Académique Documents

Professionnel Documents

Culture Documents

China Product Quality Inspection Report

Transféré par

samCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

China Product Quality Inspection Report

Transféré par

samDroits d'auteur :

Formats disponibles

With compliments from Global Sources

PRODUCT INSPECTION REPORT

Product

name

Product

PO No.

reference

Supplier

Date

name

RESULTS OVERVIEW

Part Checkpoints Findings & comments

1. Production status

2.1 Export packing

Inner packing &

2.2

labeling

2.4 Product

4 Number of defects

FINAL RESULT: Passed/ Pending/ Failed

PHOTOS OF MAIN PROBLEMS

[description]

[photo]

www.globalsources.com - Choose verified suppliers

Global Sources - Providing buyers with tools for efficient sourcing

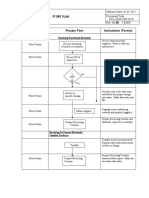

1. PRODUCTION STATUS

1.1 IF PRODUCTION IS UNDER WAY

How many lines are working on these products?

How many workers per line, and total number of

workers on these products?

When were the last materials / components

delivered?

Has bulk production started? When?

When did/will bulk production start to run at full

speed?

How many pieces are processed every day?

When does factory estimate that 50% of the

quantity will be completed?

When does factory estimate that 100% of the

quantity will be fully packed?

When does factory estimate that the order will be

shipped out?

Will the full quantity be shipped out?

1.2 IF PRODUCTION IS IN AN ADVANCED STAGE

Production status details

Finished Qty presented by Number of samples picked

factory Unfinished up

Ordered Qty

Qty

Packed Unpacked Packed Unpacked

Number of

pieces

Was it possible to pick any sample the inspector wanted? Yes / No

www.globalsources.com - Choose verified suppliers

Global Sources - Providing buyers with tools for efficient sourcing

2. EXPORT PACKING

2.1 GENERAL SPECIFICATIONS

Checkpoint Requirement Sampling Findings & comments

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

2.2 PHOTOS OF PROBLEMS

[description]

[photo]

3. INNER PACKING & LABELING

www.globalsources.com - Choose verified suppliers

Global Sources - Providing buyers with tools for efficient sourcing

3.1 GENERAL SPECIFICATIONS

Checkpoint Requirement Sampling Findings & comments

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

3.2 PHOTOS OF PROBLEMS

[description]

[photo]

4. PRODUCT

4.1 GENERAL SPECIFICATIONS

www.globalsources.com - Choose verified suppliers

Global Sources - Providing buyers with tools for efficient sourcing

Checkpoint Requirement Sampling Findings & comments

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

4.2 ON-SITE TESTS

Test name Test description & expected result Sampling Findings & comments

5 pcs

5 pcs

5 pcs

5 pcs

5 pcs

4.3 PHOTOS OF PROBLEMS

[description]

[photo]

5. NUMBER OF DEFECTS

Description of defect Defect category & No.

www.globalsources.com - Choose verified suppliers

Global Sources - Providing buyers with tools for efficient sourcing

Critical Major Minor

st

[Description of 1 defect]

[Photo]

6. LOADING SUPERVISION

6.1 THE PRODUCTS TO SHIP

www.globalsources.com - Choose verified suppliers

Global Sources - Providing buyers with tools for efficient sourcing

Checkpoint Requirement Sampling Findings and comments

Quantity to ship must be

Total quantity N/A

within +/-5% of order quantity.

Open cartons, check

Conformity to the buyers

products inside. They must 8 cartons

requirements

be the same as ordered.

6.2 THE PACKING

Checkpoint Requirement Sampling Findings & comments

5 cartons

5 cartons

5 cartons

5 cartons

5 cartons

6.3 CONDITION OF THE CONTAINER(S)

Checkpoint Requirement Sampling Findings & comments

Containers should be in good All

General condition

condition, inside and outside. containers

There should be no holes, no

All

Holes, humidity, smell strong humidity, and no

containers

smell.

Each container should be

All

Sealing sealed with a unique number

containers

(after loading).

6.4 THE LOADING PROCESS

www.globalsources.com - Choose verified suppliers

Global Sources - Providing buyers with tools for efficient sourcing

Checkpoint Requirement Sampling Findings & comments

No carton should fall on the

Dropped/damaged cartons ground or be damaged when N/A

factory loads the cartons.

If a loading plan was given to

Imposed loading plan the manufacturer, it should be N/A

respected.

If no loading plan was given

to factory, the heaviest and

Logical loading plan N/A

strongest cartons should be

loaded at the bottom.

---------------------- End of document ----------------------

This template has been prepared by quality assurance agency Sofeast Ltd exclusively for Global Sources buyers.

If you have suggestions for improvement, or if you need assistance to adapt this template to your needs, contact

Renaud Anjoran at ra@sofeast.com.

Find more templates, and the latest sourcing news and advice at GlobalSources.com/news.

www.globalsources.com - Choose verified suppliers

Vous aimerez peut-être aussi

- Product Inspection Report: Results OverviewDocument8 pagesProduct Inspection Report: Results Overviewblackberry7130gPas encore d'évaluation

- PT BMI Presentation 29.05.2017Document42 pagesPT BMI Presentation 29.05.2017Bayumi Tirta JayaPas encore d'évaluation

- Nutripot+Manual Ilovepdf Compressed+Document10 pagesNutripot+Manual Ilovepdf Compressed+Ravindra DnyansagarPas encore d'évaluation

- Quality: at GE Oil & GasDocument28 pagesQuality: at GE Oil & GasAbdulPas encore d'évaluation

- Internal Audit Report August 2021Document8 pagesInternal Audit Report August 2021vinothkumarPas encore d'évaluation

- Radiation Safety - Handling of Radioactive Sources and Generally LicensedDocument26 pagesRadiation Safety - Handling of Radioactive Sources and Generally LicensedAchraf Ben DhifallahPas encore d'évaluation

- QHSE Induction KGA Employees NewDocument30 pagesQHSE Induction KGA Employees NewlavhePas encore d'évaluation

- As 2400.13-1983 Packaging Tensional StrappingDocument6 pagesAs 2400.13-1983 Packaging Tensional StrappingSAI Global - APACPas encore d'évaluation

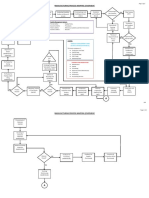

- Manufacturing Process Mapping (Overview) : Customer Requirement YESDocument2 pagesManufacturing Process Mapping (Overview) : Customer Requirement YESJohn P. BandoquilloPas encore d'évaluation

- Quality System Procedure: Introduction:-ResponsibilityDocument3 pagesQuality System Procedure: Introduction:-ResponsibilityPeracha EngineeringPas encore d'évaluation

- Blank Pdi SheetDocument2 pagesBlank Pdi SheetEngr Abdullah MughalPas encore d'évaluation

- Management Review Meeting Minutes 2022Document7 pagesManagement Review Meeting Minutes 2022AnkurPas encore d'évaluation

- Rma New Blank PC ReturnDocument1 pageRma New Blank PC Returnarshadsamudh3100% (1)

- Field Service Report - DVSG2010Document1 pageField Service Report - DVSG2010coronel_jaysonPas encore d'évaluation

- Procedure - Outsourced ProcessesDocument1 pageProcedure - Outsourced Processesdellanadia putriPas encore d'évaluation

- ISO 9001:2015 To AS9100D - QMS Upgrade Instructions / ChecklistDocument3 pagesISO 9001:2015 To AS9100D - QMS Upgrade Instructions / ChecklistHoang TanPas encore d'évaluation

- Process Sheet: Express Luck Egypt Company Express Luck Egypt CompanyDocument8 pagesProcess Sheet: Express Luck Egypt Company Express Luck Egypt Companymohamed abdullahPas encore d'évaluation

- Tata Steelium Case SolutionDocument9 pagesTata Steelium Case SolutionShailav Prakash100% (1)

- Safety Induction / Orientation Certificate: P671 Khursaniyah Southern Area - 3BDocument38 pagesSafety Induction / Orientation Certificate: P671 Khursaniyah Southern Area - 3BBenju PascualPas encore d'évaluation

- Iso-tc176-Sc2 n1017 n1017 - Iso 9000 User Survey ReportDocument9 pagesIso-tc176-Sc2 n1017 n1017 - Iso 9000 User Survey ReportDanielConceiçãoPas encore d'évaluation

- Continuously Cast Stainless Steel Slab, Bloom & BilletDocument2 pagesContinuously Cast Stainless Steel Slab, Bloom & BilletZachary PiercePas encore d'évaluation

- Inventory Carrying Cost in DetailedDocument4 pagesInventory Carrying Cost in Detailedkobi kafuPas encore d'évaluation

- Emergency Preparedness and Proper Response PlanDocument3 pagesEmergency Preparedness and Proper Response PlanCarmela Goc-ongPas encore d'évaluation

- AF-QMSP-14 Procedure For Machine Shop StoreDocument16 pagesAF-QMSP-14 Procedure For Machine Shop StoreSharif KhanPas encore d'évaluation

- Procedure For Evaluation and SelectionDocument2 pagesProcedure For Evaluation and SelectionSharif KhanPas encore d'évaluation

- Pittsburgh Hydraulic Jack Manual 66482Document12 pagesPittsburgh Hydraulic Jack Manual 66482linx316Pas encore d'évaluation

- Handle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsDocument1 pageHandle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsSAKTHIVEL APas encore d'évaluation

- APQP Format NationalDocument53 pagesAPQP Format NationalqualityPas encore d'évaluation

- 0606 Supplier Evaluation FormDocument4 pages0606 Supplier Evaluation FormSmitesh VangalwarPas encore d'évaluation

- 01-20-2016 Fleet Status Report ROWANDocument2 pages01-20-2016 Fleet Status Report ROWANnjava1978Pas encore d'évaluation

- Key Performance Indicators (Kpi) Tracker Worksheet Template: Company NameDocument2 pagesKey Performance Indicators (Kpi) Tracker Worksheet Template: Company NameTawfiq4444Pas encore d'évaluation

- Customer Feedback FormDocument1 pageCustomer Feedback FormKelvin ChinPas encore d'évaluation

- Critical Failure Factors in ERP ImplementationDocument15 pagesCritical Failure Factors in ERP Implementationdaryshini rajahPas encore d'évaluation

- Aromatics Project: Mobile Telephone PolicyDocument2 pagesAromatics Project: Mobile Telephone Policypl_rajaPas encore d'évaluation

- Store PlanDocument1 pageStore PlanFazir SubairPas encore d'évaluation

- The Company'S Factory Production Control System (FPC) FPC 0: BackgroundDocument7 pagesThe Company'S Factory Production Control System (FPC) FPC 0: BackgroundSandy D. RockPas encore d'évaluation

- Capricorn DHP Process Flow Chart NewDocument3 pagesCapricorn DHP Process Flow Chart NewmuralivijayPas encore d'évaluation

- Customer Service ReportDocument1 pageCustomer Service Reportsladjoynwa1Pas encore d'évaluation

- BMI-WI-5711-14 Ball Valve 2in-900# Manufacturing Process Rev.0Document12 pagesBMI-WI-5711-14 Ball Valve 2in-900# Manufacturing Process Rev.0MacelPas encore d'évaluation

- Master List of Forms FormatsDocument1 pageMaster List of Forms Formatschahi100% (1)

- Employee Training Record FormDocument1 pageEmployee Training Record FormAine GatdulaPas encore d'évaluation

- Company Introduction - Shinwoo ValveDocument26 pagesCompany Introduction - Shinwoo ValveLe Cam NhanPas encore d'évaluation

- Sound Velocity ChartDocument1 pageSound Velocity Chartmohsinmajeed08Pas encore d'évaluation

- TIC Supplier Standards ManualDocument24 pagesTIC Supplier Standards ManualSergio AlvarezPas encore d'évaluation

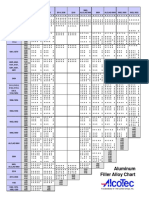

- Aluminum Filler Alloy Selection ChartDocument2 pagesAluminum Filler Alloy Selection ChartManish MPas encore d'évaluation

- Hse Manual Rev GDocument49 pagesHse Manual Rev GEIRINI KONDYLIPas encore d'évaluation

- Documentation Requirements - ISO 9001-2008 - QMS - Sterling UAE PDFDocument2 pagesDocumentation Requirements - ISO 9001-2008 - QMS - Sterling UAE PDFKaushal SutariaPas encore d'évaluation

- Daily Preventive Maintenance Check List - TURNINGDocument1 pageDaily Preventive Maintenance Check List - TURNINGAnkurPas encore d'évaluation

- INTERNAL and EXTERNAL ISSUESDocument3 pagesINTERNAL and EXTERNAL ISSUESCarex Grace ViovicentePas encore d'évaluation

- SWP - Welding WorkDocument2 pagesSWP - Welding WorkIMRANPas encore d'évaluation

- Manual de Calidad GeDocument28 pagesManual de Calidad GeMarco Antonio MoncerratePas encore d'évaluation

- Safe DrivingDocument28 pagesSafe Drivingraighnejames19Pas encore d'évaluation

- Objectives (2019 20)Document2 pagesObjectives (2019 20)Sekar KrishPas encore d'évaluation

- Ralin Group Brochure 2013Document3 pagesRalin Group Brochure 2013n1ghtfallPas encore d'évaluation

- IAQG 9101:2016 (Rev F) : Change OverviewDocument37 pagesIAQG 9101:2016 (Rev F) : Change Overviewchandravel sankarakumarPas encore d'évaluation

- Mount Meru Product Catalogue First VersionDocument20 pagesMount Meru Product Catalogue First Versionilovem2foodPas encore d'évaluation

- CA121 18audit ChecklistDocument34 pagesCA121 18audit ChecklistKanimozhivendhan VendhanPas encore d'évaluation

- Pt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesDocument0 pagePt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesZoebairPas encore d'évaluation

- Rotary Table Feeder Data SheetDocument1 pageRotary Table Feeder Data SheetclxPas encore d'évaluation

- Problem: Part Hight Out of Spec Problem PhotoDocument8 pagesProblem: Part Hight Out of Spec Problem PhotoManikandanPas encore d'évaluation

- CS FundamentalDocument7 pagesCS FundamentalsamPas encore d'évaluation

- Brute-Force Algorithms: Author(s)Document12 pagesBrute-Force Algorithms: Author(s)samPas encore d'évaluation

- Chemical Grammarpdf PDF FreeDocument75 pagesChemical Grammarpdf PDF Freesam100% (1)

- Virtual MemDocument2 pagesVirtual MemsamPas encore d'évaluation

- Ethics in MarketingDocument43 pagesEthics in Marketingsam100% (1)

- Modal Verbs With Examples in Urdu PDFDocument16 pagesModal Verbs With Examples in Urdu PDFsam67% (3)

- Sample Hardline Report - 070813Document11 pagesSample Hardline Report - 070813samPas encore d'évaluation

- KNN With Tf-Idf Based Framework For Text Categorization: SciencedirectDocument9 pagesKNN With Tf-Idf Based Framework For Text Categorization: SciencedirectsamPas encore d'évaluation

- m003 Modal VerbsDocument2 pagesm003 Modal VerbsEveLina MatejkoPas encore d'évaluation

- Timbre Analysis of Music Audio Signals With Convolutional Neural NetworksDocument5 pagesTimbre Analysis of Music Audio Signals With Convolutional Neural NetworkssamPas encore d'évaluation

- HciDocument1 pageHcisamPas encore d'évaluation

- Combining Features Extracted From Audio, Symbolic and Cultural SourcesDocument6 pagesCombining Features Extracted From Audio, Symbolic and Cultural SourcesSam ShoukatPas encore d'évaluation

- C Part 1 - Writing Proposals - External Templates.319143428Document14 pagesC Part 1 - Writing Proposals - External Templates.319143428samPas encore d'évaluation

- 504H0015 (GS-0015) - Initial Sample Inspection ReportDocument5 pages504H0015 (GS-0015) - Initial Sample Inspection ReportsamPas encore d'évaluation

- English For HicDocument7 pagesEnglish For HicsamPas encore d'évaluation

- 504H0015 (GS-0015) - Initial Sample Inspection ReportDocument5 pages504H0015 (GS-0015) - Initial Sample Inspection ReportsamPas encore d'évaluation

- 2725 Transmittal Letter PDFDocument1 page2725 Transmittal Letter PDFsamPas encore d'évaluation

- Chemical Dependence Facility Inspection Report: DetailsDocument2 pagesChemical Dependence Facility Inspection Report: DetailssamPas encore d'évaluation

- 2014-01-14 v1 6 - Appendix D - Sample RFP LetterDocument2 pages2014-01-14 v1 6 - Appendix D - Sample RFP LettersamPas encore d'évaluation

- Cs6601 Project 2 PaperDocument4 pagesCs6601 Project 2 PapersamPas encore d'évaluation

- Automatic Music Classification and The ImportanceDocument10 pagesAutomatic Music Classification and The ImportancesamPas encore d'évaluation

- Mini 10Document29 pagesMini 10RejaPas encore d'évaluation

- R&I Seat Belt Buckle Front #2Document2 pagesR&I Seat Belt Buckle Front #2Pablo LoboPas encore d'évaluation

- By Regd. Post With Ack. Due & MailDocument17 pagesBy Regd. Post With Ack. Due & MailTender 247Pas encore d'évaluation

- Motor Vehicle Insurance Alteration - 11QA580109MPA-1Document6 pagesMotor Vehicle Insurance Alteration - 11QA580109MPA-1Ästra MosesPas encore d'évaluation

- The Mother of All Maritime LinksDocument326 pagesThe Mother of All Maritime LinksNeindisciplinat RomanPas encore d'évaluation

- KR Rules For The Classification of Steel Ships - Part 1 - Classification and Surveys - 2020 PDFDocument486 pagesKR Rules For The Classification of Steel Ships - Part 1 - Classification and Surveys - 2020 PDFThang Ngo0% (1)

- Thousand Islands Bridge: 75 Years of International GoodwillDocument16 pagesThousand Islands Bridge: 75 Years of International Goodwillwdt_rpominvillePas encore d'évaluation

- Actros II III 2005 At2000st D D PDFDocument44 pagesActros II III 2005 At2000st D D PDFMircea Gilca100% (3)

- CBRT Survey ReportDocument9 pagesCBRT Survey Reportjoe poePas encore d'évaluation

- Final Paper PDFDocument130 pagesFinal Paper PDFEricabernadette AbantoPas encore d'évaluation

- Reliance Raj Ticket PDFDocument2 pagesReliance Raj Ticket PDFDeepak GourPas encore d'évaluation

- SP 91 2019 FinalDocument150 pagesSP 91 2019 FinalAmbuj Saxena82% (11)

- TM 9-1727B Engine Cooling, Engine Electrical and Engine Fuel Systems For Light Tank M5, Etc 1943Document252 pagesTM 9-1727B Engine Cooling, Engine Electrical and Engine Fuel Systems For Light Tank M5, Etc 1943RobertLockiePas encore d'évaluation

- Density Based Traffic Light Controller Using Wireless Sensor Network and Arm ProcessorDocument4 pagesDensity Based Traffic Light Controller Using Wireless Sensor Network and Arm ProcessorqaaaziPas encore d'évaluation

- Research Paper About Cabin CrewDocument4 pagesResearch Paper About Cabin Crewgphhfrgkf100% (1)

- 2015 PatriotDocument572 pages2015 PatriotLuis Pedrero100% (1)

- 4-9 All ConplitionDocument9 pages4-9 All Conplitionkaliangi bharviPas encore d'évaluation

- JCB Telescopic Material HandelerTechnical DataDocument16 pagesJCB Telescopic Material HandelerTechnical DataMoataz SamiPas encore d'évaluation

- CV Raman Global University - Corporate Simulation Test-CVGST-3 (2022)Document45 pagesCV Raman Global University - Corporate Simulation Test-CVGST-3 (2022)Rohit SarkarPas encore d'évaluation

- Meaning of ConsigneeDocument5 pagesMeaning of ConsigneeVashishth JoshiPas encore d'évaluation

- Terminologies (Route Surveying)Document1 pageTerminologies (Route Surveying)KristinePas encore d'évaluation

- CAB 282 May 2020Document49 pagesCAB 282 May 2020claudio.jc.limaPas encore d'évaluation

- Hot Rod - June 2023Document82 pagesHot Rod - June 2023Jaydev RavalPas encore d'évaluation

- The Bildkarten of Hermann BollmannDocument13 pagesThe Bildkarten of Hermann BollmannJuan Antonio Huizar SanchezPas encore d'évaluation

- Wal-Mart Supplier ModuleDocument97 pagesWal-Mart Supplier ModulePiyush Priyadarshi50% (2)

- Issue 11.04 (Vol. 43, No. 4), Fall 2011 PDFDocument16 pagesIssue 11.04 (Vol. 43, No. 4), Fall 2011 PDFStrathmore Bel PrePas encore d'évaluation

- 2014 2015 MonroeCV NumericalListing PDFDocument31 pages2014 2015 MonroeCV NumericalListing PDFTan JaiPas encore d'évaluation

- Coal Handling SystemDocument1 pageCoal Handling SystemAwaPas encore d'évaluation

- Chassis Control SystemsDocument312 pagesChassis Control SystemsAndrei Dontu100% (1)

- Melvin Yokley v. Santa Fe Trail Transportation Company, A Corporation and Paul Vernon Mitchell, 227 F.2d 534, 10th Cir. (1955)Document3 pagesMelvin Yokley v. Santa Fe Trail Transportation Company, A Corporation and Paul Vernon Mitchell, 227 F.2d 534, 10th Cir. (1955)Scribd Government DocsPas encore d'évaluation