Académique Documents

Professionnel Documents

Culture Documents

Form No. 11.20 Quality Assurance Plan

Transféré par

Pooja TripathiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Form No. 11.20 Quality Assurance Plan

Transféré par

Pooja TripathiDroits d'auteur :

Formats disponibles

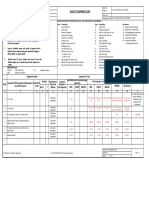

FORM NO.11.

20(DQM) F-11 REV-0

CONTRACTOR QUALITY ASSURANCE PLAN PROJECT

ORDER NO. & DATE FOR PACKAGE NO.

SUB - CONTRACTOR REFRACTORY MATERIALS PACKAGE NAME

ORDER NO. & DATE

INSTRUCTIONS FOR FILLING UP : CODES FOR EXTENT OF INSPECTION, TESTS, TEST CERTIFICATES & DOCUMENTS :

1 QAP shall be submitted for each of the equipment separately with break Code Description Code Description DOCUMENTS :

up of assembly / sub-assembly & part/component or for group of equip-

ment having same specification. 1. Visual 18. Drying & firing shrinkage D1. Laboratory test report

2. Dimensions and geometry 19. Sieve analysis D2. Dimensional drgs. showing

2 Use numerical codes as indicated for extent of inspection & tests and 3. Chemical composition 20. Warpage plan, elevation, side view

submission of test certificates & documents. Additional codes & des- 4. Apparent porosity 21. Drip slag test & cross sectional view duly

cription for extent of inspection & tests may be added as applicable for 5. True specific gravity 22. Permeability test approved.

the plant and equipment. 6. Bulk density/true density 23. Hydration resistance test D3. Copies of sub P.O. &

7. Cold crushing strength 24. Lap joint strength Technical Specification.

3 Separate identification number with quantity for equipment shall be 8. Pyrometric cone equivalent 25. Abrasion resistance D4. Calibration Certificate of all

indicated wherever equipment having same specification belonging to 9. Refractoriness under load 26. Cold bonding strength measuring instruments and

different facilities are grouped together. 10. Spalling resistance 27. Oxidation resistance gauges.

11. Permanent linear change 28. Workability

4 Weight in tonnes (T) must be indicated under column 5 for each item. after heating 29. Surface area

Estimated weights may be indicated wherever actual weights are not 12. Modulus of Rupture/ 30. Corrosion resistance

available. Flexural strength 31. Consistency

13. Reversible thermal expansion 32. Internal Inspection Report

ABBREVIATIONS USED : 14. Resistance to dis-integration effect 33.Safe working temp.

of carbon monoxide gas. 34. Lot sampling

CONTR : CONTRACTOR 15. Water absorption 35. Part assembly

16. Acid resistance 36.Control assembly.

MFR : MANUFACTURER 17. Thermal conductivity

E Q U I P M E N T D E T A I L S INSPECTION AND TESTS

Raw Material and Inprocess Test Certificates & Acceptance Criteria

Sl. Description (with equipment Identification Quantity Manufacturer's Expected Sche- stage Inspection Final Inspection / Test by documents to be Standards/IS/BS/ REMARKS/

No. heading,place of use and No. No / M T Name and Address dule of Final submitted to MECON ASME/Norms and SAMPLING PLAN

brief specification) Inspn MFR CONTR MECON MFR CONTR MECON Documents

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

( Q . A . P . NO. TO BE ALLOTTED BY MECON )

For CONTRACTOR / SUB - CONTRACTOR NO. / / / R- REV.

for MECON ( Stamp & Signature ) (Stamp & Signature ) SHEET : 1 OF 2

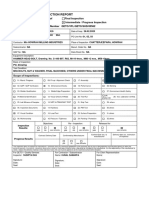

CONTINUATION SHEET FORM NO.11.20(DQM) F-11 REV-0

E Q U I P M E N T D E T A I L S INSPECTION AND TESTS

Raw Material and Inprocess Test Certificates & Acceptance Criteria

Sl. Description (with equipment Identification Quantity Manufacturer's Expected Sche- stage Inspection Final Inspection / Test by documents to be Standards/IS/BS/ REMARKS/

No. heading,place of use and No. No / M T Name and Address dule of Final submitted to MECON ASME/Norms and SAMPLING PLAN

brief specification) Inspn MFR CONTR MECON MFR CONTR MECON Documents

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

( Q . A . P . NO. TO BE ALLOTTED BY MECON )

For CONTRACTOR / SUB - CONTRACTOR NO. / / / R- REV.

for MECON ( Stamp & Signature ) (Stamp & Signature ) SHEET : 2 OF 2

Vous aimerez peut-être aussi

- Qap - LR BendDocument1 pageQap - LR BendSachin KumarPas encore d'évaluation

- Qap-Bv, PV, GVDocument10 pagesQap-Bv, PV, GVSachin KumarPas encore d'évaluation

- Qap - TCP-PCP-HPCLDocument2 pagesQap - TCP-PCP-HPCLAashish MoyalPas encore d'évaluation

- Qap - LR BendDocument1 pageQap - LR BendMecon LtdPas encore d'évaluation

- Blustar NMDC Qap R0 14 01 2017Document1 pageBlustar NMDC Qap R0 14 01 2017koushik42000Pas encore d'évaluation

- QAP Plan Elect.Document2 pagesQAP Plan Elect.insap_dineshPas encore d'évaluation

- Annexure - 1 User Manual For IMSDocument221 pagesAnnexure - 1 User Manual For IMSSumantrra ChattopadhyayPas encore d'évaluation

- 12 - 254624-400-Pl-Int-001 QapDocument2 pages12 - 254624-400-Pl-Int-001 QapNerudaArarPas encore d'évaluation

- Master Qap RefractoryDocument2 pagesMaster Qap RefractoryUmashankar Singh0% (1)

- Commissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestDocument24 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestabderrahmanePas encore d'évaluation

- 2 Kickoff Meeting for Reference 01_prv Rdd e 022_open to Trade RequirementsDocument1 page2 Kickoff Meeting for Reference 01_prv Rdd e 022_open to Trade RequirementsRhoger YmasaPas encore d'évaluation

- Forhtml - Af Imt Form 1222 Boiler or Pressure Vessel Inspection Report PDFDocument2 pagesForhtml - Af Imt Form 1222 Boiler or Pressure Vessel Inspection Report PDFReama QumsanPas encore d'évaluation

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandePas encore d'évaluation

- Power Transformer TestDocument27 pagesPower Transformer Testm khPas encore d'évaluation

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (9)

- SI306-F016 Lighting and Receptacles Installation ChecklistDocument1 pageSI306-F016 Lighting and Receptacles Installation ChecklistBrookePas encore d'évaluation

- Field Quality Plan for Agency ManufacturesDocument3 pagesField Quality Plan for Agency ManufacturesSourav RanaPas encore d'évaluation

- Contractor QAP for HT Breaker PanelDocument1 pageContractor QAP for HT Breaker Panelmadhu_bedi12Pas encore d'évaluation

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunPas encore d'évaluation

- Check List For Installation of Cooling TowersDocument2 pagesCheck List For Installation of Cooling TowersGirithar M Sundaram67% (3)

- Quality assurance plan for structural & mechanical couplingsDocument1 pageQuality assurance plan for structural & mechanical couplingsumashankarsinghPas encore d'évaluation

- QAP IP Format Electrical Instrumentation APEDocument2 pagesQAP IP Format Electrical Instrumentation APEKoushik DeyPas encore d'évaluation

- Screw Screw Screw Screw Pump Pump Pump PumpDocument2 pagesScrew Screw Screw Screw Pump Pump Pump PumpvictorvikramPas encore d'évaluation

- 10kva 25 Kva Dist - Transformer Spec Revision Dtd. 20.04.2018Document45 pages10kva 25 Kva Dist - Transformer Spec Revision Dtd. 20.04.2018Ritesh DhawalePas encore d'évaluation

- Power Transformer Technical SpecificationDocument58 pagesPower Transformer Technical SpecificationmidhunvarPas encore d'évaluation

- Surge Arrestor Commissioning ChecklistDocument7 pagesSurge Arrestor Commissioning ChecklistSyed Abbas100% (1)

- Other Requirement: BA-0496 Refap1 Project Disengager / Stripper R-300002, R-300003Document7 pagesOther Requirement: BA-0496 Refap1 Project Disengager / Stripper R-300002, R-300003GLEDSONPas encore d'évaluation

- Product Manual 3854 V2Document10 pagesProduct Manual 3854 V2amitonline09Pas encore d'évaluation

- PRS28Document40 pagesPRS28swaminathangsPas encore d'évaluation

- Compressed Air System Inspection Checklist: Section A - Customer DataDocument1 pageCompressed Air System Inspection Checklist: Section A - Customer DataAgus WG KucreetPas encore d'évaluation

- Inspection and Test Program: Fabrication / In-Process InspectionDocument10 pagesInspection and Test Program: Fabrication / In-Process InspectionGLEDSONPas encore d'évaluation

- 63-100 Kva Tf-Rural-907Document91 pages63-100 Kva Tf-Rural-907Ritesh DhawalePas encore d'évaluation

- Government of India tender for ventilation fansDocument39 pagesGovernment of India tender for ventilation fanskalaiPas encore d'évaluation

- CHECKLIST FOR INSTALLING FAHU EQUIPMENTDocument2 pagesCHECKLIST FOR INSTALLING FAHU EQUIPMENTSamer AliPas encore d'évaluation

- Final Circuits and Distribution BoardsDocument2 pagesFinal Circuits and Distribution BoardsSalahudheen anas TPas encore d'évaluation

- Job Scope For Over Hauling of Power Transformers - FinalDocument7 pagesJob Scope For Over Hauling of Power Transformers - FinalrambihariPas encore d'évaluation

- Engine Generator Set Inspection Checklist: Section A - Customer DataDocument2 pagesEngine Generator Set Inspection Checklist: Section A - Customer Datasri_lntPas encore d'évaluation

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument1 pageInspection and Test Plan: Fabrication / In-Process InspectionGLEDSONPas encore d'évaluation

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005Pas encore d'évaluation

- MD1-0-T-030-05-00370-C - ITP For CFBC Boiler Installation-ICDocument151 pagesMD1-0-T-030-05-00370-C - ITP For CFBC Boiler Installation-ICTran KhuynhPas encore d'évaluation

- Method Statement for Landscape Waterproofing WorkDocument13 pagesMethod Statement for Landscape Waterproofing WorkSurya PrakashPas encore d'évaluation

- Itr-Pgr (GRP Piping)Document10 pagesItr-Pgr (GRP Piping)mahmoudPas encore d'évaluation

- Bimetallic Thermometer TemplateDocument3 pagesBimetallic Thermometer TemplateUTKARSH GADVEPas encore d'évaluation

- Manual valve inspection data sheetDocument2 pagesManual valve inspection data sheetkais rguiguiPas encore d'évaluation

- Shunt Reactor TestDocument10 pagesShunt Reactor TestEngr Imtiaz Hussain GilaniPas encore d'évaluation

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- Sprinkler System Test QCDD FormDocument2 pagesSprinkler System Test QCDD FormMahmoud HassanPas encore d'évaluation

- Hydro Test ProceduresDocument6 pagesHydro Test ProcedureswillPas encore d'évaluation

- Generator Data Sheet PDFDocument13 pagesGenerator Data Sheet PDFTerence WoodPas encore d'évaluation

- Form CRPV-1A composite pressure vessel reportDocument2 pagesForm CRPV-1A composite pressure vessel reportEmma DPas encore d'évaluation

- Intevep-User 6Document1 pageIntevep-User 6dabirtapiaPas encore d'évaluation

- LNG-80-100937-RA-6065-00023-0000 HT PipingDocument7 pagesLNG-80-100937-RA-6065-00023-0000 HT PipingMohammad AftabPas encore d'évaluation

- Comparison ParametersDocument84 pagesComparison ParametersNazeerPas encore d'évaluation

- IR562_HMI_28.02.23Document2 pagesIR562_HMI_28.02.23Pinki Mitra DasPas encore d'évaluation

- Shic A 0005Document2 pagesShic A 000501095902062ahmedPas encore d'évaluation

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- Transformer TestingDocument37 pagesTransformer TestingVinodPas encore d'évaluation

- Check List For Installation of External Fire Hydrant PDFDocument1 pageCheck List For Installation of External Fire Hydrant PDFvishalkadam57Pas encore d'évaluation

- Pressuremeter Testing: Methods and InterpretationD'EverandPressuremeter Testing: Methods and InterpretationÉvaluation : 5 sur 5 étoiles5/5 (2)

- List of Current Files 2 Nov 17Document6 pagesList of Current Files 2 Nov 17Pooja TripathiPas encore d'évaluation

- Air Travel Requisition Form)Document1 pageAir Travel Requisition Form)Pooja TripathiPas encore d'évaluation

- GTS Hydraulics Seq 3Document4 pagesGTS Hydraulics Seq 3Pooja TripathiPas encore d'évaluation

- GS-05 - Insp - Contentx - Seq - 3Document1 pageGS-05 - Insp - Contentx - Seq - 3Pooja TripathiPas encore d'évaluation

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Pooja TripathiPas encore d'évaluation

- ManagerDocument1 pageManagerPooja TripathiPas encore d'évaluation

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Sai GowthamPas encore d'évaluation

- Aqm F 14Document4 pagesAqm F 14Pooja TripathiPas encore d'évaluation

- 054 078A Submission of Drawings DocumentsDocument1 page054 078A Submission of Drawings DocumentsPooja TripathiPas encore d'évaluation

- Ordinary Ordinary: State Girls Type StateDocument4 pagesOrdinary Ordinary: State Girls Type StatePooja TripathiPas encore d'évaluation

- Inspection Waiver Certificate: Page 1 of 1Document1 pageInspection Waiver Certificate: Page 1 of 1Pooja TripathiPas encore d'évaluation

- 26lko pg27 0 PDFDocument1 page26lko pg27 0 PDFPooja TripathiPas encore d'évaluation

- AICF Payment Success and Registration Form RequiredDocument1 pageAICF Payment Success and Registration Form RequiredPooja TripathiPas encore d'évaluation

- ApplicationForm For Teaching Posts-2016Document13 pagesApplicationForm For Teaching Posts-2016Pooja TripathiPas encore d'évaluation

- Travel Requisition PDFDocument1 pageTravel Requisition PDFPooja TripathiPas encore d'évaluation

- Air Travel Requisition Form)Document1 pageAir Travel Requisition Form)Pooja TripathiPas encore d'évaluation

- Bus BillDocument1 pageBus BillPooja TripathiPas encore d'évaluation

- 7national School 2018Document6 pages7national School 2018Pooja TripathiPas encore d'évaluation

- Bus BillDocument1 pageBus BillPooja TripathiPas encore d'évaluation

- Concrete Thrust BlockDocument4 pagesConcrete Thrust BlockHansLopezPas encore d'évaluation

- Ordinary Ordinary: State Girls Type StateDocument4 pagesOrdinary Ordinary: State Girls Type StatePooja TripathiPas encore d'évaluation

- AICF Player Registration Details for SHARANYA BALADocument1 pageAICF Player Registration Details for SHARANYA BALAPooja TripathiPas encore d'évaluation

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- Drawing Progress Monitor BV As On 30.08.16Document11 pagesDrawing Progress Monitor BV As On 30.08.16Pooja TripathiPas encore d'évaluation

- Telephone List 2017Document7 pagesTelephone List 2017Pooja TripathiPas encore d'évaluation

- BS Forwarding 22.03.2017Document1 pageBS Forwarding 22.03.2017Pooja TripathiPas encore d'évaluation

- Equipment List78Document26 pagesEquipment List78Pooja TripathiPas encore d'évaluation

- Exhibit FTI-62 Consent Agreement For Acquisition of Airgas by Air ProductsDocument4 pagesExhibit FTI-62 Consent Agreement For Acquisition of Airgas by Air ProductsPooja TripathiPas encore d'évaluation

- List of Current Files - LatestDocument5 pagesList of Current Files - LatestPooja TripathiPas encore d'évaluation

- NDT For RenewablesDocument17 pagesNDT For RenewablesAvijit MondalPas encore d'évaluation

- 1 Sean BalfeDocument25 pages1 Sean BalfeShrikant BudholiaPas encore d'évaluation

- ITP Box Setting On CHB or Macro WallDocument3 pagesITP Box Setting On CHB or Macro WallRitchie OcampoPas encore d'évaluation

- Pressure-Reducing Valves For Air or Nitrogen SystemsDocument8 pagesPressure-Reducing Valves For Air or Nitrogen SystemsDarwin DarmawanPas encore d'évaluation

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyPas encore d'évaluation

- AMCO - RBI Engineer - Mr. Laheesh KumarDocument7 pagesAMCO - RBI Engineer - Mr. Laheesh KumarOwais MalikPas encore d'évaluation

- Fabric Inspection and Shrinkage Testing ProceduresDocument6 pagesFabric Inspection and Shrinkage Testing ProceduresMayan DynastyPas encore d'évaluation

- WalkthroughDocument9 pagesWalkthroughAryaman Singh100% (1)

- Dm-2016-001 Contractual Requirements For Components and Materials Qualitymanagement v2Document28 pagesDm-2016-001 Contractual Requirements For Components and Materials Qualitymanagement v2Monica FernandezPas encore d'évaluation

- Requisition of Erector MechanicalDocument9 pagesRequisition of Erector MechanicalGunturMudaAliAkbarPas encore d'évaluation

- CBT Introduction Slides PDFDocument28 pagesCBT Introduction Slides PDFManoj Kumar100% (1)

- Business Plan Larfaco ReferenceDocument45 pagesBusiness Plan Larfaco ReferenceJoseph IsraelPas encore d'évaluation

- What Is BS en 10204, and The Differences Between EN10204-3Document7 pagesWhat Is BS en 10204, and The Differences Between EN10204-3Arpan GhoshPas encore d'évaluation

- Inspección Veterinaria Antemortem USDADocument19 pagesInspección Veterinaria Antemortem USDAAdriana Rivera PosadaPas encore d'évaluation

- Lean Six Sigma Green Belt Mock ExamDocument30 pagesLean Six Sigma Green Belt Mock ExamKhatija KamPas encore d'évaluation

- Structural AssessmentDocument48 pagesStructural AssessmentshubhamPas encore d'évaluation

- Types of BottomDocument4 pagesTypes of BottomAnakin Skywalker100% (1)

- CSWIP 3.1 Study Book 2013 Rev 2 Edition Original 600 Page (Yasser Tawfik) PDFDocument601 pagesCSWIP 3.1 Study Book 2013 Rev 2 Edition Original 600 Page (Yasser Tawfik) PDFRoy Lizarazo Pacco75% (4)

- Ammunition Stockpile Reliability Program: UnclassifiedDocument19 pagesAmmunition Stockpile Reliability Program: UnclassifiedyaserdomaPas encore d'évaluation

- Conclusion: Life Science IndustryDocument3 pagesConclusion: Life Science IndustryHTEPas encore d'évaluation

- Roush Paint Appearance Standard AS 100 1 PDFDocument6 pagesRoush Paint Appearance Standard AS 100 1 PDFBESPas encore d'évaluation

- Duties of Permanent Way OfficialsDocument14 pagesDuties of Permanent Way OfficialsRanjanjharkhandPas encore d'évaluation

- NDT and E International: Miguel Reseco Bato, Anis Hor, Aurelien Rautureau, Christian BesDocument13 pagesNDT and E International: Miguel Reseco Bato, Anis Hor, Aurelien Rautureau, Christian BesJORGE WILFREDO VERA ALVARADOPas encore d'évaluation

- Royal Brewery Car Park Tender Docs 120625Document382 pagesRoyal Brewery Car Park Tender Docs 120625christopher_bir7392100% (1)

- NTPC DPTDocument495 pagesNTPC DPTKuppan Srinivasan100% (1)

- Intershield 163 Inerta 160 - Underwater Hull AntiabrasionDocument20 pagesIntershield 163 Inerta 160 - Underwater Hull AntiabrasionrbmtavPas encore d'évaluation

- Our Ref:: Guidelines On Provision For Corrosion Protection and Periodic Structural InspectionDocument7 pagesOur Ref:: Guidelines On Provision For Corrosion Protection and Periodic Structural InspectionSalehuddin RamliPas encore d'évaluation

- Aerial Platform Scissor Lift Final 1Document13 pagesAerial Platform Scissor Lift Final 1ABeery101_228907741Pas encore d'évaluation

- Food Control System in Malaysia: 2017/SCSC/FSCF/EM/015Document14 pagesFood Control System in Malaysia: 2017/SCSC/FSCF/EM/015Valentina AdindaPas encore d'évaluation

- ITP - CCTV System InstallationDocument6 pagesITP - CCTV System InstallationGultom Juliana LiliesPas encore d'évaluation