Académique Documents

Professionnel Documents

Culture Documents

CS-2 WPS

Transféré par

Carlos SanchezDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CS-2 WPS

Transféré par

Carlos SanchezDroits d'auteur :

Formats disponibles

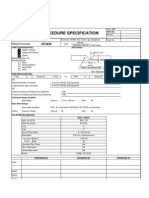

WELDING PROCEDURE SPECIFICATION

Welding Procedure Specification No. FERMI CS-2 _ Date 1/8/2008___

Revision No._1*changed joint root gap Date_ 01/16/08 ______________ Supporting PQR No.(s) FERMI CS-2

Welding Processes 1) SMAW Type 1) Manual

2)_______________________________________________ Type 2) _________________________________

(Manual, Auto, Semi)

JOINTS (QW-402)

Joint Design Double “V” Backing: Yes X No

Backing Material (Type) Root: Base Metal Remainder: Filler metal

Retainer: Yes_____________ No Type: Non-Metallic______________ Metallic (non-fusing)______________

DETAILS *

BASE METALS (QW-403)

P No. 1 Group 1 To P No. 1 Group 1

Specification Type and Grade SA 105 to SA 105

To Specification Type and Grade

OR

Chemical Analysis and Mech. Properties___________________________________________________________________________

To Chemical Analysis and Mech. Properties________________________________________________________________________

Thickness Range: PROCESS 1 PROCESS 2

Base Metal Groove.3/16-2.25 Fillet unl Groove__________ illet____________

Deposited Weld Metal Groove 3/16-2.25 Fillet unl. Groove__________ Fillet____________

Pipe Diameter Range Groove 2 7/8 min Fillet unl. Groove__________ Fillet____________

FILLER METALS (QW-404) PROCESS 1 PROCESS 2

Specification No. (SFA) 5.1

AWS No. (Class) E7018

F-No. 4

A-No. 1

Size of Filler Metals 3/32, 1/8, 5/32, 3/16__________

Deposited Weld Metal Thickness Range Groove 3/16-2.25 Fillet 2.25 max Groove__________ Fillet__________

________________________________________________________________________

Electrode-Flux (Class) N/A

Flux Trade Name N/A

Consumable Insert None

EACH BASE METAL-FILLER METAL COMBINATION SHOULD BE RECORDED INDIVIDUALLY

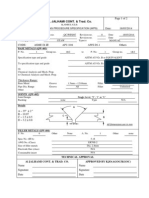

WELDING PROCEDURE SPECIFICATION

FERMI CS-2

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Positions of Groove 1G Temperature Range None

Welding Progression: Up n/a Down____________ Time Range

Positions of Fillet N/A Other_____________________________________________

PREHEAT (QW-408) GAS (QW-408)

o

Preheat Temperature Minimum 32 F Percent Composition

Interpass Temperature Maximum Not Measured Gas(es) Mixture Flow Rate

Preheat Maintenance Shielding N/A

Minimum Temperature for Welding 32oF Trailing N/A

Backing N/A

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC Direct Polarity Reverse Characteristics:

AMPS (Range) See Chart Volts (Range) See Chart

Tungsten Electrode Size and Type N/A

Mode of Metal Transfer for GMAW N/A

Electrode Wire Feed Speed Range N/A

TECHNIQUE (QW-410)

String or Weave Bead String or weave. Weave not to exceed 1/8 wide

Orifice or Gas Cup Size N/A

Initial Interpass Cleaning (Brushing, Grinding, etc.) Grind flame cut 1/16 minimum. Wire brush with steel brushes between passes.

Grinding is allowed between passes.

Method of Back Gouging Arc Gouge and grind or grinding alone to clean metal

Oscillation N/A

Contact Tube to Work Distance N/A

Multiple or Single Pass (per side) Multipass

Multiple or Single Electrodes Single

Travel Speed (Range) As Required

Peening None

Other

Filler Metal Current

Weld Type Amp. Volt Travel Speed Other

Layers Processes Class Diameter Polarity Range Range Range (Power Source)

1-5 SMAW E7018 3/32 DCRP 70-100 18-20

Bal. SMAW E7018 1/8 DCRP 100-140 19-23

E7018 5/32 DCRP 120-200 20-24

Vous aimerez peut-être aussi

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Ami-003 WPSDocument2 pagesAmi-003 WPSBenjamin BrownPas encore d'évaluation

- Plates ASTM-A240 Gr 304LDocument6 pagesPlates ASTM-A240 Gr 304Labhishek198327Pas encore d'évaluation

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- WPSDocument2 pagesWPSJuli Agus50% (2)

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- QW-482 WPS FormatDocument2 pagesQW-482 WPS FormatMardeOpamen100% (1)

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamPas encore d'évaluation

- WPS Sa 335 P91 PipeDocument3 pagesWPS Sa 335 P91 Pipecsankarananth50% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- 1 12 1Document7 pages1 12 1Chandrasekhar SonarPas encore d'évaluation

- Sample WPS For SSDocument2 pagesSample WPS For SSSachin S. SalunkhePas encore d'évaluation

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationDocument6 pagesEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasPas encore d'évaluation

- WELDING PROCEDURE AND QUALIFICATION RECORDSDocument4 pagesWELDING PROCEDURE AND QUALIFICATION RECORDSETSPas encore d'évaluation

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- Suggested Weldin Lr. VijDocument4 pagesSuggested Weldin Lr. Vijmallik017100% (2)

- WPS FormatDocument2 pagesWPS FormatAmit SarkarPas encore d'évaluation

- QW 482Document2 pagesQW 482MuchamadAsyhariPas encore d'évaluation

- Valero Aruba Refinery Welding Procedure Specification: For Insert PatchesDocument3 pagesValero Aruba Refinery Welding Procedure Specification: For Insert PatchesRaymond de WeeverPas encore d'évaluation

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónPas encore d'évaluation

- Mobil Oil Corporation Welding Procedure Specification: G. F. Letter MOC-109P 11/18/82 MOC-109P 0 11/18/82 Smaw ManualDocument2 pagesMobil Oil Corporation Welding Procedure Specification: G. F. Letter MOC-109P 11/18/82 MOC-109P 0 11/18/82 Smaw ManualRaymond de WeeverPas encore d'évaluation

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanPas encore d'évaluation

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Automatic, Manual, Machine, or Semi-Auto.Document10 pagesAutomatic, Manual, Machine, or Semi-Auto.ChE_MattPas encore d'évaluation

- WPS 204 NewDocument6 pagesWPS 204 Newarockiyathass100% (1)

- WPSDocument3 pagesWPSDhanush NairPas encore d'évaluation

- WPS Indosol 001 (ASME) RDocument2 pagesWPS Indosol 001 (ASME) RDoni HardiPas encore d'évaluation

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadPas encore d'évaluation

- WPS Format PDFDocument2 pagesWPS Format PDFHimansu Sekhar JenaPas encore d'évaluation

- 1035 03Document2 pages1035 03Anuj ShahiPas encore d'évaluation

- Fermi Lab Orbital Welding ProcedureDocument2 pagesFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- PQR Group V-Asme (WI74)Document7 pagesPQR Group V-Asme (WI74)Gusrizam DanelPas encore d'évaluation

- WPS Gtaw) - 47Document2 pagesWPS Gtaw) - 47Dharmendra BhardwajPas encore d'évaluation

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananPas encore d'évaluation

- Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchDocument4 pagesWelding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchaPas encore d'évaluation

- Des QC 8505 Ab 08Document3 pagesDes QC 8505 Ab 08Touseef RafiquePas encore d'évaluation

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenPas encore d'évaluation

- Wps FormatDocument2 pagesWps FormatParminder SinghPas encore d'évaluation

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26Pas encore d'évaluation

- Proposed Welding Procedure Specification FormatDocument2 pagesProposed Welding Procedure Specification FormatAli MoghiPas encore d'évaluation

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline Sungahid100% (2)

- Groove DesignDocument4 pagesGroove DesignElizabeth SpencePas encore d'évaluation

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS)Ravelo Jeisson100% (2)

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1Pas encore d'évaluation

- Hard Facing OverlayDocument2 pagesHard Facing OverlayAmanSharmaPas encore d'évaluation

- BK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldDocument2 pagesBK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldHarkesh RajputPas encore d'évaluation

- Design Guidelines for Surface Mount TechnologyD'EverandDesign Guidelines for Surface Mount TechnologyÉvaluation : 5 sur 5 étoiles5/5 (1)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985D'EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Pas encore d'évaluation

- Which Process?: A Guide to the Selection of Welding and Related ProcessesD'EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesPas encore d'évaluation

- Pipeline and Energy Plant Piping: Design and TechnologyD'EverandPipeline and Energy Plant Piping: Design and TechnologyÉvaluation : 5 sur 5 étoiles5/5 (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Broch Waterproofing Plan 508Document11 pagesBroch Waterproofing Plan 508mysterious_westPas encore d'évaluation

- Rust On RebarDocument4 pagesRust On Rebargwrmsa100% (21)

- The Site Inspection and Compliance TeamDocument7 pagesThe Site Inspection and Compliance Teammysterious_westPas encore d'évaluation

- 9 C 960524 F 2524 D 690 BDocument9 pages9 C 960524 F 2524 D 690 BYashika Bhathiya JayasinghePas encore d'évaluation

- Writing Work Method Statement Plain English Guidelines 0231Document24 pagesWriting Work Method Statement Plain English Guidelines 0231Vincent TengPas encore d'évaluation

- 9 C 960524 F 2524 D 690 BDocument9 pages9 C 960524 F 2524 D 690 BYashika Bhathiya JayasinghePas encore d'évaluation

- 2980245C HVAC Handbook 2013 WebDocument35 pages2980245C HVAC Handbook 2013 WebomeshchemPas encore d'évaluation

- Rust On RebarDocument4 pagesRust On Rebargwrmsa100% (21)

- Clad PQRDocument5 pagesClad PQRRinshadPas encore d'évaluation

- Clad PQRDocument5 pagesClad PQRRinshadPas encore d'évaluation

- TawjeheDocument3 pagesTawjehemysterious_westPas encore d'évaluation

- Canon EF 24 105mm F 4 L Is USM LensDocument0 pageCanon EF 24 105mm F 4 L Is USM Lensmysterious_westPas encore d'évaluation

- SteelWise Tolerances IllustratedDocument6 pagesSteelWise Tolerances IllustratedkenetjPas encore d'évaluation

- EOS 5D Mark III-p8594-c3945-en GB-1336592114Document28 pagesEOS 5D Mark III-p8594-c3945-en GB-1336592114mysterious_westPas encore d'évaluation

- ABS Shipbuilding and Repair Standards - Pub87 - SRQS - GuideDocument44 pagesABS Shipbuilding and Repair Standards - Pub87 - SRQS - Guidesamnortan100% (1)

- Welding DefectsDocument12 pagesWelding DefectsMOhammad AzHarPas encore d'évaluation

- Stills or Movies, Capture Your Story.: You CanDocument9 pagesStills or Movies, Capture Your Story.: You Canmysterious_westPas encore d'évaluation

- WPS for welding procedure FERMI CS-2Document2 pagesWPS for welding procedure FERMI CS-2mysterious_westPas encore d'évaluation

- Slip Critical BoltsDocument7 pagesSlip Critical BoltsvPas encore d'évaluation

- SteelWise Tolerances IllustratedDocument6 pagesSteelWise Tolerances IllustratedkenetjPas encore d'évaluation

- Stills or Movies, Capture Your Story.: You CanDocument9 pagesStills or Movies, Capture Your Story.: You Canmysterious_westPas encore d'évaluation