Académique Documents

Professionnel Documents

Culture Documents

Physical and Rheological Characteristics of Liquid Natural Rubber Modified

Transféré par

Barnali DebnathTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Physical and Rheological Characteristics of Liquid Natural Rubber Modified

Transféré par

Barnali DebnathDroits d'auteur :

Formats disponibles

Physical and Rheological Characteristics of Liquid Natural

Rubber Modified Bitumen

N. RADHAKRISHNAN NAIR, 1 N. M. MATHEW, 1 SABU THOMAS, 2 PRABHA CHATTERJEE, 3 M. A. SIDDIQUI 4

1

Rubber Research Institute of India, Kottayam 686 009, India

2

School of Chemical Sciences, Mahatma Gandhi University, Priyadarsini Hills P.O., Kottayam 686 650, India

3

Indian Institute of Chemical Technology, Hyderabad 500 007, India

4

Cochin Refineries Ltd., Ambalamugal 682 302, India

Received 31 October 1996; accepted 12 September 1997

ABSTRACT: Polymer modification of commercially available bitumen has been at-

tempted by the incorporation of liquid natural rubber (LNR) of medium viscosity. Both

soft and blown bitumens have been studied. Physical and rheological characteristics

of the samples were investigated. Improvement in physical properties such as shear

strength and ductility in the case of blown bitumen and resistance to flow in the case

of soft bitumen were observed. It was also found that as a result of addition of LNR,

the activation energy of flow increases in the case of soft bitumen and decreases in

blown bitumen. q 1998 John Wiley & Sons, Inc. J Appl Polym Sci 68: 5361, 1998

Key words: liquid natural rubber; bitumen; rheology; polymer modification

INTRODUCTION ing, etc. Aging is the hardening of bitumen over

time and temperature. Polymers have been found

Bitumen by itself has become inadequate in many to reduce hardening and moisture susceptibility

applications due to the changed perception on and improve the adhesion of the binder to aggre-

paving binders in recent years. Traffic factors gates. Use of rubber by a French bitumen com-

have increased with respect to both load and vol- pany for laying pavements as early as in 1902 has

ume. Higher pressures are employed for tires, been documented.1 Most bitumen binders were

and higher costs demand construction of thinner classified by a viscosity-graded system. The vis-

pavements. Hence, modification of bitumen by dif- cosities at 60 and 1357C are important to the ap-

ferent techniques has become a topic of interest. plication and use of bitumen binders. The viscos-

Modification using polymers is a widening area ity-graded system has been replaced by the pene-

due to the viscoelastic contribution of the polymer tration system in the 1960s.2 A needle is loaded

to the bitumen properties. The changes are aimed with either 100 g (257C) or 200 g (47C). The depth

at addressing major problems, such as high-tem- of penetration is measured and expressed in one

perature permanent deformation, load-associated hundredth of a centimeter. The penetration at 47C

fatigue cracking, low-temperature thermal crack- is used to describe the low-temperature properties

of bitumen binders. Other tests used to character-

ize bitumen binders are ring and ball softening

Correspondence to: N. Radhakrishnan Nair.

Journal of Applied Polymer Science, Vol. 68, 53 61 ( 1998 )

point (ASTM D113).

q 1998 John Wiley & Sons, Inc. CCC 0021-8995/98 / 010053-09 There are a large variety of polymers currently

53

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

54 RADHAKRISHNAN NAIR ET AL.

being used in the bitumen paving industry. The from scrap rubber that is considered inferior for

purpose of modification depends on the problem many structural and engineering applications.

it addresses or the type of bitumen mixture to be

modified. The extent of improvement may, how-

ever, be quite different, depending on the source

MATERIALS AND METHODS

of bitumen, the effect of origin of the petroleum,

etc. Modification with rubber improves the prop-

erties of bitumen. The effect on the bitumen is Bitumen

expressed most clearly in the toughness/tenacity Bitumen, the residue left over after the distilla-

test. Blown bitumen, also known under the name tion of petroleum, characteristically contains very

of mineral rubber, is generally not considered high molecular polar species, called asphaltenes,

suitable for blending with rubber.3 soluble in a wide range of solvents. Asphalt is

Modification with rubber permits bitumen, used extensively for paving and waterproofing.

even of low quality, to acquire attractive proper- Crude oils from different sources contain different

ties. This makes it possible to lay down suitable amounts of asphalt, and their properties vary. As-

road paving, using relatively inexpensive bitu- phalt produced for the paving industry is nor-

men. Natural rubber (NR) is a potential candi- mally a blended product so as to achieve the speci-

date among various polymers for blending with fications. Asphalt is converted into a harder prod-

bitumen. Because of its photosynthetic origin and uct by air contact at 2002707C. The modification

renewability, it is ecologically friendly. It is one involves dehydrogenation and polymerization re-

of the polymers with which bitumen modification actions. The heteroatoms like sulfur reacts prefer-

has been successfully carried out. NR is obtained entially with oxygen leaving less polar sub-

as latex from the plant Hevea braziliensis. Addi- stances, which increases incompatibility. Indus-

tion of NR to bitumen has been attempted in dif- trial emulsions prepared from blown bitumen

ferent ways. One of the earliest methods is the have applications outside the road building indus-

addition of latex, stabilized with alkali, to molten try. Casein, gelatin, blood albumin, etc., are used

bitumen under vigorous stirring. Water evapo- as peptizing agents in these cases. The emulsions

rates, and NR becomes mixed with the bitumen.4 have found a wide variety of applications, such as

Addition of rubber in powder form has also been surface coatings for asphalt pavements, for built-

attempted. These include ground vulcanized rub- up roofs, and for other weatherproof coverings.

ber powder from the rejections of various dry rub- For the present study, normal and blown bitu-

ber and latex products.5 mens were used. The soft bitumen, 80100 grade,

NR latex is the most effective additive to bitu- was a product of Cochin Refineries Ltd., Cochin.

men and the cheapest, but difficulties arise due Blown bitumen was of grade 5, on the penetration

to its water content. Vulcanized and lightly vul- scale, and was supplied by Bituminex Ltd., Amba-

canized powders are convenient to use. Smoked lamugal. It was prepared by removing the volatile

sheet or crepe rubber can be used by masticating fragments, such as gas oils, by heating to 300 to

and dispersing in fluxing oil. The present investi- 3507C and also by the application of vacuum for

gation is on the addition of liquid natural rubber 34 h.

(LNR) for improving the properties of bitumen

binders and encapsulating materials. The addi-

tion of polymer in this form is simple as a result Liquid Natural Rubber

of the dry nature of LNR, due to which problems The LNR was of medium viscosity grade with a

of frothing and fall in temperature associated with Brookfield viscosity of 1,60,000 mPa s. It was pre-

latex addition are eliminated. LNR also readily pared starting from ISNR-5 by thermal depoly-

mixes with bitumen. This method can be easily merization technique, as suggested by Claramma

adopted as one of the unit operations in a petro- et al.6 Its production involves size reduction of the

chemical complex to manufacture modified bitu- NR molecules by the combined action of mechani-

men. Stabilizing agents incorporated into the la- cal, chemical, and thermal energies. NR was first

tex can also be dispensed with. Further, NR in masticated on a two-roll mill incorporating peptiz-

the latex form is a premium grade, whereas de- ing agents and then heated in a depolymerizer at

polymerized rubber can be prepared starting even an elevated temperature to produce LNR.

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

CHARACTERISTICS OF LNR-MODIFIED BITUMEN 55

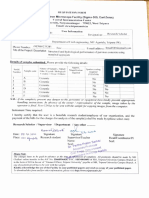

Table I Formulation of Blends Softening Point

Percent This test was carried out as per IS 1205-1958. A

Sample Percent of of Blown Liquid Natural ring and ball softening point apparatus was used.

No. Bitumen Bitumen Rubber

B0 100 Nil Nil

Ductility

B5 95 Nil 5 Ductility of the samples was determined ac-

B10 90 Nil 10 cording to the test specified in IS 1208-1958. The

B20 80 Nil 20 method consists of measuring the distance in cen-

B30 70 Nil 30

timeters to which a briquette specimen of the ma-

BB0 Nil 100 Nil terial elongates before breaking, when its two

BB5 Nil 95 5 ends are pulled apart at a rate of 50 mm/min at

BB10 Nil 90 10 27 { 0.57C.

BB20 Nil 80 20

BB30 Nil 70 30

Penetration

Standard penetration tests on the samples were

Preparation of Samples conducted as per IS 1204-1958 in a container hav-

ing a depth greater than 15 mm. A needle thor-

LNR was incorporated into bitumen by melt oughly cleaned with benzene was used. The test

blending. The bitumen was first heated to an eas- was conducted at 257C, applying a 100-g load for

ily flowable consistency, and LNR was added 5 s, and the depth was measured and expressed

slowly under stirring and was homogenized prop- in 1/100th of a centimeter.

erly. Formulations of the blends are given in Ta-

ble I.

RESULTS AND DISCUSSION

Viscosity Measurements Liquid Natural Rubber

For the measurement of viscosity of the soft bitu- For the modification of bitumen, a LNR sample

men samples, a Haake rotational viscometer was in the medium viscosity range was chosen in order

used. The sensor system used was MV1. The vis- to have a compromise between the blending pro-

cosity of the blown bitumen samples was mea- cess and the strength characteristics. The physi-

sured on a capillary rheometer attached to a cal strength of NR decreases on depolymerization,

Zwick UTM. Viscosities were measured over a and the low-molecular-weight samples exhibit

range of temperature and shear rate to study the more viscosity rather than elastic properties. On

flow behavior on the modification of bitumen with the other hand, more viscous LNR samples are

LNR. difficult to mix with other liquids, so the optimum

molecular weight of LNR has to be chosen to opti-

mize between processability and properties of the

Lap Shear Test resultant compounds.8 The molecular weight de-

tails of the LNR sample are given in Table II.

The lap shear test was used to determine the room Molecular weights (MV n and MV w ) were determined

temperature cohesive strength of modified bitu-

mens and also to study the thickening process.7

Two aluminum strips of 1 mm thick were over- Table II Properties of LNR

lapped by 2.5 cm and firmly bonded together with

a drop of molten bitumen. The test pieces were Property Measurement

held in position with alligator clips until ready for

testing. The samples were bonded together and MV n 5,057

tested after 24 h of conditioning. The test was MV w 33,360

MV w/MV n 6,598

carried out on a Zwick Universal Testing Ma-

Brookfield viscosity (mPa s) 160,000

chine. The speed of the crosshead was 5 mm/min.

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

56 RADHAKRISHNAN NAIR ET AL.

by steric exclusion chromatography (SEC) in THF Table IV Shear Stress at Different Shear Rates

on a Waters 1500 instrument fitted with 5 mm for Soft Bitumen

styragel columns (0.7 1 120 cm) of different pore

sizes (100, 31 500, and 1000 A) calibrated with Shear Rate

(s01) 4 8 150 300

polystyrene standards.

A wide range in the elution time of the polymer B0 35 49 142

molecules indicated a broad molecular weight dis- B5 40 61 117

tribution. This is also evidenced from the polydis- B10 32.5 42 63 119

persity index (MV w /MV n ). B20 5.3 67 100 233

B30 24 40 67 175

Softening Point

The observations are given in Table III. The soft-

presence of solvents remaining from distillation

ening points were found to be in the range of 29

or purposely added. Mechanical resistance to de-

537C for soft, and 96 1107C for blown bitumen.

formation and mode of failure are influenced by

The increasing trend in the softening tempera-

the low-molecular-weight materials. With much

tures with an increase in the LNR content up to

of the low-molecular-weight substances being re-

10%, and a subsequent fall on further addition,

moved during the process of preparation, the

were observed. The softening point was the

blown bitumen appeared less ductile. The pres-

highest on addition of 10% of LNR. The softening

ence of NR was found to make the soft bitumen

point is a measure of the capability of the

sample less ductile. In the case of blown bitumen,

material to resist cold flow even at higher ambi-

a slight improvement was noticed with 10% of

ents. Hence, the addition of LNR increases the

LNR (Table IV).

service temperature of bitumen for different ap-

plications.

Penetration

Ductility The penetration tests on the samples were done

at 257C, and the values are given in Table III. The

Ductility of the samples measured at 277C on the

values were found to increase with the increased

soft bitumen samples showed a continuously de-

loading of LNR. Penetration measurement gives

creasing trend with increasing concentration of

an indication about the resistance of the material

LNR. Ductility is the ability of a material to yield

to indentation. The test revealed that the samples

to tensile strains without collapsing. Bitumen is

were rendered softer by LNR at 257C. In the case

a thermoplastic material and is often subjected to

of BB0 and BB5, no difference was noticed; but,

variable mechanical reactions. The properties are

at higher loadings, the increasing trend prevailed.

affected by the conditions of loading and by the

Thus, LNR was found to impart relative softening

of the samples at low temperatures and reduction

Table III Tests on Bitumen as per BIS

in temperature susceptibility at high tempera-

tures.

Sample Softening Ductility Penetration

No. Point (7C) (at 277C/cm) Index at 257C

Lap Shear

B0 43 150 80 Figure 1 shows the results of lap shear test. In

B5 44 92 85 both the soft and hard samples, an appreciable

B10 53 26 119

increase was noticed in the force for shear failure

B20 39 25 260

B30 29 25 340

on incorporation of LNR. Peak strength was no-

ticed around 10% of LNR to soft bitumen and 5%

BB0 96 3 5 of LNR to hard bitumen. The shear test in the

BB5 107 3 5 present case has led to breakage within the mate-

BB10 110 4 18 rial rather than pealing of the bitumen from the

BB20 105 3 30

substrate, and so the values directly reflect the

BB30 100 3 40

strength of the samples. Any sign of cleavage of

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

CHARACTERISTICS OF LNR-MODIFIED BITUMEN 57

shear rates, a shear stress stabilizing trend was

noticed as being most prominent for BB0, a Bin-

gham plastic behavior of bitumen. The compound

with 30% LNR appeared closely to Newtonian be-

havior. Mildly dilatant behavior was observed at

a high shear rate. Soft material could be checked

only in the lower shear rate, whereas blown mate-

rial was tested at higher shear rates. The soft

material showed bingam plastic behavior because

the curves do not originate from zero. It is also

observed with the addition of LNR. Initially, the

viscosity increases, but later, it decreases. This

may be attributed to the presence of low-molecu-

lar-weight constituents present in soft bitumen,

which makes the rubber particle swell, thereby

increasing the viscosity. Once the rubber content

is above a minimum amount, this effect is not

observed, and rubber obviously act as flow pro-

moter. The mild dilatent behavior may be due to

the interaction of rubber with the low-molecular-

weight material in the soft bitumen. However,

this effect is not significant because of the lower

Figure 1 Influence of LNR on shear strength. shear rate range explored.

In the case of blown bitumen, the interaction

of low-molecular-weight material with rubber is

the material from the substrate was not visible. not observed as expected since the blowing pro-

The blown bitumen samples were brittle, and, cess has removed the low-molecular-weight con-

therefore, a slow test speed of 5 mm/min was used. stituents. LNR acts as a flow promoter in this case

also. Initially, at lower shear rates, a Newtonian

behavior is seen, but, later on, the viscosity de-

Viscosity Studies creases with the amount of LNR and shear rate.

When the rubber content is low, a different behav-

Effect of Shear Rate

ior is seen, which may be due to the interaction

Table IV shows the shear stress values of the soft of the rubber with residual low-molecular-weight

bitumen samples at different shear rates mea- material present in the blown bitumen.

sured at 1007C. In general, the viscosity values

showed an increasing trend with increasing shear

rate. Effect of Temperature

Among different compounds, at low shear Temperature dependence of the soft bitumen sam-

rates, the values were in a close range, but, at

ples at an arbitrary shear rate, 15 s 01 is presented

high shear rates, B10 showed the highest shear

stress value. Table V shows the corresponding

values for the blown bitumen samples. Shear Table V Shear Stress at Different Shear Rates

stress increased with increasing shear rates. for Blown Bitumen

The rate was high initially and decreased grad-

ually. The downward trend in the shear stress Shear Rate

with shear rate curve may be attributed to the (s01) 10 35 85 165 835

pseudoplastic nature of the composite. An upward

trend in the shear stress values of BB5 over the BB0 1.12 3.59 5.96 7.15 7.30

other samples showed that the addition of small BB5 1.34 2.71 4.23 9.45 7.45

quantities of LNR increased the resistance to flow. BB10 0.66 1.94 3.38 5.97 5.97

BB20 0.30 0.96 1.99 4.48 4.48

Addition of larger quantities of LNR caused a de-

BB30 0.17 0.40 0.50 0.90 1.74

cline in the stress values. Particularly, at high

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

58 RADHAKRISHNAN NAIR ET AL.

Table VI Influence of Temperature on Shear Table VIII Activation Energy of Flow

Stress (Soft Bitumen)

Sample Activation Energy (kcal/mol)

Temperature

(7C) B0 B5 B10 B20 B30 B0 24.75

B10 25.79

90 155 185 217 270 83 B30 36.38

100 49 76 63 100 67

BB0 2892

110 32 35 48 90 59

BB10 2573

120 18 22 26 48 32

BB30 1438

in Table VI. All samples showed a decrease of

where E is the activation energy of flow, and T is

viscosity with an increase in temperature. At all

the absolute temperature. The activation energy

temperatures, the shear stress values were the

values are given in Table VIII.

highest for the sample containing 20% LNR. The

For soft bitumen, the activation energy in-

general trend was that the shear stress increased

creases with increasing LNR content. The obser-

from B0 to B20 and then declined. For the sample

vation in the case of blown bitumen was the oppo-

BB30, with 30% LNR, a steady decrease in shear

site. With increasing LNR content, the activation

stress with an increase in temperature was no-

energy was found to decrease considerably. Bitu-

ticed, but the stress values were the lowest. For

men is a complex mixture consisting of asphal-

samples with a low LNR content, the rate of re-

tenes predominant in high-molecular-weight frac-

duction in viscosity was higher at low tempera-

tions surrounded by substances of several chemi-

tures. Table VII shows the corresponding values

cal structures with varying functionalities from

for blown bitumen samples.

polar aromatic to nonpolar aliphatic.9 Due to its

A gradual decrease in the stress values was

presence in soft bitumen, swelling of the added

observed for the samples on increasing LNR con-

polymer is likely to cause an increase in viscosity.

tent. The rate of reduction in the low-temperature

With the blown bitumen samples during the pro-

region was found to decrease with increasing

cess of blowing or oxidation, most of the low-mo-

LNR/bitumen ratio. Higher quantities of LNR

lecular-weight fractions are removed. As a result,

rendered the bitumen too soft at low tempera-

the influence of the polymer might be less.

tures.

Evaluation of Superposition Shift Factor

Effect of Temperature on Viscosity

The time temperature superposition principle ap-

Viscosity on logarithmic scale versus reciprocal of

plies to bitumen samples. The experimental flow

temperatures was plotted on the absolute scale.

curves for log tw versus gw were plotted at temper-

Activation energy of flow was calculated from the

atures of 70, 80, 90, and 1007C for the compounds

slope of the lines. The viscosity at higher tempera-

BB0, BB5, and BB10. The method of superposi-

ture obey the Arrhenius equation, as follows:

tion has been done by arbitrarily choosing 807C

as the reference temperature. The values of super-

h Ae 0E / RT (1)

position shift factors were obtained by choosing

log shear rates 2, 2.5, 3, and 3.5 s 01 on the refer-

ence temperature flow curve and shifting the cor-

Table VII Influence of Temperature on Shear

Stress (Blown Bitumen) responding points (constant shear rate) on the

flow curve for other temperatures to coincide with

Temperature the shear stresses. The values of the shift factors

(7C) BB0 BB5 BB10 BB20 BB30 were calculated from the following equation:

70 11.4 10.49 8.56 2.31 0.90 aT tw (ref)/ t (T ) (constant gw ) (2)

80 4.33 4.45 4.98 1.19 0.80

90 3.38 2.48 1.19 0.67 0.40

where aT is the shift factor, tw (ref) is the shear

100 1.73 1.94 0.80 0.59 0.39

stress at reference temperature, and t (T ) (con-

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

CHARACTERISTICS OF LNR-MODIFIED BITUMEN 59

Figure 2 aT versus temperature. Figure 4 Effect of LNR on shear stress at 1007C (B).

stant gw ) is the shear stress at a particular tem-

perature. The average values of shift factors were superposition method is a useful tool in predicting

calculated 10 and are plotted in Figure 2. Using the viscosities of polymer melts at any required

the appropriate average value of the shift factors, temperature by determining the viscosity at a ref-

a master flow curve at 907C was constructed and erence temperature.

is given in Figure 3. The shear rate temperature

Effect of LNR Content

Figure 4 represents the change in the shear stress

of soft bitumen compounds with a LNR content.

The values were recorded at 1007C. At lower load-

ings and lower shear rates, the values were al-

most steady. In general, the stress values showed

an increasing trend with increasing loading of

LNR. Dissolution of LNR in the low-molecular-

weight components of bitumen can cause thick-

ening and, hence, lead to high shear rates needed

to maintain the same flow rate. Figure 5 shows

the corresponding parameters for blown bitumen.

In this case, a general decrease in shear force was

observed with increasing LNR content. This may

be due to the volumetric contribution of LNR,

which has a significantly low viscosity than blown

bitumen at 1007C. Figures 6 and 7 give the influ-

ence of LNR loading on viscosity at different tem-

peratures of the soft and blown bitumen respec-

tively. As is evident from Figure 6, the viscosity

of the compounds increased up to 20% loading and

Figure 3 Super position master curve. subsequently decreased. The increase in viscosity

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

60 RADHAKRISHNAN NAIR ET AL.

Figure 5 Effect of LNR on shear stress at 1007C (BB). Figure 7 Effect of LNR on viscosity at 16.6 s 01 (BB).

could be attributed to the dissolution of LNR and existence of free LNR in the mixture. On the other

the subsequent thickening. A decrease in viscosity hand, a gradual decreasing trend in viscosity was

above 20% may be due to limiting solubility and observed with increasing LNR content in blown

bitumen irrespective of the loading. Considerable

reduction was noticed above 10%.

SUMMARY AND CONCLUSIONS

Polymer modification of bitumen was studied us-

ing LNR obtained by the depolymerization of nat-

ural rubber. LNR of molecular weight ( Mw )

around 33,000 was used. The effect of LNR on soft

bitumen as well as blown bitumen was studied.

An increase in softening point was observed by

the addition of 5 to 10% (w/w) of LNR. Ductility

decreased in the case of soft bitumen, while some

improvements were noticed in the case of blown

bitumen at 10% loading. Penetration values con-

sistently decreased in both the cases. Resistance

to shear increased on the addition of LNR and

was maximum in the region of 5 to 10% (w/w) of

rubber. It was also observed that shear stress for

all the bitumen samples increased with increas-

ing shear rate. For soft bitumen, the temperature

dependence on viscosity was prominent up to

1007C and subsequently marginal. Maximum vis-

Figure 6 Effect of LNR on viscosity at 15 s 01 (B). cosity resulted on addition of 20% LNR. Activa-

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

CHARACTERISTICS OF LNR-MODIFIED BITUMEN 61

tion energy of flow of soft bitumen increased, 4. J. Shim Tom, K. A. Kennedy, M. R. Pigott, and R. T.

while that of blown bitumen decreased on addi- Woodhams, Rubb. Chem. Technol., 53, 88 (1980).

tion of LNR. 5. R. D. Thompson, MRPRA Technical Bulletin No. 9,

1962.

6. N. M. Claramma, N. Radhakrishnan Nair, and

N. M. Mathew, Ind. J. Nat. Rubber Res., 4(1), 1

(1992).

REFERENCES 7. L. Ciplijauskas, M. R. Piggott, and R. T. Wood-

hams, in Ions in Polymers, Advances in Chemistry

Series 187, Adi Eisenberg, Ed., American Chemical

1. D. C. Thompson, in Bitumenous Materials: Asphalt, Society, Washington, DC, p. 171 (1980).

Tars and Pitches, Vol. 1 A. J. Hosberg, Ed., Robert 8. I. R. Gelling and P. G. Mente, Current Development

Kreiger Publishing Co., 1979. in Product Manufacture, RRIM, Kuala Lumpur,

2. V. P. Puzinauskas, Properties of Asphalt Cements, 1993, pp. 193205.

Research Rep 80, Asphalt Institute, Nov. 1980. 9. R. S. Winnifold and R. A. Witherspoon, Fundamen-

3. L. H. Lewandowski, Rubb. Chem. Technol., 67, 447 tal Aspects of Petroleum Chemistry, 1967, p. 261.

(1994). 10. J. S. Anand, Int. Plast. Eng. Technol., 1, 25 (1994).

8E20 / 8E20$$4834 02-03-98 08:34:00 polaas W: Poly Applied 4834

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Importance of Nonlinear Anisotropic Modeling of Granular Base For Predicting Maximum Viscoelastic Pavement Responses Under Moving Vehicular LoadingDocument10 pagesImportance of Nonlinear Anisotropic Modeling of Granular Base For Predicting Maximum Viscoelastic Pavement Responses Under Moving Vehicular LoadingBarnali DebnathPas encore d'évaluation

- Finite-Element Model For Urban Pavement Rutting: Analysis of Pavement Rehabilitation MethodsDocument5 pagesFinite-Element Model For Urban Pavement Rutting: Analysis of Pavement Rehabilitation MethodsBarnali DebnathPas encore d'évaluation

- Record: Strength and Defortnation Characteristics of Pavetnent SectionsDocument112 pagesRecord: Strength and Defortnation Characteristics of Pavetnent SectionsBarnali DebnathPas encore d'évaluation

- Liu 2015Document11 pagesLiu 2015Barnali DebnathPas encore d'évaluation

- Effects of Nonuniform Tire Contact Stresses On Pavement ResponseDocument7 pagesEffects of Nonuniform Tire Contact Stresses On Pavement ResponseBarnali DebnathPas encore d'évaluation

- Automation in Construction: SciencedirectDocument10 pagesAutomation in Construction: SciencedirectBarnali DebnathPas encore d'évaluation

- Nonlinear Pavement Foundation Modeling For Three-Dimensional Finite-Element Analysis of Flexible PavementsDocument14 pagesNonlinear Pavement Foundation Modeling For Three-Dimensional Finite-Element Analysis of Flexible PavementsBarnali DebnathPas encore d'évaluation

- Parameter Identification and Analysis of A Slab Track System Using 3D ABAQUS ProgramDocument10 pagesParameter Identification and Analysis of A Slab Track System Using 3D ABAQUS ProgramBarnali DebnathPas encore d'évaluation

- Three-Dimensional Pavement Analysis With Nonlinear Subgrade MaterialsDocument8 pagesThree-Dimensional Pavement Analysis With Nonlinear Subgrade MaterialsBarnali DebnathPas encore d'évaluation

- Address For. Correspondence/ 1billing:: Scanning Microscope (Sigma-300Document1 pageAddress For. Correspondence/ 1billing:: Scanning Microscope (Sigma-300Barnali DebnathPas encore d'évaluation

- Aggregate-Based Modulus of Elasticity For Florida Concrete: ArticleDocument10 pagesAggregate-Based Modulus of Elasticity For Florida Concrete: ArticleBarnali DebnathPas encore d'évaluation

- Is 383 1970 PDFDocument24 pagesIs 383 1970 PDFPartha SarkarPas encore d'évaluation

- Use of Over Burnt Brick Aggregates in Pavement Construction: September 2006Document9 pagesUse of Over Burnt Brick Aggregates in Pavement Construction: September 2006Barnali DebnathPas encore d'évaluation

- 777-JBMS-Original Article-1819-1-10-20201207Document15 pages777-JBMS-Original Article-1819-1-10-20201207Barnali DebnathPas encore d'évaluation

- Permeability Predictions For Sand-Clogged Portland Cement Pervious Concrete Pavement SystemsDocument8 pagesPermeability Predictions For Sand-Clogged Portland Cement Pervious Concrete Pavement SystemsBarnali DebnathPas encore d'évaluation

- Reclaimed Asphalt Pavement As A Substitution To Natural Coarse Aggregate For The Production of Sustainable Pervious Concrete Pavement MixesDocument11 pagesReclaimed Asphalt Pavement As A Substitution To Natural Coarse Aggregate For The Production of Sustainable Pervious Concrete Pavement MixesBarnali DebnathPas encore d'évaluation

- Suresha2010 Article EffectOfAggregateGradationsOnP PDFDocument13 pagesSuresha2010 Article EffectOfAggregateGradationsOnP PDFBarnali DebnathPas encore d'évaluation

- Is 8112 1989Document17 pagesIs 8112 1989biswashree10Pas encore d'évaluation

- Is - 08112 - 2013Document14 pagesIs - 08112 - 2013sangitaghaisasPas encore d'évaluation

- Effect of Moisture On Asphalt Concrete Paving Mixtures: Standard Test Method ForDocument5 pagesEffect of Moisture On Asphalt Concrete Paving Mixtures: Standard Test Method ForBarnali DebnathPas encore d'évaluation

- NumericalAnalysisonSeismicResponseofMulti StoriesReinforcedConcreteBuildingsUndertheEffectofInfiniteBoundaryofSoil StructureInteractionDocument7 pagesNumericalAnalysisonSeismicResponseofMulti StoriesReinforcedConcreteBuildingsUndertheEffectofInfiniteBoundaryofSoil StructureInteractionBarnali DebnathPas encore d'évaluation

- Li2012 PDFDocument12 pagesLi2012 PDFBarnali DebnathPas encore d'évaluation

- For Effect: Lineal-Path Function Heterogeneous MaterialsDocument10 pagesFor Effect: Lineal-Path Function Heterogeneous MaterialsBarnali DebnathPas encore d'évaluation

- Lu1992 LPF IIDocument8 pagesLu1992 LPF IIBarnali DebnathPas encore d'évaluation

- Documents - Tips Adhesive and Cohesive Properties of Asphalt Aggregate Systems Subjected ToDocument23 pagesDocuments - Tips Adhesive and Cohesive Properties of Asphalt Aggregate Systems Subjected ToBarnali DebnathPas encore d'évaluation

- Sumanasooriya - Pore Structure Features and Proportioning - As PublishedDocument11 pagesSumanasooriya - Pore Structure Features and Proportioning - As PublishedBarnali DebnathPas encore d'évaluation

- Explorer LicenseDocument23 pagesExplorer LicensepingbackPas encore d'évaluation

- Aimil Offer 07082017Document6 pagesAimil Offer 07082017Barnali DebnathPas encore d'évaluation

- Effect of Using Waste Material As Filler in Bituminous Mix DesignDocument7 pagesEffect of Using Waste Material As Filler in Bituminous Mix DesignAboalmaail AlaminPas encore d'évaluation

- CAD CAM TemporaryDocument9 pagesCAD CAM TemporarySaleh AlmohammadPas encore d'évaluation

- MSDS CR2032 DBV 2017Document5 pagesMSDS CR2032 DBV 2017Humberto GarciaPas encore d'évaluation

- DLL - Science 5 - Q1 - W5Document9 pagesDLL - Science 5 - Q1 - W5HEVER TORRESPas encore d'évaluation

- Engineering & Design Handbook EditedDocument140 pagesEngineering & Design Handbook EditedHermanPas encore d'évaluation

- 13C05 Economic StudyDocument110 pages13C05 Economic StudyRenzo Cadag MacasilPas encore d'évaluation

- 1sbc100122c0202 ch04Document47 pages1sbc100122c0202 ch04mathankumar1980Pas encore d'évaluation

- Gas Chromatography ReferencesDocument18 pagesGas Chromatography ReferencesrizkiekanandaPas encore d'évaluation

- Receipe 80Document20 pagesReceipe 80hisaj4uPas encore d'évaluation

- Wright 93Document335 pagesWright 93Catanescu Alexandru-LaurentiuPas encore d'évaluation

- Sika PDS E Plastomix TPIDocument2 pagesSika PDS E Plastomix TPIlwin_oo2435100% (1)

- Monthly ReportDocument15 pagesMonthly ReportMae Ann GonzalesPas encore d'évaluation

- Materials in Orthodontics / Orthodontic Courses by Indian Dental AcademyDocument124 pagesMaterials in Orthodontics / Orthodontic Courses by Indian Dental Academyindian dental academy100% (2)

- Process Optimization - Cost ReductionDocument9 pagesProcess Optimization - Cost ReductionBhaskar (भास्कर) Agate (आगटे)Pas encore d'évaluation

- The Detection of Alpha Prime in Duplex Stainless SteelsDocument10 pagesThe Detection of Alpha Prime in Duplex Stainless Steelsapply19842371Pas encore d'évaluation

- Sample - Summary Transmission DT19Document2 pagesSample - Summary Transmission DT19Deni IndraPas encore d'évaluation

- Presentation1. AEC GeoTech LANDFILLDocument22 pagesPresentation1. AEC GeoTech LANDFILLAyan BorgohainPas encore d'évaluation

- A Review - Use of Clay in The Manufacture of Lightweight AggregateDocument8 pagesA Review - Use of Clay in The Manufacture of Lightweight AggregatesergioPas encore d'évaluation

- Pre-Hole Diameter Optimization in High Speed Drilling Considering Machining CostDocument2 pagesPre-Hole Diameter Optimization in High Speed Drilling Considering Machining CostSreejith S NairPas encore d'évaluation

- Fbabf JNBJFNNN NkinDocument56 pagesFbabf JNBJFNNN NkinMajor ShobhitPas encore d'évaluation

- Refrigeration Practical 1Document6 pagesRefrigeration Practical 1SamPas encore d'évaluation

- Mustekham 2 Coal HSLM 400-23Document207 pagesMustekham 2 Coal HSLM 400-23babarPas encore d'évaluation

- ME - 32021 Materials and Geometry of Cutting ToolsDocument27 pagesME - 32021 Materials and Geometry of Cutting ToolsWILYPas encore d'évaluation

- Product Mix of HavellsDocument4 pagesProduct Mix of HavellsPriyanka Agarwal100% (1)

- Toyotomi FF V30TDocument24 pagesToyotomi FF V30TEnzoPas encore d'évaluation

- 092116Document7 pages092116kupaloidPas encore d'évaluation

- Types of BoilerDocument8 pagesTypes of Boilerjay0% (1)

- 1:24 Scale Residential Architectural Modeling: What You NeedDocument10 pages1:24 Scale Residential Architectural Modeling: What You NeedNerinel Coronado100% (1)

- Kep Dirjen Migas No-84-K 38 DJM 1998Document21 pagesKep Dirjen Migas No-84-K 38 DJM 1998NyomanPas encore d'évaluation

- Keyhole Welding With CF-TIG (Cathode Focussed GTA) : Research PaperDocument7 pagesKeyhole Welding With CF-TIG (Cathode Focussed GTA) : Research PaperMatija BušićPas encore d'évaluation

- Homemade Field 0effect Transistor98Document18 pagesHomemade Field 0effect Transistor98Ali IjazPas encore d'évaluation