Académique Documents

Professionnel Documents

Culture Documents

Building Information Modeling For Quality Management in Infrastructure

Transféré par

რაქსშ საჰაTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Building Information Modeling For Quality Management in Infrastructure

Transféré par

რაქსშ საჰაDroits d'auteur :

Formats disponibles

COMPUTING IN CIVIL AND BUILDING ENGINEERING ASCE 2014 65

Building Information Modeling for Quality Management in Infrastructure

Construction Projects

Namhun Lee1, Talat Salama2, and George Wang3

Downloaded from ascelibrary.org by UNITEC NEW ZEALAND LIBRARY on 11/08/17. Copyright ASCE. For personal use only; all rights reserved.

1

Assistant Professor, Manufacturing & Construction Management Department,

Central Connecticut State University, New Britain, CT 06050; PH (860) 832-2624;

email: leen@ccsu.edu

2

Associate Professor, Manufacturing & Construction Management Department,

Central Connecticut State University, New Britain, CT 06050; PH (860) 832-2619;

email: talats@ccsu.edu

3

Associate Professor, Department of Construction Management, East Carolina

University, Greenville, NC 27858; PH (252) 737-1887; email: wangg@ecu.edu

ABSTRACT

With the growing use of Building Information Modeling (BIM) for vertical

building projects, the use of BIM in infrastructure projects steadily increases.

Construction companies that build infrastructure facilities are expecting the adoption

of BIM since they have observed high return on investment (ROI) resulting from

BIM for vertical building projects. In this paper, the focus is placed on the utilization

of BIM for quality management in highway and bridge construction. A review of the

literature on quality information model and quality control process is presented. The

application of BIM for quality management is described. The results of pilot study

by the authors on the model-driven approach to quality assurance (QA) and quality

control (QC) is reviewed. Finally the issues and obstacles to BIM implementation in

the infrastructure sector are discussed. Discussions in this paper are the critical

aspects of the utilization of BIM for quality management in infrastructure

construction project. Based on the results of this study, great potential of using BIM

for quality management in infrastructure projects has been identified. Nonetheless,

only limited amount of literature on this topic is currently available. It is believed

that this study will set a stepping stone to future research and practice for promoting

BIM technology in horizontal construction projects.

INTRODUCTION

Construction projects generate a large amount of complex information during

its lifecycle, which is generally stored in document formats. Such information

provides important potential for future use. The use of the information and

knowledge produced during the construction process becomes more and more

important in construction management.

The concept of computer product modeling originated in the 1970s. It is a set

of interacting policies, processes and technologies generating a methodology to

manage the essential building design and project data in digital format throughout the

Computing in Civil and Building Engineering (2014)

COMPUTING IN CIVIL AND BUILDING ENGINEERING ASCE 2014 66

buildings lifecycle (Penttil 2006). In recent years, BIM has been proposed as an

information integration platform to facilitate construction project management. It is

critical to realize the integration between BIM and other information platforms

applied in construction management since various information formats are actually

being used. To support the integration of construction information, BIM data sharing

and information exchanges among different formats/software should be standardized.

Downloaded from ascelibrary.org by UNITEC NEW ZEALAND LIBRARY on 11/08/17. Copyright ASCE. For personal use only; all rights reserved.

Currently, the Industry Foundation Classes (IFC) standard has been commonly used

(Froese 2003). Using the IFC standard, building products data can be expressed and

exchanged.

BIM has been widely used in commercial building construction to not only

virtually build a facility prior to its actual physical construction, but also simulate and

analyze potential impacts (Smith 2007). However, very little information is available

on using BIM in infrastructure construction projects. According to the 2012 McGraw

Hill SmartMarket Report, several terms have already been coined for BIM for

infrastructure, such as Civil BIM, Civil Information Modeling, Horizontal BIM,

and Heavy BIM. Regardless of terms, the main objective is to utilize model-based

technologies and processes in the infrastructure sector. One of the utilization

scenarios would be the use of BIM as a tool for quality information integration for

highway and bridge construction. Construction companies which build heavy, civil,

and transportation facilities are expecting the adoption of BIM in their projects since

they have observed high ROI resulting from BIM for vertical building projects.

BACKGROUND

The purpose of project quality management is to achieve the conditions of

products or services that meet or exceed the customers requirements and

expectations. Information resources include the sequence of operations, controls, and

checks that have to be implemented during construction. Prior to the commencement

of construction work, general contractors are required to prepare specific project

quality management plans which detail the control procedures. The quality

management plans must comply with applicable ISO 9000 standards and/or technical

specifications for a project. In addition, they must demonstrate the ability to deal with

the principles and practice of product and service quality assurance and quality

control.

Quality planning should focus on identifying quality standards relevant to the

project, implementing quality policies and procedures, and managing responsibility

for continuous process improvement. Moreover, inspection and test plans must be

developed to verify if the product complies with the contract document. When

planning conditions controlled for construction activities, a careful consideration

should be given to the following:

Specific jobsite environments

Construction means, methods, techniques, sequences or procedures

Materials, equipment and workmanship for the work

Quality standards for the work

Product characteristics, tolerances, and requirements

Clear responsibility for the quality of the portion of the work

Computing in Civil and Building Engineering (2014)

COMPUTING IN CIVIL AND BUILDING ENGINEERING ASCE 2014 67

Control Procedures for inspection and test as well as nonconformities

Records as evidence that the work process controls remain effective

In general quality control process, QA and QC data should be collected from

the general- and sub-contractors. For state highway agencys (SHA) highway

construction projects, the current practice is that the contractor(s) is responsible for

Downloaded from ascelibrary.org by UNITEC NEW ZEALAND LIBRARY on 11/08/17. Copyright ASCE. For personal use only; all rights reserved.

QC and agencies is responsible for QA. The creation and implementation of a

model-driven approach which integrates the Product, Process, and Organization (PPO)

model with BIM technology for quality management has the potential to facilitate and

enrich a collaboration and integration with other disciplines through quality

information integration. Responsibilities of project participants for the process and

product of construction should be clearly identified and defined. A typical horizontal

construction project has a complex web of interrelationships among numerous project

participants in organization structures (Bass 2000). Due to this fact, it may be

difficult to identify a participant accountable for a quality defect. Therefore,

construction quality must be ensured through confirming responsibilities for each

participant.

QUALITY INFORMATION MODEL

The Deming management method has been widely spread in the field of

quality management since the early 1980s. The purpose of the Deming management

method is to improve the practice of quality management (Deming 1981). The

Deming management method consists of fourteen imperative points which are

principles of transformation for quality management (Deming 1986). Through the

fourteen points, Deming emphasizes the importance of process control (continuous

improvement) and organizational structure (internal and external cooperation) for

improvement of product (customer satisfaction). From this perspective, general

contractors should focus on clearly identifying and defining product, process, and

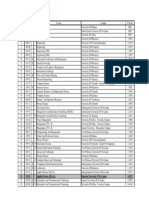

organizational issues (Harmel et al. 2006). Figure 1 illustrates a quality information

matrix using the PPO model of quality control.

Figure 1. Quality Information Matrix.

Computing in Civil and Building Engineering (2014)

COMPUTING IN CIVIL AND BUILDING ENGINEERING ASCE 2014 68

During construction, contractors should monitor and control the three aspects

through a simple quality visual control tool which uses different color codes to reflect

the quality of construction performance. For instance, red check marks mean quality

failure, green check marks mean quality pass, and black check marks mean not

started (Refer to Figure 1). In addition, more color coding may be added to provide

other information. For example, a gray background color means completed, a

Downloaded from ascelibrary.org by UNITEC NEW ZEALAND LIBRARY on 11/08/17. Copyright ASCE. For personal use only; all rights reserved.

yellow background color means on-going, and a white background color means

not started.

In this paper, the term product refers to individual component to be

controlled for quality in highway and bridge construction projects. Each component

has several variables such as material, shape, size, location, and performance

characteristics. The term organization refers to management structure and

personnel who are involved in managing work process controls and rectifying

nonconformities, if any. The term process refers to methods for quality

measurement and analysis and procedures to deal with nonconforming products.

QUALITY CONTROL PROCESS

Quality control process implies a set of practices that integrate methodological

approaches into quality management. It is implemented by consistent quality

evaluation and control, called PDCA (Plan-Do-Check-Act) cycle (Shewhart 1931;

Deming, 1981), in order to monitor and improve a product, service, and process.

In the PDCA cycle, the first step, Plan has several elements. General

contractors must analyze quality policies, scope statements, product descriptions, and

standards and regulations. Then, specific and clear goals must be identified including

control procedures, inspection and test plans, and associated checklists. Goals are

equivalent to construction specifications in which all the quality requirements

including materials and methods to be used and performance features must be

specified. The second step is the Do step, where the sequence of operations is

implemented. The third step is the Check step in which the results of the

completed operations are analyzed by elements of quality conformance and

nonconformance. At some points during or after task performance, feedback should

be provided by quality representatives. Act is the final step. Such components

determined as non-conforming work should be corrected or reworked for quality

improvement.

Product #1 Product #2

Quality Standards Quality Standards

Quality Pass

Inspection Quality Control Plan

Quality Control Plan Execution of QC

and Test

Quality Failure

Feedback

Figure 2. Quality Control Process Flowchart.

Computing in Civil and Building Engineering (2014)

COMPUTING IN CIVIL AND BUILDING ENGINEERING ASCE 2014 69

The PDCA cycle essentially emphasizes continuous improvement in quality

management. Through this cycle, contractors must deal with the tasks and risks

involved with quality control process. Figure 2 illustrates a flowchart of fundamental

quality control process.

Quality control of highway pavement and bridge construction has been

Downloaded from ascelibrary.org by UNITEC NEW ZEALAND LIBRARY on 11/08/17. Copyright ASCE. For personal use only; all rights reserved.

studied from various perspectives. In the quality management plan, applicable

quality standards such as ISO 9000 and performance specifications must be identified.

In addition, control procedures must be specified in detail and personnel

responsibilities and authorities must be clearly defined. More recently in the

construction industry, general contractors are expecting the adoption of BIM for

quality management in infrastructure construction projects since they have observed

high ROI from utilizing BIM in vertical building projects.

BIM FOR QUALITY MANAGMENT

A model-driven approach to QA/QC combines the PPO model with BIM

technology to improve the quality of highway and bridge construction. Typically in

highway and bridge construction, poor quality results from (1) misunderstanding of

quality standards and control procedures for highway pavement and bridge

components, (2) ambiguous responsibility for defective or nonconforming work, and

(3) neglect of continuous quality improvement.

Using BIM technology for quality management, quality information

integration can be embodied in a 3D model. Different layers on the 3D model can

provide essential information about the quality of building components, the quality of

materials and equipment, quality standards, and control procedures within a single

information platform. In addition, clear and specific information about the

responsibility assignment can be connected to the 3D model. In this way, project

participants can better communicate about the progress of construction work. All

project participants including owners, architects, engineers, contractors, suppliers,

and subcontractors should have access to the 3D model and collaboratively proceed

in the construction work faster and smoother, considering all aspects of quality

requirements.

Parametric-oriented 4D BIM models can simulate the specific or entire

process of highway and bridge construction to identify design errors, reduce

uncertainties, and improve level of quality. Furthermore, other information such as

schedule, safety, and resource can be added to the 3D model. Therefore, the

successful application of the model-driven approach to QA/QC has great potential of

communication, coordination, and collaboration in horizontal construction projects.

SURVEY AND RESULTS

To understand the current practices and viewpoints on using BIM for quality

management in highway and bridge construction, a pilot study was conducted.

Eleven BIM professionals in U.S. construction firms were asked to fill out a

questionnaire intended for this initial study. The response rate was 45.5% with five

Computing in Civil and Building Engineering (2014)

COMPUTING IN CIVIL AND BUILDING ENGINEERING ASCE 2014 70

individuals. Among them, sixty percent reported having worked in the construction

industry for over five years. All respondents were from larger companies with an

average annual revenue of over $500 million and 250 or more employees.

Question 1: What would be the on-site QA/QC tasks?

Review and analyze specified quality standards, testing and inspection

Downloaded from ascelibrary.org by UNITEC NEW ZEALAND LIBRARY on 11/08/17. Copyright ASCE. For personal use only; all rights reserved.

procedures, and quality control practices

Develop and monitor the QA programs of the organizations involved in

construction operations, including personnel qualifications and training, when

applicable

Perform field testing and inspection

File documents and records to document management systems to keep

evidence

Question 2: What would be contributing factors to noncompliance?

Poor communications

Poor engineering designs

Improper quality control practices

Failure to adhere to the code of professional ethics

Question 3: Do you think a model-driven approach to QA/QC would be effective? If

yes, why?

100% responded that a model-driven approach would be effective to quality

improvement. One respondent succinctly stated, Using BIM is very effective

because it provides us visual representations of the work process. This results in

better job coordination as well as better communication. Another respondent

summarized, Accuracy of construction designs and information will increase

because BIM can be used as an analytical tool to ensure compliance to quality

standards. A third respondent described, The BIM model supports the inspection

progress by connecting quality information such as inspection and test plans or

quality standards to the model. In addition, the rest of the respondents mentioned

that BIM decreases complaints from suppliers and subcontractors, and reduces

change orders and rework.

ISSUES AND OBSTACLES TO HORIZONTAL BIM

One of the main issues and obstacles to BIM implementation in infrastructure

projects may be the competitive bidding process. Most highway and bridge projects

are initiated by the public sector, most likely, the state highway agencies. The

contract is usually awarded to the contractor who submitted the lowest bid. In this

bidding process, there may be no room for BIM costs to win the bid. BIM

technology usually takes initial costs even though it ultimately provides cost savings

by the end of the project. Moreover, the public sector has had low interests in taking

risks involved in the adoption of BIM technology, investing money in infrastructure

development.

Computing in Civil and Building Engineering (2014)

COMPUTING IN CIVIL AND BUILDING ENGINEERING ASCE 2014 71

Due to the nature of infrastructure construction projects, BIM implementation

would be difficult. Infrastructure such as bridges and highways is considered less

complex than buildings. Nevertheless, many participants are involved in the

construction process. A common project goal is well shared, but project participants

such as subcontractors and suppliers typically try to retain their own ways in doing

their business to maximize their profit.

Downloaded from ascelibrary.org by UNITEC NEW ZEALAND LIBRARY on 11/08/17. Copyright ASCE. For personal use only; all rights reserved.

According to Rowlinson and Walker (1995), there are no QA/QC standards

for infrastructure projects due to the nature of one-off production and non-

standardized members. Consequently, it takes much more time and effort to create

3D models since there is no official standardized product model. The created 3D

models of building components will hardly be reused at other projects.

Finally, Lee et al. (2013) emphasize that there is a lack of BIM skilled

personnel and insufficient BIM education and training programs. This would be

another major barrier to utilizing BIM in infrastructure projects.

DISCUSSIONS AND CONCLUSION

BIM technology has been used for detecting design errors prior to actual

construction and achieving better communication among project participants in

vertical construction project. Without a doubt, general contractors who mostly work

for horizontal infrastructure projects will have the same benefits from using BIM

technology.

We believe that one of the major BIM application areas is to use BIM as a

QA/QC tool for highway pavement and bridge components. In the quality control

process, QA and QC data are to be collected from general and sub-contractors using

Information and Communication Technologies (ICT) to improve the quality control

process. The creation and implementation of a model-driven approach, integrating

the Product, Process, and Organization (PPO) model with BIM technology, for

quality management has the potential to facilitate and enrich a collaboration and

integration with other disciplines. With support of ICT and BIM technology, quality

information integration can be embodied through different layers on the 3D model to

provide essential quality information including quality standards, requirements, and

control procedures within a collaborative and integrated information repository.

BIM technology will allow for easy access to data sharing and information

exchanges for quality control in infrastructure projects, utilizing an integrated

database, providing the dynamic simulation of the construction process, and

identifying critical control point deviations from the state DOT specifications.

Therefore, the accuracy of quality control process will increase and the overall

quality of highway and bridge construction will be improved.

In a typical infrastructure construction project, there are various stakeholders

involved in QA/QC. Within the organizational structure of the stakeholders, only a

limited number of QA/QC personnel are responsible for an increasingly large

workload, managing complex quality control practices. According to Autodesk

(2012), a more immediate increase in efficiency is expected from BIM

implementation in an infrastructure project, which results in quality improvement and

Computing in Civil and Building Engineering (2014)

COMPUTING IN CIVIL AND BUILDING ENGINEERING ASCE 2014 72

reduction in cost overrun. To ensure the continued quality of rehabilitation of the

infrastructure facilities, a model-driven approach should be considered.

In conclusion, BIM technology has great potential as a quality management

tool. BIM technology should be adopted to improve the integration and collaboration

in infrastructure construction projects. The information integration resulting from the

utilization of ICT and BIM technology enables us to enhance the overall project

Downloaded from ascelibrary.org by UNITEC NEW ZEALAND LIBRARY on 11/08/17. Copyright ASCE. For personal use only; all rights reserved.

quality and the quality management in accordance with the customers requirements

and expectations.

REFERENCES

Autodesk, (2012). BIM for infrastructure: a vehicle for business transformation.

Autodesk,

http://images.autodesk.com/adsk/files/valueofBIM_wp__en_FINAL.pdf (Dec.

8, 2013)

Bass, R. (2000). Quality control of soil-cement construction for water resources.

Soil-Cement and Other Construction Practices in Geotechnical Engineering,

ASCE, 13-25.

Deming, W. E. (1981). Improvement of quality and productivity through action by

management. National Productivity Review, 1(1), 12-22.

Deming, W. E. (1986). Out of the crisis. Cambridge: Massachusetts Institute of

Technology, Center for Advanced Engineering Study.

Froese, T. (2003). Future directions for IFC-Based interoperability. ITcon, Vol. 8,

Special Issue IFC - Product models for the AEC arena.

Harmel, G., Bonjour, E., & Dulmet, M. (2006). Product, process, and organization

architectures modeling: from strategic expectations to strategic competencies.

The 12th IFAC Symposium on Information Control Problems in

Manufacturing, INCOM06, Saint-Etienne, France.

Lee, N., Dossick, C. S., & Foley, S. P. (2013) A Guideline for Building Information

Modeling in construction engineering and management education.. Journal

of Professional Issues in Engineering Education and Practice, 139(4), 266

274

McGraw Hill Construction (2012). The business value of BIM for infrastructure:

addressing Americas infrastructure challenge with collaboration and

technology, McGraw-Hill Construction SmartMarket Report, New York.

Penttil, H. (2006). Describing the changes in architectural information technology

to understand design complexity and free-form architectural expression.

ITcon. 11, 395408.

Rowlinson, S. M. & Walker, A. (1995). The Construction Industry in Hong Kong.

Hong Kong: Longman.

Shewhart, W. A. (1931). Economic control of quality of manufactured product. New

York: Van Nostrand.

Smith, Deke (2007). An introduction to Building Information Modeling (BIM).

Journal of Building Information Modeling, Fall 2007, 1214.

Computing in Civil and Building Engineering (2014)

Vous aimerez peut-être aussi

- Building Information Modeling (BIM) PDFDocument12 pagesBuilding Information Modeling (BIM) PDFTello G. AlvaroPas encore d'évaluation

- Keith Potts, Nii Ankrah-Construction Cost Management - Learning From Case Studies-Routledge (2014)Document7 pagesKeith Potts, Nii Ankrah-Construction Cost Management - Learning From Case Studies-Routledge (2014)christian garciaPas encore d'évaluation

- Building Information Modelling and Heritage DocumentationDocument8 pagesBuilding Information Modelling and Heritage DocumentationzawPas encore d'évaluation

- Rosetta NetDocument24 pagesRosetta NetYashpal SinghPas encore d'évaluation

- BIM Thesis NESPAKHOUSE PDFDocument110 pagesBIM Thesis NESPAKHOUSE PDFzubair-scribdPas encore d'évaluation

- W25 - BIM Implementation Strategies PDFDocument69 pagesW25 - BIM Implementation Strategies PDFLam Thanh HoangPas encore d'évaluation

- (2015) Measuring The Impact of BIM On Complex BuildingsDocument60 pages(2015) Measuring The Impact of BIM On Complex BuildingsTan Jin HongPas encore d'évaluation

- Generating Construction Schedules Through Automatic Data Extraction Using Open BIM (Building Information Modeling) TechnologyDocument11 pagesGenerating Construction Schedules Through Automatic Data Extraction Using Open BIM (Building Information Modeling) TechnologyCPittmanPas encore d'évaluation

- Digital Twin For LogisticsDocument33 pagesDigital Twin For LogisticsKelompok 3A100% (1)

- EUBIM Handbook Web OptimizedDocument84 pagesEUBIM Handbook Web OptimizedRicardo FigueiraPas encore d'évaluation

- BIM Level of DevelopmentDocument6 pagesBIM Level of Developmentmahi kkPas encore d'évaluation

- Defect Control in SemiconductorsD'EverandDefect Control in SemiconductorsK. SuminoPas encore d'évaluation

- Greenspan DesignConsiderationsDocument50 pagesGreenspan DesignConsiderationscrazynupPas encore d'évaluation

- London 2018 Summit Major Project Delivery and Digital TransformationDocument54 pagesLondon 2018 Summit Major Project Delivery and Digital TransformationMuhammad NakibPas encore d'évaluation

- An IFC Handbook For Addressing Project-Induced In-MigrationDocument176 pagesAn IFC Handbook For Addressing Project-Induced In-MigrationInternational Finance Corporation (IFC)100% (1)

- NBS National BIM Report 2018Document27 pagesNBS National BIM Report 2018Tharaka KodippilyPas encore d'évaluation

- Open BIM Interdisciplinary Collaboration Strategies For A Plural WorldDocument9 pagesOpen BIM Interdisciplinary Collaboration Strategies For A Plural WorldMatej MihićPas encore d'évaluation

- GSA BIM Guide 05 Version 2.1Document76 pagesGSA BIM Guide 05 Version 2.1septi dwi cahyaniPas encore d'évaluation

- BIMDocument8 pagesBIMMuhd ZulFadliPas encore d'évaluation

- A Case Study of Building Performance Analyses UsinDocument10 pagesA Case Study of Building Performance Analyses UsinRizwan DogerPas encore d'évaluation

- ArchiCAD 16 and COBieDocument22 pagesArchiCAD 16 and COBieUntal AparicioPas encore d'évaluation

- Virtual Furniture Using Augmented Reality TechniqueDocument3 pagesVirtual Furniture Using Augmented Reality TechniqueEditor IJRITCCPas encore d'évaluation

- BIM 403 - BIM and SchedulingDocument47 pagesBIM 403 - BIM and SchedulingAbhishek PandeyPas encore d'évaluation

- The Digital Twin of The City of Zurich For Urban PDocument14 pagesThe Digital Twin of The City of Zurich For Urban Pjay pasiliao100% (1)

- Digital Twins White PaperDocument4 pagesDigital Twins White PaperashutsPas encore d'évaluation

- Maritime Globalpresentation en Jan2020 OptimizedDocument207 pagesMaritime Globalpresentation en Jan2020 OptimizeddlopezarPas encore d'évaluation

- Application of GIS and BIM Integration TechnologyDocument8 pagesApplication of GIS and BIM Integration Technologymec3dsPas encore d'évaluation

- NtuDocument32 pagesNtuJustin ChongPas encore d'évaluation

- 3 - Overview of Main Current MSR Projects - V3Document29 pages3 - Overview of Main Current MSR Projects - V3abasakPas encore d'évaluation

- Introduction About BimDocument30 pagesIntroduction About Bimshanga75Pas encore d'évaluation

- WATER 4.0: Made in GermanyDocument16 pagesWATER 4.0: Made in GermanyMariaPas encore d'évaluation

- An Application Framework of Digital Twin and Its Case StudyDocument13 pagesAn Application Framework of Digital Twin and Its Case StudyJoão VitorPas encore d'évaluation

- 7-2 Industrial IoT. and Digital TwinsDocument45 pages7-2 Industrial IoT. and Digital TwinsChen YooPas encore d'évaluation

- BIM Teaching Strategies: An Overview of The Current ApproachesDocument7 pagesBIM Teaching Strategies: An Overview of The Current ApproachesHortencia TeixeiraPas encore d'évaluation

- CIC BIM Protocol University of CambridgeDocument21 pagesCIC BIM Protocol University of CambridgeLuis Fernando RodriguezPas encore d'évaluation

- BIM in AEC IndustryDocument9 pagesBIM in AEC Industryanupam.koulPas encore d'évaluation

- IPMS Updates20100406 IsensDocument39 pagesIPMS Updates20100406 Isenspikes89Pas encore d'évaluation

- DesignScript Summary User ManualDocument20 pagesDesignScript Summary User ManualEsper AshkarPas encore d'évaluation

- Bim: Construction of EfficencyDocument10 pagesBim: Construction of Efficencyel_residentePas encore d'évaluation

- 1 Intro Engineers BIM 120416Document25 pages1 Intro Engineers BIM 120416faheem2005rajaPas encore d'évaluation

- Digital TwinDocument14 pagesDigital TwinfatimaPas encore d'évaluation

- The Buildingsmart Glossary of Terms: International Alliance For Interoperability Model Support Group January 2007Document33 pagesThe Buildingsmart Glossary of Terms: International Alliance For Interoperability Model Support Group January 2007Nagaratna Reddy100% (1)

- BIM Architectural Model AuditDocument4 pagesBIM Architectural Model AuditMaría M. Castillo F.Pas encore d'évaluation

- Bryde Et Al (2012) - The Project Benefits of BIM PDFDocument10 pagesBryde Et Al (2012) - The Project Benefits of BIM PDFSérgio BragaPas encore d'évaluation

- Sustainable Design & BIM TechnologyDocument155 pagesSustainable Design & BIM TechnologybimarabiaPas encore d'évaluation

- IoT of Civil InfrastructuresDocument4 pagesIoT of Civil InfrastructuresIJORATPas encore d'évaluation

- Information Management in Construction PDFDocument64 pagesInformation Management in Construction PDFdmlinuxPas encore d'évaluation

- A Study of The Concept of Future-Proofing in Healtcare Building Asset Menagement and The Role of BIM in Its DeliveryDocument285 pagesA Study of The Concept of Future-Proofing in Healtcare Building Asset Menagement and The Role of BIM in Its DeliveryFausto FaviaPas encore d'évaluation

- 01 BIM in BridgeDesign ThesisDocument83 pages01 BIM in BridgeDesign Thesismoderntalking87100% (1)

- BIM Collaboration in The AEC Industry by Mats Thomassen PDFDocument120 pagesBIM Collaboration in The AEC Industry by Mats Thomassen PDFCarlos Ramos Fernandez100% (1)

- Putting The I in BIM: UK Government BIM StrategyDocument26 pagesPutting The I in BIM: UK Government BIM Strategypaci87Pas encore d'évaluation

- International Home of Openbim: Decision Time in TokyoDocument4 pagesInternational Home of Openbim: Decision Time in TokyolaurenssenPas encore d'évaluation

- 04 HDB BIM Model Quality Checklist - Jun17Document6 pages04 HDB BIM Model Quality Checklist - Jun17Bharat MaddulaPas encore d'évaluation

- Project Control Using BIM PDFDocument77 pagesProject Control Using BIM PDFUtkarsh SuranaPas encore d'évaluation

- The Utilization of Bim Software On Vancouver International Airport, Terminal Renovation ProjectDocument21 pagesThe Utilization of Bim Software On Vancouver International Airport, Terminal Renovation ProjectVictor OkhoyaPas encore d'évaluation

- Building Information Modeling and Green DesignDocument18 pagesBuilding Information Modeling and Green Designmy.nafi.pmp5283Pas encore d'évaluation

- Igor Starkov - Digital Twins and Lifecyle BIMDocument21 pagesIgor Starkov - Digital Twins and Lifecyle BIMUtomo Aryo WPas encore d'évaluation

- Best 20 Building Information Modeling (BIM) Software in 2019 PDFDocument31 pagesBest 20 Building Information Modeling (BIM) Software in 2019 PDFJulioedgPas encore d'évaluation

- Construction With Digital Twin Information SystemsDocument27 pagesConstruction With Digital Twin Information SystemsvijayPas encore d'évaluation

- Employment Application Form NZDocument3 pagesEmployment Application Form NZრაქსშ საჰაPas encore d'évaluation

- Building Contract WorkshopDocument99 pagesBuilding Contract Workshopრაქსშ საჰაPas encore d'évaluation

- 20210526-Riverside Residences Stage 3 - Tender MethodologyDocument12 pages20210526-Riverside Residences Stage 3 - Tender Methodologyრაქსშ საჰაPas encore d'évaluation

- Prince Aloysius Kunnappillil AloysiusDocument14 pagesPrince Aloysius Kunnappillil Aloysiusრაქსშ საჰაPas encore d'évaluation

- Curriculum Vitae: ObjectiveDocument4 pagesCurriculum Vitae: Objectiveრაქსშ საჰაPas encore d'évaluation

- Standard For Network Water Pump Stations: Ver. 1 Date: 18 June 2020Document26 pagesStandard For Network Water Pump Stations: Ver. 1 Date: 18 June 2020რაქსშ საჰაPas encore d'évaluation

- Rakesh Saha: ObjectiveDocument4 pagesRakesh Saha: Objectiveრაქსშ საჰაPas encore d'évaluation

- Semester 1, 2019 Examination: School of Engineering & Applied TechnologyDocument8 pagesSemester 1, 2019 Examination: School of Engineering & Applied Technologyრაქსშ საჰაPas encore d'évaluation

- App E1 Site Selection Summary Appendix EDocument128 pagesApp E1 Site Selection Summary Appendix Eრაქსშ საჰაPas encore d'évaluation

- ! 2.1.1. Business Ethics 2017Document38 pages! 2.1.1. Business Ethics 2017რაქსშ საჰაPas encore d'évaluation

- CV Combined 14 March 2018Document91 pagesCV Combined 14 March 2018რაქსშ საჰაPas encore d'évaluation

- 3D CoordinationDocument29 pages3D Coordinationრაქსშ საჰაPas encore d'évaluation

- 4D Phase Planning: CONS 7825 Advanced BIM in Construction Bim Use 2017 - AssignmentDocument10 pages4D Phase Planning: CONS 7825 Advanced BIM in Construction Bim Use 2017 - Assignmentრაქსშ საჰაPas encore d'évaluation

- Huawei PDFDocument8 pagesHuawei PDFრაქსშ საჰაPas encore d'évaluation

- Westpac Feb4Document2 pagesWestpac Feb4რაქსშ საჰა100% (1)

- Income CertificateDocument1 pageIncome Certificateრაქსშ საჰაPas encore d'évaluation

- 85 Customs Street Apartment Tower: Section 88 Resource Consent Application and Assessment of Environmental EffectsDocument79 pages85 Customs Street Apartment Tower: Section 88 Resource Consent Application and Assessment of Environmental Effectsრაქსშ საჰაPas encore d'évaluation

- Irons 1403371 UE Assignment 1Document22 pagesIrons 1403371 UE Assignment 1რაქსშ საჰაPas encore d'évaluation

- 1 Human Relations - Nature of The PeopleDocument26 pages1 Human Relations - Nature of The Peopleრაქსშ საჰაPas encore d'évaluation

- 6100 Draft 1 MethodologyDocument11 pages6100 Draft 1 Methodologyრაქსშ საჰაPas encore d'évaluation

- Autodesk University Workshop - 4d Simulation and Construction Planning - 2015-04-06Document7 pagesAutodesk University Workshop - 4d Simulation and Construction Planning - 2015-04-06რაქსშ საჰაPas encore d'évaluation

- 01 0071 0848762 00 - Statement - 2017 12 08Document2 pages01 0071 0848762 00 - Statement - 2017 12 08რაქსშ საჰაPas encore d'évaluation

- Advanced Bim in Construction Cons 7825 2015 s2Document2 pagesAdvanced Bim in Construction Cons 7825 2015 s2რაქსშ საჰაPas encore d'évaluation

- 0-CA CONS 6812 - 2017 - Exam - Marking ScheduleDocument7 pages0-CA CONS 6812 - 2017 - Exam - Marking Scheduleრაქსშ საჰაPas encore d'évaluation

- Advanced Bim in Construction Cons 7825 2015 s2 PDFDocument2 pagesAdvanced Bim in Construction Cons 7825 2015 s2 PDFრაქსშ საჰაPas encore d'évaluation

- Dr. Tadisina Kishen Kumar ReddyDocument2 pagesDr. Tadisina Kishen Kumar ReddyReeta DuttaPas encore d'évaluation

- IVMS ID High Yield Microbiology Antimicrobial Pharmacology and IDDocument58 pagesIVMS ID High Yield Microbiology Antimicrobial Pharmacology and IDiahmed3000100% (1)

- UBIQUITOSDocument26 pagesUBIQUITOSAvinash ThakurPas encore d'évaluation

- Eng Under GradDocument86 pagesEng Under GradDavid Adeyinka RamgobinPas encore d'évaluation

- SCCL Hallticket E&MDocument2 pagesSCCL Hallticket E&MVamshi Krishna100% (1)

- Unit Structure - IDocument100 pagesUnit Structure - IAbhilash K R NairPas encore d'évaluation

- Student No. Full Name Campus Course: See NotesDocument38 pagesStudent No. Full Name Campus Course: See NoteskapitannwelPas encore d'évaluation

- RalgebrDocument6 pagesRalgebrkiranPas encore d'évaluation

- Maulana Abul Kalam Azad University of Technology6thDocument1 pageMaulana Abul Kalam Azad University of Technology6tharindamsinharayPas encore d'évaluation

- APPSC GROUP 4 RESULTS 2012 - West Godavari Group 4 Merit ListDocument702 pagesAPPSC GROUP 4 RESULTS 2012 - West Godavari Group 4 Merit ListReviewKeys.comPas encore d'évaluation

- 32 015 K Applied Science (Phy - SC.) Rajarata University of Sri Lanka 1.0197Document1 page32 015 K Applied Science (Phy - SC.) Rajarata University of Sri Lanka 1.0197Sriyan PasqualPas encore d'évaluation

- Pranav Gaur ResumeDocument2 pagesPranav Gaur ResumePranav gaurPas encore d'évaluation

- CV SSanyalDocument8 pagesCV SSanyalSanjoy SanyalPas encore d'évaluation

- Communication Systems Engineering Proakis Solution Manual PDFDocument2 pagesCommunication Systems Engineering Proakis Solution Manual PDFNatashaPas encore d'évaluation

- Writing in A Natural Science Discourse CommunityDocument18 pagesWriting in A Natural Science Discourse Communityapi-242697314Pas encore d'évaluation

- Paolo ManansalaDocument2 pagesPaolo ManansalaPaolo ManansalaPas encore d'évaluation

- Mec531 Course Outline 2013Document4 pagesMec531 Course Outline 2013arina azharyPas encore d'évaluation

- Computer and Systems Engineering (CSE) Master of Science ProgramsDocument7 pagesComputer and Systems Engineering (CSE) Master of Science ProgramsBilal KhanPas encore d'évaluation

- Computer Architecture NotesDocument320 pagesComputer Architecture NotesgireeshkrPas encore d'évaluation

- SQLSat 765 Graph Databases PDFDocument48 pagesSQLSat 765 Graph Databases PDFVukašin MančićPas encore d'évaluation

- Academic Spin OffsDocument341 pagesAcademic Spin OffsAntonioPas encore d'évaluation

- Induction Week AssignmentDocument2 pagesInduction Week AssignmentmdharmapuramPas encore d'évaluation

- Notice XII 17.11Document3 pagesNotice XII 17.11Muskan SinghPas encore d'évaluation

- IntroSession LogDocument6 pagesIntroSession LogVinoth SivaperumalPas encore d'évaluation

- BS Aeronautical Engineering (BSAE) - School of AviationDocument9 pagesBS Aeronautical Engineering (BSAE) - School of AviationUniversity of Perpetual Help System DALTAPas encore d'évaluation

- Chapter 9Document5 pagesChapter 9JefPas encore d'évaluation

- Ieee 2021-22 BigdataDocument4 pagesIeee 2021-22 BigdataNexgen TechnologyPas encore d'évaluation

- B.S Information Technology2008Document8 pagesB.S Information Technology2008kupaloidPas encore d'évaluation

- History of Supply Chain ManagementDocument4 pagesHistory of Supply Chain ManagementSafijo AlphonsPas encore d'évaluation

- Lecture Notes in STSDocument4 pagesLecture Notes in STSAngela Danielle Tan100% (1)