Académique Documents

Professionnel Documents

Culture Documents

Starter Clutch Inspection

Transféré par

r_chulinCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Starter Clutch Inspection

Transféré par

r_chulinDroits d'auteur :

Formats disponibles

A HILLIARD CORPORATION

FIELD INSPECTION PROCEDURE

FOR OVERRUNNING CLUTCH

FOR HYDRAULIC STARTER DRIVE

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 1 of 9

1.0 FOREWARD

Hilliard recommends periodic inspection and overhaul of the special overrunning clutch.

Inspection is recommended every 8,000 to 10,000 hours of turbine operation without

clutch condition monitoring**. An inspection overhaul should be performed every 20,000

to 25,000 hours of turbine operation. It is recommended that the unit be returned to the

factory for inspection overhaul and test. However the following instructions will serve as

a guide for inspection of the unit on site. Refer to the clutch drive assembly and outline

drawings.

(** Clutch Condition Monitoring a speed probe and/or RTD is used on the overrunning

clutch to monitor clutch. Speed probe and/or RTD is incorporated into turbine control

system with appropriate alarms and shutdowns.

2.0 INSPECTION PROCEDURE

Attachment A is a Clutch Inspection/Return Questionnaire. This form should be filled out

completely at the time of inspection/return.

See the section on Seal Inspection for recommended inspection procedure prior to

removing clutch from the engine.

2.1 PIPING AND CONNECTIONS:

Disconnect all piping and remove the clutch drive from engine and move the clutch to a

clean work area. The strainer in the oil drain line should be inspected for any signs of

debris. The presence of debris may be an indication of internal problems with the clutch

drive.

Note: In removing the oil inlet/outlet piping from the clutch drive it is important to look for

any indications of debris in the clutch ports and piping.

2.2 CLUTCH DRIVE CASING:

Visually inspect the external appearance of the clutch drive. The paint should be

inspected for blistering and discoloration due to heat deterioration. These could be signs

of improper oil flow in the clutch resulting in clutch damage.

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 2 of 9

2.3 SHAFT ROTATION CHECK:

Once the clutch drive has been moved to a clean work area the clutch drive input (motor

side figure 1) and output (AGB side figure 2) shafts should be rotated by hand in

both directions. The shafts should spin freely. No bearing roughness should be evident.

A dial indicator can be used to check for excessive radial and axial movement of the

shafts. Radial movement larger than .005 (0.13 mm) and axial movement greater than

.060 (1.52mm) may be an indication of internal problems with the clutch drive.

Figure 1 Figure 2

Clutch Drive Input Shaft Clutch Drive Output Shaft

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 3 of 9

2.4 SHAFT ENGAGEMENT CHECK:

Hold the input shaft of the clutch drive and rotate the output shaft by hand. The output

shaft should rotate freely in the counter-clockwise direction (see figure 3) as viewed from

the AGB side. Any roughness encountered may indicate internal clutch problems. The

output shaft should engage when rotated by hand in the clockwise direction. Failure of

the clutch to engage indicates internal clutch problems.

Hold the output shaft of the clutch drive and rotate the input shaft by hand. The input

shaft should engage in the clockwise direction (see figure 4) as viewed from the

hydraulic motor side. Failure of the clutch to engage indicates internal clutch problems.

Figure 3 Figure 4

Free rotation of the output shaft in the Engaging direction of the input shaft in the

CCW direction. (Input shaft held tight) CW direction. (Output shaft held tight)

NOTE:

On model 6601-01-118-D, directions of rotation are opposite what is listed above. I.e.

the output side should rotate freely in the CLOCKWISE direction when the input shaft if

held, and engage when rotated COUNTERCLOCKWISE.

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 4 of 9

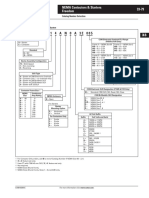

2.5 SPLINE CHECK:

The input (figure 5) and output (figure 6) spline should be checked for damage. Splines

should be checked for fretting, wear, corrosion, and impact damage. Damage to the

splines may indicate installation problems that could result in internal clutch damage.

Figure 5 Figure 6

Internal input spline. External output spline.

(Hydraulic motor side) (AGB side)

2.6 CASING CONNECTIONS:

Refer to figure 7. Inspect casing for signs of oil leakage from any of the connections (oil

inlet, purge air, oil drain, and optional connections). There should be no evidence of

leakage form these connections.

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 5 of 9

2.7 ORIFICE INSPECTION:

Refer to figure 7. The oil orifice (figure 7a) and the purge air orifice (figure 7b) should be

inspected. Both orifices should be free of any signs of dirt or obstruction. Obstruction to

the orifice will result in abnormal oil flow in the clutch drive and result in clutch damage.

Purge Air

Optional

Sight Gage

Oil Inlet

Oil Drain

Figure 7

Clutch connections

Figure 7a Figure 7b

Oil Inlet orifice Purge air orifice

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 6 of 9

2.8 SEAL INSPECTION:

Prior to removal (while turbine is running) the AGB and motor side cavity drain should be

inspected for leaking oil. If oil flow is present, measurements should be taken to

determine the rate.

Check the input (hydraulic motor side) seal for signs of oil leakage (figure 8). There

should be no signs of oil in the cavity between the clutch drive and hydraulic motor. The

presence of oil is an indication of failure of the lip seal.

The output (AGB side) of the clutch drive can be equipped with two types of seals: Lip

seal (figure 9) or labyrinth seal (figure 10). Check the seal for signs of oil leakage. The

lip seal design should show no signs of leakage. Visually inspect the lip seal for tearing

and signs of high temperatures. The labyrinth seal design can display signs of minimal

leakage. Inspect the labyrinth for missing material.

Figure 8 Figure 9

Input end Output End Lip Seal

Figure 10

Output End Labyrinth Seal

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 7 of 9

2.9 OIL SUMP:

View the inside of the clutch housing through the oil drain connection. Inspect oil sump

for debris such as metal particles. Inspect the inside of the casing for signs of oil coking.

Figure 11

Oil Drain Connection

3.0 CONCLUSION:

Hilliard recommends that the starter be removed from service if any of the above

inspection items indicate possible internal clutch problems. It is recommended that the

unit be returned to the factory for complete inspection and over haul of the clutch drive

assembly.

4.0 INSTALLATION:

Follow installation instruction for appropriate hydraulic drive model.

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 8 of 9

CLUTCH DRIVE INSPECTION/RETURN QUESTIONAIRE

Company:_____________________ Site Location:_____________________

Hilliard Model No.:_______________

Unit Serial No.:__________________

Engine Manufacturer/Model:____________________________________________

Equipment Being Driven:______________________________________________

Serial No. In Service Date:___/___/___ Purchase Date: ___/___/___

No. of Operating Hours after Serial No. Installation:________________________

No. of Cranks after Serial No. Installation:_______________________________

Reason for Inspection/Return: ______10,000 Hour Inspection

______Oil Leakage

______Clutch Lock-up

______Other (describe)____________________

ATTACHMENT A

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION AND SUCH INFORMATION MAY NOT BE

DISCLOSED TO OTHERS OR USED FOR ANY PURPOSE WITHOUT WRITTEN PERMISSION FROM THE

HILLIARD CORP. COPYRIGHT 2003 THE HILLIARD CORPORTION, ALL RIGHTS RESERVED.

Revision Level: A 6600-7F-143-A

Date of Revision: February 15, 2005 Issue Date: April 25, 2003

Page 9 of 9

Vous aimerez peut-être aussi

- Service Bulletin: V2500-ENG-79-0108Document11 pagesService Bulletin: V2500-ENG-79-0108duythienddtPas encore d'évaluation

- LT SL Lm5000-Ind-03-001 r0Document2 pagesLT SL Lm5000-Ind-03-001 r0Alejandro Romero BallestasPas encore d'évaluation

- Nigeria Gas Specification - GACNDocument1 pageNigeria Gas Specification - GACNOlusegun OyebanjiPas encore d'évaluation

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocument4 pagesList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZPas encore d'évaluation

- Datasheet lm500 PDFDocument2 pagesDatasheet lm500 PDFvcharlesPas encore d'évaluation

- Maintenance Manual For GPB30Document65 pagesMaintenance Manual For GPB30Aceel FitchPas encore d'évaluation

- Gas Turbine Lm5000 Operations ManualDocument4 pagesGas Turbine Lm5000 Operations ManualMuhammad Ilham RiyadiPas encore d'évaluation

- V2500 Eng 72 0660Document43 pagesV2500 Eng 72 0660sujit50% (2)

- B767 Freighter Mechanical DifferencesDocument176 pagesB767 Freighter Mechanical DifferencesHéber Luiz Zunarelli MartinsPas encore d'évaluation

- MECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Document4 pagesMECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Camila MayorgaPas encore d'évaluation

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Water Wash System DescriptionDocument2 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Water Wash System DescriptionAndrea Cupello100% (1)

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Hydraulic Start System DescriptionDocument5 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Hydraulic Start System DescriptionAndrea Cupello100% (1)

- Valves 9600 BOM Customer.4Document2 pagesValves 9600 BOM Customer.4Al Gusto Tequeños y MasPas encore d'évaluation

- F646 CompleteSampleDocument36 pagesF646 CompleteSampleraj4523Pas encore d'évaluation

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionDocument4 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionAndrea CupelloPas encore d'évaluation

- 1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesDocument8 pages1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesArgenomSaubiPas encore d'évaluation

- Technical Paper - SGT400 ASME 2002Document9 pagesTechnical Paper - SGT400 ASME 2002usaid saifullahPas encore d'évaluation

- 4 - Inspection - Interval - Extension W5015DA PDFDocument12 pages4 - Inspection - Interval - Extension W5015DA PDFEDBPas encore d'évaluation

- Nerador BUENODocument340 pagesNerador BUENORonald arcila caraucanPas encore d'évaluation

- Compressor C65Document1 pageCompressor C65frdnPas encore d'évaluation

- Product Manual 40183 (Revision K, 8/2018) : EML100 ActuatorDocument24 pagesProduct Manual 40183 (Revision K, 8/2018) : EML100 Actuatoracil stop100% (1)

- Gas Turbine Compressor IssuesDocument9 pagesGas Turbine Compressor IssuesJJPas encore d'évaluation

- CCJ3 Air Inlet Filters FinalDocument7 pagesCCJ3 Air Inlet Filters FinalDomingo Pinto100% (1)

- Solar Centaur 40 DSDocument2 pagesSolar Centaur 40 DSabuahnfPas encore d'évaluation

- المواد المرمزة والمطلوبة ترميزها بملف واحدDocument247 pagesالمواد المرمزة والمطلوبة ترميزها بملف واحدMahdi HassanPas encore d'évaluation

- LM 2500 PlusDocument2 pagesLM 2500 Plusalexandr_popov_2Pas encore d'évaluation

- IOPTC PLC4TurbineDocument4 pagesIOPTC PLC4TurbineStarlightbrightPas encore d'évaluation

- Lm2500 ManifoldDocument2 pagesLm2500 ManifoldDenis JimenezPas encore d'évaluation

- VBR Strategic Spare Parts Planning-2Document18 pagesVBR Strategic Spare Parts Planning-2jampukPas encore d'évaluation

- Data Sheet RVO 07011Document2 pagesData Sheet RVO 07011cvg ertd100% (1)

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air SystemmiladPas encore d'évaluation

- 825 Series Product Overview & General DataDocument30 pages825 Series Product Overview & General Datamauricio cañonPas encore d'évaluation

- Actuador Limitorque MX y QXDocument6 pagesActuador Limitorque MX y QXManuel FernizaPas encore d'évaluation

- SBLM2500 Ind 217Document5 pagesSBLM2500 Ind 217Daniil SerovPas encore d'évaluation

- Spare Part WS2&R2Document24 pagesSpare Part WS2&R2Anonymous Mm6ffYPas encore d'évaluation

- LT SL Lm2500-Ind-00-001 r0Document1 pageLT SL Lm2500-Ind-00-001 r0sithulibraPas encore d'évaluation

- Igv 7eaDocument2 pagesIgv 7eaSamir BenabdallahPas encore d'évaluation

- Lampiran 1 Standar InspectionDocument7 pagesLampiran 1 Standar InspectionFitra SPas encore d'évaluation

- Gek105060 File0060 PDFDocument12 pagesGek105060 File0060 PDFHelton OliveiraPas encore d'évaluation

- Spare Parts For Gas Turbine F9E For Instrument & Control - RehabDocument1 pageSpare Parts For Gas Turbine F9E For Instrument & Control - RehabhakimsalimiPas encore d'évaluation

- TTDsistema DonaldsonDocument12 pagesTTDsistema Donaldsonforo0% (1)

- F Class Inspection Maintenance Fact SheetDocument1 pageF Class Inspection Maintenance Fact SheetMartinPas encore d'évaluation

- Banco de Baterias SBM 184-2Document48 pagesBanco de Baterias SBM 184-2jorge28csPas encore d'évaluation

- DDocument18 pagesDMahmoud El-abdPas encore d'évaluation

- Uk-Standard Asme Bladder AccumulatorDocument3 pagesUk-Standard Asme Bladder AccumulatorRamin SoadPas encore d'évaluation

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet RittirutPas encore d'évaluation

- Manual Mto 1203 - 5,6 MWDocument98 pagesManual Mto 1203 - 5,6 MWAgustin BaratcabalPas encore d'évaluation

- G761 CDS6673 D Moog Trubleshooting ManualDocument4 pagesG761 CDS6673 D Moog Trubleshooting ManualRamesh BabuPas encore d'évaluation

- SB LM2500 Ind 312 R1Document7 pagesSB LM2500 Ind 312 R1Daniil SerovPas encore d'évaluation

- RX3i 1Document7 pagesRX3i 1cachuco1234Pas encore d'évaluation

- Equipment Definition: Component LiteratureDocument5 pagesEquipment Definition: Component LiteratureAbbas AkbarPas encore d'évaluation

- MicroNet MN 50 Controller Installation Instructions F-26617 - 07.10Document16 pagesMicroNet MN 50 Controller Installation Instructions F-26617 - 07.10Sergio HitcarPas encore d'évaluation

- SBLM2500 IND 174rev1Document7 pagesSBLM2500 IND 174rev1Daniil SerovPas encore d'évaluation

- Amozesh Gas TurbineDocument114 pagesAmozesh Gas Turbinearmin heidari100% (1)

- Constant Settable Droop Design Standard of GEDocument4 pagesConstant Settable Droop Design Standard of GEPraveen PeethambaranPas encore d'évaluation

- 2UEB000131 REV D Spare Part Manual WebDocument52 pages2UEB000131 REV D Spare Part Manual WebMariem Kammoun100% (1)

- Device Summary EnglishDocument14 pagesDevice Summary Englishكاظم محمدPas encore d'évaluation

- Saturn - Russia 12MW Gas TurbineDocument22 pagesSaturn - Russia 12MW Gas Turbinedndudc100% (1)

- 6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFDocument1 page6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFLenin RamonPas encore d'évaluation

- Spare Parts List For LM Gas Turbines SeriesDocument3 pagesSpare Parts List For LM Gas Turbines SeriesMohamed Bin IerousPas encore d'évaluation

- SB643 Crankcase Nut Safety Wire Inspection PDFDocument14 pagesSB643 Crankcase Nut Safety Wire Inspection PDFMARIA AUXILIADORA ESPINOZA TANDAZOPas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Product CatalogDocument3 888 pagesProduct Catalogr_chulinPas encore d'évaluation

- Links Mundo de Ingles de DisneyDocument1 pageLinks Mundo de Ingles de Disneyr_chulin100% (1)

- Turbine Controls Limited Leicester, United KingdomDocument8 pagesTurbine Controls Limited Leicester, United Kingdomr_chulinPas encore d'évaluation

- January 2015: Lunes Tuesday Wednesday Thursday Friday Saturday SundayDocument12 pagesJanuary 2015: Lunes Tuesday Wednesday Thursday Friday Saturday SundayCatherine M Borquez CHPas encore d'évaluation

- Corona Rotate Lec MachDocument2 pagesCorona Rotate Lec Machr_chulinPas encore d'évaluation

- January 2015: Lunes Tuesday Wednesday Thursday Friday Saturday SundayDocument12 pagesJanuary 2015: Lunes Tuesday Wednesday Thursday Friday Saturday SundayCatherine M Borquez CHPas encore d'évaluation

- Onis Brochure GB 2015Document16 pagesOnis Brochure GB 2015r_chulinPas encore d'évaluation

- Corporate Presentation OCT 2014Document70 pagesCorporate Presentation OCT 2014r_chulinPas encore d'évaluation

- Onis Brochure GB 2015Document16 pagesOnis Brochure GB 2015r_chulinPas encore d'évaluation

- Corporate Presentation OCT 2014Document70 pagesCorporate Presentation OCT 2014r_chulinPas encore d'évaluation

- Pinnacle Flo, InC.Document16 pagesPinnacle Flo, InC.r_chulinPas encore d'évaluation

- Glosario Español-Ingles de Palabras y Expresiones Utiles (05 09 2012)Document143 pagesGlosario Español-Ingles de Palabras y Expresiones Utiles (05 09 2012)20santiago11Pas encore d'évaluation

- Waukesha Bearings - Thrust Bearings For ESPs - A4Document2 pagesWaukesha Bearings - Thrust Bearings For ESPs - A4r_chulinPas encore d'évaluation

- Arran CadorDocument4 pagesArran Cadorr_chulinPas encore d'évaluation

- GB 2457 ADocument16 pagesGB 2457 Ar_chulinPas encore d'évaluation

- Turbine Controls Limited Leicester, United KingdomDocument8 pagesTurbine Controls Limited Leicester, United Kingdomr_chulinPas encore d'évaluation

- Gas Liquid Separation Technology PDFDocument24 pagesGas Liquid Separation Technology PDFr_chulinPas encore d'évaluation

- Saturno 20Document80 pagesSaturno 20r_chulin100% (1)

- Meritor Axle MT 40 143MA NDocument55 pagesMeritor Axle MT 40 143MA Nford62bPas encore d'évaluation

- Chapter 5Document64 pagesChapter 5pintu13Pas encore d'évaluation

- Greenhouse Effect - WikipediaDocument7 pagesGreenhouse Effect - WikipediaalexokoriePas encore d'évaluation

- Astm A182 f22 Class 3Document3 pagesAstm A182 f22 Class 3VõTạPas encore d'évaluation

- Brige Lauching Cap 1 PDFDocument16 pagesBrige Lauching Cap 1 PDFAnonymous VkzquW39Pas encore d'évaluation

- SAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKDocument73 pagesSAI GLOBAL, Index House, Ascot, Berks, SL5 7EU, UKtracyhopyPas encore d'évaluation

- Assimilable Organic Carbon Formation During Ultraviolet - Hydrogen Peroxide Advanced Oxidation Treatment of Surface WaterDocument207 pagesAssimilable Organic Carbon Formation During Ultraviolet - Hydrogen Peroxide Advanced Oxidation Treatment of Surface WaterMonicaRossetimPas encore d'évaluation

- Valve PagesDocument5 pagesValve PagesJoyal ThomasPas encore d'évaluation

- ACI 232.1 Use of Pozzolans in ConcreteDocument24 pagesACI 232.1 Use of Pozzolans in ConcreteSree Nivas100% (1)

- IJEART02714Document6 pagesIJEART02714erpublicationPas encore d'évaluation

- Test PDFDocument6 pagesTest PDFDr. L. Bhanuprakash Reddy100% (1)

- Plastic Roads: Presented By-Akash Chakole (First Year MBBS, GMC Nagpur)Document27 pagesPlastic Roads: Presented By-Akash Chakole (First Year MBBS, GMC Nagpur)Chandu CKPas encore d'évaluation

- Inspection & Maintenance of Dams: Dam Safety GuidelinesDocument79 pagesInspection & Maintenance of Dams: Dam Safety Guidelinesvishu1909100% (1)

- Ms2N Synchronous Servomotors: Project Planning ManualDocument408 pagesMs2N Synchronous Servomotors: Project Planning ManualGuido PerezPas encore d'évaluation

- Greenbrier Europe Freight Wagon Catalogue (2018)Document188 pagesGreenbrier Europe Freight Wagon Catalogue (2018)Aaron Hore100% (2)

- DP Misc Wnt5 x86-32 ChangelogDocument5 pagesDP Misc Wnt5 x86-32 ChangelogBrandal KalocyPas encore d'évaluation

- T Turboexpander Alternative FuelingDocument24 pagesT Turboexpander Alternative FuelingJose Luis Rodriguez LópezPas encore d'évaluation

- ProxTransSysOpDocument41 pagesProxTransSysOpNorman MoralesPas encore d'évaluation

- Liebherr Enquiry Data Sheet Hydraulic Cylinders EsDocument2 pagesLiebherr Enquiry Data Sheet Hydraulic Cylinders EsDaniel Castillo PeñaPas encore d'évaluation

- Infobasic ProgrammingDocument10 pagesInfobasic Programmingjaved73bdPas encore d'évaluation

- Exp-3 (Speed Control by V-F MethodDocument4 pagesExp-3 (Speed Control by V-F MethoduttamPas encore d'évaluation

- West Beverly Homes-BoqDocument6 pagesWest Beverly Homes-BoqERICPas encore d'évaluation

- IC Course Guide BookDocument5 pagesIC Course Guide BookAddisu AyelePas encore d'évaluation

- Uahel NoticeDocument2 pagesUahel NoticeChiranjivi ChudharyPas encore d'évaluation

- Seb 1242-Soil Mechanics II SuppDocument2 pagesSeb 1242-Soil Mechanics II Suppcharler kinyuajPas encore d'évaluation

- Ntu IgpDocument6 pagesNtu IgpRobertCallaghanPas encore d'évaluation

- Operation Manual - A Table of ContentsDocument506 pagesOperation Manual - A Table of ContentsErvin PregPas encore d'évaluation

- Detailed Lesson Plan in IctDocument4 pagesDetailed Lesson Plan in IctJai AidamusPas encore d'évaluation