Académique Documents

Professionnel Documents

Culture Documents

BS en 10279 Summary

Transféré par

Bui Chi Tam0 évaluation0% ont trouvé ce document utile (0 vote)

540 vues1 pageSummary tolerance of Steel Channel

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentSummary tolerance of Steel Channel

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

540 vues1 pageBS en 10279 Summary

Transféré par

Bui Chi TamSummary tolerance of Steel Channel

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

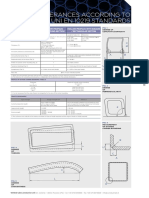

BS EN 10279 : 2000

Hot rolled steel channels

Tolerances on shape, dimension and mass

Tolerances on Dimensions and Shape

Section Height (h) Table 1. Tolerances for taper flange channels

The deviation from nominal on section hight (h) shall Property Range Tolerance

be within the tolerance given in Table 1 for tapered Designation

mm mm mm

flange channels and parallel flange channels. Height Height h < 65 1.5

is measured over the web h 65< h < 200 2.0

200< h

3.0

Flange Width (b) < 400

400< h 4.0

The deviation from nominal on flange width (b) shall

Flange Width b < 50 1.5

be within the tolerance given in Table 1 for tapered b 50 < b < 2.0

flange channels and parallel flange channels. 100 < b <

3.0

125

Web Thickness (s) 125 < b 4.0

The deviation from nominal on web thickness (s), Web thickness s < 10 0.5

when measured at the mid-height position of the web, s 10 < s < 15 0.7

15 < s 1.0

shall be within the tolerance given in Table 1 for

Flange thickness t < 10 * - 0.5

tapered flange channels and parallel flange channels. t 10 < t < 15 * - 1.0

15 < t * - 1.5

Flange Thickness (t) Heel radius All sizes < 0.3t

The deviation from nominal on flange thickness (t), r3

Out of squareness b < 100 2.0

when measured at a distance of b/2 from the toe of k=k1 100 < b 2.5% of b

the flange, shall be within the tolerance given in Web flatness h < 100 0.5

Table 1 for tapered flange channels and parallel 100< h

f 1.0

flange channels. < 200

200< h

1.5

< 400

Heel Radius (r3)

The radius of the heel radius (r3) shall not exceed 0,3t 400< h 1.5

where t is the flange thickness

Straightness h < 150 0.3% of

Out of Squareness (k + k1) and web bow (f) 150< h 0.2% of

qxx

i. The out of squareness of the section (k + k1) shall < 300 l

0.15% of

not exceed the maximum given in Table 1 for tapered 300< h

l

flange channels and parallel flange channels. qyy h < 150 0.5% of

150< h 0.3% of

ii. The web flatness (f) shall not exceed the < 300 l

maximum given in Table 1 for tapered flange 300< h 0.2% of

channels and parallel flange channels. Standard Length All +100 0

Alternative standard l All 50

Straightness (qxx or qyy) (by agreement)

The straightness (qxx or qyy) shall conform to the Mass per unit length kg/m h < 125 6%

requirements given in Table 1 for tapered flange 125 < h 4%

channels and parallel flange channels.

Parkers

www.parkersteel.co.uk

BUY STEEL ONLINE BS EN ISO 9001 : 2000

Vous aimerez peut-être aussi

- Flat Products Catalogue: Coils SheetsDocument24 pagesFlat Products Catalogue: Coils SheetsAmro HassaninPas encore d'évaluation

- BS en 10059Document3 pagesBS en 10059Nilesh PatilPas encore d'évaluation

- Structural Steel - S235, S275, S355 Chemical Composition, Mechanical Properties and Common ApplicationsDocument5 pagesStructural Steel - S235, S275, S355 Chemical Composition, Mechanical Properties and Common ApplicationsAndika PusbiantoPas encore d'évaluation

- ISO 3506-2 - Mechanical PropertiesDocument2 pagesISO 3506-2 - Mechanical PropertiesPMartina100% (1)

- En 12451 1999Document24 pagesEn 12451 1999victoraghiPas encore d'évaluation

- Carbon Structural Steels: National Standard of The People'S Republic of ChinaDocument8 pagesCarbon Structural Steels: National Standard of The People'S Republic of ChinaNicolás GuerreroPas encore d'évaluation

- Stuewe 201708 Catalogue Type-HsdDocument25 pagesStuewe 201708 Catalogue Type-HsdJorge A VilalPas encore d'évaluation

- JIS5402 For FRC Rooftile PDFDocument5 pagesJIS5402 For FRC Rooftile PDFQuảng Nguyễn HồngPas encore d'évaluation

- Pendulum Impact Testers - Impact Testing Machine - Aimil - Com - PDFDocument12 pagesPendulum Impact Testers - Impact Testing Machine - Aimil - Com - PDFAimil100% (1)

- Geomet 500bDocument1 pageGeomet 500bellisforheroesPas encore d'évaluation

- Sist en 754 2 2017Document13 pagesSist en 754 2 2017Oussama OussPas encore d'évaluation

- Iso 887-2000Document10 pagesIso 887-2000BaoPas encore d'évaluation

- En 10029 PDFDocument5 pagesEn 10029 PDFmanuela vilas boasPas encore d'évaluation

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Document16 pagesVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraPas encore d'évaluation

- BS en 641-1995Document19 pagesBS en 641-1995SpakkGroup SrlPas encore d'évaluation

- Iso 7452 2013 en PDFDocument8 pagesIso 7452 2013 en PDFfahmi aballiPas encore d'évaluation

- Structural Steel S235 S275 S355 Chemical Composition Mechanical Properties and Common ApplicationsDocument5 pagesStructural Steel S235 S275 S355 Chemical Composition Mechanical Properties and Common ApplicationsCharles OnyecherePas encore d'évaluation

- Oliver Equation Paper-1928Document38 pagesOliver Equation Paper-1928dps32100% (1)

- Cyprus National Annex en 1993-1-1Document11 pagesCyprus National Annex en 1993-1-1ruovPas encore d'évaluation

- DIN en 10305-3-Steel Tubes For Precision Applications-Technical Delivery ConditionsDocument23 pagesDIN en 10305-3-Steel Tubes For Precision Applications-Technical Delivery ConditionsGökhan ÇiçekPas encore d'évaluation

- BS5400 Part 4 Training Course - TE EpsomDocument19 pagesBS5400 Part 4 Training Course - TE EpsomjologscresenciaPas encore d'évaluation

- BS en 10052-94Document35 pagesBS en 10052-94HosseinPas encore d'évaluation

- GB 700-88Document5 pagesGB 700-88nazarasimPas encore d'évaluation

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDFrancisco RojasPas encore d'évaluation

- Din 555 1983Document6 pagesDin 555 1983Manuel OrtizPas encore d'évaluation

- EN 10210-2 2006 Hot Finished Structural Hollow Sections of Non Alloy and Fine Grain Steels - Part 2 Tolerances Dimensions and Sectional Properties PDFDocument32 pagesEN 10210-2 2006 Hot Finished Structural Hollow Sections of Non Alloy and Fine Grain Steels - Part 2 Tolerances Dimensions and Sectional Properties PDFJoao MendesPas encore d'évaluation

- Shear Capacity of Steel Plate Girders With Large Web OpeningsDocument3 pagesShear Capacity of Steel Plate Girders With Large Web OpeningsPauloAndresSepulvedaPas encore d'évaluation

- En10272-01 (2008)Document42 pagesEn10272-01 (2008)kpurnimaPas encore d'évaluation

- NA To Sls en 1993-1-3Document12 pagesNA To Sls en 1993-1-3Shan Sandaruwan AbeywardenePas encore d'évaluation

- InitialState ExemploDocument9 pagesInitialState ExemplopheifangPas encore d'évaluation

- S355 European Standard SteelDocument7 pagesS355 European Standard SteelmaiquelernPas encore d'évaluation

- Standards Comparison Steels For Offshore StructuresDocument9 pagesStandards Comparison Steels For Offshore Structureshvdb72Pas encore d'évaluation

- Material Data Sheet en Aw 6082 Almgsi1Document1 pageMaterial Data Sheet en Aw 6082 Almgsi1pankajrs.mechengineer4502Pas encore d'évaluation

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsAdnan NajemPas encore d'évaluation

- En ISO 12345-1999 Soldadura - Termos e Ilustrações de Juntas SoldadasDocument53 pagesEn ISO 12345-1999 Soldadura - Termos e Ilustrações de Juntas Soldadastiago_valentePas encore d'évaluation

- BS en 10204 2004 - 05Document12 pagesBS en 10204 2004 - 05EsakkirajaPas encore d'évaluation

- Chemical Composition % of Steel S690QL (1.8928) : EN 10025-6-2004Document1 pageChemical Composition % of Steel S690QL (1.8928) : EN 10025-6-2004Miodrag TopalovicPas encore d'évaluation

- HRN ISO en 12944-1 - Korozivna Zastita Celicnih Konstrukcija Premazima - Dio 1. Osnovne InformacijeDocument32 pagesHRN ISO en 12944-1 - Korozivna Zastita Celicnih Konstrukcija Premazima - Dio 1. Osnovne InformacijeMarko VrcaPas encore d'évaluation

- Tyco - Sintakote - Design - Manual - Nov2004editionDocument140 pagesTyco - Sintakote - Design - Manual - Nov2004editionmottmac50% (2)

- Junction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6Document3 pagesJunction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6met-calcPas encore d'évaluation

- DIN 18800-7 Antrag EnglDocument9 pagesDIN 18800-7 Antrag Englgorgika papandPas encore d'évaluation

- BS en 10028-5-2009Document19 pagesBS en 10028-5-2009anupsharma2522_98756Pas encore d'évaluation

- Technical Lamination SDocument4 pagesTechnical Lamination SirmakPas encore d'évaluation

- Duplex Stainless Steel.Document14 pagesDuplex Stainless Steel.Muhammed Sulfeek100% (1)

- 16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGDocument2 pages16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGJerzy RistujczinPas encore d'évaluation

- DSI GEWI Threadbar System EMEA PDFDocument12 pagesDSI GEWI Threadbar System EMEA PDFjuan carlosPas encore d'évaluation

- GBT 1591-2008 - High Strength Low Alloy Structural SteelDocument16 pagesGBT 1591-2008 - High Strength Low Alloy Structural SteelDarren ThoonPas encore d'évaluation

- B455Document3 pagesB455basha100% (1)

- Dos A OilDocument5 pagesDos A OilimranPas encore d'évaluation

- Colly Pop Rivet 222Document95 pagesColly Pop Rivet 222Andreas LidströmPas encore d'évaluation

- En 10253 3Document50 pagesEn 10253 3Thanh Nguyen VanPas encore d'évaluation

- 10056Document1 page10056sajay2010Pas encore d'évaluation

- BS EN 10056-2 AngleDocument1 pageBS EN 10056-2 AngleMahfuz AlamPas encore d'évaluation

- Parkers: BS EN 10034: 1993Document2 pagesParkers: BS EN 10034: 1993Scythe 961Pas encore d'évaluation

- H Beam STDDocument2 pagesH Beam STDPamungkasPas encore d'évaluation

- BS en 755-9-2008Document14 pagesBS en 755-9-2008rajeshmahrnPas encore d'évaluation

- Structural Tolerances Bs4 - 2004Document4 pagesStructural Tolerances Bs4 - 2004Anonymous 8bH7sXpcEHPas encore d'évaluation

- A500 Spec PDFDocument2 pagesA500 Spec PDFUgur SenPas encore d'évaluation

- A500 Spec SheetDocument2 pagesA500 Spec SheetMikku KattaPas encore d'évaluation

- NORSOK Standard - Material Data Sheets For PipingDocument1 pageNORSOK Standard - Material Data Sheets For PipingBui Chi TamPas encore d'évaluation

- TCVN7571-11 - 2019 - Thép CDocument14 pagesTCVN7571-11 - 2019 - Thép CBui Chi TamPas encore d'évaluation

- TCVN7571-5 - 2019 - THÉP GÓC CẠNH ĐỀU VÀ KHÔNG ĐỀU - DUNG SAI HỆ MÉT VÀ HỆ INCHDocument18 pagesTCVN7571-5 - 2019 - THÉP GÓC CẠNH ĐỀU VÀ KHÔNG ĐỀU - DUNG SAI HỆ MÉT VÀ HỆ INCHBui Chi TamPas encore d'évaluation

- BS Iso 668-2020Document23 pagesBS Iso 668-2020Bui Chi Tam100% (1)

- ANSI/BHMA A156.1-2016: American National Standard For Butts and HingesDocument1 pageANSI/BHMA A156.1-2016: American National Standard For Butts and HingesBui Chi TamPas encore d'évaluation

- NZ Metal Roof and Wall Cladding - Code of Practice Rev02 PDFDocument380 pagesNZ Metal Roof and Wall Cladding - Code of Practice Rev02 PDFBui Chi TamPas encore d'évaluation

- 04en - Part4 Dynamic Longitudinal Impact Test For Gas ContainersDocument12 pages04en - Part4 Dynamic Longitudinal Impact Test For Gas ContainersBui Chi TamPas encore d'évaluation

- ANSI - AHG2-4545FB (A2112) Test Report of Butt HingesDocument6 pagesANSI - AHG2-4545FB (A2112) Test Report of Butt HingesBui Chi TamPas encore d'évaluation

- Jis Z 3410Document14 pagesJis Z 3410Bui Chi TamPas encore d'évaluation

- EN 10130 Web - Datasheet - b3.1Document3 pagesEN 10130 Web - Datasheet - b3.1Bui Chi TamPas encore d'évaluation

- 1040363-014 Rev 01 Technical Data BookDocument209 pages1040363-014 Rev 01 Technical Data BookBui Chi TamPas encore d'évaluation

- NORSOK Standard - Material Data Sheets For PipingDocument1 pageNORSOK Standard - Material Data Sheets For PipingBui Chi TamPas encore d'évaluation

- NZ Metal Roof and Wall Cladding - Code of Practice Rev02 PDFDocument380 pagesNZ Metal Roof and Wall Cladding - Code of Practice Rev02 PDFBui Chi TamPas encore d'évaluation

- 0341Document22 pages0341Bui Chi TamPas encore d'évaluation

- New PDE PPM G00 BD 0016 000.02 Shipping InstructionsDocument15 pagesNew PDE PPM G00 BD 0016 000.02 Shipping InstructionsBui Chi TamPas encore d'évaluation

- Guidance Note For ToleranceDocument5 pagesGuidance Note For ToleranceBui Chi TamPas encore d'évaluation

- JIS Z2241-1993 Method of Tensile Test For Metallic MaterialsDocument12 pagesJIS Z2241-1993 Method of Tensile Test For Metallic MaterialsBui Chi TamPas encore d'évaluation

- Ferrous Material & Mettalurgy II - 2008 PDFDocument30 pagesFerrous Material & Mettalurgy II - 2008 PDFBui Chi TamPas encore d'évaluation

- Blood. Honor. Steel.: RAW Your Blade AND Join THE Fight FOR OkuganDocument15 pagesBlood. Honor. Steel.: RAW Your Blade AND Join THE Fight FOR OkuganNokowire TVPas encore d'évaluation

- No Slip Socks: Follow UsDocument2 pagesNo Slip Socks: Follow UsrezgsfsfgPas encore d'évaluation

- XAS 185 JDU7 FINAL - tcm795-2750265 PDFDocument2 pagesXAS 185 JDU7 FINAL - tcm795-2750265 PDFRodrigo Andres Diaz BascuñanPas encore d'évaluation

- CrazyTalk Animator 2 Pipeline ManualDocument796 pagesCrazyTalk Animator 2 Pipeline ManualHữu TâmPas encore d'évaluation

- 7WD AbbreviatedDocument1 page7WD AbbreviatedyahinnPas encore d'évaluation

- Carburetion Catalog 2002Document305 pagesCarburetion Catalog 2002LukidjPas encore d'évaluation

- Shaolin Soccer Movie Review ReportDocument11 pagesShaolin Soccer Movie Review ReportAsad AttarwalaPas encore d'évaluation

- Chapter 4Document13 pagesChapter 4Ryan SuarezPas encore d'évaluation

- The Pelican BriefDocument5 pagesThe Pelican BriefVanina BuonagemmaPas encore d'évaluation

- Poetry Focus StatementsDocument2 pagesPoetry Focus StatementsSam Jon100% (1)

- Unit 22 Lo2 Production BookletDocument29 pagesUnit 22 Lo2 Production Bookletapi-265014579Pas encore d'évaluation

- A.AN - THE Karta PracyDocument2 pagesA.AN - THE Karta PracyJeremi WasilewskiPas encore d'évaluation

- Vocal Technique 6 Slides - PGDocument31 pagesVocal Technique 6 Slides - PGJorge Lopez100% (1)

- B1 Quiz 2Document2 pagesB1 Quiz 2Назар КуликPas encore d'évaluation

- Company List by DinDocument216 pagesCompany List by DinDheerajOmprasadPas encore d'évaluation

- EFT W3 Types of TourismDocument19 pagesEFT W3 Types of TourismAndik GigihPas encore d'évaluation

- Movie ReviewDocument8 pagesMovie Reviewapi-314128207Pas encore d'évaluation

- Ayushi PDFDocument61 pagesAyushi PDFayushi kanoujiaPas encore d'évaluation

- Personality Traits BingoDocument5 pagesPersonality Traits BingoCelia Olivia ParedesPas encore d'évaluation

- Interim CatalogueDocument90 pagesInterim CatalogueMorne BotesPas encore d'évaluation

- Programme Final A6Document44 pagesProgramme Final A6Phyllis StephenPas encore d'évaluation

- Getting Started With: Create Your Own Games, Animations, Interactive Stories, and MoreDocument15 pagesGetting Started With: Create Your Own Games, Animations, Interactive Stories, and MorezulfikarPas encore d'évaluation

- Algoritma Tata Laksana Cervical Myofascial Pain Syndrome Dengan ObesitasDocument1 pageAlgoritma Tata Laksana Cervical Myofascial Pain Syndrome Dengan ObesitasEga Jaya100% (1)

- Buyers Guide For MDUDocument18 pagesBuyers Guide For MDUjatinrastogi28Pas encore d'évaluation

- Turkish Infinitives and English Gerunds or Infinitives-SignedDocument20 pagesTurkish Infinitives and English Gerunds or Infinitives-Signedyuksel goknel100% (2)

- (Suite 7) : Silvius Leopold WeissDocument19 pages(Suite 7) : Silvius Leopold Weissfabrigene0% (1)

- Universal Studios Fanfare Arranged by Trey MickelsonDocument3 pagesUniversal Studios Fanfare Arranged by Trey MickelsonVitor AlexandrePas encore d'évaluation

- Weichai Wp6g125e23Document64 pagesWeichai Wp6g125e23Maria PazPas encore d'évaluation

- Dark AcademiaDocument2 pagesDark AcademiaEloise Dorothy Patiño100% (1)

- Sf1uwfjuu - Medical Image Distribution, Networks, and CommunicationsDocument17 pagesSf1uwfjuu - Medical Image Distribution, Networks, and Communicationsivanne zaidePas encore d'évaluation