Académique Documents

Professionnel Documents

Culture Documents

Az Nlof2000 Series

Transféré par

Swarnava SanyalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Az Nlof2000 Series

Transféré par

Swarnava SanyalDroits d'auteur :

Formats disponibles

MeRck

technical datasheet

AZ nLOF 2000 Series

Negative Tone Photoresists for Single Layer Lift-Off

APPLICATION TYPICAL PROCESS

AZ nLOF 2000 Series i-line photoresists are engineered to Soft Bake: 110C/60-90s

simplify the historically complex image reversal and multi- Rehydration Hold: None

layer lift-off lithography processes. Ideal lift-off pattern Expose: 365nm sensitive

profiles are achieved using a standard expose/post expose

Post Expose Bake: 110C/60s

bake/develop process flow. These photoresists are very fast

and printed features are thermally stable to >200C. Develop: Puddle, spray or immersion

Developer Type: MIF

TMAH developer compatible

Single coat thicknesses from 2.0 to >10m * PEB is required for proper imaging

May be processed with vertical sidewalls for RIE etching

SPIN CURVES (150MM Silicon) OPTICAL CONSTANTS*

Cauchy A 1.5946

Cauchy B (m2) 0.01188

Cauchy C (m4) 0.00028

n @ 633nm 1.626

k @ 633nm 0

* Unexposed photoresist film

COMPANION PRODUCTS

Thinning/Edge Bead Removal

AZ EBR Solvent or AZ EBR 70/30

MIF Developers

AZ 300MIF, AZ 726MIF, AZ 917MIF

Removers

2.0m lines and 2.0m iso trench

AZ 400T, AZ Remover 770 3.5m thick AZ nLOF 2035

72mJ/cm2 i-line Exposure

AZ 300 MIF Develop (120s)

Merck KGaA, Darmstadt, Germany Rev. 3/2016

AZ nLOF 2000 Series

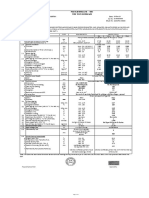

EXAMPLE PROCESS (2.0m Film Thickness on Si)

Process Step Parameters

Prime HMDS 140C/60s (vapor)

Coat 2.0m thick film AZ nLOF 2020 (33cPs) on bare Si * Pattern profiles can be modified by

varying exposure dose and PEB

Soft Bake 110C, 60 seconds, direct contact hotplate temperature. See profile optimization

matrix for additional information.

Exposure i-line @ 66mJ/cm2 nominal (0.54NA) Nikon Stepper*

Post Expose Bake 110C*, 60 seconds, direct contact hotplate

Develop AZ 300MIF, 60s single puddle

Resolution @ 1.0m Lines 1.0m Lines

66mJ/cm2 Through Dose DoF @ 66mJ/cm2

0.95m 62mJ/cm2 -0.2m

0.85m 66mJ/cm2 0.2m

0.80m 70mJ/cm2 0.6m

0.70m 74mJ/cm2 1.0m

Merck KGaA, Darmstadt, Germany Rev. 3/2016

AZ nLOF 2000 Series

EXAMPLE PROCESS (3.5m Film Thickness on Si)

Process Step Parameters

Prime HMDS 140C/60s (vapor)

Coat 3.5m thick film AZ nLOF 2035 (79cPs) on bare Si * Pattern profiles can be modified by

varying exposure dose and PEB

Soft Bake 110C, 60s, direct contact hotplate temperature. See profile optimization

matrix for additional information.

Post Bake Delay None

Expose i-line @ 80mJ/cm2 nominal (0.548NA) Nikon Stepper*

Post Expose Bake 110C*, 60 seconds, direct contact hotplate

Develop AZ 300MIF, 120s single puddle

Resolution @ 2.0m Lines 2.0m Lines

80mJ/cm2 Through Dose DoF @ 80mJ/cm2

2.00m 72mJ/cm2 -1.0m

1.50m 80mJ/cm2 0.0m

1.10m 88mJ/cm2 1.0m

0.90m 96mJ/cm2 1.8m

Merck KGaA, Darmstadt, Germany Rev. 3/2016

AZ nLOF 2000 Series

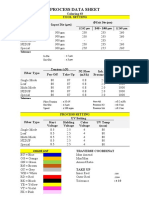

EXAMPLE PROCESS (7.0m Film Thickness on Si)

Process Step Parameters

Prime HMDS 140C/60s (vapor)

Coat 7.0m thick film AZ nLOF 2070 (330cPs) on bare Si

Soft Bake 110C, 90s, direct contact hotplate

Post Bake Delay None

Expose i-line @ various doses (0.54NA) Nikon Stepper

Post Expose Bake 110C, 90 seconds, direct contact hotplate

Develop AZ 300MIF, 2 x 60 second puddles

BOTTOM CD vs. EXPOSURE DOSE (Mask CD = 7.0m dense lines)

Dose: 174mJ/cm2 Dose: 186mJ/cm2 Dose: 198mJ/cm2

Bottom CD: 4.45m Bottom CD: 4.84m Bottom CD: 5.31m

EXAMPLE PEB SENSITIVITY (3.5m Film Thickness on Si)

PEB 105C/60sec

Top size: 1.734 Slope = 0.038 m/C

Bottom: 0.726m

Top CD (m)

PEB 110C / 60sec

Top: 1.992 m

Bottom: 1.439m

PEB 115C / 60sec

Top: 2.062 m

PEB Temperature (C)

Bottom: 1.687m

Merck KGaA, Darmstadt, Germany Rev. 3/2016

AZ nLOF 2000 Series

SAMPLE PROCESS WINDOWS on Si (FT = 2.0m and 3.5m)

Linearity (dense lines) Exposure Latitude (1.0m dense lines)

Printed CD (m)

Printed CD (m)

Linear to 3:1 Elat =~30%

Aspect Ratio

Mask CD (m) Exposure Dose (mJ/cm2)

Coat: AZ nLOF 2020 @ FT=2.0m

Soft Bake: 110C/60s

Expose: Nikon Stepper @ 0.54NA

Post Expose Bake: 110C/60s

Develop: AZ 300MIF 60s puddle

Linearity (dense lines) Exposure Latitude (2.0m dense lines)

Printed CD (m)

Printed CD (m)

Linear to 3:1

Aspect Ratio Elat =>50%

Mask CD (m) Exposure Dose (mJ/cm2)

Coat: AZ nLOF 2020 @ FT=3.5m

Soft Bake: 110C/60s

Expose: Nikon Stepper @ 0.54NA

Post Expose Bake: 110C/60s

Develop: AZ 300MIF 120s puddle

Merck KGaA, Darmstadt, Germany Rev. 3/2016

AZ nLOF 2000 Series

EXAMPLE PROFILE TUNING BY VARYING PEB AND EXPOSURE DOSE

Process Step Parameters

Prime HMDS 140C/60s (vapor)

Coat 2.0m thick film AZ nLOF 2020 (33cPs) on bare Si

Soft Bake 110C, 60 seconds, direct contact hotplate

Exposure i-line @ varying dose (0.54NA) Nikon Stepper

Post Expose Bake Various as indicated

Develop AZ 300MIF, 60s single puddle

Profile Response to Varying Dose and PEB Temperature

PEB 105C PEB 110C PEB 115C

60mJ/cm2

70mJ/cm2

80mJ/cm2

90mJ/cm2

100mJ/cm2

Merck KGaA, Darmstadt, Germany Rev. 3/2016

AZ nLOF 2000 Series

PROCESS CONSIDERATIONS

SUBSTRATE PREPARATION

Substrates must be clean, dry, and free of organic residues. Oxide forming substrates (Si, etc.)

should be HMDS primed prior to coating AZ nLOF 2000. Contact your AZ product representative

for detailed information on pre-treating with HMDS.

SOFT BAKE

Soft bake times and temperatures may be application specific. Process optimization is

recommended to ensure optimum pattern profiles and stable lithographic and adhesion

performance. Soft bake temperatures for AZ nLOF 2000 should be in the 100-110C range. Delays

between soft bake and exposure should be minimized for optimum performance.

EXPOSURE

AZ nLOF 2000 requires exposure energy at the 365nm wavelength.

POST EXPOSE BAKE

A PEB is required for proper imaging of AZ nLOF 2000. PEB temperatures and times may be

application specific. As a general rule, PEB temperatures should be in the 100 to 115C range. As

with any chemically amplified photoresist, CDs in nLOF 2000 will exhibit some dependency on

PEB temperature (< 0.04m/C is typical).

DEVELOPING

AZ nLOF 2000 series photoresists are compatible with industry standard 0.26N (2.38%) TMAH

developers. AZ 300MIF is recommended.

HARD BAKE

Hard baking (post develop bake) improves adhesion in wet etch or plating applications and

improves pattern stability in dry etch or deposition chambers. AZ nLOF materials are extremely

thermally stable and may be hard baked at temperatures above 150C.

HARD BAKE STABILITY FOR LARGE PADS IN AZ nLOF 2070 (7.0m Film Thickness)

115C Hard Bake 120C Hard Bake 125C Hard Bake 130C Hard Bake

STRIPPING

AZ nLOF 2000 Series resists are compatible with industry standard solvent based removers. AZ

400T or AZ Remover 770 is recommended.

Merck KGaA, Darmstadt, Germany Rev. 3/2016

AZ nLOF 2000 Series

COMPATIBLE MATERIALS

AZ nLOF 2000 Series materials are compatible with all commercially available lithography

processing equipment. Compatible materials of construction include glass, quartz, PTFE, PFA,

stainless steel, HDPE, polypropylene, and ceramic. AZ nLOF 2000 series photoresists are not

recommended for use on copper substrates.

STORAGE

AZ nLOF 2000 Series materials are combustible liquids. Store in sealed original containers in a

well ventilated, dry area away from heat, light, oxidizers, reducers, and sources of ignition.

Recommended storage temperature is 30-55F.

HANDLING/DISPOSAL

AZ nLOF 2000 Series materials contain PGMEA (1-Methoxy-2-propanol acetate). Refer to the

current version of the MSDS and to local regulations for up to date information on safe

handling and proper disposal. Wear solvent resistant gloves, protective clothing, and eye/face

protection.

AZ nLOF 2000 is compatible with drain lines handling similar organic solvent based materials.

North America: Germany: Korea: Singapore:

EMD Performance Materials Merck Performance Materials Merck Performance Materials Merck Performance Materials

70 Meister Avenue (Germany) GmbH (Korea) Ltd. Pte. Ltd.

Somerville, NJ USA 08876 Wiesbaden, Germany Seoul, Korea Jurong East, Singapore

(908) 429-3500 +49 611 962 4031 +82 2 2056 1316 +65 68900629

Taiwan: Japan: China:

Merck Performance Materials Merck Performance Materials Merck Electronic Materials

Co. Ltd. G. K. Shanghai, China

Hsinchu, Taiwan Tokyo, Japan +86 (21) 2083 2362

+886 3 5970885#375 +81 3 5453 5062

www.emd-performance-materials.com

www.emd-performance-materials.com

Products are warranted to meet the specifications set forth on their label/packaging and/or certificate of analysis at the time of shipment or for the

expressly stated duration. EMD MAKES NO REPRESENTATION OR WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY OR

The information contained herein is true and accurate to the best of our knowledge at time of printing. All recommendations or

FITNESS FOR A PARTICULAR USE REGARDING OUR PRODUCTS OR ANY INFORMATION PROVIDED IN CONNECTION THEREWITH. Customer is responsible

suggestions are offered determine

for and must independently without suitability

guarantee as specific

of EMDs productsconditions of use

for customers are beyond

products, intendedouruse control. Thereincluding

and processes, is no implied warranty of

the non-infringement

merchantability orintellectual

of any third parties fitness for purpose

property ofEMD

rights. theshall

product

not in or

anyproducts described

event be liable herein.

for incidental, In submitting

consequential, thisexemplary

indirect, information, no liability

or special damagesis

assumed

of any kind or license

resulting fromorany

other

use orrights

failureexpressed or implied

of the products: withsubject

All sales are respect to any

to EMDs existing

complete orand

Terms pending patent,

Conditions patent

of Sale. application,

Prices are subject to or

trademarks.

change withoutObservance of all regulations

notice. EMD reserves and patents

the right to discontinue is the without

products responsibility of the user. AZ and the AZ logo are registered trademarks

prior notice.

of Merck KGaA, Darmstadt, Germany or its affiliates.

EMD, EMD Performance Materials, AZ, the AZ logo, and the vibrant M are trademarks of Merck KGaA, Darmstadt, Germany.

Merck KGaA, Darmstadt, Germany Rev. 3/2016

Vous aimerez peut-être aussi

- Tds Az Eci 3000 SeriesDocument11 pagesTds Az Eci 3000 SeriesIgor_uhuPas encore d'évaluation

- Addigy FPB 2684 000000 A - en - 86299607 22256723 22681304Document4 pagesAddigy FPB 2684 000000 A - en - 86299607 22256723 22681304propornhub42Pas encore d'évaluation

- LEXAN 9030 and Lexan 9030 TG Datasheet PDFDocument2 pagesLEXAN 9030 and Lexan 9030 TG Datasheet PDFIbrahim Levent AkkoyunluPas encore d'évaluation

- HDPE Physical PropertiesDocument7 pagesHDPE Physical PropertiesshaffetiPas encore d'évaluation

- LEXAN FST3403tDocument3 pagesLEXAN FST3403tJose Ramon Florez OrdizPas encore d'évaluation

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviPas encore d'évaluation

- Lexan™ Exell™ D - Sheet DatasheetDocument3 pagesLexan™ Exell™ D - Sheet DatasheetAmritraj CharlesPas encore d'évaluation

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełPas encore d'évaluation

- Lexan™ Exell D STP - Sheet DatasheetDocument2 pagesLexan™ Exell D STP - Sheet DatasheetAmritraj CharlesPas encore d'évaluation

- AZ4562 Photresist - TDS PDFDocument3 pagesAZ4562 Photresist - TDS PDFahmed pashaPas encore d'évaluation

- SL Somos PerFORM Material Specifications PDFDocument2 pagesSL Somos PerFORM Material Specifications PDFTushar Prakash ChaudhariPas encore d'évaluation

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperPas encore d'évaluation

- Makrolon® ET3137: Grades / ExtrusionDocument4 pagesMakrolon® ET3137: Grades / ExtrusionDiegoTierradentroPas encore d'évaluation

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaPas encore d'évaluation

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierPas encore d'évaluation

- Policarbonato Teijin Panlite Ad-5503Document1 pagePolicarbonato Teijin Panlite Ad-5503marioPas encore d'évaluation

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviPas encore d'évaluation

- Somos PerFORM SS-PDS Letter PDFDocument2 pagesSomos PerFORM SS-PDS Letter PDFAdriano AraujoPas encore d'évaluation

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroPas encore d'évaluation

- 1.A-DQ BN SR 2Y 1.200N CT-General-2021.04.07-03Document7 pages1.A-DQ BN SR 2Y 1.200N CT-General-2021.04.07-03Emre YıldırımPas encore d'évaluation

- HLG 5 DatasheetDocument2 pagesHLG 5 DatasheetNorden ConradPas encore d'évaluation

- F.O. ADSS SpecificationDocument4 pagesF.O. ADSS SpecificationDinatel ComercialPas encore d'évaluation

- Document PDFDocument2 pagesDocument PDFAnthony KasenaPas encore d'évaluation

- Impact Modified PS CLEAR: Key Features ApplicationsDocument1 pageImpact Modified PS CLEAR: Key Features ApplicationsIceMan3Pas encore d'évaluation

- DPF 390 FlexDocument3 pagesDPF 390 FlexCESAR GUERREROPas encore d'évaluation

- Specification of ABS-Like Resin: Writer Proofreader Translator: ReviewersDocument8 pagesSpecification of ABS-Like Resin: Writer Proofreader Translator: ReviewersAlejandro PerezPas encore d'évaluation

- Profile 45 250 Sandwich Panel Techincal DatasheetDocument2 pagesProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaPas encore d'évaluation

- DAE SSPS 2004 PresentationDocument32 pagesDAE SSPS 2004 PresentationRavi Kumar ChPas encore d'évaluation

- LEXAN™ Resin - 141R - Europe - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 141R - Europe - Technical - Data - SheetMinh Quãng PhạmPas encore d'évaluation

- 12.02.2020 TTC - Kohinoor SalesDocument1 page12.02.2020 TTC - Kohinoor SalesAlok PandeyPas encore d'évaluation

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDocument5 pagesHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaPas encore d'évaluation

- GT-E1120C SVCM Final AnyserviceDocument58 pagesGT-E1120C SVCM Final AnyserviceELECTRONICA TRUJILLOPas encore d'évaluation

- Connecting The Future: Core-to-Core Alignment Splicing 6sec Tube-Heating 9secDocument2 pagesConnecting The Future: Core-to-Core Alignment Splicing 6sec Tube-Heating 9secMatheus Gomes VieiraPas encore d'évaluation

- Image Reversal Photoresist: Product Data SheetDocument4 pagesImage Reversal Photoresist: Product Data SheetSOtgonborPas encore d'évaluation

- Volumic - FT - en - Cuivre80 UltraDocument1 pageVolumic - FT - en - Cuivre80 UltraKamel IfrahPas encore d'évaluation

- 3192-Od (10.02.2023)Document1 page3192-Od (10.02.2023)Rohan KabirPas encore d'évaluation

- 70S Plus E High 20181017Document2 pages70S Plus E High 20181017tiuganstefanPas encore d'évaluation

- Data Teknis Alcoflux KoreaDocument40 pagesData Teknis Alcoflux KoreaDebby saputraPas encore d'évaluation

- Makrolon 2858 ISO enDocument4 pagesMakrolon 2858 ISO enRushyanth KRPas encore d'évaluation

- Achieve™ Advanced PP7123KNE1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP7123KNE1: Polypropylene Impact CopolymermosesPas encore d'évaluation

- NIC Components NSPU SeriesDocument2 pagesNIC Components NSPU SeriesNICCompPas encore d'évaluation

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoPas encore d'évaluation

- Pa6 GF30 - Macplast Marenyl 6natgf30 FCDocument2 pagesPa6 GF30 - Macplast Marenyl 6natgf30 FCarmandoPas encore d'évaluation

- Technical Data SheetDocument2 pagesTechnical Data Sheetrenaat.vanwayenbergePas encore d'évaluation

- 70S Plus E 3Document2 pages70S Plus E 3Bashrat SofiPas encore d'évaluation

- Exxonmobil™ Axo3Be3: Polypropylene Impact CopolymerDocument2 pagesExxonmobil™ Axo3Be3: Polypropylene Impact CopolymermosesPas encore d'évaluation

- Arlon 38NDocument4 pagesArlon 38NRavindrakumar ParvathiniPas encore d'évaluation

- Ds Lc15dx enDocument3 pagesDs Lc15dx enradule021Pas encore d'évaluation

- Simplex Fiber Optic Cordage: DescriptionDocument2 pagesSimplex Fiber Optic Cordage: DescriptionMuhamad Andri KurniawanPas encore d'évaluation

- PrimeCliq4 CatalogDocument5 pagesPrimeCliq4 CatalogedwardPas encore d'évaluation

- Emerge™ Pc/Abs 7740: Technical InformationDocument3 pagesEmerge™ Pc/Abs 7740: Technical InformationbobPas encore d'évaluation

- A Ttention Oem'S Micro Irt/CDocument2 pagesA Ttention Oem'S Micro Irt/Cluat1983Pas encore d'évaluation

- Datasheet SBPE510438 en USDocument2 pagesDatasheet SBPE510438 en USmechanical09Pas encore d'évaluation

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroPas encore d'évaluation

- Adss 120m SpanDocument2 pagesAdss 120m SpanAdriana RosadoroPas encore d'évaluation

- Process Data Sheet: M M M M MDocument23 pagesProcess Data Sheet: M M M M MaariefmaulanaPas encore d'évaluation

- 3m VHB Tape 5958frDocument9 pages3m VHB Tape 5958frDonald A HuntPas encore d'évaluation

- Tutorial Sheet 7Document2 pagesTutorial Sheet 7Swarnava SanyalPas encore d'évaluation

- Indian Institute of Technology Delhi ELL 201: Digital Electronic Circuits Laboratory Experiment 7: Sequence GeneratorDocument1 pageIndian Institute of Technology Delhi ELL 201: Digital Electronic Circuits Laboratory Experiment 7: Sequence GeneratorSwarnava SanyalPas encore d'évaluation

- Tutorial 5Document6 pagesTutorial 5Swarnava SanyalPas encore d'évaluation

- Liftoff TechniquesDocument4 pagesLiftoff TechniquesSwarnava SanyalPas encore d'évaluation

- Indian Institute of Technology DelhiDocument1 pageIndian Institute of Technology DelhiSwarnava SanyalPas encore d'évaluation

- UntitledDocument2 pagesUntitledSwarnava SanyalPas encore d'évaluation

- PMT - MCP100 - Sem 2 - 2016-17Document8 pagesPMT - MCP100 - Sem 2 - 2016-17Swarnava SanyalPas encore d'évaluation

- Exp5 - Polarization of Light PDFDocument10 pagesExp5 - Polarization of Light PDFSwarnava SanyalPas encore d'évaluation

- 4 Orbit SolutionDocument15 pages4 Orbit SolutionSwarnava SanyalPas encore d'évaluation

- AbcdDocument1 pageAbcdSwarnava SanyalPas encore d'évaluation

- Course Content For IIT DELHIDocument2 pagesCourse Content For IIT DELHISwarnava SanyalPas encore d'évaluation

- Iisc Physics BSC Syllabus PDFDocument6 pagesIisc Physics BSC Syllabus PDFSwarnava SanyalPas encore d'évaluation

- Switching Lab-05b Configuring InterVLAN RoutingDocument2 pagesSwitching Lab-05b Configuring InterVLAN RoutingHernan E. SalvatoriPas encore d'évaluation

- Nikasil e AlusilDocument5 pagesNikasil e AlusilIo AncoraioPas encore d'évaluation

- Topic 1 - ICT Tools at USP - Theoretical Notes With Google AppsDocument18 pagesTopic 1 - ICT Tools at USP - Theoretical Notes With Google AppsAvantika PrasadPas encore d'évaluation

- Negative Feedback AmplifierDocument31 pagesNegative Feedback AmplifierPepPas encore d'évaluation

- Learning TheoryDocument7 pagesLearning Theoryapi-568999633Pas encore d'évaluation

- Grasa LO 915Document2 pagesGrasa LO 915Angelo Carrillo VelozoPas encore d'évaluation

- Work Site Inspection Checklist 1Document13 pagesWork Site Inspection Checklist 1syed hassanPas encore d'évaluation

- IPS PressVest Premium PDFDocument62 pagesIPS PressVest Premium PDFLucian Catalin CalinPas encore d'évaluation

- Biscotti: Notes: The Sugar I Use in France, Is CalledDocument2 pagesBiscotti: Notes: The Sugar I Use in France, Is CalledMonica CreangaPas encore d'évaluation

- P66 M10 CAT B Forms and Docs 04 10Document68 pagesP66 M10 CAT B Forms and Docs 04 10VinayPas encore d'évaluation

- Statistical Techniques EE 532Document1 pageStatistical Techniques EE 532AdnanPas encore d'évaluation

- Profibus Adapter Npba-02 Option/Sp Profibus Adapter Npba-02 Option/SpDocument3 pagesProfibus Adapter Npba-02 Option/Sp Profibus Adapter Npba-02 Option/Spmelad yousefPas encore d'évaluation

- Contemp Person Act.1Document1 pageContemp Person Act.1Luisa Jane De LunaPas encore d'évaluation

- 3g Node B On Ip MediaDocument79 pages3g Node B On Ip MediaBsskkd KkdPas encore d'évaluation

- 1st Problem Solving Assignment - Barrels of Apples - M383 Sp22.docx-2Document4 pages1st Problem Solving Assignment - Barrels of Apples - M383 Sp22.docx-2Kor16Pas encore d'évaluation

- Rin Case StudyDocument4 pagesRin Case StudyReha Nayyar100% (1)

- D. Das and S. Doniach - Existence of A Bose Metal at T 0Document15 pagesD. Das and S. Doniach - Existence of A Bose Metal at T 0ImaxSWPas encore d'évaluation

- Antifraud PlaybookDocument60 pagesAntifraud PlaybookDani UsmarPas encore d'évaluation

- Durability of Prestressed Concrete StructuresDocument12 pagesDurability of Prestressed Concrete StructuresMadura JobsPas encore d'évaluation

- Reference by John BatchelorDocument1 pageReference by John Batchelorapi-276994844Pas encore d'évaluation

- Mobile Services: Your Account Summary This Month'S ChargesDocument3 pagesMobile Services: Your Account Summary This Month'S Chargeskumarvaibhav301745Pas encore d'évaluation

- What Is Denim? Why It's Called Denim?: Properties of Denim FabricDocument21 pagesWhat Is Denim? Why It's Called Denim?: Properties of Denim Fabricrahmanshanto623100% (1)

- For ClosureDocument18 pagesFor Closuremau_cajipePas encore d'évaluation

- Jones Et - Al.1994Document6 pagesJones Et - Al.1994Sukanya MajumderPas encore d'évaluation

- Ged 102 Mathematics in The Modern WorldDocument84 pagesGed 102 Mathematics in The Modern WorldKier FormelozaPas encore d'évaluation

- Lotus Exige Technical InformationDocument2 pagesLotus Exige Technical InformationDave LeyPas encore d'évaluation

- A2 UNIT 5 Culture Teacher's NotesDocument1 pageA2 UNIT 5 Culture Teacher's NotesCarolinaPas encore d'évaluation

- The Beauty of Laplace's Equation, Mathematical Key To Everything - WIRED PDFDocument9 pagesThe Beauty of Laplace's Equation, Mathematical Key To Everything - WIRED PDFYan XiongPas encore d'évaluation

- Assignment RoadDocument14 pagesAssignment RoadEsya ImanPas encore d'évaluation

- Chestionar 2Document5 pagesChestionar 2Alex AndruPas encore d'évaluation