Académique Documents

Professionnel Documents

Culture Documents

Load Cell Transducer Apd4059

Transféré par

Pipe CastilloCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Load Cell Transducer Apd4059

Transféré par

Pipe CastilloDroits d'auteur :

Formats disponibles

Strain Gauge/Bridge/Load Cell/Pressure Transducer to DC Transmitters, Field Rangeable

APD 4059

Input: 100 to 10,000 Bridges, 0.5 mV/V to 40 mV/V, 1-10 VDC Excitation

Output: 0-1 V to 10 V or 0-2 mA to 4-20 mA (Sink or Source)

OO Drive up to Four 350 Bridges Connect mA Output

OO Adjustable Excitation Power Supply for Sink or Source Removable Plugs

OO Sense Lead Compensation

File E145968

OO One Minute Setup for Hundreds of I/O Ranges 85-265 VAC, 60-300 VDC Hundreds of Range

OO Removable Plugs for Faster Installation model only

Selections

OO Non-Interactive Zero and Span

OO Full 3-Way Input/Output/Power Isolation Output LoopTracker

OO Input and Output LoopTracker LEDs

H H H H H H

H H H H H

LED

H H H H H H

H H H H H

H H H H H H

H H H H H

H H H H H H

H H H H H

OO Output Test or Calibration Resistor Options

H H H H H H

Applications Made in USA

Test Switch for

QQ Load Cell Weighing Systems and Scales Calibration Resistor

QQ Strain Gauge Pressure Sensors and Transducers

QQ Tanks, Scales, Extruder Melt Pressure, Crane Loads

Quick Link Zero and Span for

Strain Gauge Input Ranges api-usa.com/4059 Output

100 to 10,000 bridges at 10 VDC

Up to four 350 bridges at 10 VDC

Minimum: 0 to 5 mV range 0.5 mV/V sensitivity Input LoopTracker

Maximum: 0 to 400 mV range 40 mV/V sensitivity Free Factory LED

Millivolt output range is determined by the sensor sensitivity I/O Setup!

(mV/V) and the excitation voltage: Internal/External

mV/V sensitivity X excitation voltage = total mV range Calibration Resistor

Input Impedance Options

200 k typical

Common Mode Rejection 1 Minute

Setup!

Connect up to 4

100 dB minimum Load Cells

Calibration Resistor Options

M01 option: Switch with calibration resistor inside module. Housing and Connectors

Specify resistor value. IP 40, requires installation in panel or enclosure

M02 option: Switch for external (load cell) calibration resistor. For use in Pollution Degree 2 Environment

Mount vertically to a 35 mm DIN rail

Excitation Voltage

Switch Selectable: 0-10 VDC in 1 V increments Four 4-terminal removable connectors, 14 AWG max wire size

Maximum Output: 10 VDC maximum at 120 mA Dimensions Universal Power

Drive Capability: Up to four 350 bridges at 10 VDC 0.89" W x 4.62" H x 4.81" D

Fine Adjustment: 5% via multi-turn potentiometer 22.5 mm W x 117 mm H x 122 mm D

Stability: 0.01% per C Height includes connectors

Sense Lead Compensation Power

Better than 0.01% per 1 change in leadwire resistance Standard: 85-265 VAC, 50/60 Hz or 60-300 VDC

Maximum leadwire resistance: 10 with 350 at 10 VDC D option: 9-30 VDC (either polarity) or 10-32 VAC

LoopTracker Power: 2 to 5 Watts depending on number of load cells

Variable brightness LEDs for input/output loop level and status Description Sink/Source Versatility

DC Output Ranges The APD 4059 accepts an input from one to four strain gauges, For maximum versatility the APD 4059 milliamp output can be

Voltage (10 mA max.): 0-1 VDC to 0-10 VDC bridge type sensors, load cells, or pressure transducers. It selectively wired for sinking or sourcing. This allows connec-

Bipolar Voltage (10 mA max.): 5 VDC or 10 VDC filters, amplifies, and converts the resulting millivolt signal tion to any type of mA input receiving device.

Current: 0-2 mADC to 0-20 mADC into the selected DC voltage or current output that is linearly LoopTracker

Compliance, drive at 20 mA: 20 V, 1000 drive related to the input. API exclusive features include two LoopTracker LEDs (green for

Current output can be selectively wired for sink or source The full 3-way (input, output, power) isolation makes this mod- input, red for output) that vary in intensity with changes in the

Output Calibration ule useful for ground loop elimination, common mode signal process input and output signals. These provide a quick visual

Multi-turn zero and span potentiometers rejection or noise pickup reduction. picture of your process loop at all times and can greatly aid in

15% of span adjustment range typical The adjustable excitation power supply generates a stable saving time during initial startup and/or troubleshooting.

Zero offset switch: 100% of span in 15% increments source of voltage to drive from one to four 350 (or greater) Output Test

Output Ripple and Noise devices. Sense lead circuitry is included to cancel the effects An API exclusive feature includes the test button to provide a

Less than 10 mVRMS ripple and noise of leadwire resistance, if required. fixed output (independent of the input) when held depressed.

Output Test Input, output, excitation and zero offset are field configurable, The output test button greatly aids in saving time during initial

Sets output to test level when pressed via external rotary and slide switches. Offsets up to 100% startup and/or troubleshooting. The test output level is potenti-

Adjustable 0-100% of span of span can be used to cancel sensor offsets or non-zero ometer adjustable from 0 to 100% of output span.

Not available with M01 or M02 options deadweights (taring). Non-interactive zero and span simplifies The output test is not available with the M01 or M02 options. A

Accuracy calibration. calibration resistor switch replaces the test button.

0.1% of span (includes adjustment resolution and linearity) Model Input Output Power

Response Time

APD 4059 Field configurable. Specify the following if Field configurable. Specify follow- 85-265 VAC or 60-300 VDC

70 milliseconds typical (14.2 Hz)

factory is to set switches ing if factory is to set switches

DF option: 10 millisecond response time typical (100 Hz)

Bridge mV/V or mV range Output range

Contact factory for custom response times APD 4059 D 9-30 VDC or 10-32 VAC

Excitation voltage Output type (V or mA)

Isolation

1200 VRMS min. Optionsadd to end of model number Accessoryorder as separate line item

Full isolation: power to input, power to output, input to output M01 Switch with built-in calibration resistor. Specify API BP4 Spare removable 4 terminal plug, black

Ambient Temperature Range and Stability resistor value.

10C to +60C operating ambient M02 Switch for external calibration resistor.

Better than 0.02% of span per C stability DF 10 millisecond response time, or consult factory

U Conformal coating for moisture resistance

1220 American Way Libertyville, IL 60048 03-17

BSOLUTE ROCESS NSTRUMENTS, Inc. Phone: 800-942-0315 Fax: 800-949-7502 api-usa.com

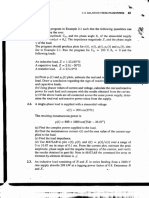

Precautions, Range Setup APD 4059

Precautions Switch A Excitation Voltage Using Offset Switch C

WARNING! All wiring must be performed by a qualified electrician Refer to the sensor manufacturer's recommendations to deter- Offset switch C allows canceling or taring of non-zero dead-

or instrumentation engineer. See diagram for terminal designa- mine what excitation voltage to use. weights or other sensor offsets such as:

tions and wiring examples. Consult factory for assistance. Set Excitation rotary switch A to desired excitation voltage. OO Compensate for tare weights or scale deadweight to get

WARNING! Avoid shock hazards! Turn signal input, output, and After installation the Excitation fine adjust potentiometer may zero output when a load is on the platform.

power off before connecting or disconnecting wiring, or remov- be used to precisely trim this voltage, if desired. OO Compensate for low-output sensors (e.g., less than 1 mV/V)

ing or installing module. that may have large zero offsets. Switch C can realign the

Prcautions Excitation Switch A zero control so it has enough range to produce a zero output.

ATTENTION! Tout le cblage doit tre effectu par un lec- 10 V A

OO Raising the offset to allow calibration of bipolar sensors

tricien ou ingnieur en instrumentation qualifi. Voir le dia- 9V 9 such as 10 mV.

gramme pour dsignations des bornes et des exemples de 8V 8

OO Lowering the offset to compensate for elevated input

cblage. Consulter l'usine pour assistance. 7V 7 ranges such as 10-20 mV.

ATTENTION! viter les risques de choc! Fermez le signal 6V 6

1. Switch C does not interact with any other switch and is the

d'entre, le signal de sortie et l'alimentation lectrique avant 5V 5 only switch needed to correct zero offsets. Its only purpose

de connecter ou de dconnecter le cblage, ou de retirer ou 4V 4 is to adjust or cancel effects of the low end of the input

d'installer le module. 3V 3 range not corresponding nominally to 0 mV. Setting this

Range Selection 2V 2 switch to 0 results in no offset.

It is generally easier to select ranges before installing the mod- 1V 1 2. To RAISE the output zero, rotate switch C from 1 thru 7,

ule on the DIN rail. The tables list available settings for excita-

0V 0 until the Zero control can be set for your application.

tion voltages, ranges and offsets. Any custom range settings

will be listed on the module's serial number label 3. To LOWER the output zero, rotate switch C from 9 thru F,

until the Zero control can be set for your application.

Rotary switches and a slide switches on the side of the module I/O Range Selection Switches B, D, E

are used to select input and output ranges to match your 4. If switch positions are changed, repeat the calibration pro-

1. From the table below, find the rotary switch combination that cedure on the last page.

application. matches your I/O ranges and set rotary switches B and D.

Switch A: Excitation voltage 2. For taring, deadweight, zero offset, or a bipolar sensor refer Offset % of Span Switch C

Switch B: Input range to the "Offset Switch C" section at right. Otherwise set 105% 7

Switch C: Input offset switch C to zero. 90% 6

Switch D: Output range 3. Set switch E to "V" for voltage output or "I" for current 75% 5

output. 60% 4

Switch E : Set to "V" for voltage output or

Set to "I" for current output 4. For ranges that fall between the listed ranges use the next 45% 3

highest setting and trim the output signal with the zero and 30% 2

Determine how much output in millivolts the load cell will pro-

duce at full load. Multiply the manufacturer's mV/V sensitivity span potentiometers as described in the Calibration section. 15% 1

specification by the applied excitation voltage. 0% 0

For example, a load cell rated for 3 mV/V sensitivity using 10 15% 9

VDC excitation will produce an output of 0 to 30 mV for load 30% A

variations from 0 to 100%. 45% B

3 mV/V sensitivity X 10 VDC excitation = 30 mV range 60% C

75% D

90% E

105% F

Output 0-1 V 0-2 V 0-4 V 1-5 V 0-5 V 0-8 V 2-10 V 0-10 V 5 V 10 V 0-2 mA 0-4 mA 0-8 mA 2-10 mA 0-10 mA 0-16 mA 4-20 mA 0-20 mA

Switches

BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE BCDE

Input

0-5 mV 200V 208V 201V 206V 209V 202V 207V 203V 204V 205V 200I 208I 201I 206I 209I 202I 207I 203I

0-10 mV A00V A08V A01V A06V A09V A02V A07V A03V A04V A05V A00I A08I A01I A06I A09I A02I A07I A03I

0-20 mV 300V 308V 301V 306V 309V 302V 307V 303V 304V 305V 300I 308I 301I 306I 309I 302I 307I 303I

0-25 mV 600V 608V 601V 606V 609V 602V 607V 603V 604V 605V 600I 608I 601I 606I 609I 602I 607I 603I

0-30 mV E00V E08V E01V E06V E09V E02V E07V E03V E04V E05V E00I E08I E01I E06I E09I E02I E07I E03I

0-40 mV B00V B08V B01V B06V B09V B02V B07V B03V B04V B05V B00I B08I B01I B06I B09I B02I B07I B03I

0-50 mV 000V 008V 001V 006V 009V 002V 007V 003V 004V 005V 000I 008I 001I 006I 009I 002I 007I 003I

0-100 mV 800V 808V 801V 806V 809V 802V 807V 803V 804V 805V 800I 808I 801I 806I 809I 802I 807I 803I

0-120 mV F00V F08V F01V F06V F09V F02V F07V F03V F04V F05V F00I F08I F01I F06I F09I F02I F07I F03I

0-200 mV 100V 108V 101V 106V 109V 102V 107V 103V 104V 105V 100I 108I 101I 106I 109I 102I 107I 103I

0-250 mV 400V 408V 401V 406V 409V 402V 407V 403V 404V 405V 400I 408I 401I 406I 409I 402I 407I 403I

0-300 mV C00V C08V C01V C06V C09V C02V C07V C03V C04V C05V C00I C08I C01I C06I C09I C02I C07I C03I

0-400 mV 900V 908V 901V 906V 909V 902V 907V 903V 904V 905V 900I 908I 901I 906I 909I 902I 907I 903I

API maintains a constant effort to upgrade and improve its

products. Specifications are subject to change without notice.

Consult factory for your specific requirements.

1220 American Way Libertyville, IL 60048

BSOLUTE ROCESS NSTRUMENTS, Inc. Phone: 800-942-0315 Fax: 800-949-7502 api-usa.com

Wiring and Installation APD 4059

M01 Option: Internal Calibration Resistor Mounting to a DIN Rail Output Wiring 4-20 mA

The APD 4059 M01 has a user-specified internal calibration Install module vertically on a 35 mm DIN rail in a protective Device

resistor. A switch on the front of the module allows switching enclosure away from heat sources. Do not block air flow. Current sinking output Ri

of the APD's internal calibration resistor in or out of the circuit. 1. Tilt front of module downward and position against DIN rail. switch E set to I Loop + +

The sensor manufacturer should provide the percentage of full- External device provides Power

2. Clip lower mount to bottom edge of DIN rail. power to output loop Source +

scale output for the transducer when using the APD's internal

3. Push front of module upward until upper mount snaps into place.

resistor for calibration. 1 2 3 4

Removal

M02 Option: Load Cell Calibration Resistor Passive

1. Push up on the bottom back of the module.

The APD 4059 M02 has provisions for a load cell with its own 4-20 mA

2. Tilt front of module downward to release upper mount Current sourcing output Device

calibration resistor. A switch on the front of the module allows switch E set to I

from top edge of DIN rail. Ri

switching of the load cell internal calibration resistor in or out +20 V at terminal 4

3. The module can now be removed from the DIN rail. +20V

of the circuit.

Refer to the load cell manufacturer's specifications and the 1 2 3 4

wiring diagram when connecting a transducer with its own

Voltage

internal calibration resistor.

Voltage output Device

The transducer's calibration resistor wires are connected to switch E set to V +

terminals 5 and 11 on the APD 4059.

If the transducer only has one calibration resistor wire, connect 1 2 3 4

it to terminal 5.

Input

Refer to strain gauge manufacturers data sheet for wire color-

No Sense Leads

Jumper 6 to 12

coding and identification. Polarity must be observed when M02 option ONLY if sense leads

Cal.

connecting inputs. for load cell are NOT used

Upper Mount with built-in

CAUTION: Do not miswire the load cell and never short the cal. resistor.

excitation leads together. This will cause internal damage to Connect to 5 6 7 8

Lower Mount

the module. terminals 5

No Sense Leads and 11

Spring Clip Exc + Excitation

When no sense leads are used, jumper terminals 6 and 12. Output

With Sense Leads VEX + Test Cal.

Some bridges or load cells have one or two sense leads.

Sense leads allow the APD 4059 to compensate for leadwire Sig Sig Test

V0 Strain +

resistance effects. Connect the sense leads if used. Polarity Gauge V0 +

must be observed. Span

Output 1 2 3 4 Input

Never jumper terminals 6 and 12 when using sense leads. VEX Zero

Output 5 6 7 8

Cal. and Sense Exc APD 4059

Polarity must be observed when connecting the signal output. Strain Gauge to DC

Isolated Transmitter

If your device accepts a current input, determine if it provides Do not connect

power to the current loop or if it must be powered by the APD anything to 9 10 11 12

module. Use a multi-meter to check for voltage at the device's unused terminals

input terminals. Typical voltage may be 9-24 VDC.

Exc

Sig +

Exc +

Sig

Type of Device for Output Term. + Term.

mA (current) input device that powers

the current loop. Switch E set to I. 2 () 3 (+)

mA (current) input device that is pas-

sive. APD module provides the loop 3 () 4 (+20 V) With Sense Leads

power. Switch E set to I. M02 option

Sense +

for load cell

Cal.

Measuring/recording device accepts a

voltage input. Switch E set to V. 3 () 4 (+) with built-in

Input 9 10 11 12 cal. resistor.

Module Power Connect to 5 6 7 8

Power 13 14 15 16 terminals 5

Check model/serial number label for module operating voltage Sense +

and 11

to make sure it matches available power. Connect power last.

Excitation

When using DC power, either polarity is acceptable, but for Exc + Output

consistency with similar API products, positive (+) can be wired VEX + Test Cal.

to terminal 13 and negative () can be wired to terminal 16. Shield wires should be grounded at one end only

Connect I/O wiring before power wiring. Sig Sig Test

V0 Strain +

Colors shown are an example only. Gauge V0 +

CAUTION: To maintain full isolation avoid wiring DC power sup- See manufacturer's specifications for wiring designations. Span

plies in common with output and unit power. Input

To maintain full isolation avoid combining power supplies VEX Zero

in common with input, output, or unit power.

Exc Sense APD 4059

Strain Gauge to DC

Isolated Transmitter

9 10 11 12

Exc

Sig +

Exc +

Sig

Sense

Cu 60/75C Module Power 13 14 15 16

conductors 13 Power AC or DC +

14 AWG 14 Earth Ground

max. 16 Power AC or DC

1220 American Way Libertyville, IL 60048

BSOLUTE ROCESS NSTRUMENTS, Inc. Phone: 800-942-0315 Fax: 800-949-7502 api-usa.com

Calibration, Operation, Diagnostics, Load Cell Information APD 4059

Basic Calibration Calibration with Resistor Options M01 or M02 Operation

The Zero, Span, and Excitation potentiometers are used to cali- Use this calibration procedure if your APD 4059 was ordered Strain gauges and load cells are normally passive devices

brate the output. This calibration procedure does not account with a calibration resistor or if your sensor has its own internal that are commonly referred to as bridges due to their

for offsets or tare weights. If your system has an offset, tare calibration resistor. four-resistor Wheatstone bridge configuration. These sensors

weight or deadweight, refer to the Offset Switch procedure. The M01 option uses a resistor installed internally in the APD require a precise excitation source to produce an output that is

To achieve optimum results, the system should be calibrated 4059. The resistance is specified by the transducer manu- directly proportional to the load, pressure, etc. that is applied

using an accurate bridge simulator, pressure calibrator, or facturer. to the sensor.

calibration weights depending on the application. The M02 option is specified when the transducer incorporates The exact output of the sensor (measured in millivolts) is deter-

1. Apply power to the module and allow a minimum 20 minute an internal calibration resistor. The transducer must be con- mined by the sensitivity of the sensor (mV/V) and the excitation

system warm up time. nected per the manufacturer's specifications. voltage applied.

2. Using an accurate voltmeter across terminals 10 and 12, The sensor manufacturer should provide the percentage of An additional input, the sense lead, monitors the voltage drop

adjust the Excitation voltage potentiometer on front of the full-scale output for the transducer when using a calibration in the sensor leads and automatically compensates the excita-

APD 4059 for the exact voltage desired. resistor. This is often 80% of maximum output. tion voltage at the module in order to maintain a constant

excitation voltage at the sensor.

3. With the input set at zero or the minimum, adjust the Zero 1. Apply power to the module and allow a minimum 20 minute

pot on front of the APD 4059 for a zero or low-end output system warm up time. The APD 4059 provides the excitation voltage to the sensors

(for example, 4 mA for a 4-20 mA output). and receives the resulting millivolt signal in return. This input

2. Using an accurate voltmeter across terminals 10 and 12,

signal is filtered and amplified, then offset, if required, and

4. The zero pot may also be adjusted for a zero reading on adjust the Excitation voltage potentiometer on front of the

passed to the output stage. Depending on the output configu-

the output display instrumentation, e.g. control system or APD 4059 for the exact voltage desired.

ration selected, a DC voltage or current output is generated.

process indicator. Adjusting the zero pot this way eliminates 3. With the input set at zero or the minimum, adjust the Zero

calibration errors in the display instrumentation. GREEN LoopTracker Input LED Provides a visual indica-

potentiometer on front of the APD 4059 for a zero or low-

tion that a signal is being sensed by the input circuitry of the

5. Set the input at maximum, and then adjust the Span pot for end output (for example, 4 mA for a 4-20 mA output).

module. It also indicates the input signal level by changing in

the exact maximum output desired. The Span control should 4. The zero pot may also be adjusted for a zero reading on intensity as the process changes from minimum to maximum.

only be adjusted when the input signal is at its maximum. the output display instrumentation, e.g. control system or If the LED fails to illuminate, or fails to change in intensity as

Output Test Function process indicator. Adjusting the zero pot this way eliminates the process changes, this may indicate a problem with module

Models with the M01 or the M02 option do not have a Test calibration errors in the display instrumentation. power or signal input wiring.

function. With either of these options the Test Cal. potentiom- 5. Set the APD 4059 Test toggle switch to the Test position. RED LoopTracker Output LED Provides a visual indication

eter is non-functional. The calibration resistor is switched into the circuit to unbal- that the output signal is functioning. It becomes brighter as the

When the Test button is depressed it will drive the output with a ance the bridge. input and the corresponding output change from minimum to

known good signal that can be used as a diagnostic aid during 6. Adjust the span pot to the for the % output specified by the maximum. For current outputs, the RED LED will only light if

initial start-up or troubleshooting. When released, the output transducer manufacturer. This is often 80% of maximum the output loop current path is complete. For either current or

will return to normal. output. voltage outputs, failure to illuminate or a failure to change in

The Test Cal. potentiometer can be used to set the test output 7. Return the Test switch to the opposite position and readjust intensity as the process changes may indicate a problem with

to the desired level. It is factory set to approximately 50% out- the zero pot if necessary. the module power or signal output wiring.

put. It is adjustable from 0 to 100% of the output span. Press

and hold the Test button and adjust the Test Cal. potentiometer

for the desired output level.

Diagnostic Voltage Measurements Positive Negative Meter Reading Meter Reading

Using a meter with at least 10 megaohm input impedance, Meter Lead Meter Lead No pressure/load Full pressure/load

measure the voltage coming from the strain gauge at the loca- + Exc. Exc. Excitation Voltage Excitation Voltage

tions shown. Sensitivity is measured in mV/V. + Sig. Exc. + Excitation Voltage Excitation Voltage + ( x Excitation Voltage x Sensitivity)

Sig. Exc. + Excitation Voltage Excitation Voltage ( x Excitation Voltage x Sensitivity)

+ Sig. Sig. Zero Volts Excitation Voltage x Sensitivity

Typical Wiring Color Codes for Load Cells

Always consult manufacturer. Exceptions and/or custom wire colors exist!

Manufacturer + Exc. Exc. + Signal Signal Shield + Sense Sense Manufacturer + Exc. Exc. + Signal Signal Shield + Sense Sense

A&D Red White Green Blue Yellow Nikkei Red Black Green White Bare

Allegany Green Black White Red Bare OmegaDyne Red, D, F Blk., C, E Green A White B Bare

American/Amcell Green Black White Red Bare Pennsylvania Orange Blue Green White Bare

Artech Red Black Green White Bare Philips Red Blue Green Gray Bare

Beowulf Green Black White Red Bare Presage Promotion Blue White Red Black Yellow

BLH Green Black White Red Yellow Revere Green Black White Red Orange

Cardinal Green Black White Red Bare Revere Red Black Green White Orange

Celtron Red Black Green White Bare Rice Lake Red Black Green White Bare

Digi Matex Red White Green Yellow Silver Sensortronic Red Black Green White Bare

Dillon (DQ+) Green White Black Red Orange Sensortronic (col.) Green Black White Red Bare

Electroscale Red Black Green White Bare Sensotec/Honeywell Red Black White Green Bare

Entran Red Black Yel./Grn. White Sentran Red Black Green White Bare

EverGreen Green Black White Red Bare SMD Red Black White Green Bare

Flintec Green Black White Red Yellow Strainsert Red Black Green White Bare

Force Measurement Red Black Green White Bare Stellar STI Red Black White Green Bare

Futek Red Black Green White Stellar STI Red Black Green White Bare

General Sensor Red Black Green White Bare Stellar STI A D B C Bare

GSE Red Black White Green Bare Stellar STI A, B C, D F E Bare

HBM Green Black White Red Yellow T-Hydronics Red Black Green White Bare

HBM (PLC/SBE) Red Black Green White Yellow Tedea Huntleigh Green Black Red White Bare Blue Brown

Interface Red Black Green White Bare Thames Side Red Blue Green Yellow Bare

Kubota Red White Green Blue Yellow Toledo Green Black White Red Yellow

LeBow Red Black Green White Bare Totalcomp Red Black Green White Bare

Mettler Toledo White Blue Green Black Orange Yellow Red Transducer Tech. Red A Black D Green C White B Bare G

National Scale Green Black White Red Yellow Transducers Inc. Red Black Green White Orange

NCI Red Black White Green Bare Yellow Blue Weigh-Tronix Green Black White Red Or./Wh. Yellow Blue

1220 American Way Libertyville, IL 60048

BSOLUTE ROCESS NSTRUMENTS, Inc. Phone: 800-942-0315 Fax: 800-949-7502 api-usa.com

Vous aimerez peut-être aussi

- Strain Gauge/Bridge/Load Cell/Pressure Transducer To DC Transmitters, Field Rangeable APD 4059Document4 pagesStrain Gauge/Bridge/Load Cell/Pressure Transducer To DC Transmitters, Field Rangeable APD 4059luat1983Pas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Api 4058 GDocument4 pagesApi 4058 Gluat1983Pas encore d'évaluation

- DC To DC Transmitters, Isolated, Field Rangeable API 4380 G: Bsolute Rocess NstrumentsDocument2 pagesDC To DC Transmitters, Isolated, Field Rangeable API 4380 G: Bsolute Rocess NstrumentsharounPas encore d'évaluation

- Api4380g DC2DC Transmitter, IsolatedDocument2 pagesApi4380g DC2DC Transmitter, IsolatedJimmy F HernandezPas encore d'évaluation

- Apax 508020180910102319Document1 pageApax 508020180910102319Samdan NamhaisurenPas encore d'évaluation

- Surge GeneratorDocument5 pagesSurge Generatorpawan kumar raiPas encore d'évaluation

- RISH Ducer F11 Transducer For Measuring Frequency: D C B ADocument1 pageRISH Ducer F11 Transducer For Measuring Frequency: D C B AMahesh KumbharPas encore d'évaluation

- Industrial Automation Companies India - Canopus InstrumentsDocument2 pagesIndustrial Automation Companies India - Canopus InstrumentscanopusinstrumentsPas encore d'évaluation

- Eiadp1020 DTS0183 enDocument4 pagesEiadp1020 DTS0183 enHalenaBuanPas encore d'évaluation

- SIL 2 Load Cell Isolating ConverterDocument2 pagesSIL 2 Load Cell Isolating ConverterkorpaapPas encore d'évaluation

- Pulse Output Device (POD) Electronic Encoder: Product Overview E100-50Document4 pagesPulse Output Device (POD) Electronic Encoder: Product Overview E100-50ArevaLemaPas encore d'évaluation

- MPP Catalog en ImpDocument7 pagesMPP Catalog en ImproyPas encore d'évaluation

- Champ T400: The World Class Inverter Based DC WelderDocument2 pagesChamp T400: The World Class Inverter Based DC WelderNaresh APas encore d'évaluation

- DB Ca04pa04Document2 pagesDB Ca04pa04AriNetoPas encore d'évaluation

- ONExia Parker P Series CatalogDocument14 pagesONExia Parker P Series Cataloghoussem houssemPas encore d'évaluation

- LAC74.1 Installation Guide V.2Document1 pageLAC74.1 Installation Guide V.2tarik tarikPas encore d'évaluation

- Crown 660aDocument2 pagesCrown 660aAndres AltamiranoPas encore d'évaluation

- Dynalco SST-2000A.data SheetDocument2 pagesDynalco SST-2000A.data Sheetalimoya13Pas encore d'évaluation

- 9000C User ManualDocument5 pages9000C User ManualImtiyaz MakandarPas encore d'évaluation

- Entrelec Signal ConverterDocument2 pagesEntrelec Signal ConverterVikaas JainPas encore d'évaluation

- TemporizadorDocument12 pagesTemporizadorsouzaguimaraisericPas encore d'évaluation

- MPP Catalog en A4Document6 pagesMPP Catalog en A4Panthera tigrisPas encore d'évaluation

- T8200 tube optimizer user manualDocument16 pagesT8200 tube optimizer user manualPaolo MaghacotPas encore d'évaluation

- Harman/Kardon AVR 254 Service Manual)Document189 pagesHarman/Kardon AVR 254 Service Manual)jrubins100% (1)

- Iraudamp 17Document13 pagesIraudamp 17Carlos AlvarezPas encore d'évaluation

- Magnetic Flow E&HDocument20 pagesMagnetic Flow E&HThanachai TengjirathanapaPas encore d'évaluation

- ASHE TX Series Signal Isolators GuideDocument2 pagesASHE TX Series Signal Isolators GuidemuralimskPas encore d'évaluation

- Analog Input/output Modules - EM 231 Analog Input ModulesDocument11 pagesAnalog Input/output Modules - EM 231 Analog Input ModulesLượng TrầnPas encore d'évaluation

- High Voltage Regulator 2Document8 pagesHigh Voltage Regulator 2ashfaqPas encore d'évaluation

- Walchem PH - Sensors 102029Document4 pagesWalchem PH - Sensors 102029marcosPas encore d'évaluation

- C & Tanδ Meter for Insulation MaterialsDocument4 pagesC & Tanδ Meter for Insulation MaterialsBash MatPas encore d'évaluation

- PA1001ADocument4 pagesPA1001AavryonePas encore d'évaluation

- 22KW-30KW InverterDocument1 page22KW-30KW InverterMAROC INVESTISSEMENTPas encore d'évaluation

- AVR110 Service Manual: Harman/kardonDocument127 pagesAVR110 Service Manual: Harman/kardonRicardo CachorrãoPas encore d'évaluation

- Harman Kardon Avr8000Document242 pagesHarman Kardon Avr8000videosonPas encore d'évaluation

- 4015 Extended Specifications V1 2Document31 pages4015 Extended Specifications V1 2SHAHID KHAN CHANNARPas encore d'évaluation

- LED Multifunctional Power InstrumentDocument28 pagesLED Multifunctional Power InstrumentPurevee PureveePas encore d'évaluation

- Proximity Sensors Capacitive Amplifier GuideDocument2 pagesProximity Sensors Capacitive Amplifier Guideshawn hagerichPas encore d'évaluation

- UP4 Din BrochureDocument2 pagesUP4 Din BrochuresenthilrsenthilPas encore d'évaluation

- Champ T400: The World Class Inverter Based DC WelderDocument2 pagesChamp T400: The World Class Inverter Based DC WelderWickyPas encore d'évaluation

- D1010-046 Ism0066 enDocument14 pagesD1010-046 Ism0066 enYoussef HabiballahPas encore d'évaluation

- Sedona Programmable Controller P-Ion: SpecificationsDocument2 pagesSedona Programmable Controller P-Ion: SpecificationsHarun KaripPas encore d'évaluation

- PartoSanat InvtDocument72 pagesPartoSanat InvtDio AlfaroPas encore d'évaluation

- Quarter Brick Single1Document4 pagesQuarter Brick Single1yuryPas encore d'évaluation

- AVR-45 (SM) PDFDocument87 pagesAVR-45 (SM) PDFJory2005Pas encore d'évaluation

- AVR1A Voltage Sensing RelayDocument2 pagesAVR1A Voltage Sensing Relaysulaimani keedaPas encore d'évaluation

- 11 000 Measuring Equipment SummaryDocument38 pages11 000 Measuring Equipment SummaryAdrian GarciaPas encore d'évaluation

- Ds 5510 5516 0610Document2 pagesDs 5510 5516 0610frdnPas encore d'évaluation

- Electronic relays: Measuring and monitoring relaysDocument2 pagesElectronic relays: Measuring and monitoring relaysDan Alexandru NeaguPas encore d'évaluation

- Bag Data Sheet Zitares CCD Ls 4chDocument6 pagesBag Data Sheet Zitares CCD Ls 4chSingh SarandeepPas encore d'évaluation

- HarmanKardon AVR347 7.1 RecDocument218 pagesHarmanKardon AVR347 7.1 RecBill MathesPas encore d'évaluation

- Harman Kardon AVR 645 Service ManualDocument139 pagesHarman Kardon AVR 645 Service ManualAlaa KanjPas encore d'évaluation

- Extended Specifications: Transmille 4010 Advanced Multiproduct CalibratorDocument31 pagesExtended Specifications: Transmille 4010 Advanced Multiproduct CalibratorJulian MoraPas encore d'évaluation

- SCT-1100 and SCT-2200 Advanced Series: Approvals ApprovalsDocument4 pagesSCT-1100 and SCT-2200 Advanced Series: Approvals Approvalsproduccion multipackPas encore d'évaluation

- Joystick TerexDocument16 pagesJoystick TerexEpure GabrielPas encore d'évaluation

- Prod PDF 1051492176905Document3 pagesProd PDF 1051492176905cs9218Pas encore d'évaluation

- Ael1046 Universal Lab TrainerDocument2 pagesAel1046 Universal Lab TrainerCarbon Nano TubePas encore d'évaluation

- Copias Problemas Capitulo - 2Document5 pagesCopias Problemas Capitulo - 2Pipe CastilloPas encore d'évaluation

- Potencia Taller - 7b - SolucionDocument9 pagesPotencia Taller - 7b - SolucionPipe CastilloPas encore d'évaluation

- AS300+MS300 CANopen Network SetupDocument5 pagesAS300+MS300 CANopen Network SetupPipe Castillo100% (1)

- SmartGuard 600 - Channel ConfigurationsDocument2 pagesSmartGuard 600 - Channel ConfigurationsPipe CastilloPas encore d'évaluation

- 04463848Document11 pages04463848Pipe CastilloPas encore d'évaluation

- 1791DS - Module Replacement GuidelinesDocument1 page1791DS - Module Replacement GuidelinesPipe CastilloPas encore d'évaluation

- BD80 InstructionsDocument24 pagesBD80 InstructionsPipe CastilloPas encore d'évaluation

- Potencia Taller - 7a - SolucionDocument5 pagesPotencia Taller - 7a - SolucionPipe CastilloPas encore d'évaluation

- BD80 Instructions PDFDocument24 pagesBD80 Instructions PDFPipe CastilloPas encore d'évaluation

- DC AC Inverter IGBT Card PDFDocument26 pagesDC AC Inverter IGBT Card PDFPipe CastilloPas encore d'évaluation

- Tigerclassic ValvesDocument53 pagesTigerclassic ValvesPipe CastilloPas encore d'évaluation

- CVP - Advanced Vision Guided Robotics - Steven Prehn PDFDocument48 pagesCVP - Advanced Vision Guided Robotics - Steven Prehn PDFPipe CastilloPas encore d'évaluation

- 04 Counting Loops and AccumulatorsDocument9 pages04 Counting Loops and AccumulatorsPipe Castillo100% (1)

- RSEmulate 5000 or SoftLogix5800 Fails To UninstallDocument2 pagesRSEmulate 5000 or SoftLogix5800 Fails To UninstallPipe CastilloPas encore d'évaluation

- Introduction to Databases and Structured Query Language (SQLDocument61 pagesIntroduction to Databases and Structured Query Language (SQLPipe CastilloPas encore d'évaluation

- Understanding Shielded CableDocument5 pagesUnderstanding Shielded Cablewasim_scribedPas encore d'évaluation

- Alphawire Understanding Shielded CableDocument2 pagesAlphawire Understanding Shielded CablePipe CastilloPas encore d'évaluation

- Sqltutorialbasiccommands 130310014513 Phpapp01Document19 pagesSqltutorialbasiccommands 130310014513 Phpapp01ChandrakantShindePas encore d'évaluation

- SQL DB Toc Fromms05Document39 pagesSQL DB Toc Fromms05Pipe CastilloPas encore d'évaluation

- Table of Contents for SQL Server DocumentationDocument85 pagesTable of Contents for SQL Server DocumentationPipe CastilloPas encore d'évaluation

- SQL DB Toc Fromms04Document74 pagesSQL DB Toc Fromms04Pipe CastilloPas encore d'évaluation

- Ten Common Database Design Mistakes - Simple TalkDocument26 pagesTen Common Database Design Mistakes - Simple TalkPipe CastilloPas encore d'évaluation

- SQL DB Toc Fromms03Document128 pagesSQL DB Toc Fromms03Pipe CastilloPas encore d'évaluation

- SQL Server 2017 DatasheethugDocument2 pagesSQL Server 2017 DatasheethugPipe CastilloPas encore d'évaluation

- BODINE-AC Sync Gearmotors Application NoteDocument3 pagesBODINE-AC Sync Gearmotors Application NotePipe CastilloPas encore d'évaluation

- SQL DB Toc Fromms02Document159 pagesSQL DB Toc Fromms02Pipe CastilloPas encore d'évaluation

- Dec 2017 Encompass Webinar SlidesDocument24 pagesDec 2017 Encompass Webinar SlidesPipe CastilloPas encore d'évaluation

- KepServer Enterprise 9.00 driver listDocument2 pagesKepServer Enterprise 9.00 driver listPipe CastilloPas encore d'évaluation

- Internal Controls and Risk Management: Learning ObjectivesDocument24 pagesInternal Controls and Risk Management: Learning ObjectivesRamil SagubanPas encore d'évaluation

- Teodorico M. Collano, JR.: ENRM 223 StudentDocument5 pagesTeodorico M. Collano, JR.: ENRM 223 StudentJepoyCollanoPas encore d'évaluation

- Mil B 49430BDocument36 pagesMil B 49430Bparam.vennelaPas encore d'évaluation

- The Influence of Teleworking On Performance and Employees Counterproductive BehaviourDocument20 pagesThe Influence of Teleworking On Performance and Employees Counterproductive BehaviourCHIZELUPas encore d'évaluation

- Detect Plant Diseases Using Image ProcessingDocument11 pagesDetect Plant Diseases Using Image Processingvinayak100% (1)

- Radiograph Evaluation ChecklistDocument2 pagesRadiograph Evaluation ChecklistZulfadli Haron100% (1)

- CFLM1 Chapter 1Document24 pagesCFLM1 Chapter 1Jonathan TawagPas encore d'évaluation

- Tomas Del Rosario College: Department: EDUCATIONDocument12 pagesTomas Del Rosario College: Department: EDUCATIONveehneePas encore d'évaluation

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pagesEngine Controls (Powertrain Management) - ALLDATA RepairXavier AlvarezPas encore d'évaluation

- Lecture 6Document16 pagesLecture 6Dina Saad EskanderePas encore d'évaluation

- Non-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesDocument2 pagesNon-Destructive Examination & Standard CF Acceptance For - Forgsd - Pipe Work Stub PiecesveeramalaiPas encore d'évaluation

- Language II Module 2 Adjectives and AdverbsDocument25 pagesLanguage II Module 2 Adjectives and AdverbsCarla Arredondo MagnerePas encore d'évaluation

- Syllabus Agri 2015Document248 pagesSyllabus Agri 2015parvathivignesh279Pas encore d'évaluation

- Giljang - Bsn2-A10 - Sas 1-3Document7 pagesGiljang - Bsn2-A10 - Sas 1-3Cherylen Casul GiljangPas encore d'évaluation

- Crafting and Executing StrategyDocument33 pagesCrafting and Executing Strategyamoore2505Pas encore d'évaluation

- Action Plan On GadDocument1 pageAction Plan On GadCherish Devora ArtatesPas encore d'évaluation

- COP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDocument4 pagesCOP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDavid CarrilloPas encore d'évaluation

- Shop SupervisionDocument38 pagesShop SupervisionSakura Yuno Gozai80% (5)

- Sinavy Pem Fuel CellDocument12 pagesSinavy Pem Fuel CellArielDanieli100% (1)

- Wiley Wesleyan UniversityDocument36 pagesWiley Wesleyan UniversityBirunda SilvaPas encore d'évaluation

- Timeline of Internet in The PhilippinesDocument29 pagesTimeline of Internet in The PhilippinesJhayson Joeshua Rubio100% (1)

- 2002 AriDocument53 pages2002 AriMbarouk Shaame MbaroukPas encore d'évaluation

- Stage TwoDocument34 pagesStage TwoThar LattPas encore d'évaluation

- Materials Technical Specification.: Stainless SteelDocument6 pagesMaterials Technical Specification.: Stainless SteelMario TirabassiPas encore d'évaluation

- Campbell Soup Case-StudyDocument3 pagesCampbell Soup Case-StudyraghudeepaPas encore d'évaluation

- SEW Motor Brake BMGDocument52 pagesSEW Motor Brake BMGPruthvi ModiPas encore d'évaluation

- Managerial Performance Evaluation ProceduresDocument3 pagesManagerial Performance Evaluation Procedures1robcortesPas encore d'évaluation

- J05720020120134026Functions and GraphsDocument14 pagesJ05720020120134026Functions and GraphsmuglersaurusPas encore d'évaluation

- U-PJT WASHER-MD SimpleUX WEB SSEC-01 EU EnglishDocument76 pagesU-PJT WASHER-MD SimpleUX WEB SSEC-01 EU EnglishszerenguettiPas encore d'évaluation

- SEM 3037E Tower Piping.Document52 pagesSEM 3037E Tower Piping.Kodali Naveen KumarPas encore d'évaluation