Académique Documents

Professionnel Documents

Culture Documents

MaterialData - 56973 2

Transféré par

red_beastDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MaterialData - 56973 2

Transféré par

red_beastDroits d'auteur :

Formats disponibles

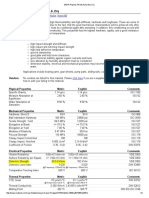

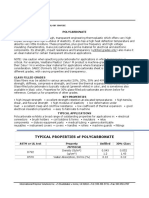

Polimersan Plastics POLIPOLEN® (Polyethylene) UHMW-PE 1000

Categories: Polymer; Thermoplastic; Polyethylene; HDPE; High Density Polyethylene (HDPE), Ultra High Molecular Weight

Material PE 1000: Polyethylene with very high molecular weight (UHMW - PE 1000; Ultra High Molecular Weight Polyethylene). Polyethylenes with molecular weight

Notes: higher than 3 million gr/mol. POLIPOLEN® PE (POLYETHYLENE) is maintained from coke oven gas or from natural gas or from Ethene or Ethane which is

produced by cracking of petroleum. Monomer, is polymerized by low pressure or high pressure method and then can be maintained as high density (PE-YY

0,941 and 0,965 g/cm³) or low (normal) density polyethylene(PE-NY 0,914 and 0,925 g/cm³). Other differences of various PE types are according to their

melting degrees and opposite proportional connection occurs according to their relative molecular weights. In other words, when its melting degree is at the

lowest level, its relative molecular weight is at the highest level and e.g. its mechanical specialties are the best.

POLIPOLEN has quite a low density. Its flexibility rate is high and it is resistant to strokes even at low temperatures. It has a very high molecular weight

(molecular chain length). It has a high corrosion resistance because of its high molecular chain. According to the results of the "sand slurry" corrosion test

which is made as per "DIN" standards, POLIPOLEN 1000 , has shown the highest corrosion resistance among the solid materials( e.g. steels, tree, other

engineering plastics.)

PROPERTIES OF POLIPOLEN®:

l Very high stroke resistance

l Very high corrosion resistance

l Very high chemical resistance

l Getting lubricated itself and slicky

l Excellent electrical resistance

l Quietness while processing and reducing vibrations

l Easy processing

l Low friction rate

l Very low water absorption

GENERAL USAGE AREAS OF POLIPOLEN®:

l Coal warehouses and conveyor systems

l Gutters

l Chain conveyor guides

l Elevators

l Electric power stations

l Cement industry

l Lime industry

l Palister industry

l Food industry

l Cutting and chopping plates

l Chopping blocks

l Conveyor screws

l Sliding elements

l Flat guides

l Profiles

l Bobbins

l Star and screw conveyors

l Elevator systems

l Sliding bearings

l Gears

l Motor landing plates

l Stopper valves

l Closing claps

l Acid pumps

l Filters

Information provided by Polimersan Polimer Kimya San.Tic.Ltd.Sti.

Vendors: No vendors are listed for this material. Please click here if you are a supplier and would like information on how to add your listing to this material.

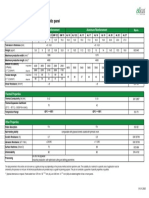

Physical Properties Metric English Comments

Specific Gravity >= 0.930 g/cc >= 0.930 g/cc ISO.1183 DN.53479

Water Absorption <= 0.0200 % <= 0.0200 % ISO.62 DN.53495

Mechanical Properties Metric English Comments

Hardness, Shore D 60.0 - 70.0 60.0 - 70.0 DN.53505

Ball Indentation Hardness 38.0 MPa 5510 psi ISO.2039-2

Tensile Strength at Break >= 40.0 MPa >= 5800 psi ISO.527 DN.53455

Tensile Strength, Yield >= 20.0 MPa >= 2900 psi ISO.527 DN.53455

Elongation at Break >= 350 % >= 350 % ISO.527 DN.53455

Elongation at Yield 20.0 % 20.0 % ISO.527 DN.53455

Modulus of Elasticity >= 0.600 GPa >= 87.0 ksi ISO.178 DN.53452

Charpy Impact, Notched 21.0 J/cm² 99.9 ft-lb/in² ISO.179 DN.53453

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM / Page 1 / 2

Electrical Properties Metric English Comments

Volume Resistivity >= 5.00e+16 ohm-cm >= 5.00e+16 ohm-cm ISO.167 DN.53482

Surface Resistance >= 1.00e+13 ohm >= 1.00e+13 ohm ISO.167 DN.53482

Dielectric Strength >= 45.0 kV/mm >= 1140 kV/in ISO.243 DN.53481

Thermal Properties Metric English Comments

CTE, linear 20.0 µm/m-°C 11.1 µin/in-°F DN.53752

@Temperature 20.0 °C @Temperature 68.0 °F

Melting Point 130 - 133 °C 266 - 271 °F

Maximum Service Temperature, Air 70.0 °C 158 °F ISO.75 DN.53461

Descriptive Properties

Corrosion 1 DN.58836 Sand Slurry Test

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a consistent format. Users requiring more precise data for scientific or

engineering calculations can click on the property value to see the original value as well as raw conversions to equivalent units. We advise that you only use the original value or one of its raw conversions in your

calculations to minimize rounding error. We also ask that you refer to MatWeb's disclaimer and terms of use regarding this information. Click here to view all the property values for this datasheet as they were

originally entered into MatWeb.

MatWeb, Your Source for Materials Information - WWW.MATWEB.COM / Page 2 / 2

Vous aimerez peut-être aussi

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาPas encore d'évaluation

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismPas encore d'évaluation

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaPas encore d'évaluation

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.mePas encore d'évaluation

- Aluminium A380Document1 pageAluminium A380Ashokkumar VellorePas encore d'évaluation

- PA 6.6 Nylon 6.6Document2 pagesPA 6.6 Nylon 6.6Naeem KhanPas encore d'évaluation

- Borealis Supercopo™ Lh4201R Polyethylene Insulation Compound, CrosslinkableDocument2 pagesBorealis Supercopo™ Lh4201R Polyethylene Insulation Compound, CrosslinkableAnonymous 1AAjd0Pas encore d'évaluation

- Hojas TécnicasDocument2 pagesHojas TécnicasalejandrocharlescollPas encore d'évaluation

- Nylacast Moly Cast Nylon 6, MoS2 FilledDocument3 pagesNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmPas encore d'évaluation

- Fluorseals PTFE 15% Glass FilledDocument1 pageFluorseals PTFE 15% Glass FilledPriyadarshini Krishnaswamy0% (1)

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenPas encore d'évaluation

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANPas encore d'évaluation

- LEXAN 9030 and Lexan 9030 TG Datasheet PDFDocument2 pagesLEXAN 9030 and Lexan 9030 TG Datasheet PDFIbrahim Levent AkkoyunluPas encore d'évaluation

- Corundum, Aluminum Oxide, Alumina, 99.9%, Al ODocument2 pagesCorundum, Aluminum Oxide, Alumina, 99.9%, Al OIbra WandaPas encore d'évaluation

- Aluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument2 pagesAluminum 5182-H34: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyLuis BadoffPas encore d'évaluation

- Pe1000 PDFDocument2 pagesPe1000 PDFrohitdakngPas encore d'évaluation

- SUS 316 Material Properties PDFDocument1 pageSUS 316 Material Properties PDFYudo ArdianPas encore d'évaluation

- PLEXIGLAS Satinice df20 8N - ENDocument2 pagesPLEXIGLAS Satinice df20 8N - ENmstevkaPas encore d'évaluation

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalDocument2 pagesLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúPas encore d'évaluation

- Data Sheet - Polyfelt® TS HD (100 600-td-02-19)Document1 pageData Sheet - Polyfelt® TS HD (100 600-td-02-19)andriarisetiawanPas encore d'évaluation

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinPas encore d'évaluation

- 303-Cruicible SteelDocument2 pages303-Cruicible SteelARUNKANNANPas encore d'évaluation

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless Steeldaniel enrique romero robayoPas encore d'évaluation

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANPas encore d'évaluation

- PA6EDocument1 pagePA6EDiego ReggianiniPas encore d'évaluation

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluPas encore d'évaluation

- 316 Stainless Steel, Anneal...Document3 pages316 Stainless Steel, Anneal...Moisés Vázquez ToledoPas encore d'évaluation

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMAPas encore d'évaluation

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanPas encore d'évaluation

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaPas encore d'évaluation

- Covestro Bayblend® FR3000 PC - ABS BlendDocument2 pagesCovestro Bayblend® FR3000 PC - ABS Blendavinashchauhan2695Pas encore d'évaluation

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepPas encore d'évaluation

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyPas encore d'évaluation

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabPas encore d'évaluation

- MaterialData 6937Document1 pageMaterialData 6937Cristobal Gutierrez CarrascoPas encore d'évaluation

- Fluorseals Ptfe Unfilled: Advertise With Matweb!Document2 pagesFluorseals Ptfe Unfilled: Advertise With Matweb!Priyadarshini KrishnaswamyPas encore d'évaluation

- 316L-SS-annealed BarDocument2 pages316L-SS-annealed BarARUNKANNANPas encore d'évaluation

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoPas encore d'évaluation

- General Information: 9.6 PP 100 / 20 PP 1.2Document3 pagesGeneral Information: 9.6 PP 100 / 20 PP 1.2vijayPas encore d'évaluation

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoPas encore d'évaluation

- RTP 2500 FR ADocument2 pagesRTP 2500 FR ASoopPas encore d'évaluation

- Aluminum 7175 T736Document3 pagesAluminum 7175 T736TylerLALA100% (1)

- Radipol A45 TDSDocument1 pageRadipol A45 TDSxy2zjgPas encore d'évaluation

- Aluminum 1060-Data-SheetDocument2 pagesAluminum 1060-Data-SheetMaruda8382Pas encore d'évaluation

- 303-Stainless Steel-Annealed BarDocument2 pages303-Stainless Steel-Annealed BarARUNKANNANPas encore d'évaluation

- Duracon M90 44Document2 pagesDuracon M90 44PradeepPas encore d'évaluation

- RTP 299 X 90078 SSC 63023Document2 pagesRTP 299 X 90078 SSC 63023kls.thorodinsonPas encore d'évaluation

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviPas encore d'évaluation

- ABS Toyolac 920 555 (Toray Plastics)Document1 pageABS Toyolac 920 555 (Toray Plastics)Nguyễn Xuân KỳPas encore d'évaluation

- Plexiglas Satinice Df21 8n - enDocument3 pagesPlexiglas Satinice Df21 8n - enjonathan6657Pas encore d'évaluation

- K300 TDSDocument2 pagesK300 TDSM. Kürşad ArslanPas encore d'évaluation

- Datasheet Cawiton PR13615 - 001Document1 pageDatasheet Cawiton PR13615 - 001Fred HahnPas encore d'évaluation

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackPas encore d'évaluation

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidPas encore d'évaluation

- 528N - Electrically Non-Conductive Hose: Performance Exceeds SAE 100 R8 / ISO 3949 Type R8 / DIN EN 855 Type R8Document1 page528N - Electrically Non-Conductive Hose: Performance Exceeds SAE 100 R8 / ISO 3949 Type R8 / DIN EN 855 Type R8Jas SumPas encore d'évaluation

- 528N PDFDocument1 page528N PDFZoran JankovPas encore d'évaluation

- F1 Model Block: Technical DatasheetDocument2 pagesF1 Model Block: Technical DatasheetRafael ObiciPas encore d'évaluation

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraPas encore d'évaluation

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionD'EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionÉvaluation : 5 sur 5 étoiles5/5 (1)

- User Guide: Elcometer 147Document4 pagesUser Guide: Elcometer 147sergioPas encore d'évaluation

- Top 40 Civil Engineer Interview QuestionsDocument18 pagesTop 40 Civil Engineer Interview QuestionsAkhtar Ali100% (2)

- Bio Well InformationDocument5 pagesBio Well InformationPradyuman PatelPas encore d'évaluation

- TB Welding-English PDFDocument20 pagesTB Welding-English PDFdanghpPas encore d'évaluation

- Exercises in Cell BiologyDocument65 pagesExercises in Cell BiologyZvijezdaPas encore d'évaluation

- Thermo 2, Lecture1 PDFDocument99 pagesThermo 2, Lecture1 PDFMaricar HababagPas encore d'évaluation

- Conclusion and Recommendations HTDocument1 pageConclusion and Recommendations HTAdiel AdriePas encore d'évaluation

- Cve3008 Mid-Term Test (27.10.2022)Document4 pagesCve3008 Mid-Term Test (27.10.2022)damell scottPas encore d'évaluation

- Single Phase Matrix ConverterDocument9 pagesSingle Phase Matrix Converteranahope93Pas encore d'évaluation

- INFO-Sheet Fumis ALPHADocument2 pagesINFO-Sheet Fumis ALPHAAnthony GilmorePas encore d'évaluation

- NA Curve FittingDocument31 pagesNA Curve FittingRadwan HammadPas encore d'évaluation

- Coprime FactorisationDocument20 pagesCoprime FactorisationasgharPas encore d'évaluation

- Strength Performance of Full-Size Structural Timber of Dryobalanops Species of Sarawak, MalaysiaDocument7 pagesStrength Performance of Full-Size Structural Timber of Dryobalanops Species of Sarawak, Malaysiaqidunk ipsiPas encore d'évaluation

- Topical Revision Notes Biology O Level PDFDocument140 pagesTopical Revision Notes Biology O Level PDFBilal Akram79% (19)

- R7222301 Mass Transfer & SeparationDocument2 pagesR7222301 Mass Transfer & SeparationsivabharathamurthyPas encore d'évaluation

- Lab 8 Ee ReportDocument10 pagesLab 8 Ee Reportshikazi ziki100% (1)

- Lecture 24 - Strength Analysis of FuselagesDocument6 pagesLecture 24 - Strength Analysis of FuselagesgavinPas encore d'évaluation

- MechatronicsDocument61 pagesMechatronicsSajitha ManuPas encore d'évaluation

- Instrumentation: Biochemistry Laboratory Prepared By: Shanny G. Estera, RPHDocument39 pagesInstrumentation: Biochemistry Laboratory Prepared By: Shanny G. Estera, RPHMika ForwardPas encore d'évaluation

- Constant Effort SupportsDocument31 pagesConstant Effort SupportsKen SidhartaPas encore d'évaluation

- Wave Propagation in Shallow Water: Ert - C WDocument24 pagesWave Propagation in Shallow Water: Ert - C WMarco QuirozPas encore d'évaluation

- Crashworthiness Optimization Design of Thin Walled Tube Filled With Re Entrant Triangles HoneycombsDocument13 pagesCrashworthiness Optimization Design of Thin Walled Tube Filled With Re Entrant Triangles Honeycombsash ketchumPas encore d'évaluation

- Review On Fabrication of 3 Axis Spray Painting Machine Ijariie1981Document4 pagesReview On Fabrication of 3 Axis Spray Painting Machine Ijariie1981Anonymous Clyy9NPas encore d'évaluation

- FiltrationDocument15 pagesFiltrationDominador Velasco jr100% (2)

- Mustang Timing Belts D e 0616Document50 pagesMustang Timing Belts D e 0616xyz008Pas encore d'évaluation

- International Conference: 26-27 (Saturday-Sunday)Document5 pagesInternational Conference: 26-27 (Saturday-Sunday)suryamishraPas encore d'évaluation

- (19MT18302) Modeling and Analysis of Electrical Machines (Theory)Document3 pages(19MT18302) Modeling and Analysis of Electrical Machines (Theory)Prabhu MoorthyPas encore d'évaluation

- Algebra2 Glenco EOCDocument62 pagesAlgebra2 Glenco EOCDeborah LeePas encore d'évaluation

- Tank Design CalculationDocument20 pagesTank Design CalculationHairil HerliansyahPas encore d'évaluation

- Chul Park The Limits of Two-Temperature ModelDocument13 pagesChul Park The Limits of Two-Temperature ModellazharPas encore d'évaluation