Académique Documents

Professionnel Documents

Culture Documents

Quick Disconnect

Transféré par

Anonymous zwSP5gvCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Quick Disconnect

Transféré par

Anonymous zwSP5gvDroits d'auteur :

Formats disponibles

THE BASICS OF QUICK DISCONNECTS

Quick disconnect fittings (abbreviated as QDCs or QDs) are used to provide fast

Contents and easy connection and disconnection of fluid lines. These fittings are also known

as quick connects or quick release couplings. Typically quick disconnect fittings are

The Basics of Quick Disconnects operated by hand. They often are used to replace fitting connections which require

tools to assemble and disassemble. There are a myriad of quick disconnect fittings

Snap Type (Ball Latching) types and they are found in all industries.

Non-Latching

Quick disconnects greatly improve the end users experience by simplifying

connections/disconnections and preventing fluid leakage. Engineers can use quick

No Shut-off

disconnects to enhance the serviceability of their design and add value to their

Single Shut-off

product. The ease and speed of connections and disconnections will also save

Double Shut-off

valuable time during testing and development.

Dry Break

Effective Orifice Rating

Pressure Rating

Use with Vacuum

Seal Material

Multi Line Quick Disconnects

Common Quick Disconnect Applications

To ensure success, many design considerations must be taken into account before specifying a quick disconnect. Since these

fittings have a number of components in the waterway (fluid path), they often have higher pressure drop than simpler fittings.

Designers should confirm that the fitting can deliver the flow performance required by their design. Quick disconnects can also

have pressure limitations so be sure the specified fitting can handle the maximum service pressures in the application. Material

selection is vitally important. All materials of construction must be compatible with the working fluid. The same goes for temperature

compatibility.

Other important questions to ask prior to specifying a quick disconnect are: Does the disconnect need to operate with the use of

only one hand? Do you need a shut-off mechanism in either or both ends of the connector? Or is no shut off mechanism(s) preferred

to maximize flow capacity when connected? Is dry breaking (discussed later in this tutorial) required? Is a non-latching disconnect

required? Are there multiple fluid lines that require simultaneous connection/disconnection? Will the disconnect have to operate

under vacuum? What type of tubing or hose will be connected to the quick disconnect?

You can find Beswicks available quick Excellence in Miniature

disconnects in our online catalog at

http://catalog.beswick.com/

beswick engineering co., inc. | Miniature Fluid Power Products

284 Ocean Rd. | Greenland, NH 03840-2442 | 603-433-1188

www.beswick.com

THE BASICS OF QUICK DISCONNECTS

Beswick offers a wide range of quick disconnects to meet many challenging applications. Beswick quick disconnects

are available in ball latching (also known as snap type), bayonet, threaded and non-latching connection styles. In

addition, many of these styles are available in single and double shutoff, non-shutoff and dry break sealing. Available

materials are brass, electroless nickel plated brass, 303 and 316 stainless steels for metallic components and

Buna-N, EPDM, Viton, Silicone and Perfluoroelastomers (such as Chemraz and Kalrez) for elastomers.

SNAP TYPE (ball latching)

Snap type (ball latching) quick disconnects are the most common

style. They are designed with a spring loaded ball latching

mechanism which automatically locks the two halves of the fitting

together when they are pushed together. When the releasing

sleeve (knurled for easy handling) is pulled back, the internal end

and external ends quickly disengage from each other. This quick

release feature is advantageous in designs that require numerous

connections throughout the life cycle of the product because they

are so simple to operate. Also, they can be disconnected one

handed. These QDCs can handle pressures up to approximately

500 psig.

NON-LATCHING (BLIND-MATE)

Non-latching quick disconnects, also commonly referred to as

blind-mate quick disconnects, are used in applications where quick

serviceability in a compact envelope is required. Typically, a non-

latching quick disconnect will be selected when a portion of the

device requires frequent change out, when the releasing sleeve Beswick can provide non-latching versions

may be inaccessible, or when the customer wishes to integrate of many quick disconnects on a custom or

the quick disconnect directly into a mounting plate of their own special order basis.

design. Test trays, animal cages, and umbilical lines are examples

of applications that benefit from non-latching quick disconnects.

Many types of quick disconnects can be supplied as non-latching so

inquire with the manufacturer.

beswick engineering co., inc. | Miniature Fluid Power Products

284 Ocean Rd. | Greenland, NH 03840-2442 | 603-433-1188

www.beswick.com

THE BASICS OF QUICK DISCONNECTS

NO SHUT-OFF

Quick disconnects without shut-offs are often used when high

flow rates are required. They are generally limited to applications

involving low pressure air or other non-hazardous gases because

the fluid is not contained in either half of the assembly upon

disconnection.

SINGLE SHUT-OFF

The internal half of the assembly contains a valve preventing flow

from escaping. This design is advantageous when you wish to fill

or evacuate pressure from a chamber or portable device and then

disconnect the fill line. When using single shut-off connectors, be

sure the end users are cautioned to wear eye protection when

connecting and disconnecting these fittings to avoid possible

injury from an energized fluid line or exposure to the fluid.

DOUBLE SHUT-OFF

Double-shut off quick disconnects have shut-off valves within

both the internal and external ends. These shut-off valves retain

pressure in both fluid lines when the assembly is disconnected.

This is ideal when the fluid is a liquid, an expensive gas, or

flammable gas (also consider a dry break quick disconnect).

While double shut-off quick disconnects are provided with shut-off

valves in both ends of the connector it is important to understand

that fluid can still leak out, usually from the external end, when

connecting or disconnecting if the fluid lines are under pressure.

DRY BREAK

If a level of sealing beyond that provided by a double shut-off

quick disconnect is required, dry break quick disconnects should

be specified. Dry break quick disconnects ensure that the shut

off valves in both the internal end and external ends are fully shut-

off prior to disconnection. Also, the two halves of the disconnect

make a seal before the shut off valves are opened during

connection. Dry break disconnects (often termed no spill)

typically have very low dead volume to prevent trapped fluid from

escaping or dripping when disconnected. This no spill feature

is especially important when the fluid is a liquid, an expensive

gas, a toxic gas, or a flammable gas where minimal leakage is

paramount.

beswick engineering co., inc. | Miniature Fluid Power Products

284 Ocean Rd. | Greenland, NH 03840-2442 | 603-433-1188

www.beswick.com

THE BASICS OF QUICK DISCONNECTS

EFFECTIVE ORIFICE RATING

Where high flow requirements are a major design consideration, be

sure to specify a quick disconnect with an adequate Cv or effective

orifice rating. Beswick miniature quick disconnect assemblies have

effective orifices ranging from 0.018 inch (0.46 mm) to 0.180 inch

(4.6 mm) diameter. Predictably, the size of the fitting gets larger as

the effective orifice rating increases. The M3 sized, dry break quick

disconnects (with a 0.018 inch diameter effective orifice) have a

maximum hexagonal section of 0.25 inch (6.4 mm). The Beswick high

flow dry break quick disconnect, with a 0.180 inch diameter effective

orifice, has a maximum hexagonal section of 0.563 inch (14.3 mm).

PRESSURE RATING

It is important to choose a quick disconnect with an adequate pressure

rating. The Beswick snap type quick disconnect designs are rated up

to a maximum of 300 to 500 psig. For higher pressure applications, up

to 3,000 psig, consider using screw or bayonet styles quick disconnect. 1/4 twist bayonet style quick disconnects are

The bayonet style quick disconnect has the advantage of being able to suitable for up to 3,000 psig

disconnect one handed by turning the connection a turn. The bayonet

design features adds extra strength to accommodate higher pressure.

The designer should however keep in mind that connection at these

higher pressures can be difficult or impossible when the user must

overcome the forces (force = pressure x area) acting on the shut-off

mechanism(s) as well as the forces generated by the shut-off springs.

USE WITH VACUUM

High pressures are not the only pressure related issue with quick disconnects. Vacuum applications can often be challenging to

reliably seal, particularly on double shut-off and dry break assemblies. Often, the internal side of a double shut off can handle

full vacuum while the external side can only handle light (a small amount of) vacuum. Dont take it for granted, be sure the quick

disconnect you specify offers the level of sealing your vacuum application requires.

BODY MATERIAL

When choosing a quick disconnect, be sure the materials of construction are appropriate for the intended application. Carbon steel

and C36000, which is a free machining grade of brass, are cost effective material options that provide increased strength and

temperature resistance compared to plastic components, while offering increased service life. If corrosive fluids are flowing through

the quick disconnect, consider specifying stainless steel. 303 and 316 stainless steels are ideal choices for corrosion resistance

and increased strength. Plastic quick disconnects can also be selected for corrosion resistance and lower cost however the trade

off is increased package size (plastic has lower strength than metal and therefore thicker wall sections are required) and reduced

impact resistance and reduced long-term durability. For these reasons, plastic is often not an option in miniature quick disconnects.

beswick engineering co., inc. | Miniature Fluid Power Products

284 Ocean Rd. | Greenland, NH 03840-2442 | 603-433-1188

www.beswick.com

THE BASICS OF QUICK DISCONNECTS

SEAL MATERIAL

Elastomeric seal materials must also be carefully chosen for the application.

Beswick quick disconnects are designed with O-ring seals to ensure leak

tight operation. Buna (also known as Buna-N or Nitrile) is our standard O-ring

material since it is cost effective and offers compatibility with the majority of

applications. If greater chemical or temperature compatibility is an issue there

are other, off the shelf, choices as well as specialty elastomers to suit almost

any application. EPDM, Viton, Silicone and Perfluoroelastomers (such as

Chemraz and Kalrez) are all readily available. Seal selection can be critical

in applications that involve extreme conditions such as very aggressive fluids

and wide temperature extremes. Fortunately there are countless variations on

the standard O-ring material formulations to meet demanding applications.

MULTI LINE QUICK DISCONNECT

In complex machines it is often necessary to simultaneously disconnect multiple fluid lines. As you can imagine, it is

vital that each fluid line be properly connected to prevent misconnections of the flow paths. Beswick multiple line quick

disconnects, known as a MLQDCs, offers this capability. The MLQDC are available in 4, 6 and 8 line configurations and

incorporates features to ensure correct orientation of the fluid lines during operation. Often it is possible to connect and

disconnect the multiple line quick disconnects with one hand. They are available in single shut off and double shut off (dry

break varieties are possible too) with the same choice of materials as our single line disconnects.

Available in 4, 6 and 8 line configurations

THREAD & TUBING CONNECTIONS

Lastly, be sure to specify the proper connection on the quick disconnect. Beswick QDCs are available with M3, M5, 10-

32, -28, M8 and 1/8 NPT threaded connections. Tube barbs are available for 1/16 inch, 5/64 inch (2.0 mm), 3/32 inch

(2.5 mm), 1/8 inch, 0.170 inch and inch inside diameter tubing. For higher pressures, higher temperatures, or for rigid

tubing integral compression fittings are also available. Manifold mounting designs are offered for applications which require

mounting one or both halves of the quick disconnect to a panel.

beswick engineering co., inc. | Miniature Fluid Power Products

284 Ocean Rd. | Greenland, NH 03840-2442 | 603-433-1188

www.beswick.com

COMMON QUICK DISCONNECT APPLICATIONS

Quick disconnects can be found in many types of machinery, such as: food packaging equipment, semiconductor production

machinery, drug and explosive detection devices, toxic gas detection monitors, analytical instruments, pneumatic tools,

air compressors, hydraulic power equipment such as snow plows, medical devices, automated assembly machinery, and

dental equipment. The applications are almost endless.

PNEUMATIC AND HYDRAULIC TOOLS AND COMPRESSORS

Probably the most well known use of quick disconnects is on pneumatically and

hydraulically powered tools and machinery. If youve ever visited an automobile repair

shop or seen a snow plow up close you likely noticed a quick disconnect positioned at the

end of the fluid lines. Quick disconnects make tool change over a breeze.

FOOD PACKAGING MACHINERY

Packaging machinery up-time is critical to the food packaging industry. Money is lost when

machinery is down for repair. Packaging equipment often runs around the clock with an

operator or service technician standing nearby to make sure the equipment is running

smoothly and without fail. Quick disconnects ensure that the operators can perform

changeovers rapidly thereby minimizing down time and fluid leaks. Quick disconnects help

the operator maximize machine up-time and profit for the company.

SEMICONDUCTOR PRODUCTION MACHINERY

The semiconductor manufacturing process involves the handling of chemicals, de-ionized

water, gases, heat transfer fluids, and frequently the use of pneumatics and vacuum. There

are also demanding temperature and pressure requirements in the lengthy manufacturing

and test processes used to turn a silicon wafer into finished IC (integrated circuit) chips.

The fluid handling equipment must be highly reliable, ultra-clean, compatible with the fluid,

durable, fast and leak free.

DRUG AND EXPLOSIVE DETECTION DEVICES

Since the 911 terrorist attack explosive detection equipment and toxic gas detection

equipment has become common place in public places such as airports, government

buildings, military facilities, and arenas. Airports and entry ports use this equipment to

scan passengers, luggage, and freight for explosives and narcotics. Most of the detection

equipment used for this purpose incorporate quick disconnects for improved serviceability.

beswick engineering co., inc. | Miniature Fluid Power Products

284 Ocean Rd. | Greenland, NH 03840-2442 | 603-433-1188

www.beswick.com

COMMON QUICK DISCONNECT APPLICATIONS

GAS DETECTION DEVICES

Before a worker enters a confined space such as a manhole or mine shaft it is necessary,

for safety, to sample the ambient air prior to entering the enclosed space. Gas detection

devices come equipped with long sampling probes to allow workers to test for gases such

as CO2, CO, Hydrogen Sulfide, Methane, Oxygen, and other toxic and flammable gases.

These detectors must be user friendly. Often quick disconnects are specified so that

probe lines can be easily switched. Gas detection devices are also used in aerospace,

semiconductor, chemical processing, medical, and pharmaceutical industries.

MEDICAL BLOOD ANALYZERS

Medical laboratories use blood testing equipment for running high volume medical tests.

These analyzers operate rapidly around the clock. Internal connections are usually

fixed in place but when a service call is needed, the machines may need to be quickly

disconnected from supply lines and then disassembled for troubleshooting.

ANALYTICAL INSTRUMENTS

Instruments are used to test water and air for purity. They are also used to test the

composition of pharmaceuticals and other compounds. Many gases and liquids are

involved in the testing procedure and often the fluid lines must be quickly connected and

disconnected without loss of the gas or liquid.

DENTAL EQUIPMENT

Dental devices such as dental chairs, drills, ultrasonic descalers, and anesthesia machines

are designed with various types of tubing to carry water, compressed air, and anesthesia

gases. The functionality of this dental equipment is greatly increased by the use of

quick disconnects especially when tools, or portions of the machine, must be removed

for cleaning, repair, and/or sterilization. The productivity of the hygienist and dentist is

improved with quick disconnects, as connections do not have to be unthreaded, and

sections of a malfunctioning machine can be easily removed when repair work is required.

In summary, quick disconnects greatly improve the users ability to accomplish work by minimizing the time

spent to make and break fluid connections. There are several types of quick disconnects as well as various

shut-off configurations to consider for each application. Material selection is also important especially if the fluid

is aggressive or if wide temperature swings are anticipated. Consult a trusted fluid power manufacturer or fluid

power expert to insure you select the best quick disconnect model for your product.

beswick engineering co., inc. | Miniature Fluid Power Products

284 Ocean Rd. | Greenland, NH 03840-2442 | 603-433-1188

www.beswick.com

Vous aimerez peut-être aussi

- Evaluation FormDocument1 pageEvaluation FormAnonymous zwSP5gvPas encore d'évaluation

- Evaluation FormDocument1 pageEvaluation FormAnonymous zwSP5gvPas encore d'évaluation

- SuppliersDocument1 pageSuppliersAnonymous zwSP5gvPas encore d'évaluation

- HAZIDDocument2 pagesHAZIDAnonymous zwSP5gvPas encore d'évaluation

- Mess Bill Jan+FebDocument1 pageMess Bill Jan+FebAnonymous zwSP5gvPas encore d'évaluation

- Water Gas Shift Reaction Kinetics and Reactor Modeling For Fuel Cell Grade Hydrogen PDFDocument8 pagesWater Gas Shift Reaction Kinetics and Reactor Modeling For Fuel Cell Grade Hydrogen PDFKmilo BolañosPas encore d'évaluation

- Tubular ReactorDocument2 pagesTubular ReactorAnonymous zwSP5gvPas encore d'évaluation

- Mess Bill Jan+Feb PDFDocument1 pageMess Bill Jan+Feb PDFAnonymous zwSP5gvPas encore d'évaluation

- Diesel Fuel ASTM LimitsDocument1 pageDiesel Fuel ASTM LimitsAnonymous zwSP5gvPas encore d'évaluation

- Fish FoodDocument6 pagesFish FoodAnonymous zwSP5gvPas encore d'évaluation

- Simulation of Aqua Ammonia Refrigeration System Using The Cape Open To Cape Open Coco Simulator PDFDocument4 pagesSimulation of Aqua Ammonia Refrigeration System Using The Cape Open To Cape Open Coco Simulator PDFAnonymous zwSP5gvPas encore d'évaluation

- Robur Abso en 02 2019Document35 pagesRobur Abso en 02 2019Anonymous zwSP5gvPas encore d'évaluation

- ZhuozhouDocument1 pageZhuozhouAnonymous zwSP5gvPas encore d'évaluation

- Mess Bill Jan+FebDocument1 pageMess Bill Jan+FebAnonymous zwSP5gvPas encore d'évaluation

- Diesel Fuel ASTM LimitsDocument1 pageDiesel Fuel ASTM LimitsAnonymous zwSP5gvPas encore d'évaluation

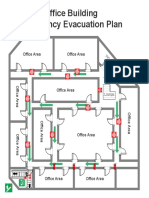

- Emergency Evacuation PlanDocument1 pageEmergency Evacuation PlanAnonymous zwSP5gvPas encore d'évaluation

- Neutron PoisonsDocument27 pagesNeutron PoisonsAnonymous zwSP5gvPas encore d'évaluation

- UK Conductive Heater RangeDocument4 pagesUK Conductive Heater RangeAnonymous zwSP5gvPas encore d'évaluation

- HAZIDDocument2 pagesHAZIDAnonymous zwSP5gvPas encore d'évaluation

- Blast Furnace Heat and Material Balance Using MS-Excel-SolverDocument11 pagesBlast Furnace Heat and Material Balance Using MS-Excel-SolverAnonymous zwSP5gvPas encore d'évaluation

- Construction Completion Report FormDocument1 pageConstruction Completion Report FormG-SamPas encore d'évaluation

- Graduate Assessment Test (GAT 2018-III) GAT General: (Result)Document1 pageGraduate Assessment Test (GAT 2018-III) GAT General: (Result)Anonymous zwSP5gvPas encore d'évaluation

- StandardsDocument9 pagesStandardsmanoj983@gmail.comPas encore d'évaluation

- Hazard Identification Study SS RISK4 160410 1Document2 pagesHazard Identification Study SS RISK4 160410 1Anonymous zwSP5gvPas encore d'évaluation

- HandbookTable of ContentsDocument6 pagesHandbookTable of ContentsAnonymous zwSP5gvPas encore d'évaluation

- Construction Completion Report Form For Submittal Exception ProcessDocument3 pagesConstruction Completion Report Form For Submittal Exception ProcessAnonymous zwSP5gvPas encore d'évaluation

- ..:: Proposals For ELMO RIETSCHLE PUMPS::.Document5 pages..:: Proposals For ELMO RIETSCHLE PUMPS::.Anonymous zwSP5gvPas encore d'évaluation

- Construction Completion Report FormDocument2 pagesConstruction Completion Report FormAnonymous zwSP5gvPas encore d'évaluation

- Nust CV FormDocument8 pagesNust CV FormAnonymous zwSP5gvPas encore d'évaluation

- Siphon - Sizing 6 PDocument6 pagesSiphon - Sizing 6 PJaber Osmani100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Maintenance of A Coal Fired Power PlantDocument11 pagesMaintenance of A Coal Fired Power PlantRuel Agon Jr.100% (1)

- Indowud Brochure Revised PDFDocument10 pagesIndowud Brochure Revised PDFsurabhi narangPas encore d'évaluation

- Congreso Ccps 2013Document116 pagesCongreso Ccps 2013gustav agudeloPas encore d'évaluation

- PACKAGING OF MEAT AND MEAT PRODUCTSDocument46 pagesPACKAGING OF MEAT AND MEAT PRODUCTSrajesh bethaPas encore d'évaluation

- Fine and Extra-Fine Vibrating Mill GrindingDocument5 pagesFine and Extra-Fine Vibrating Mill GrindingdearistyaPas encore d'évaluation

- 13 Fluid and Electrolyte Balance محاضرةDocument69 pages13 Fluid and Electrolyte Balance محاضرةRasheed SadekPas encore d'évaluation

- XMTC DatasheetDocument4 pagesXMTC DatasheetSelva RajPas encore d'évaluation

- CentrifugationDocument12 pagesCentrifugationVytheeshwaran Vedagiri100% (16)

- MSDS - TD - OIL - 22 For Chimpo GearboxDocument7 pagesMSDS - TD - OIL - 22 For Chimpo GearboxKritbordin RintaPas encore d'évaluation

- Chemistry Unit 3B NotesDocument13 pagesChemistry Unit 3B NotesShuchi HossainPas encore d'évaluation

- COMPACT 99B Inlet Valve ManualDocument4 pagesCOMPACT 99B Inlet Valve Manualalwill09Pas encore d'évaluation

- Origins and Transformations of Dissolved Organic Matter in Large Arctic RiversScientific ReportsDocument11 pagesOrigins and Transformations of Dissolved Organic Matter in Large Arctic RiversScientific ReportsEstefania GrisalesPas encore d'évaluation

- EQUILIBRIUM - MCQ WorksheetDocument17 pagesEQUILIBRIUM - MCQ WorksheetAster LeePas encore d'évaluation

- Composite MaterialsDocument399 pagesComposite MaterialsCharlton S.Inao100% (1)

- Air Pollution Control Technology Fact Sheet: EPA-452/F-03-017Document0 pageAir Pollution Control Technology Fact Sheet: EPA-452/F-03-017widhisaputrawijayaPas encore d'évaluation

- DEP 30.48.00.32-Gen-Feb-2012 Coating of FastenersDocument17 pagesDEP 30.48.00.32-Gen-Feb-2012 Coating of FastenersDevam RajPas encore d'évaluation

- 2009 - Turner, J. W. - Death of A Child From Topical DiphenhydramineDocument2 pages2009 - Turner, J. W. - Death of A Child From Topical DiphenhydramineMaria KandelaPas encore d'évaluation

- Pittsburgh Coal ConferenceDocument68 pagesPittsburgh Coal ConferenceNileshPas encore d'évaluation

- NF A49-711 Steel Tubes External Polypropylene CoatingDocument40 pagesNF A49-711 Steel Tubes External Polypropylene CoatingDARYONO sudaryonoPas encore d'évaluation

- Biology For QLD An Aust Perp 3E Units1!2!9780190310219 Sample Chapter 3 Low Res SecureDocument38 pagesBiology For QLD An Aust Perp 3E Units1!2!9780190310219 Sample Chapter 3 Low Res SecureRocil Clyde LumbayPas encore d'évaluation

- Brosur Mixer Pump MP 25 MIXIT PUTZMEISTER Mortar Machine Shotcrete Plastering Painting Floor Screed Concrete Repairing Grouting IndonesiaDocument2 pagesBrosur Mixer Pump MP 25 MIXIT PUTZMEISTER Mortar Machine Shotcrete Plastering Painting Floor Screed Concrete Repairing Grouting IndonesiaPierre RoringPas encore d'évaluation

- Extra BMP Unit 1Document40 pagesExtra BMP Unit 1V R SrinivasanPas encore d'évaluation

- Thermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesDocument2 pagesThermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesAnonymous sAmJfcVPas encore d'évaluation

- Project Content ChemistryDocument6 pagesProject Content ChemistryPrathmesh MorePas encore d'évaluation

- AUGMENTIN Syrup: What Is in This Leaflet?Document5 pagesAUGMENTIN Syrup: What Is in This Leaflet?Rafaela LennyPas encore d'évaluation

- Jin Shuren: 1. The Present Situation of Chinese Modified StarchDocument13 pagesJin Shuren: 1. The Present Situation of Chinese Modified StarchTatiana AlvaradoPas encore d'évaluation

- Laboratory Manual Machine Shop 1 PDFDocument59 pagesLaboratory Manual Machine Shop 1 PDFVinz Bryan AlmacenPas encore d'évaluation

- UV Led TransmittanceDocument6 pagesUV Led TransmittanceAmandinePas encore d'évaluation

- 0s SangDocument77 pages0s SangBijin PulikkottilPas encore d'évaluation

- Constructing Key Questions for PBL in ScienceDocument3 pagesConstructing Key Questions for PBL in ScienceJboar TbenecdiPas encore d'évaluation