport belt 2 1008606-3 Triple track X5-left 1008606-7 is spare

18M5 motor 1008606-4 option buffer

18M7, Right buffer transport belt 2 1008606-5 Triple track X6 right 1008606-7 is spare

18M8 motor 1008606-6 option buffer

18M3 Center powered rail 1 1006236-1 Powered X3-Feed 1006236-4 is spare

motor rail option

18M6 Left powered rail 1 1006236-2 Triple track X5-left 1006236-4 is spare

option buffer

18M9 Right powered rail 1 1006236-3 Triple track X6 right 1006236-4 is spare

option buffer

17M1, XYY Stepper motors 3 1006251-1, Standard X4-Align

17M2, 1006251-2,

17M3 1006251-3

19M1, Squeegee Stepper 2 7569M-1, Standard X2-Print

19M2 motors 7569M-2,

7569M-3

29M1 Squeegee Carriage motor 1 1006957 Standard X2-Print

24M1 Camera X motor 1 1008423 Standard X4-Align

24M2 Camera Y motor 1 1008424 Standard X4-Align

35M1 Paste Dispenser drive 1 1009267 Paste X2-Print

motor Dispense

option

22M1 USC Vacuum motor 1 P6870 Vacuum X2-Print See Document 1006587

motor for install instructions

option

21M1 USC Paper index motor 1 CA-975 wiper X2-Print

option

21M2 USC Pump motor 1 1006830 wiper X2-Print

option

23M1 Toling Index motor 1 1006281 AutoToolin X2-Print

g option

31M1 Heatsink cooling fan 1 10024861 Standard N/A XT75 Rail powers fan/

fan part of 7545M assy

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 Z Amplifier Troubleshooting Chart

Z Amplifier Troubleshooting Chart

Error Error Meaning What to Check

Displayed

At Amplifier over-temp fault Check amplifier

bF Output is disabled due to under voltage or over Possible issue: Regen Resistor,

voltage condition check X77-FU1/X77-R1

CF Configuration fault Programming of Pac Sci unit

d disabled (normal display - not an error condition)

E Enabled (normal display - not an error condition)

FE Following error Excessive load on table?

FL Feedback loss Check Resolver cable from X77-J3 to motor

Ot Over temp motor fault Check motor

P Pause input is active Check wiring to X77-J1

Os Over speed fault Check resolver wiring

SC Short circuit fault Check wiring to amplifier - all connections!

Blank display means no power - Pac Sci should Check X77 Contacter for 24vDC at A1 and A2

be off with system power is off

AccuFlex Test Points

Signal Designation Location

Ovp J9 x60

Video J2 x60

Ovs J1 x60

Camera Y position CH B J6 x60

Camera Y position CH A J5 x60

Camera X position CH B J4 x60

Camera X position CH A J3 x60

paste carriage position CH A J7 x60

paste carriage position CH B J8 x60

2-26 Accuflex Preventive Maintenance Guide

.....

PREVENTIVE MAINTENANCE

AccuFlex Signal LEDs

AccuFlex Signal LEDs

LED Description Signal Type Color ID Location of LED

paste carriage - Output green N/A x60

paste carriage + Output green N/A x60

rear squeegee phase 4 Output green N/A x60

rear squeegee phase 3 Output green N/A x60

rear squeegee phase 2 Output green N/A x60

rear squeegee phase 1 Output green N/A x60

front squeegee phase 4 Output green N/A x60

front squeegee phase 3 Output green N/A x60

front squeegee phase 2 Output green N/A x60

front squeegee phase 1 Output green N/A x60

eject home right Input green N/A x60

eject home left Input green N/A x60

stencil locate (not used) Input green N/A x60

squeegee carriage home Input green N/A x60

rear squeegee nearly home Input green N/A x60

rear squeegee home (not used) Input green N/A x60

front squeegee nearly home Input green N/A x60

front squeegee home (not used) Input green N/A x60

paste cartridge down Input green N/A x60

paste cartridge up Input green N/A x60

paste cartridge empty Input green N/A x60

paste cartridge home Input green N/A x60

paste cartridge position CH A Input green N/A x60

paste cartridge position CH B Input green N/A x60

5VS present Power green N/A x60

12V present Power green N/A x60

tooling magnet 1 + Output green N/A x60

tooling magnet 2 + Output green N/A x60

look up + Output green N/A x60

look down + Output green N/A x60

camera x+ Output green N/A x60

camera x - Output green N/A x60

camera y +(bypassed) Output green N/A x60

camera y - (bypassed) Output green N/A x60

camera x position CH A Input green N/A x60

camera x position CH B Input green N/A x60

camera y position CH A Input green N/A x60

camera y position CH B Input green N/A x60

Accuflex Preventive Maintenance Guide

PREVENTIVE MAINTENANCE

2 AccuFlex Signal LEDs

LED Description Signal Type Color ID Location of LED

tooling sensor 1 Input green N/A x60

tooling sensor 2 Input green N/A x60

board stop Input green N/A x60

camera x limit left Input green N/A x60

camera x limit right (not used) Input green N/A x60

camera x home Input green N/A x60

42vp Power green D1 x1,x2,x3,x4,x5,x6

24vs Power green D2 x1,x2,x3,x4,x5,x6

24v Power green D3 x1,x2,x3,x4,x5,x6

5vp Power green D4 x1,x2,x3,x4,x5,x6

12v Power green D5 x1,x2,x3,x4,x5,x6

5VS present Power green D6 x1,x2,x3,x4,x5,x6

reset Check amber D7 x1,x2,x3,x4,x5,x6

cpu active (blinks with processor speed) Check amber D8 x1,x2,x3,x4,x5,x6

over current (on signals an error condition) Check red D9 x1,x2,x3,x4,x5,x6

over temperature (on signals an error Check red D10 x1,x2,x3,x4,x5,x6

condition)

wiper latch Output green D1 x62

wiper paper index Output green D2 x62

5VS present Power green D1 x68

12vs present Power green D2 x68

12vs present Power green D1 x64

12vp Power green N/A x14 (not on Hispeed Z)

24vp Power green N/A x14 (not on Hispeed Z)

42vp Power green N/A x14 (not on Hispeed Z)

over current (on signals an error condition) Check red N/A x14 (not on Hispeed Z)

over temperature (on signals an error Check red N/A x14 (not on Hispeed Z)

condition)

x home Input green D3 x67

x limit right (not usd) Input green D2 x67

12V present Power amber D1 x67

5v present Power amber D6 x67

x position channel A Input green D4 x67

x position channel B Input green D5 x67

A/D signal Input red D1 x73

5v present Power green D2 x73

12V present Power green D2 x73

2-28 Accuflex Preventive Maintenance Guide

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hy Gain AntenaDocument7 pagesHy Gain AntenaIrwan Wiradinata SondaPas encore d'évaluation

- Towards 4.0: The Smelter of The FutureDocument4 pagesTowards 4.0: The Smelter of The FutureShyamal VermaPas encore d'évaluation

- EDS 06-0017 Customer Installation Earthing Design PDFDocument47 pagesEDS 06-0017 Customer Installation Earthing Design PDFRajendra Prasad ShuklaPas encore d'évaluation

- Product Design SpecificationDocument2 pagesProduct Design SpecificationCharlie100% (1)

- Chapter 4 Chemical Reactions 4 3 To 4 6Document38 pagesChapter 4 Chemical Reactions 4 3 To 4 6api-313987777Pas encore d'évaluation

- Industrial Revolution - Script WritingDocument3 pagesIndustrial Revolution - Script WritingAaron SinyorPas encore d'évaluation

- Steels For Construction Special Steels Structural Steel Construction Steel dd11 PickledDocument2 pagesSteels For Construction Special Steels Structural Steel Construction Steel dd11 PickledhelderfsnPas encore d'évaluation

- Fluent Combustion 15.0 L02-Non-PremixedDocument30 pagesFluent Combustion 15.0 L02-Non-PremixedrafsebePas encore d'évaluation

- CAD CAM TemporaryDocument9 pagesCAD CAM TemporarySaleh AlmohammadPas encore d'évaluation

- Manual HECHT 650 GB PDFDocument14 pagesManual HECHT 650 GB PDFEmaPas encore d'évaluation

- Solid - Liquid ExtractionDocument20 pagesSolid - Liquid ExtractionFikriyatul KhaeriyahPas encore d'évaluation

- Wastewater Treatment by Effluent Treatment PlantsDocument8 pagesWastewater Treatment by Effluent Treatment Plantsvaibhavm0502Pas encore d'évaluation

- Renishaw CMM Technology GuideDocument330 pagesRenishaw CMM Technology GuideGabi OnofreiPas encore d'évaluation

- Canal Trough DesignDocument18 pagesCanal Trough DesignGarg Tj100% (1)

- Experiment 1 - Data SheetDocument4 pagesExperiment 1 - Data SheetApple PinpinPas encore d'évaluation

- Eco Levels For TextileDocument8 pagesEco Levels For Textilehimelhimel34Pas encore d'évaluation

- Brick Water TanksDocument76 pagesBrick Water TanksAnonymous iTzCnM100% (2)

- Fuse BibleDocument164 pagesFuse BiblepaulPas encore d'évaluation

- Cassida Fluid CR 46 - SD - (Gb-En)Document9 pagesCassida Fluid CR 46 - SD - (Gb-En)Huu Tri HuynhPas encore d'évaluation

- 0.drying Heat Pumps-Part IDocument17 pages0.drying Heat Pumps-Part IDr-Abhijit SinhaPas encore d'évaluation

- RE7ML11BU TelemecaniqueDocument22 pagesRE7ML11BU TelemecaniqueHugo FermartiPas encore d'évaluation

- Goodfellow SRMs AlloyDocument306 pagesGoodfellow SRMs AlloytqthienPas encore d'évaluation

- 5R110W Assembly PDFDocument16 pages5R110W Assembly PDFLuis VelazquezPas encore d'évaluation

- 08 Plasticity 01 Introduction PDFDocument11 pages08 Plasticity 01 Introduction PDFAmmar A. AliPas encore d'évaluation

- High Power Laser ApplicationsDocument22 pagesHigh Power Laser Applicationsvanniya vanniyaPas encore d'évaluation

- Homemade Field 0effect Transistor98Document18 pagesHomemade Field 0effect Transistor98Ali IjazPas encore d'évaluation

- Transteel Elite GetDocument20 pagesTransteel Elite GetCharlPas encore d'évaluation

- High Velocity Oil FlushDocument2 pagesHigh Velocity Oil FlushNatanael CarpelotiPas encore d'évaluation

- Rate December 2008Document1 pageRate December 2008lkovijayPas encore d'évaluation

- ISO - 286-2 Shaft Limits TolerancesDocument2 pagesISO - 286-2 Shaft Limits TolerancesMixtli Garcia100% (1)