Académique Documents

Professionnel Documents

Culture Documents

Kinetic Energy Recovery System

Transféré par

Shivam AgarwalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kinetic Energy Recovery System

Transféré par

Shivam AgarwalDroits d'auteur :

Formats disponibles

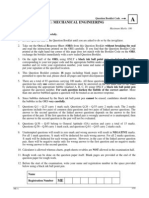

KINETIC ENERGY RECOVERY SYSTEM (KERS)

ON ANY VEHICLE

ABSTRACT

STUDENT NAME REGN. NO EMAIL ID CONTACT

SHIVAM AGARWAL130909058 shivam.agarwal.5667@gmail.com 7406323466

UNDER THE GUIDANCE OF

DR.VIJAY G.S.

Associate Professor - Senior Scale

Department of Mechanical and Manufacturing Engineering

MANIPAL INSTITUTE OF TECHNOLOGY

DEPARTMENT OF MECHANICAL AND MANUFACTURING ENGINEERING

MANIPAL INSTITUTE OF TECHNOLOGY

(A constituent Institute of MANIPAL UNIVERSITY)

MANIPAL - 576 104, KARNATAKA, INDIA

JANUARY 2017- MAY 2017

1. INTRODUCTION- THE KINETIC ENERGY RECOVERY SYSTEM (KERS) IS A MECHANICAL SYSTEM

WHICH WORKS ON THE PRINCIPLE OF ENERGY CONSERVATION. DURING BRAKING, A LOT OF

KINETIC ENERGY GETS WASTED AS A RESULT. IN KERS THIS ENERGY INSTEAD OF GETTING

WASTED GETS SAVED AS A POTENTIAL ENERGY IN A RESERVOIR WHICH CAN BE A COUPLING,

FLYWHEEL.ETC DEPENDING ON THE PURPOSE. BECAUSE OF CONSIDERABLE INCREASE IN THE

EFFICIENCY OF A VEHICLE, THE KERS HAS BECOME AN ACTIVE AREA OF INTEREST AND

RESEARCH. VEHICLES EQUIPPED WITH KERS DEVICES ARE ABLE TO TAKE SOME OF ITS

KINETIC ENERGY OUT SLOWING DOWN THE VEHICLE. THIS IS A FORM OF BRAKING IN WHICH

ENERGY IS NOT WASTED, INSTEAD GETS STORED IN SOME DEVICE. USING A PROPER

MECHANISM, THIS ENERGY THAT IS STORED IN TERMS OF POTENTIAL ENERGY CAN BE

CONVERTED BACK INTO KINETIC ENERGY TO GIVE THE VEHICLE AN EXTRA BOOST OF POWER.

IN THE LITERATURE REVIEW DIFFERENT TYPES OF AVAILABLE KERS SYSTEMS ARE COMPARED

AND A MECHANICAL BASED KERS SYSTEM IS FOUND TO BE THE BEST SUITABLE FOR A

BICYCLE. THERE ARE TWO TYPES OF KINETIC ENERGY RECOVERY SYSTEMS WHICH HAVE

GAINED POPULARITY IN RECENT DAYS. ONE IS ELECTRICAL KERS AND ANOTHER IS

MECHANICAL KERS. BOTH HAVE THEIR RESPECTIVE PROS AND CONS. THE ELECTRICAL

SYSTEM IS LESS EFFICIENT BUT IT CAN STORE POWER FOR A LONGER DURATION AND GIVES

US THE AGILITY TO MANIPULATE THE TORQUE AND RPM OUTPUT AS PER OUR

REQUIREMENT. IN THE OTHER HAND THE MECHANICAL SYSTEM HAS A BETTER EFFICIENCY

(NEARLY TWICE AS THAT OF THE PRIOR ONE) BUT IT IS PRONE TO DECAY DUE TO ITS

INHERENT PROPERTY OF FRICTION, THOUGH IT IS VERY SMALL IN VALUE, HENCE CANNOT BE

STORED FOR LONER PERIOD AND NEED TO BE USED WITHIN A SHORT PERIOD OF TIME. IN

THE REAL WORLD WE CAN FIND MANY SITUATIONS WHERE WE NEED TO USE THE

RECOVERED KINETIC ENERGY WITH IN VERY SHORT SPAN OF TIME OF ITS RECOVERY AND WE

DONT EVEN NEED A WIDE RANGE OF TORQUE AND RPM OUTPUT AS A PARTICULAR RANGE

OF TORQUE & RPM COMBINATIONS SATISFY OUR REQUIREMENTS COMPLETELY. A BICYCLE IS

A PERFECT EXAMPLE OF THIS KIND.DIFFERENT TPYES OF KERS ARE-

Mechanical KERS: THE MECHANICAL KERS UTILISES A FLYWHEEL AS A FLYWHEEL AS THE

ENERGY STORAGE DEVICE AND A VARIABLE DRIVE TRANSMISSION TO CONTROL AND

TRANSFER THE ENERGY TO AND FROM THE DRIVELINE. THE TRANSFER OF VEHICLE KINETIC

ENERGY TO FLYWHEEL KINETIC ENERGY CAN BE SEEN AS A MOMENTUM EXCHANGE. ENERGY

IS TRANSFERRED FROM THE VEHICLE TO THE FLYWHEEL. IN DOING THIS THE SPEED OF THE

VEHICLE DECREASES AND THAT OF THE FLYWHEEL INCREASES WHICH WE CAN EFFECTIVELY

CALL AS A BRAKING. AT THE START OF BREAKING PROCESS THE VEHICLE HAS A HIGHER

SPEED THAN THE FLYWHEEL, GIVING A CERTAIN SPEED RATIO BETWEEN THEM WHEREAS AT

THE END OF BRAKING THE VEHICLE HAS A LOWER SPEED THAN THE FLYWHEEL SO THE RATIO

OF SPEEDS HAS CHANGED. EXAMINATION OF THE ENERGY TRANSFER SHOWS THAT THE

RATIO BETWEEN VEHICLE SPEED AND FLYWHEEL SPEED NECESSARILY CHANGES

CONTINUOUSLY DURING THE ENERGY TRANSFER EVENT.

ELECTRICAL KERS: ELECTRICAL KINETIC ENERGY RECOVERY SYSTEM CONVERTS THE KINETIC

ENERGY INTO CHEMICAL ENERGY FOR STORAGE AND AN ELECTRIC MOTOR GENERATOR

SYSTEM IS USED AS THE ENERGY TRANSFER AND CONTROL MEDIA. THE COMMON

COMPONENTS USED IN BATTERY STORAGE TYPE KINETIC ENERGY RECOVERY SYSTEM ARE

ELECTRIC PROPULSION MOTOR /GENERATOR, POWER ELECTRONICS INVERTER, AND THE

QUAD FLYWHEEL STORAGE. CAPACITORS ARE FUNDAMENTAL ELECTRICAL CIRCUIT

ELEMENTS THAT STORE ELECTRICAL ENERGY IN THE ORDER OF MICROFARADS AND HELPS IN

FILTERING]. THE MAIN FUNCTION OF A CAPACITOR IS TO GET CHARGED AND DISCHARGED

ELECTRICITY. A SUPER-CAPACITOR IS AN UPGRADED VERSION OF A CAPACITOR HAVING

SPECIAL FEATURES SUCH AS LONG LIFE, RAPID CHARGING, LOW INTERNAL RESISTANCE, HIGH

POWER DENSITY, AND SIMPLE CHARGING METHOD AS COMPARED TO CAPACITORS AND

BATTERIES

HYDRAULIC KERS: REGENERATIVE BRAKING IN VEHICLES USING A VARIABLE DISPLACEMENT

HYDRAULIC PUMP/MOTOR TOGETHER WITH A HYDRO PNEUMATIC ACCUMULATOR HAS

ATTRACTED CONSIDERABLE INTEREST DURING THE LAST 2025 YEARS. SUCH A SYSTEM IS

PARTICULARLY SUITABLE FOR APPLICATION IN CITY. DESPITE THE SIGNIFICANT GAINS IN THE

EFFICIENT USE OF ENERGY THAT THE USE OF THIS SYSTEM HAS NOT ATTAINED GREAT

POPULARITY .THE ADDED COST, WHICH MAY REPRESENT 1015% OF THE TOTAL FOR THE

VEHICLE, IS ONE OF THE MAJOR DRAWBACKS OF THIS SYSTEM.

HYDRO-ELECTRIC KERS: A HYDRAULIC ELECTRIC SYNERGY SYSTEM (HESS) IS A HYDRAULIC

ACCUMULATOR AND BATTERY HYBRID ENERGY SYSTEM. THIS SYSTEM FOLLOWS HYBRID

ENERGY STRUCTURE TO INTEGRATE A HIGH SPECIFIC ENERGY BATTERY WITH A HIGH POWER

HYDRAULIC ACCUMULATOR TO GET REQUIRED OUTPUT. HENCE IT OVERCOMES THE

DRAWBACKS OF A SINGLE ENERGY STORAGE SOURCE TYPE KERS.

2. OBJECTIVES- FOLLOWING ARE THE OBJECTIVES AIMED TO BE ACHIEVED WITH THE PROJECT:-

A. STORE ENERGY WHEN BRAKES ARE APPLIED

B. SHOULD BE ABLE TO PROVIDE A SORT OF RETURN ENERGY TO ACCELERATE.

C. SHOULD BE LIGHT WEIGHT AND ECONOMICAL

D. ENVIRONMENTAL FRIENDLY

E. SHOULD HAVE CONTROLLED RELEASE

F. SHOULD BE AESTHETICALLY PLEASING

3. METHODOLOGY- A PARTICULAR FLOWCHART SHOLUD BE FOLLOWED FOR ACHIEVING THE

OBJECTIVES IN THE GIVEN TIME CONSTRAINT. THE PATTERN IS AS FOLLOWS-

A. IDENTIFYING COMPONENTS OF KERS

B. WORKING PRINCIPLES

C. DESIGN PROCEDURES FOR VARIOUS COMPONENTS

D. FEA ANALYSIS USING ANSYS

4. NOVELTY/UNIQUENESS THIS PROJECT RESULTED IN A DESIGN OF A COMPLETELY CLUTCH

BASED KERS SYSTEM CONTRARY TO THE GENERAL SYSTEMS USED IN AUTOMOBILES. IF

FEASIBLE , THIS SYSTEM COULD BE USED IN INDIAN PUBLIC TRANSPORT SYSTEMS.

5. NAME OF THE GUIDE WITH CONTACT DETAILS AND EMAIL ADDRESS- DR.VIJAY G.S.,

ASSOCIATE PROFESSOR-SENIOR SCALE, DEPT OF MECHANICAL AND MANUFACTURING

ENGINEERING.

CONTACT NO- +91-9980032104

EMAIL ADDRESS-vijay.gs@manipal.edu

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Operations ManagementDocument290 pagesOperations Managementrockon60594% (104)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Fall 17 Masters GuideDocument50 pagesFall 17 Masters GuideShivam Agarwal80% (5)

- Christy Desmet Jim Casey Eds - Shakespeare:Not ShakespeareDocument316 pagesChristy Desmet Jim Casey Eds - Shakespeare:Not ShakespeareJimmy NewlinPas encore d'évaluation

- Shanta BhaiDocument49 pagesShanta BhaiShivam AgarwalPas encore d'évaluation

- POM-Introduction PDFDocument40 pagesPOM-Introduction PDFShivam AgarwalPas encore d'évaluation

- Syllabi GATE2017 PDFDocument73 pagesSyllabi GATE2017 PDFAnkit Kumar AJPas encore d'évaluation

- Cover LetterDocument2 pagesCover LetterShivam AgarwalPas encore d'évaluation

- DeekshantRekhi 130909296 MEDocument1 pageDeekshantRekhi 130909296 MEShivam AgarwalPas encore d'évaluation

- IES Syllabus For Mechanical Engineering ME PDFDocument3 pagesIES Syllabus For Mechanical Engineering ME PDFvenuPas encore d'évaluation

- Chapter 5 Gyroscope PDFDocument16 pagesChapter 5 Gyroscope PDFRa BalamuruganPas encore d'évaluation

- DeekshantRekhi 130909296 MEDocument1 pageDeekshantRekhi 130909296 MEShivam AgarwalPas encore d'évaluation

- POM-Introduction PDFDocument40 pagesPOM-Introduction PDFShivam AgarwalPas encore d'évaluation

- POM IntroductionDocument40 pagesPOM IntroductionShivam AgarwalPas encore d'évaluation

- QpmeDocument16 pagesQpmeSandeep PandeyPas encore d'évaluation

- OrganizingDocument46 pagesOrganizingShivam AgarwalPas encore d'évaluation

- Quasi Turbine: By-Shivam Agarwal Roll No - 12 Section-D 130909058 Dept. of Mechanical and Manufacturing EngineeringDocument37 pagesQuasi Turbine: By-Shivam Agarwal Roll No - 12 Section-D 130909058 Dept. of Mechanical and Manufacturing EngineeringShivam AgarwalPas encore d'évaluation

- Components of Pneumatic SystemDocument100 pagesComponents of Pneumatic SystemSidharth DavePas encore d'évaluation

- Chapter 5 Gyroscope PDFDocument16 pagesChapter 5 Gyroscope PDFRa BalamuruganPas encore d'évaluation

- Rahul Assembly FinalDocument3 pagesRahul Assembly FinalShivam AgarwalPas encore d'évaluation

- Nptel - Iitm.ac - in Courses Webcourse-Contents IISc-BANG Basic Thermodynamics PDF Module 1Document32 pagesNptel - Iitm.ac - in Courses Webcourse-Contents IISc-BANG Basic Thermodynamics PDF Module 1lakumas15Pas encore d'évaluation

- 56Document6 pages56Shivam AgarwalPas encore d'évaluation

- TML Distribution Company LimitedDocument19 pagesTML Distribution Company LimitedShivam AgarwalPas encore d'évaluation

- Improvement of Drr2 LineDocument8 pagesImprovement of Drr2 LineShivam AgarwalPas encore d'évaluation

- Module 5Document17 pagesModule 5captainhassPas encore d'évaluation

- Chapter 7-STEERING System-1 PDFDocument22 pagesChapter 7-STEERING System-1 PDFShivam AgarwalPas encore d'évaluation

- Chapter6-Drive To WheelsDocument21 pagesChapter6-Drive To WheelsShivam AgarwalPas encore d'évaluation

- New Doc 3 - 1Document1 pageNew Doc 3 - 1Shivam AgarwalPas encore d'évaluation

- Syllabi GATE2017 PDFDocument73 pagesSyllabi GATE2017 PDFAnkit Kumar AJPas encore d'évaluation

- Se 1613 Tcic bsIIIDocument2 pagesSe 1613 Tcic bsIIIShivam AgarwalPas encore d'évaluation

- MARXISMDocument10 pagesMARXISMJulianna AngelesPas encore d'évaluation

- The Script 2Document18 pagesThe Script 2Yazid Yoga WinataPas encore d'évaluation

- Fiction QuizDocument6 pagesFiction QuizJoveth TampilPas encore d'évaluation

- HIST 368 SylabusDocument6 pagesHIST 368 SylabusJason LabrecquePas encore d'évaluation

- Ephsians LectureDocument4 pagesEphsians LectureAl MusawirPas encore d'évaluation

- WBSU - Sanskrit - Hons WB State UniversityDocument7 pagesWBSU - Sanskrit - Hons WB State Universityjayanta mandalPas encore d'évaluation

- Nightfall and Other Stories - Isaac AsimovDocument175 pagesNightfall and Other Stories - Isaac Asimovbog_hitman47100% (1)

- Chinese Workbook L4 1 PDFDocument6 pagesChinese Workbook L4 1 PDFAnonymous xACn7mcpfPas encore d'évaluation

- Agastya StavaDocument8 pagesAgastya StavaBalingkangPas encore d'évaluation

- British Literature Test 1 Chap 1-5Document3 pagesBritish Literature Test 1 Chap 1-5Dr Kalyani Vallath0% (1)

- A Princess of Mars Part 4Document4 pagesA Princess of Mars Part 4Sheila IncaPas encore d'évaluation

- MeaningDocument32 pagesMeaningapi-322216976Pas encore d'évaluation

- Eng Class IVDocument9 pagesEng Class IVKanza FatimaPas encore d'évaluation

- AgamismDocument4 pagesAgamismsivanyaalanPas encore d'évaluation

- Ni Chuilleanain - To Niall WoodsDocument9 pagesNi Chuilleanain - To Niall WoodslaurelizabethPas encore d'évaluation

- David C Paul-Charles Ives in The Mirror - American Histories of An Iconic ComposerDocument314 pagesDavid C Paul-Charles Ives in The Mirror - American Histories of An Iconic ComposerNenad Dragan Jovananović100% (3)

- Pre RomanticDocument288 pagesPre RomanticabdullahPas encore d'évaluation

- Lit3 Anthology 2022 2023Document52 pagesLit3 Anthology 2022 2023Carlos SevillaPas encore d'évaluation

- Elmer - Mid Term E3Document3 pagesElmer - Mid Term E3Anonymous feBqteoPas encore d'évaluation

- Niyogibooks CatalogueDocument211 pagesNiyogibooks CatalogueSuneelPas encore d'évaluation

- ConclusionDocument3 pagesConclusionshadi sabouriPas encore d'évaluation

- Entire Bible in 180 DaysDocument2 pagesEntire Bible in 180 DaysJaden_JPas encore d'évaluation

- Hsslive Xii Poetic DevicesDocument3 pagesHsslive Xii Poetic DevicesSergPas encore d'évaluation

- English Group AssignmentDocument10 pagesEnglish Group AssignmentAasifKNazarPas encore d'évaluation

- Tintern AbbeyDocument2 pagesTintern AbbeyManu JamesPas encore d'évaluation

- Unit 2 Movies and EntertainmentDocument28 pagesUnit 2 Movies and EntertainmentAnonymous bjz5SOJmPas encore d'évaluation

- TwilightDocument13 pagesTwilightAnn-Katherine SPas encore d'évaluation

- The Road Not TakenDocument2 pagesThe Road Not TakenMaroua TouilPas encore d'évaluation