Académique Documents

Professionnel Documents

Culture Documents

Solutions ProblemSet8 Sem22007

Transféré par

clearcastingCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Solutions ProblemSet8 Sem22007

Transféré par

clearcastingDroits d'auteur :

Formats disponibles

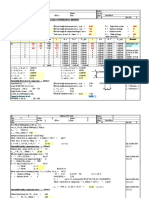

ENGG1050 Problem Set 8: Second Law for Engineering Processes

Solutions

1. Air is compressed in a piston-cylinder device in a reversible and isothermal manner. The entropy change of

air and the work done are to be determined.

Assumptions 1 At specified conditions, air can be treated as an ideal gas. 2 The process is specified to be

reversible.

Properties The gas constant of air is R = 0.287 kJ/kg.K (Table A-1).

Analysis (a) Noting that the temperature remains constant, the entropy change of air is determined from

T2 0 P P

Sair = c p ,avg ln R ln 2 = R ln 2

T1 P1 P1

400 kPa

= (0.287 kJ/kg K )ln = 0.428 kJ/kg K

AIR

90 kPa Q

Also, for a reversible isothermal process, T = const

q = Ts = (293 K )( 0.428 kJ/kg K ) = 125.4 kJ/kg

qout = 125.4 kJ/kg

(b) The work done during this process is determined from the closed system energy balance,

E Eout = Esystem

1in

424 3 1424 3

Net energy transfer Change in internal, kinetic,

by heat, work, and mass potential, etc. energies

Win Qout = U = mcv (T2 T1 ) = 0

win = qout = 125.4 kJ/kg

2. Air is compressed steadily by a 5-kW compressor from one specified state to another specified state. The

rate of entropy change of air is to be determined.

Assumptions At specified conditions, air can be treated as an ideal gas. 2 Air has variable specific heats.

Properties The gas constant of air is R = 0.287 kJ/kg.K (Table A-1).

Analysis From the air table (Table A-17), P2 = 600 kPa

T1 = 290 K o T2 = 440 K

s1 = 1.66802 kJ/kg K

P1 = 100 kPa

T2 = 440 K o AIR

s 2 = 2.0887 kJ/kg K COMPRESSOR

P2 = 600 kPa 5 kW

Then the rate of entropy change of air becomes

P

S&sys = m& s2o s1o R ln 2

P1 P1 = 100 kPa

T1 = 290 K

600 kPa

= (1.6/60 kg/s ) 2.0887 1.66802 (0.287 kJ/kg K ) ln

100 kPa

= 0.00250 kW/K

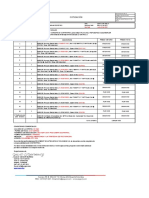

3. Air is compressed in a piston-cylinder device in a reversible and adiabatic manner. The final temperature

and the work are to be determined for the cases of constant and variable specific heats.

Assumptions 1 At specified conditions, air can be treated as an ideal gas. 2 The process is given to be

reversible and adiabatic, and thus isentropic. Therefore, isentropic relations of ideal gases apply.

Properties The gas constant of air is R = 0.287 kJ/kg.K (Table A-1). The specific heat ratio of air at low to

moderately high temperatures is k = 1.4 (Table A-2).

Analysis (a) Assuming constant specific heats, the ideal gas isentropic relations give

(k 1) k 0.4 1.4

P 800 kPa

T2 = T1 2 = (290 K ) = 525.3 K

P1 100 kPa

ENGG1050 Problem Set 8: Solutions - Semester 1 2006 1

Then,

Tavg = (290 + 525.3)/2 = 407.7 K

cv ,avg = 0.727 kJ/kg K

We take the air in the cylinder as the system. The energy balance for

this stationary closed system can be expressed as

E Eout = Esystem

1in424 3 1424 3 AIR

Net energy transfer Change in internal, kinetic,

by heat, work, and mass potential, etc. energies Reversible

Win = U = m(u2 u1 ) mcv (T2 T1 )

Thus,

win = cv ,avg (T2 T1 ) = (0.727 kJ/kg K )(525.3 290 ) K = 171.1 kJ/kg

(b) Assuming variable specific heats, the final temperature can be determined using the relative pressure

data (Table A-17),

Pr1 = 1.2311

T1 = 290 K

u1 = 206.91 kJ/kg

and

800 kPa T = 522.4 K

P

Pr2 = 2 Pr1 = (1.2311) = 9.849 2

P1 100 kPa u2 = 376.16 kJ/kg

Then the work input becomes

win = u2 u1 = (376.16 206.91) kJ/kg = 169.25 kJ/kg

4. Steam enters an adiabatic turbine at a specified state, and leaves at a specified state. The mass flow rate of

the steam and the isentropic efficiency are to be determined.

Assumptions 1 This is a steady-flow process since there is no change with time. 2 Potential energy changes

are negligible. 3 The device is adiabatic and thus heat transfer is negligible.

Analysis (a) From the steam tables (Tables A-4 and A-6),

P1 = 7 MPa h1 = 3650.6 kJ/kg

T1 = 600C s1 = 7.0910 kJ/kg K

P2 = 50 kPa

h2 a = 2780.2 kJ/kg

T2 = 150C

There is only one inlet and one exit, and thus m &1 = m&2 = m

& . We take the actual turbine as the system, which

is a control volume since mass crosses the boundary. The energy balance for this steady-flow system can be

expressed in the rate form as

E& E& out = E& system0 (steady) =0

1in

424 3 1442443 1

Rate of net energy transfer Rate of change in internal, kinetic,

by heat, work, and mass potential, etc. energies

E& in = E& out 6 MW

H2O

m& (h1 + V12 / 2) = W&a,out + m& ( h2 + V12 /2) (since Q& pe 0)

V 2 V12

W&a,out = m& h2 h1 + 2

2

Substituting, the mass flow rate of the steam is determined to be 2

(140 m/s) 2 (80 m/s) 2 1 kJ/kg

6000 kJ/s = m& 2780.2 3650.6 +

2 1000 m 2 /s 2

m& = 6.95 kg/s

(b) The isentropic exit enthalpy of the steam and the power output of the isentropic turbine are

s 2 s s f 7.0910 1.0912

P2 s = 50 kPa x2s = = = 0.9228

s fg 6.5019

s 2 s = s1 h = h + x h = 340.54 + (0.9228)(2304.7 ) = 2467.3 kJ/kg

2s f 2 s fg

and

ENGG1050 Problem Set 8: Solutions - Semester 1 2006 2

( {(

W&s,out = m& h2 s h1 + V22 V12 / 2 ) })

(140 m/s) 2 (80 m/s) 2 1 kJ/kg

W&s,out = (6.95 kg/s ) 2467.3 3650.6 +

2 1000 m /s

2 2

= 8174 kW

Then the isentropic efficiency of the turbine becomes

W& 6000 kW

T = a = = 0.734 = 73.4%

&

Ws 8174 kW

5. Air enters an adiabatic compressor with an isentropic efficiency of 84% at a specified state, and leaves at a

specified temperature. The exit pressure of air and the power input to the compressor are to be determined.

Assumptions 1 This is a steady-flow process since there is no change with time. 2 Kinetic and potential

energy changes are negligible. 3 The device is adiabatic and thus heat transfer is negligible. 4 Air is an

ideal gas with variable specific heats.

Properties The gas constant of air is R = 0.287 kPa.m3/kg.K (Table A-1) 2

Analysis (a) From the air table (Table A-17),

T1 = 290 K

h1 = 290.16 kJ/kg, Pr1 = 1.2311 AIR

T2 = 530 K

h2 a = 533.98 kJ/kg C = 84%

h2 s h1

From the isentropic efficiency relation C = ,

h2 a h1 2.4 m3/s

h2 s = h1 + C (h2 a h1 ) 1

= 290.16 + (0.84)(533.98 290.16 ) = 495.0 kJ/kg

Pr2 = 7.951

Then from the isentropic relation ,

Pr

P2 Pr2

= P2 = 2

P = 7.951 (100 kPa ) = 646 kPa

P1 Pr1 Pr 1 1.2311

1

(b) There is only one inlet and one exit, and thus m &1 = m

&2 = m& . We take the actual compressor as the

system, which is a control volume since mass crosses the boundary. The energy balance for this steady-

flow system can be expressed as

E& E& out = E& system0 (steady) =0

1in

424 3 1442443

Rate of net energy transfer Rate of change in internal, kinetic,

by heat, work, and mass potential, etc. energies

E& in = E& out

W&a,in + m& h1 = m& h2 (since Q& ke pe 0)

W&a,in = m& ( h2 h1 )

P1V&1 (100 kPa )(2.4 m 3 /s)

where m& = = = 2.884 kg/s

RT1 (0.287 kPa m 3 /kg K )(290 K )

Then the power input to the compressor is determined to be

W& = (2.884 kg/s)(533.98 290.16) kJ/kg = 703 kW

a,in

6. Hot combustion gases are accelerated in a 92% efficient adiabatic nozzle from low velocity to a specified

velocity. The exit velocity and the exit temperature are to be determined.

Assumptions 1 This is a steady-flow process since there is no change with time. 2 Potential energy changes

are negligible. 3 The device is adiabatic and thus heat transfer is negligible. 4 Combustion gases can be

treated as air that is an ideal gas with variable specific heats.

Analysis From the air table (Table A-17),

P1 = 260 kPa AIR

T1 = 1020 K

h1 = 1068.89 kJ/kg, Pr1 = 123.4 T1 = 747C P2 = 85 kPa

V1 = 80 m/s

N = 92%

From the isentropic relation ,

ENGG1050 Problem Set 8: Solutions - Semester 1 2006 3

P 85 kPa

Pr2 = 2 Pr1 = (123.4) = 40.34 h2 s = 783.92 kJ/kg

P1 260 kPa

There is only one inlet and one exit, and thus m &1 = m

&2 = m

& . We take the nozzle as the system, which is a

control volume since mass crosses the boundary. The energy balance for this steady-flow system for the

isentropic process can be expressed as

E& E& out = E& system0 (steady) =0

1in

424 3 1442443

Rate of net energy transfer Rate of change in internal, kinetic,

by heat, work, and mass potential, etc. energies

E& in = E& out

m& (h1 + V12 / 2) = m& (h2 s + V 22s /2) (since W& = Q& pe 0)

V 22s V12

h2 s = h1

2

Then the isentropic exit velocity becomes

2

/s 2

V 2 s = V12 + 2(h1 h2 s ) = (80 m/s)2 + 2(1068.89 783.92)kJ/kg 1000 m = 759.2 m/s

1 kJ/kg

Therefore,

V2 a = N V2 s = 0.92 (759.2 m/s ) = 728.2 m/s

The exit temperature of air is determined from the steady-flow energy equation,

h2 a = 1068.89 kJ/kg

(728.2 m/s)2 (80 m/s)2 1 kJ/kg

2 1000 m 2 /s 2 = 806.95 kJ/kg

From the air table we read T2a = 786.3 K

7. Cold water is heated by hot water in a heat exchanger. The rate of heat transfer and the rate of entropy

generation within the heat exchanger are to be determined.

Assumptions 1 Steady operating conditions exist. 2 The heat exchanger is well-insulated so that heat loss to

the surroundings is negligible and thus heat transfer from the hot fluid is equal to the heat transfer to the

cold fluid. 3 Changes in the kinetic and potential energies of fluid streams are negligible. 4 Fluid properties

are constant.

Properties The specific heats of cold and hot water are given to be 4.18 and 4.19 kJ/kg.C, respectively.

Analysis We take the cold water tubes as the system, which is a

control volume. The energy balance for this steady-flow system

can be expressed in the rate form as Cold water

& & & 0 (steady) 15C

E Eout = Esystem =0

1in424 3 1442443 0.25 kg/s

Rate of net energy transfer Rate of change in internal, kinetic,

by heat, work, and mass potential, etc. energies Hot water

E& in = E& out 100C

Q& in + m& h1 = m& h2 (since ke pe 0) 3 kg/s

45C

Q& in = m& c p (T2 T1 )

Then the rate of heat transfer to the cold water in this heat exchanger becomes

Q& in = [m& c p (Tout Tin )]cold water = (0.25 kg/s)(4.18 kJ/kg.C)(45C 15C) = 31.35 kW

Noting that heat gain by the cold water is equal to the heat loss by the hot water, the outlet temperature of

the hot water is determined to be

Q& 31.35 kW

Q& = [m& c p (Tin Tout )]hot water

Tout = Tin = 100C = 97.5C

m& c p (3 kg/s)(4.19 kJ/kg.C)

(b) The rate of entropy generation within the heat exchanger is determined by applying the rate form of the

entropy balance on the entire heat exchanger:

ENGG1050 Problem Set 8: Solutions - Semester 1 2006 4

S&in S&out + S&gen = S&system0 (steady)

1424 3 { 1442443

Rate of net entropy transfer Rate of entropy Rate of change

by heat and mass generation of entropy

m& 1s1 + m& 3s3 m& 2 s2 m& 3s4 + S&gen = 0 (since Q = 0)

m& cold s1 + m& hot s3 m& cold s2 m& hot s4 + S&gen = 0

S&gen = m& cold ( s2 s1 ) + m& hot ( s4 s3 )

Noting that both fluid streams are liquids (incompressible substances), the rate of entropy generation is

determined to be

T T

S&gen = m& coldc p ln 2 + m& hot c p ln 4

T1 T3

45 + 273 97.5 + 273

= (0.25 kg/s)(4.18 kJ/kg.K)ln + (3 kg/s)(4.19 kJ/kg.K)ln

15 + 273 100 + 273

= 0.0190 kW/K

8. Liquid water is heated in a chamber by mixing it with superheated steam. For a specified mixing

temperature, the mass flow rate of the steam and the rate of entropy generation are to be determined.

Assumptions 1 This is a steady-flow process since there is no change with time. 2 Kinetic and potential

energy changes are negligible. 3 There are no work interactions.

Properties Noting that T < Tsat @ 200 kPa = 120.21C, the cold water and the exit mixture streams exist as a

compressed liquid, which can be approximated as a saturated liquid at the given temperature. From Tables

A-4 through A-6,

1200 kJ/min

P1 = 200 kPa h1 h f @ 20o C = 83.91 kJ/kg

s s = 0.2965 kJ/kg K

T1 = 20C 1 f @ 20o C

20C

1

P2 = 200 kPa h2 = 2769.1 kJ/kg 2.5 kg/s MIXING

CHAMBER 60C

T2 = 150C s 2 = 7.2810 kJ/kg K 3

200 kPa

P3 = 200 kPa h3 h f @60o C = 251.18 kJ/kg 2 150C

s s = 0.8313 kJ/kg K

T3 = 60C 3 f @ 60o C

Analysis (a) We take the mixing chamber as the system, which is a control volume. The mass and energy

balances for this steady-flow system can be expressed in the rate form as

0 (steady)

Mass balance: m& m& = E&

in out =0

system m& + m& = m& 1 2 3

Energy balance:

E& E& out = E& system0 (steady) =0

1in424 3 1442443

Rate of net energy transfer Rate of change in internal, kinetic,

by heat, work, and mass potential, etc. energies

E& in = E& out

m& 1h1 + m& 2 h2 = Q& out + m& 3h3

Combining the two relations gives Q& out = m& 1h1 + m& 2 h2 (m& 1 + m& 2 )h3 = m& 1 (h1 h3 ) + m& 2 (h2 h3 )

Solving for m

& 2 and substituting, the mass flow rate of the superheated steam is determined to be

Q& out m& 1 (h1 h3 ) (1200/60kJ/s) (2.5 kg/s )(83.91 251.18)kJ/kg

m& 2 = = = 0.166 kg/s

h2 h3 (2769.1 251.18)kJ/kg

Also, m& 3 = m& 1 + m& 2 = 2.5 + 0.166 = 2.666 kg/s

(b) The rate of total entropy generation during this process is determined by applying the entropy balance

on an extended system that includes the mixing chamber and its immediate surroundings so that the

boundary temperature of the extended system is 25C at all times. It gives

ENGG1050 Problem Set 8: Solutions - Semester 1 2006 5

S& S&out + S&gen = S&system0 = 0

1in

424 3 { 14243

Rate of net entropy transfer Rate of entropy Rate of change

by heat and mass generation of entropy

Q& out

m& 1s1 + m& 2 s2 m& 3s3 + S&gen = 0

Tb,surr

Substituting, the rate of entropy generation during this process is determined to be

Q&

S&gen = m& 3 s3 m& 2 s2 m& 1s1 + out

Tb,surr

= (2.666 kg/s )(0.8313 kJ/kg K ) (0.166 kg/s )(7.2810 kJ/kg K )

(1200 / 60 kJ/s)

(2.5 kg/s )(0.2965 kJ/kg K ) +

298 K

= 0.333 kW/K

9. Steam is accelerated in a nozzle from a velocity of 70 m/s to 320 m/s. The exit temperature and the rate of

entropy generation are to be determined.

Assumptions 1 This is a steady-flow process since there is no change with time. 2 Potential energy changes

are negligible. 3 There are no work interactions. 4 The device is adiabatic and thus heat transfer is

negligible.

Properties From the steam tables (Table A-6), P1 = 4 MPa Steam P2 = 3 MPa

h1 = 3331.2 kJ/kg T1 = 450 C V2 = 320 m/s

P1 = 4 MPa V1 = 70 m/s

s1 = 6.9386 kJ/kg K

T1 = 450 C

v 1 = 0.08004 m 3 /kg

Analysis (a) There is only one inlet and one exit, and thus m&1 = m

&2 = m

& . We take nozzle as the system,

which is a control volume since mass crosses the boundary. The energy balance for this steady-flow system

can be expressed in the rate form as

E& E& out = E& system0 (steady) =0

1in424 3 1442443

Rate of net energy transfer Rate of change in internal, kinetic,

by heat, work, and mass potential, etc. energies

E& in = E& out

m& (h1 + V12 / 2) = m& (h2 + V 22 /2) (since Q& W

& pe 0)

V 22 V12

0 = h2 h1 +

2

Substituting,,

or, h2 = 3331.2 kJ/kg

(320 m/s)2 (70 m/s)2 1 kJ/kg

= 3282.4 kJ/kg

2 1000 m 2 /s 2

Thus,

P2 = 3 MPa T2 = 422.3C

h2 a = 3282.4 kJ/kg s 2 = 6.9976 kJ/kg K

The mass flow rate of steam is

m& =

1

v1

A1V1 =

1

( )

7 10 4 m 2 (70 m/s ) = 0.6122 kg/s

0.08004 m 3 /kg

(b) Again we take the nozzle to be the system. Noting that no heat crosses the boundaries of this combined

system, the entropy balance for it can be expressed as

S&in S&out + S&gen = S&system0 = 0

1424 3 { 14243

Rate of net entropy transfer Rate of entropy Rate of change

by heat and mass generation of entropy

m& s1 m& s2 + S&gen = 0

S&gen = m& (s2 s1 )

Substituting, the rate of entropy generation during this process is determined to be

ENGG1050 Problem Set 8: Solutions - Semester 1 2006 6

S&gen = m& (s2 s1 ) = (0.6122 kg/s )(6.9976 6.9386)kJ/kg K = 0.0361 kW/K

10. h = 3069.3kJ / kg

Inlet conditions 1

s1 = 7.7022kJ / kg.K

Just about the same value, thus adiabatic reversible

h = 2971.0

Outlet conditions 2

s2 = 7.7086

So the first law gives, for the flow system,

2 2

h2 + v2 h1 + v1 = q/ w /

2 g c 2 g c

or

v22 v2 10 2

= h1 + 1 h2 = 3069300 + 2971000 = 98350

2gc 2gc 2

v2 = 444 m/s (This is quite fast because the speed of sound in steam is C = 564 m/s)

11. - 10o C 60o C

2bar 14bar

Entering Leaving

h1 = 392900 J / kg h2 = 434000 J / kg

s = 1734.4 J / kg.K s = 1735.7 J / kg.K

1 2

Since s2 > s1, the second law is satisfied, this is just about ideal.

Now evaluate the work needed to do the job.

Wsh = h2 h1 = 434000 392900

= 41100 J / kg

So

Wsh = m& h = (5kg / s )(41100 J / kg )

= 205500W = 205kW

For an adiabatic reversible compressor we find W& sh = 205kW

For the real compressor W& s should be larger still, or W& sh > 205

The actual one designed for is W& = 150kW

s

It is too small for the job.

ENGG1050 Problem Set 8: Solutions - Semester 1 2006 7

Vous aimerez peut-être aussi

- Chapter 10 Vapor and Combined Power CyclesDocument29 pagesChapter 10 Vapor and Combined Power Cyclesnamsun100% (1)

- Refrigeration ProblemsDocument3 pagesRefrigeration Problemsanask15Pas encore d'évaluation

- SampleDocument5 pagesSampleMark Anthony RazonPas encore d'évaluation

- Assignment and Its Solution - Airstandardcycle and VapourcycleDocument24 pagesAssignment and Its Solution - Airstandardcycle and VapourcycleMatthias100% (1)

- 74311Document18 pages74311amdevaPas encore d'évaluation

- SHEET4 AnswersDocument20 pagesSHEET4 AnswersHamadaMohassabPas encore d'évaluation

- Mechanical Engineering Laboratory 1 PlanimeterDocument8 pagesMechanical Engineering Laboratory 1 PlanimeterChristopher Lennon Dela CruzPas encore d'évaluation

- HT-026 SolutionDocument2 pagesHT-026 SolutionKTINE08Pas encore d'évaluation

- 07 - Steam Generator FamiliarizationDocument6 pages07 - Steam Generator FamiliarizationJoren HuernoPas encore d'évaluation

- Machine Desing 1 Exam #2 Problem Solving InstructionsDocument2 pagesMachine Desing 1 Exam #2 Problem Solving InstructionsMarc JabarPas encore d'évaluation

- Ref MathDocument7 pagesRef MathMd.Tanvir RahmanPas encore d'évaluation

- ME374 - Final Examination 1Document2 pagesME374 - Final Examination 1Christian Breth BurgosPas encore d'évaluation

- Chapter 1Document15 pagesChapter 1سعيد بن إدريس100% (1)

- Heat Transfer Reviewer UpdatedDocument23 pagesHeat Transfer Reviewer UpdatedRavin SolPas encore d'évaluation

- Assignments HMTDocument2 pagesAssignments HMTPiyush AgarawalPas encore d'évaluation

- Solved Problems A Solved Refrigeration ProblemsDocument29 pagesSolved Problems A Solved Refrigeration Problemsbasil.delacruzPas encore d'évaluation

- Actual Vapor Compression Refrigeration Cycle Part 1Document12 pagesActual Vapor Compression Refrigeration Cycle Part 1jjPas encore d'évaluation

- Ciclos RefrigeracionDocument64 pagesCiclos RefrigeracionSergyPas encore d'évaluation

- Dryer 001Document1 pageDryer 001asdasdasdasdPas encore d'évaluation

- Theory of Machines: Solution ManualDocument18 pagesTheory of Machines: Solution ManualAdnan PirbhaiPas encore d'évaluation

- Questions #1 For Heat TransferDocument2 pagesQuestions #1 For Heat TransferWinniePas encore d'évaluation

- Ref Systems Lecture Notes 1Document9 pagesRef Systems Lecture Notes 1Retro GamerPas encore d'évaluation

- Step 1: Draw A Diagram To Represent The SystemDocument7 pagesStep 1: Draw A Diagram To Represent The SystemRyan Cristian BorsiguePas encore d'évaluation

- Chapter 1 Thermodynamics 2Document2 pagesChapter 1 Thermodynamics 2afiqzeroPas encore d'évaluation

- A. Otto Cycle (Gasoline Engine)Document22 pagesA. Otto Cycle (Gasoline Engine)John Manuel BautistaPas encore d'évaluation

- Assignment1 Cruz FrancisPaulo M MECp1Document3 pagesAssignment1 Cruz FrancisPaulo M MECp1Francis Paulo CruzPas encore d'évaluation

- CH 06Document15 pagesCH 06hirenpatel_universalPas encore d'évaluation

- Mechanical Engineering ProblemsDocument2 pagesMechanical Engineering ProblemsEnriv YasiladPas encore d'évaluation

- Me6301 QBDocument46 pagesMe6301 QBNaveen Dhanuraj100% (1)

- ME432 Power Plant Engineering May Jun 2007 PDFDocument3 pagesME432 Power Plant Engineering May Jun 2007 PDFBala MuruganPas encore d'évaluation

- Sheet 1 - Introduction To Heat Transfer MechanismsDocument2 pagesSheet 1 - Introduction To Heat Transfer MechanismsAhmed YousryPas encore d'évaluation

- HjjooDocument28 pagesHjjooJohn Patrick DaglePas encore d'évaluation

- Hvac Rpoblems NewDocument20 pagesHvac Rpoblems NewGrace Joy CariPas encore d'évaluation

- Actual Vapor Compression CycleDocument7 pagesActual Vapor Compression CycleDeniell Joyce MarquezPas encore d'évaluation

- Lesson No. 2 in Machine Design 1Document19 pagesLesson No. 2 in Machine Design 1Carl JavierPas encore d'évaluation

- Solar AngleDocument17 pagesSolar AngleRichard ManongsongPas encore d'évaluation

- Air Conditioning DefinitionsDocument29 pagesAir Conditioning DefinitionsRay RavelPas encore d'évaluation

- Chapter 5Document28 pagesChapter 5Anthony Leire MontealtoPas encore d'évaluation

- Example Question FinalDocument22 pagesExample Question Finalgazile0% (1)

- PIPE ProblemsDocument7 pagesPIPE ProblemsEarl James RoquePas encore d'évaluation

- Chapter 9 - Part 1Document63 pagesChapter 9 - Part 1muhammad izzul100% (1)

- Machine Elements: Cams: Group 7 Charlie Dionisio R - Jhun Lemos Jerphoenix Mullaneda Arsilio SilverioDocument21 pagesMachine Elements: Cams: Group 7 Charlie Dionisio R - Jhun Lemos Jerphoenix Mullaneda Arsilio SilverioDeniell Joyce MarquezPas encore d'évaluation

- 15me03 Basic ThermodynamicsDocument20 pages15me03 Basic ThermodynamicsVaratha Rajan0% (1)

- UNIT-1: What Is The Difference Between Refrigeration & Air Conditioning?Document8 pagesUNIT-1: What Is The Difference Between Refrigeration & Air Conditioning?Udit NarayanPas encore d'évaluation

- Final Assignment 1 - ThermodynamicsDocument2 pagesFinal Assignment 1 - Thermodynamicsjovan avery dalluay0% (2)

- 2-1 Sketch Careful The Kinematic Diagrams and Find Their Total Degrees of Freedom. A. An Automobile Hood Hinge MechanismDocument14 pages2-1 Sketch Careful The Kinematic Diagrams and Find Their Total Degrees of Freedom. A. An Automobile Hood Hinge Mechanismchala nigussiePas encore d'évaluation

- Thermal Questions KonguDocument9 pagesThermal Questions Konguabu19870% (1)

- Thermodynamics MwanDocument16 pagesThermodynamics Mwanyeng botzPas encore d'évaluation

- Belt Drive Types Material Applications Advantages Disadvantages PPT 1Document19 pagesBelt Drive Types Material Applications Advantages Disadvantages PPT 1Sandesh yadavPas encore d'évaluation

- Me6301 Engineering Thermodynamics - Syllabus, 2&16 Mark QuestionsDocument43 pagesMe6301 Engineering Thermodynamics - Syllabus, 2&16 Mark Questionsdellibabu509Pas encore d'évaluation

- (Lab No. 1) Determination of Viscosity of A Given Liquid Using Viscometer.Document15 pages(Lab No. 1) Determination of Viscosity of A Given Liquid Using Viscometer.Haider AliPas encore d'évaluation

- Brayton CycleDocument5 pagesBrayton CycleDanang Wahdiat Aulia IshaqPas encore d'évaluation

- HW-4-sphere WithoutDocument1 pageHW-4-sphere WithoutSafaa Hameed Al Nasery100% (1)

- CLINT E. MOSENABRE FluidsDocument5 pagesCLINT E. MOSENABRE FluidsClint MosenabrePas encore d'évaluation

- ConductionDocument34 pagesConductionguna sekaranPas encore d'évaluation

- Machine Elements L2Document31 pagesMachine Elements L2Julie Ann D. GaboPas encore d'évaluation

- Weekly Exam 3Document5 pagesWeekly Exam 3Deyn EstoquePas encore d'évaluation

- 2300 HW 13 SolDocument4 pages2300 HW 13 SolFrederick DugayPas encore d'évaluation

- Chapter 4Document3 pagesChapter 4nick thompsonPas encore d'évaluation

- Chapter 4 PDFDocument3 pagesChapter 4 PDFSusana PérezPas encore d'évaluation

- Year 12 Physics Exam ReviewDocument7 pagesYear 12 Physics Exam ReviewclearcastingPas encore d'évaluation

- CHEM1020 Module4 ViewingDocument180 pagesCHEM1020 Module4 ViewingclearcastingPas encore d'évaluation

- CHEM1020 Module3 ViewingDocument137 pagesCHEM1020 Module3 ViewingclearcastingPas encore d'évaluation

- Mate1000 sln07Document3 pagesMate1000 sln07clearcastingPas encore d'évaluation

- CHEM1020 Module2 ViewingDocument265 pagesCHEM1020 Module2 ViewingclearcastingPas encore d'évaluation

- CHEM1020 Module1 ViewingDocument199 pagesCHEM1020 Module1 ViewingclearcastingPas encore d'évaluation

- CHEM1020 - General InfoDocument5 pagesCHEM1020 - General InfoclearcastingPas encore d'évaluation

- Finite Element Analysis TutorialDocument3 pagesFinite Element Analysis TutorialclearcastingPas encore d'évaluation

- Course Notes 3 PDFDocument65 pagesCourse Notes 3 PDFclearcastingPas encore d'évaluation

- Course Notes 2 PDFDocument108 pagesCourse Notes 2 PDFclearcastingPas encore d'évaluation

- Trip Generation: CIVL3420Document15 pagesTrip Generation: CIVL3420clearcastingPas encore d'évaluation

- Reynolds Number: Re: VL VLDocument19 pagesReynolds Number: Re: VL VLclearcastingPas encore d'évaluation

- ENGG1050 Problem Set 5: First Law Steady Flow Problems SolutionsDocument8 pagesENGG1050 Problem Set 5: First Law Steady Flow Problems SolutionsclearcastingPas encore d'évaluation

- Prob 6Document2 pagesProb 6clearcastingPas encore d'évaluation

- Prob 7Document1 pageProb 7clearcastingPas encore d'évaluation

- 1 - Earth PressureDocument14 pages1 - Earth PressureclearcastingPas encore d'évaluation

- Solutions ProblemSet10 Sem22007Document4 pagesSolutions ProblemSet10 Sem22007clearcastingPas encore d'évaluation

- Solutions ProblemSet9 Sem22007Document3 pagesSolutions ProblemSet9 Sem22007clearcastingPas encore d'évaluation

- Prof Engin A02Document126 pagesProf Engin A02clearcastingPas encore d'évaluation

- Solution-ME F314Document3 pagesSolution-ME F314sai ramPas encore d'évaluation

- Plate ColumnsDocument3 pagesPlate ColumnsK SrikanthPas encore d'évaluation

- Thermal Energy Storage and Sensibile Energy StorageDocument30 pagesThermal Energy Storage and Sensibile Energy StoragesayoojPas encore d'évaluation

- Seismic Stag 6343Document67 pagesSeismic Stag 6343akujeePas encore d'évaluation

- C - Fluid Mechanics - PP - AnsDocument4 pagesC - Fluid Mechanics - PP - Anszyx xyzPas encore d'évaluation

- Extruder TypesDocument36 pagesExtruder Typesrasheedshaikh2003Pas encore d'évaluation

- ASME PTC 7.1 Displacement PumpsDocument22 pagesASME PTC 7.1 Displacement PumpsLorenzo Antonio CordovaPas encore d'évaluation

- Sistema Electrico DL300Document5 pagesSistema Electrico DL300Juan Luque LPas encore d'évaluation

- Introduction To Hydraulics Open Channel Flow Open Channels and Their PropertiesDocument28 pagesIntroduction To Hydraulics Open Channel Flow Open Channels and Their PropertiesCharles BongPas encore d'évaluation

- Ultrasonic Testing PDFDocument217 pagesUltrasonic Testing PDFHendi Rohendi83% (6)

- Die Design Fundamentals by PaquinDocument4 pagesDie Design Fundamentals by PaquinJayesh NairPas encore d'évaluation

- 7 - Psy - Chart - XLS Cooling CoilDocument28 pages7 - Psy - Chart - XLS Cooling CoilRanu JanuarPas encore d'évaluation

- Race 2019Document418 pagesRace 2019Sadia KhanPas encore d'évaluation

- BID ESG 21 048 Rev. 0 (Jun082021)Document1 pageBID ESG 21 048 Rev. 0 (Jun082021)Alexander Charry GiraldoPas encore d'évaluation

- Closed Form Solutions For Element Matrices of 4-Node Rectangular Plate Element Using IFMDocument10 pagesClosed Form Solutions For Element Matrices of 4-Node Rectangular Plate Element Using IFMMallesh NenkatPas encore d'évaluation

- Lecture Notes PDFDocument118 pagesLecture Notes PDFmiaPas encore d'évaluation

- Ventilator-Centrifugal-CBD-Sodeca 575 Lei 1570mchDocument5 pagesVentilator-Centrifugal-CBD-Sodeca 575 Lei 1570mchSilviu-Ionut DumitrachePas encore d'évaluation

- Kech 10Document46 pagesKech 10Vijaya PrakashPas encore d'évaluation

- Effective Thermal Design of Cooling TowersDocument6 pagesEffective Thermal Design of Cooling TowersandrshoPas encore d'évaluation

- Shear Wall CalculationDocument1 pageShear Wall CalculationSandeep ShakyaPas encore d'évaluation

- Chapter 5Document61 pagesChapter 5abdu yimerPas encore d'évaluation

- K-10. Parameter Dinamis TanahDocument17 pagesK-10. Parameter Dinamis TanahFurqon HabibiePas encore d'évaluation

- Sprinkler 2 01 2021Document2 pagesSprinkler 2 01 2021rajaPas encore d'évaluation

- Design and Analysis of Shell and Tube Heat ExchangerDocument8 pagesDesign and Analysis of Shell and Tube Heat ExchangerawusomPas encore d'évaluation

- PSVDocument38 pagesPSVSajid Raza100% (1)

- Information On Noise and Vibration.: Schindler 3300 Schindler 5300Document8 pagesInformation On Noise and Vibration.: Schindler 3300 Schindler 5300Herbert M. GomesPas encore d'évaluation

- Hues 0303Document167 pagesHues 0303Anonymous nbozs80lygPas encore d'évaluation

- Data Sheet ECW 100 400Document3 pagesData Sheet ECW 100 400Vidiya NovelinPas encore d'évaluation

- Asme Sec Viii D2 Ma App 5 PDFDocument15 pagesAsme Sec Viii D2 Ma App 5 PDFMarín HernándezPas encore d'évaluation

- Ame Homework Solutions 1 Fall 2011Document33 pagesAme Homework Solutions 1 Fall 2011Ťhåŕüñ Kūmæř GøwđPas encore d'évaluation