Académique Documents

Professionnel Documents

Culture Documents

FPSO Zafaarana MOM 7-12-2017 PDF

Transféré par

Elhamy M. SobhyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FPSO Zafaarana MOM 7-12-2017 PDF

Transféré par

Elhamy M. SobhyDroits d'auteur :

Formats disponibles

--..

PM~

~ .,

MINUTES OF MEETING

Project: Rehabilitation of FPSO ballast Tanks 35 & 3P

St eel Renewal Work{PHASE 2}

Vessel:

Date:

Time:

Zaafarana FPSO

7/12/2017

06:30Am

ATTENDEES ~

Name Company Title Sign at ~ I I

Lucian Feodorov /Sorin Lita THOME Vessel Master /\<"'); . j

Bilan Anthoni /lllia Morkovin THOME Vessel chief officer 7t'f;' -

~\ KL

Mahmoud Hendy/ Mohamed Omar /Momen

Mahmoud/Islam Hassan

Ashraf Abdallah/Omar El deeb/Amr Saad

GEM SA

GEM SA

Proj. Eng.

HSE MGR.

~.

!1.Shrt/~

. , .. '

fi/;Jd_.l!/d/1 J

Mohamed Abdelaziz/ Ayman said GEM SA HSE. Eng.

Ahmed Abdel Monsief /Moh. Shabaan GEM SA HSE. Eng. J.,/\~.:Ll.........._

Hossam mohamed/Ahmed Attia PMS OCM ~p~ -

Mohab Awny/Mohamed Motawae PMS Project Engineer J>...~- 1.. ~'/\"'\.,..-

Tamir El sheimy I Ahmed Zaky PMS HSE Eng. "- ~ ' -/!

...

Mohamed Ali Eid/Mustafa Hashem PMS QC Eng. ' /

Item Description

1. Ooerations- Previous 24 Hours:

1.1 Fit up of two brackets (D-44) and three brackets (D-161) attached to cross Tie beam (D-34/34A) @FR97.

1.2 Welding of cross Tie beam (D-34/D-34A) at FR97 .

1.3 Welding of stringer face plate (D-68C) attached to Hatch open #1 .

1.4 Welding of one stiffener (D-24C) attached to stringer between FR90 to 91.

1.5 Fitup and welding of 10 Zinc Anodes at tank bottom between FR91 to 92

1.6 Fit up of two brackets (D-44) and three brackets (D-161) attached to cross Tie beam (D-34/3 4A) @FR97 .

Approximate Total installed Total Awarded quantity Approxim ate weight to be progress % from

Today installed (tons)

(tons) to date (tons) installed (ton s) awarded quantity(%)

2.17 188.27 200 348 94.14%

Operations - planned for today:

1.7 Continue steel renewal with stringer face plate and vertical web frame platting, stiffener and brackets attached to BHD90 below stringer .

2. Safet~ Issues

PMS safety comments

2.1 PMS has issued the bridging document to GEMSA and waiting for approval.

2.2 Add itional housekeeping is required for 3S tank

During removing scrap from tank , tagline was connected to scrap directly without shackle, sto p operation and install shackle to avoid any

2.3

cutting in the tagline .

GEMSA safety comments

It's mandatory that PMS either to provide fire retardant ventilation hose or rigid plastic ducts covered with fire habitat near hot work

2.4

areas, plastic ducts is not accepted to be placed adjacent to any hot work areas.

2.5 It's required to reduce number of oxygen and acetylene cylin ders on deck

2.6 All the Rigging gears should be color coded .

2.7 Air ducts supplying welding electrode oven pressure tent on deck were disconnected and re install it again at night shift.

2.8 Rigging gears without safety latch were removed from work area

2.9 Miscommunication between Rigger foreman and chain hoist operator , stop operation and resolve problem .

3. GEMSA COMMENTS:

Repairing the section from FR90 to FR94 doesn't require stress analysis but prior cutting, stresses has to be calculated by the onboard

3.1

approved Loadicator to ensure that the local stresses between frame 90 to 93 are below 75%.

Loadicator calculations for max. stresses% for FR90 and FR94 Max. bending moment% Max.SF%

3.2 FR90 22.8 17.7

FR94 3.1 37.4

FR98 26.6 2S.7

FWD draft= 4.6m, AFT draft= 10.79 m, Mid ship Draft= 7.7, sea state= lm swell. According t o the above info. PMS to mark water line

3.3

inside tank to ensure that Welding Procedure is followed according to its location (above/ below w ater line).

3.4 All hot work in 3P should completed before end of December

3.5 Received material from pms to be enough not for more than one /two weeks we don't have space on board (STBD)

3.6 Its required to review and update Standard Operation Procedure (SOP) by concerned parties.

4. PMS COMMENTS:

4.1 The required material for bars for man hand ,leg step and railing are on board .

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Oil and Gas Companies Registered in GhanaDocument27 pagesOil and Gas Companies Registered in GhanaFrancis A. Somuah80% (5)

- Total Pms Scope of Work: Days Start Date End DateDocument6 pagesTotal Pms Scope of Work: Days Start Date End DateElhamy M. SobhyPas encore d'évaluation

- PreqlistDocument70 pagesPreqlistElhamy M. SobhyPas encore d'évaluation

- Inspection and Test Plan - Mechanical Works (Qcitp) : Document ReviewDocument28 pagesInspection and Test Plan - Mechanical Works (Qcitp) : Document ReviewJay Chris L. Beron100% (4)

- Business PlanDocument16 pagesBusiness PlanElhamy M. Sobhy100% (1)

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocument1 pageDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyPas encore d'évaluation

- 5600 ManualeDocument59 pages5600 ManualePaulmankePas encore d'évaluation

- HRSG Bundles Erection PresentationDocument73 pagesHRSG Bundles Erection PresentationtermdoxaPas encore d'évaluation

- CCTV Mounting and PolesDocument112 pagesCCTV Mounting and Poleshusnikhalil100% (1)

- Marine and Offshore Products and Solutions Paroc INTDocument28 pagesMarine and Offshore Products and Solutions Paroc INTVictor OliveiraPas encore d'évaluation

- Technical Specification For Fire Detection and Alarm SystemDocument11 pagesTechnical Specification For Fire Detection and Alarm SystemIppiPas encore d'évaluation

- HACCP ChecklistDocument3 pagesHACCP ChecklistTim Qu100% (4)

- Project Name: Modification of MIDTAP Jetty at El Dekhela PortDocument1 pageProject Name: Modification of MIDTAP Jetty at El Dekhela PortElhamy M. SobhyPas encore d'évaluation

- Copy of June -موقف الاحواض 2020Document1 pageCopy of June -موقف الاحواض 2020Elhamy M. SobhyPas encore d'évaluation

- Sr. Item Page Description Responsible Department Meeting 27 Dec. 2017 2 2.1 Firing Line Configuration (Ws0-3) WS0Document1 pageSr. Item Page Description Responsible Department Meeting 27 Dec. 2017 2 2.1 Firing Line Configuration (Ws0-3) WS0Elhamy M. SobhyPas encore d'évaluation

- Marine Energy Event - Marcelle AskewDocument18 pagesMarine Energy Event - Marcelle AskewElhamy M. SobhyPas encore d'évaluation

- Tug 501 Particulars PDFDocument1 pageTug 501 Particulars PDFElhamy M. SobhyPas encore d'évaluation

- Crest 2 Particular PDFDocument1 pageCrest 2 Particular PDFElhamy M. SobhyPas encore d'évaluation

- Guy Wire Detail 2Document32 pagesGuy Wire Detail 2Ken SuPas encore d'évaluation

- Ashrae Journal On Reheat: Dan Int-HoutDocument7 pagesAshrae Journal On Reheat: Dan Int-HoutSergio GarroPas encore d'évaluation

- p04 Purchase Section List Updated As On 22112021Document9 pagesp04 Purchase Section List Updated As On 22112021MUDIT AGARWALPas encore d'évaluation

- Profile of SAFE ZONE HI-TECH & LOGISTICS LTD.Document32 pagesProfile of SAFE ZONE HI-TECH & LOGISTICS LTD.Rdb HaxorPas encore d'évaluation

- Vent-Axia Acoustic Solution Brochure 0Document44 pagesVent-Axia Acoustic Solution Brochure 0Catalin StrugariuPas encore d'évaluation

- American Home Protect Contract.Document29 pagesAmerican Home Protect Contract.Jose ManzanillaPas encore d'évaluation

- Smacna Standard Access DoorsDocument2 pagesSmacna Standard Access Doorsthermosol5416Pas encore d'évaluation

- SHPDDocument32 pagesSHPDManuel Alvarez MPas encore d'évaluation

- WKH ManualDocument60 pagesWKH ManualantmangPas encore d'évaluation

- HVAC Duct As A Communication ChannelDocument19 pagesHVAC Duct As A Communication ChannelchandruPas encore d'évaluation

- MTZ Package AnsalDocument77 pagesMTZ Package AnsalHazem HassonPas encore d'évaluation

- 1 - Operation Manual For Axial FanDocument12 pages1 - Operation Manual For Axial FanASHWANIPas encore d'évaluation

- Installation & Service Manual: Roof Top Packaged Cool & Heat PumpDocument29 pagesInstallation & Service Manual: Roof Top Packaged Cool & Heat PumpMarlou RabinaPas encore d'évaluation

- DDGJ-1.2-1500-LY Operaion ManualDocument14 pagesDDGJ-1.2-1500-LY Operaion Manualsandeep7426Pas encore d'évaluation

- Huba Control: Relativ and Differential Pressure SwitchDocument4 pagesHuba Control: Relativ and Differential Pressure SwitchHue Kin FeiPas encore d'évaluation

- Spec en 4G40Z02312P1-05Document23 pagesSpec en 4G40Z02312P1-05Ageng A. PooPas encore d'évaluation

- Fire and Smoke Dampers Smoke Extract FansDocument8 pagesFire and Smoke Dampers Smoke Extract FanschainuPas encore d'évaluation

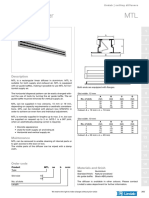

- Difuzori Linijski - MTL - Lineo - UKDocument7 pagesDifuzori Linijski - MTL - Lineo - UKSiktonPas encore d'évaluation

- CES 163 2015 ES 11 Mechanical VentilationDocument92 pagesCES 163 2015 ES 11 Mechanical VentilationZena TilahunPas encore d'évaluation

- Guia de Mantención VESDADocument38 pagesGuia de Mantención VESDAClaudio Godoy ZepedaPas encore d'évaluation

- Installation Instruction w11199606 RevcDocument12 pagesInstallation Instruction w11199606 RevcEniolemPas encore d'évaluation

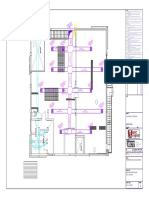

- KFC - Remera II - Mechanicall PlansDocument3 pagesKFC - Remera II - Mechanicall PlansHazem EsamPas encore d'évaluation