Académique Documents

Professionnel Documents

Culture Documents

DMRC - Ground Anchors - Info Sheet PDF

Transféré par

VardhanDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DMRC - Ground Anchors - Info Sheet PDF

Transféré par

VardhanDroits d'auteur :

Formats disponibles

U-Turn Retrievable Ground Anchors

to Support 19m Deep Excavation at

Proposed New Delhi Station for

Airport Metro Express Line

Introduction

Delhi Metro Rail Corporation (DMRC), in a plan to

connect the Indira Gandhi International (IGI) Airport with

the New Delhi Railway Station, is constructing an

Multi-level exclusive Airport Metro Express Line (AMEL). As part of

car park

these plans, an underground metro station and multi level

car park are being constructed (see Figure 1 for plan

layout), which requires 11m to 19m deep excavation. The

Station designed retaining wall system for the proposed

Building excavation includes soldier pile wall in combination with

60T U-turn retrievable ground anchors at different levels.

Site Stratigraphy

Figure 1: Layout showing Station Building The site in general consists of silty clays with depth of

and Multi-Level Car Park Locations

bedrock varying from as low as 5m to as deep as 20m.

The rock can be described as weathered to hard

Quartzite.

U-Turn Retrievable Ground Anchors

U-turn retrievable ground anchors facilitate the removal of

anchor strands after construction of the intended wall. The

steel strands are covered with PVC jacket, turned over a

U-loop (U-turn saddle) at the bottom and connected to a

Figure 2: Typical Fabricated

reinforcement rod (see Figure 2). In addition, each loop

Ground Anchor has grout pipe for secondary grouting. The ground anchor

is fabricated with combination of three individual U-loops

(i.e. 6-strands at the top) of different lengths, spaced at

Client predetermined design spacing.

Delhi Metro Rail Corporation (DMRC)

Main Contractor

The steel strands used are 12.7mm diameter (7ply) LRPC

Alpine-Samsung-HCC JV conforming to IS: 14268 1995, which has an ultimate

tensile strength (breaking load) of about 187kN. The

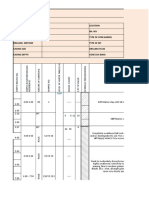

Project details anchors are designed to withstand a working load of 60T

Site No. 76/187/714

350 nos. of U-turn Retrievable Ground Anchors and a test load of 66T (i.e. 1.1 times the working load).

Execution Period Site Execution

August 2008 to January 2009

In general, site execution constitutes of drilling, grouting

Executing Branch and stressing followed by retrieval of anchor strands at

Keller Ground Engineering (I) Pvt Ltd. later stage.

305, Best Arcade Building,

Plot-3, Sector-12, Dwarka, Drilling

New Delhi, India, PIN 110075.

Tel. +91 11 2803 2268 Hydraulically operated Casagrande C6 rotary drill rig is

Fax +91 11 2803 2280 used for drilling a cased hole of 152mm diameter to a

E-mail info@kellerindia.com length of 22m at an inclination of 30deg with the

www. k ellerf areas t. c om horizontal. The hole is then washed for the possible loose

material / slush at the bottom of the drilled hole. Figure 3

represents typical drilling in progress.

U-Turn Retrievable Ground Anchors

to Support 19m Deep Excavation at

Proposed New Delhi Station for

Airport Metro Express Line

Grouting

The grout mix is prepared with appropriate water-cement

ratio and special additives to inject the primary grout

followed by secondary grouting under high pressure. The

high pressure secondary grouting enables the fracturing

of primary grout and formation of effective bond with the

surrounding soil.

As part of the systematic quality control on site, operating

parameters (such as flow rate, grout pressure and total

grout volume) for each grouting stage is recorded. Typical

schematic cross-section showing the two levels of ground

Figure 3: Drilling in Progress using anchors is shown in Figure 4.

Casagrande C6 Rig

Stressing

The installed anchors are then allowed for curing period of

about 10 days. In the mean while, the waler beam is fixed

to enable the stressing activity at the end of curing period.

After the curing period, the each and every anchor is

tested / stressed using a multi strand pre-stressing jack of

requisite capacity. This multi strand pre-stressing jack

enables to stress all loops / strands together.

The anchors are stressed to a test load of 66T (i.e. 1.1

times the working load of 60T). After stressing to a test

load, the anchors are locked at the pre-determined design

Figure 4: Typical Cross-Section of the locking loads. Figure 5 and 6 represents typical stressing

Ground Anchors activity in progress and overall site view, respectively.

Figure 5: Anchor Stressing in Progress Figure 6: Overall Site View with Completed Anchors

Vous aimerez peut-être aussi

- IKEA Industry Energy Saving Handbook PDFDocument133 pagesIKEA Industry Energy Saving Handbook PDFMARIUS GOVOREANUPas encore d'évaluation

- Metro InstrumentationDocument20 pagesMetro Instrumentationdafo407Pas encore d'évaluation

- Bangkok Cable Tunnel 230KVDocument10 pagesBangkok Cable Tunnel 230KVSivagnana SundaramPas encore d'évaluation

- SAP - Understanding LockboxDocument7 pagesSAP - Understanding LockboxFederico GavuzzoPas encore d'évaluation

- Navigating You Through Tax Technology Solutions - SAPDocument87 pagesNavigating You Through Tax Technology Solutions - SAPmustafa100% (2)

- Practical Applications of Ground ImprovementDocument12 pagesPractical Applications of Ground ImprovementprashantlingayatPas encore d'évaluation

- Is 2911 (PART 1, Sec-1) 2010 Design & Construction of Pile FoundationDocument22 pagesIs 2911 (PART 1, Sec-1) 2010 Design & Construction of Pile FoundationNaga Manikanta Tatikonda100% (1)

- Performance of Soil Nailed Wall and Ground Anchor As Retaining Structure For A Drill & Blast Tunnel PortalDocument4 pagesPerformance of Soil Nailed Wall and Ground Anchor As Retaining Structure For A Drill & Blast Tunnel PortalGabby KenPas encore d'évaluation

- Mid-Tunnel Underground Docking of The TBMsDocument10 pagesMid-Tunnel Underground Docking of The TBMsfreezefreezePas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- Jack-In Pile On Weathered GraniteDocument4 pagesJack-In Pile On Weathered GraniteShamsul Bahrin SulaimanPas encore d'évaluation

- Secant Piling Shoring System With Circular ConfigurationDocument6 pagesSecant Piling Shoring System With Circular Configurationsivananda reddy100% (1)

- List of Top French Companies in IndiaDocument11 pagesList of Top French Companies in IndiaPayal Kathiawadi100% (1)

- Radio Navigation QBDocument64 pagesRadio Navigation QBVijay Samuel J100% (3)

- Method Statement For ExcavationDocument2 pagesMethod Statement For ExcavationGkou Dojku100% (1)

- CND Course OutlineDocument26 pagesCND Course OutlinesigmaPas encore d'évaluation

- Deep Foundation Practice - BarrettesDocument9 pagesDeep Foundation Practice - Barrettesssi3k100% (1)

- Ground Improvement Techniques in MalaysiaDocument12 pagesGround Improvement Techniques in MalaysiaAnonymous dlSmlsymHPas encore d'évaluation

- Bank Statement PDFDocument188 pagesBank Statement PDFragaveyndhar maniPas encore d'évaluation

- Geology of UAEDocument12 pagesGeology of UAEVardhanPas encore d'évaluation

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsD'EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsPas encore d'évaluation

- LP-PTG-701002 Inst Spec Rev DDocument79 pagesLP-PTG-701002 Inst Spec Rev DSyahirul AlimPas encore d'évaluation

- Productivity Analysis of Diaphragm Wall Construction in Jurong FormationDocument8 pagesProductivity Analysis of Diaphragm Wall Construction in Jurong FormationAdeLyPas encore d'évaluation

- A Reinforced Soil Mix Wall Cofferdam Supported by High Capacity Removable Soil AnchorsDocument9 pagesA Reinforced Soil Mix Wall Cofferdam Supported by High Capacity Removable Soil AnchorsHüseyin EkiciPas encore d'évaluation

- Manual M250 M370 M400Document222 pagesManual M250 M370 M400Carlos Quispe100% (1)

- Catálogo de Pruebas Estándar IEEE para Transformadores Tipo SecoDocument83 pagesCatálogo de Pruebas Estándar IEEE para Transformadores Tipo SecoBanner Ruano100% (2)

- Soil Nailed Retaining WallDocument4 pagesSoil Nailed Retaining WallB Divya jyothiPas encore d'évaluation

- Ground Anchor DesignDocument4 pagesGround Anchor DesignVardhanPas encore d'évaluation

- Introduction of Bus Rapid Transit (BRT) System in Kathmandu Ring Road.Document7 pagesIntroduction of Bus Rapid Transit (BRT) System in Kathmandu Ring Road.Hemant Tiwari100% (9)

- Black Cotton Soil PaperDocument5 pagesBlack Cotton Soil PaperYu Paing HanPas encore d'évaluation

- Ground Anchors & Compaction Grouting-ICUST 2011Document11 pagesGround Anchors & Compaction Grouting-ICUST 2011suvraPas encore d'évaluation

- Driven NailsDocument10 pagesDriven NailskomalPas encore d'évaluation

- Tower Transmission Foundation Barrette FoundationDocument6 pagesTower Transmission Foundation Barrette FoundationWr ArPas encore d'évaluation

- Sample Design and Installation of Steel Sheet PileDocument8 pagesSample Design and Installation of Steel Sheet PileRenandPas encore d'évaluation

- LNG PAR Modules of Ichthys LNG Project (April 2018) .... !!!!Document5 pagesLNG PAR Modules of Ichthys LNG Project (April 2018) .... !!!!David PierrePas encore d'évaluation

- Six Rows of High Capacity Removable Anchors Support Deep Soil Mix Cofferdam Barley Payne Mcbarron European Conference Amsterdam 1999Document7 pagesSix Rows of High Capacity Removable Anchors Support Deep Soil Mix Cofferdam Barley Payne Mcbarron European Conference Amsterdam 1999Kenny CasillaPas encore d'évaluation

- DFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDocument10 pagesDFI 2016 Innovative Deep Foundation Support Using Ductile Iron Piles PrintDaniel MarínPas encore d'évaluation

- Paper WTC2020 - ID 639 FINAL PDFDocument6 pagesPaper WTC2020 - ID 639 FINAL PDFTayo RobertsPas encore d'évaluation

- Final ZawZawAye CutCoverTunnel SEACETUS2017 20feb17 Ohm RDocument9 pagesFinal ZawZawAye CutCoverTunnel SEACETUS2017 20feb17 Ohm Rzaw69Pas encore d'évaluation

- Unu-Gtp-Sc-19-0206 Drilling in Menengai High Temperature Field - The Experience and LessonsDocument9 pagesUnu-Gtp-Sc-19-0206 Drilling in Menengai High Temperature Field - The Experience and LessonsPrince MubaiwaPas encore d'évaluation

- Prediction and Performances of Short Embedded Cast In-Situ Diaphragm Wall For Deep Excavation in Bangkok Subsoil, 1998Document7 pagesPrediction and Performances of Short Embedded Cast In-Situ Diaphragm Wall For Deep Excavation in Bangkok Subsoil, 1998freezefreezePas encore d'évaluation

- BridgeAbutmentTechnicalPaper Aligarh PKG - 3Document10 pagesBridgeAbutmentTechnicalPaper Aligarh PKG - 3Gajendra BishtPas encore d'évaluation

- Jaydeep WaghDocument54 pagesJaydeep Waghankit kadamPas encore d'évaluation

- 2294-Article Text-4125-1-10-20180102Document6 pages2294-Article Text-4125-1-10-20180102AkshatshuklaPas encore d'évaluation

- Tunnelling in Soft Ground in The UKDocument5 pagesTunnelling in Soft Ground in The UKDavid DufourPas encore d'évaluation

- 2014 Jacquard tc207 Foundations by Prestressing Anchors of The "Villa Mediterranee enDocument5 pages2014 Jacquard tc207 Foundations by Prestressing Anchors of The "Villa Mediterranee enLucas HoodPas encore d'évaluation

- Paper - TopProject - CoulterMartinDocument9 pagesPaper - TopProject - CoulterMartinherdiana_hanifahildaPas encore d'évaluation

- Stal9781614996569 1185Document5 pagesStal9781614996569 1185Vignesh VenkatasubramanianPas encore d'évaluation

- Rock Fissure Grouting in Singapore GraniteDocument6 pagesRock Fissure Grouting in Singapore GraniteShumei ZhouPas encore d'évaluation

- Ground Movement Analysis of Pipe Roof Construction in Soft ClayDocument6 pagesGround Movement Analysis of Pipe Roof Construction in Soft ClayMH Enc Const TrdPas encore d'évaluation

- PermanchDocument5 pagesPermanchSharyn PolleyPas encore d'évaluation

- 7 PDFDocument4 pages7 PDFdineshkumar chockalingamPas encore d'évaluation

- High-Capacity Hoisting at Rondout West Branch Tunnel ProjectDocument9 pagesHigh-Capacity Hoisting at Rondout West Branch Tunnel ProjectneckitoPas encore d'évaluation

- Presentation 151025074120 Lva1 App6892 PDFDocument66 pagesPresentation 151025074120 Lva1 App6892 PDFKap Kolkata100% (1)

- Hydropower Project Summary and Particular ExperienceDocument17 pagesHydropower Project Summary and Particular ExperienceAlbert FaragPas encore d'évaluation

- Soil-Foundation-Superstructure Interaction For The Tallest Tower in The World The Kingdom TowerDocument14 pagesSoil-Foundation-Superstructure Interaction For The Tallest Tower in The World The Kingdom TowerZakaria MahmudPas encore d'évaluation

- Pile Foundations As Settlement Reducer For Large Ms Storage TanksDocument4 pagesPile Foundations As Settlement Reducer For Large Ms Storage Tanksrtwueee fcbcPas encore d'évaluation

- Ground Improvement Techniques For Railway Embankments Malaysia (Published Version)Document12 pagesGround Improvement Techniques For Railway Embankments Malaysia (Published Version)Eric ChanPas encore d'évaluation

- JSCE2017 Suthiwarapirak&EricDocument2 pagesJSCE2017 Suthiwarapirak&Ericeric bargasPas encore d'évaluation

- Installation of Monopiles by Vibrohammers For The Riffgat ProjectDocument14 pagesInstallation of Monopiles by Vibrohammers For The Riffgat ProjectDoThanhTungPas encore d'évaluation

- Study On Rigid Pavement Analysis and DesignDocument11 pagesStudy On Rigid Pavement Analysis and DesignAbdinur Ibrahim AnshurPas encore d'évaluation

- Hulme 2023 Win T316 Tunnelling in AirportDocument13 pagesHulme 2023 Win T316 Tunnelling in AirportnaytunPas encore d'évaluation

- Spillway Execution PDFDocument7 pagesSpillway Execution PDFtonykebbePas encore d'évaluation

- TH 07 12Document10 pagesTH 07 12svs dmrPas encore d'évaluation

- Application of Artificial Ground Freezing Method For Tunnel Construction in Hong Kong - A Construction Case in Harbour Area Treatment Scheme Stage 2ADocument12 pagesApplication of Artificial Ground Freezing Method For Tunnel Construction in Hong Kong - A Construction Case in Harbour Area Treatment Scheme Stage 2ADangol RupeshPas encore d'évaluation

- ICE-Ground Improvment Techniques For Railway EmbankmentsDocument13 pagesICE-Ground Improvment Techniques For Railway EmbankmentsRachel OpiyoPas encore d'évaluation

- GE May 1978 Small Diameter Bored Injection PilesDocument6 pagesGE May 1978 Small Diameter Bored Injection PilesnvmhumgPas encore d'évaluation

- Shaft Design Q-SystemDocument17 pagesShaft Design Q-SystemcoldplatePas encore d'évaluation

- PR174 Hong Kong International AirportDocument2 pagesPR174 Hong Kong International AirportWang MaxPas encore d'évaluation

- Ground Deformations Above A Large Shallow Tunnel EDocument10 pagesGround Deformations Above A Large Shallow Tunnel ECarlos ValdésPas encore d'évaluation

- Longwall Mining at Shallow Depth of Cover in IndiaD'EverandLongwall Mining at Shallow Depth of Cover in IndiaPas encore d'évaluation

- Sewage Disposal Works: Their Design and ConstructionD'EverandSewage Disposal Works: Their Design and ConstructionPas encore d'évaluation

- Bill of Quantity D WALLDocument1 pageBill of Quantity D WALLVardhanPas encore d'évaluation

- NQ Values - M J Tomlinson PDFDocument1 pageNQ Values - M J Tomlinson PDFVardhanPas encore d'évaluation

- Bore LogDocument4 pagesBore LogVardhanPas encore d'évaluation

- Components For Face RecognitionDocument6 pagesComponents For Face RecognitionVardhanPas encore d'évaluation

- Fig. 4.17 Bearing Capacity Factors of Berezantsev Et AlDocument1 pageFig. 4.17 Bearing Capacity Factors of Berezantsev Et AlVardhanPas encore d'évaluation

- Hollow Core Bar Micropiles - Design Parameters Interpreted From 404 Load TestsDocument10 pagesHollow Core Bar Micropiles - Design Parameters Interpreted From 404 Load TestsVardhanPas encore d'évaluation

- Leading A Healthy Lifestyle: Dr.G.KathyayaniDocument20 pagesLeading A Healthy Lifestyle: Dr.G.KathyayaniVardhanPas encore d'évaluation

- GeologyDocument35 pagesGeologyVardhanPas encore d'évaluation

- Eurocode Design of Underground Metro Structures: D. R. BeadmanDocument5 pagesEurocode Design of Underground Metro Structures: D. R. BeadmanMimoza MimiPas encore d'évaluation

- Installation and Testing of 260 Hollow Core Bar MicropilesDocument6 pagesInstallation and Testing of 260 Hollow Core Bar MicropilesVardhanPas encore d'évaluation

- Design of Twoway SlabDocument6 pagesDesign of Twoway SlabVardhanPas encore d'évaluation

- Motores Mahindra PDFDocument8 pagesMotores Mahindra PDFirmaos170% (1)

- Chapter 4: Trends in Information Systems Development: System TheoryDocument19 pagesChapter 4: Trends in Information Systems Development: System TheoryMina twicePas encore d'évaluation

- FAQ-Lecture 12 To 14Document3 pagesFAQ-Lecture 12 To 14jtorerocPas encore d'évaluation

- Mysql v5.6Document204 pagesMysql v5.6Adrian LozadaPas encore d'évaluation

- Máquina Moer Alumina PDFDocument36 pagesMáquina Moer Alumina PDFDulce GabrielPas encore d'évaluation

- Neral SpecificationsDocument471 pagesNeral SpecificationsM. Harry YusufPas encore d'évaluation

- Unitrac 80WDocument1 pageUnitrac 80WprogramacionavanzadaPas encore d'évaluation

- Ladder Risk AssessmentDocument3 pagesLadder Risk Assessmentvasanth pugazhendhiPas encore d'évaluation

- 340 Dobain HSH - EN - 2019 V1Document8 pages340 Dobain HSH - EN - 2019 V1Gabriel CaraveteanuPas encore d'évaluation

- Resume (Salim Ahmed) MEPDocument3 pagesResume (Salim Ahmed) MEPSalim AhmedPas encore d'évaluation

- E Cat Prosp 2009 Low ResDocument35 pagesE Cat Prosp 2009 Low ResRahman MoushumiPas encore d'évaluation

- Lesco Price List 2011Document12 pagesLesco Price List 2011AboudoulePas encore d'évaluation

- CraneDocument24 pagesCraneagungPas encore d'évaluation

- Shaker PDFDocument8 pagesShaker PDFyorf1989Pas encore d'évaluation

- 08ESS - Introducing Server AdministrationDocument22 pages08ESS - Introducing Server Administrationcarles_perezPas encore d'évaluation

- RA 7925 Report MecLawsDocument6 pagesRA 7925 Report MecLawsxydiaPas encore d'évaluation

- Dbms FileDocument31 pagesDbms FileAdam MoorePas encore d'évaluation

- Bump and Valve Industries in IndiaDocument4 pagesBump and Valve Industries in IndiajeronPas encore d'évaluation

- Percona Server 5.5.34-32.0Document195 pagesPercona Server 5.5.34-32.0Mas KliwonPas encore d'évaluation