Académique Documents

Professionnel Documents

Culture Documents

Masterkure 100WB

Transféré par

Doby YuniardiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Masterkure 100WB

Transféré par

Doby YuniardiDroits d'auteur :

Formats disponibles

MASTERKURE 100WB Interim Datasheet

Wax emulsion based concrete curing compound

DESCRIPTION Application Measured Efficiency

rate water loss index*

MASTERKURE 100WB is a ready to use, liquid 2 2

5 m /L 0.31 kg/m 90%

membrane curing compound based on selected grades

*Efficiency index is the quantity of water that is retained

of paraffin wax, which when applied on to surfaces of

in the concrete panel after 72 hours, expressed as

newly placed or freshly deshuttered concrete, provides

percentage of the water originally present before

an efficient curing membrane.

application of the membrane.

It is supplied in clear and white pigmented versions -

the pigmented version is to minimise the heat PROPERTIES

absorption by concrete from intense sunlight.

MASTERKURE 100WB meets the requirements of AS Supply form : Liquid

3799-1990 - ‘Specification for Liquid Membrane Colour (as supplied) : White

Forming Curing Compounds for Concrete’ - when

applied at the recommended application rate. Colour (as applied) pigmented : White

unpigmented : Clear

RECOMMENDED FOR Density : 0.99 kg/L

MASTERKURE 100WB is recommended for curing flat APPLICATION

concrete works - both internal and external. It is also

ideal for situations where the curing membrane also has Apply the white pigmented version on external concrete

to act as a bond breaker. Applications include ; surfaces or where the intensity of sunlight is high. On

• curing external concrete paving, runways, concrete internal surfaces or under normal circumstances,

roads, etc. unpigmented version is sufficient.

• curing road pavements and to prevent the base Use MASTERKURE 100WB as supplied without

course from bonding to top course. dilution. Stir well before use (rolling drums containing the

• as a curing and bond breaking membrane in lift slab product is an effective method). Apply after the final

construction. finishing operation as soon as the concrete surface has

MASTERKURE 100WB is not recommended for hardened sufficiently to prevent marring.

application where subsequent renders, toppings or Delaying the application until the next day will allow

coatings are to be applied. substantial loss of moisture reducing the effectiveness of

the curing membrane.

FEATURES AND BENEFITS The surface should be damp but with no free water on it.

In the case of formed concrete, apply immediately after

Improved moisture Facilitates more efficient striking the formwork. If the surface has dried out,

retention in concrete hydration of cement for greater dampen the concrete before application.

strength and superior wear For best results, apply an even coat by a low pressure

resistance. spray equipment (knapsack sprayer) or with a wide short

Prevents rapid water Reduced plastic shrinkage nap roller or brush. With all methods, take adequate care

evaporation cracks and dusting. to prevent marring of the concrete surface.

Water based Safe to use. No harmful Apply the curing compound evenly on all exposed

2

vapours. Not a fire hazard. concrete surfaces at a minimum rate of 5 m /L so as to

White pigmented Reduced heat on concrete form a continuous film.

(only in pigmented surface from intense sunlight.

version) Treated area easily identified. EQUIPMENT

One time application Avoids messy and repetitive

water curing. Saves labour. Low pressure sprayer, short nap wide roller or brush.

CLEANING

TYPICAL PERFORMANCE DATA

Clean the tools and equipment using hot water

AS 3799 - 1990 specification requires that curing

immediately after use. If the curing compound has dried

compounds achieve an efficiency index of 90% in 72

out, use a solvent such as mineral turpentine for

hours.

cleaning.

Water retention and efficiency tests conducted on

MASTERKURE 100WB provided the following results.

Head Office Factories Representative Offices

Plaza GRI 10th & 11th Floor Jl. Daan Mogot Km.14 Jl. Jababeka V Blok I-1 Grand Residence Office Park, Komp. Pertokoan Royal Sunggal

Jl. HR Rasuna Said Blok X-2 No.1 Cengkareng, Cikarang Industrial Estate 1st Floor Jl. Gagak Hitam No. A-12

Jakarta 12950 Jakarta 11750 Bekasi 17530 Jl. Darmo Harapan Complex 1 Ring Road – Sunggal

Tel.: (6221) 5262481, 5262505 Tel.: (6221) 6190007 Tel.: (6221) 8934339 Surabaya 60187 Medan, Sumatera Utara 20128

Fax: (6221) 5262493, 5262515 Fax: (6221) 6190741 Fax: (6221) 8934342 Tel.: (6231) 7326705 Tel.: (6261) 8447110

Fax: (6231) 7326730 Fax: (6261) 8444072

MASTERKURE 100WB Interim Datasheet

ESTIMATING DATA PRECAUTIONS

Actual coverage depends upon the method of Health : MASTERKURE 100WB is non toxic and does

application, the texture and porosity of the surface. The not normally require any special precaution while

recommended coverage of MASTERKURE 100WB is 5 handling.

2 2

m /L. Material requirement, therefore, is 0.2 L/m . Fire : Not flammable.

PACKAGING OTHER USEFUL PRODUCTS

MASTERKURE 100WB is available in 205 L drums. Masterkure : A range of high performance curing

compounds for curing concrete and mortar, based on

STORAGE

polymers, wax and chlorinated rubber.

MASTERKURE 100WB should be stored in a well Mastertop : A range of industrial flooring products that

enclosed place shaded from direct sunlight at moderate includes resin based floor screeds and coatings, dry

temperatures. shake iron aggregate based floor hardeners and iron

aggregate based floor screed.

SHELF LIFE Rheobuild : A range of high performance super

plasticisers to produce rheoplastic concrete.

MASTERKURE 100WB has a shelf life of 6 months if Emaco : A range of high performance structural repair

stored as recommended in unopened original mortars available in pourable, pumpable and sprayable

containers. grades, for high build (up to 120 mm) and medium build

(up to 40 mm) applications

Barra repair system : Includes corrosion protective

coating for steel, polymer bonding agents, and Barra

range of polymer modified repair mortars for; anchoring,

surface levelling, high build in vertical and over head

situations.

SMk 1100WB/3/1096

The technical information and application advice given in this BASF Construction Chemicals

publication are based on the present state of our best scientific and practical knowledge. As the

STATEMENT OF information herein is of a general nature, no assumption can be made as to a product's suitability for a

RESPONSIBILITY particular use or application and no warranty as to its accuracy, reliability or completeness either

expressed or implied is given other than those required by law. The user is responsible for checking the

suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by

BASF Construction Chemicals either orally or in writing may be followed, modified or rejected by the

NOTE owner, engineer or contractor since they, and not BASF Construction Chemicals, are responsible for

carrying out procedures appropriate to a specific application.

Vous aimerez peut-être aussi

- Flexural Strength ConcreteDocument3 pagesFlexural Strength ConcreteShantanu DuttaPas encore d'évaluation

- Code of Practice For Precast Concrete ConstructionDocument73 pagesCode of Practice For Precast Concrete ConstructionAlaaGaballa100% (4)

- Functional Polymer Coatings: Principles, Methods, and ApplicationsD'EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsÉvaluation : 1 sur 5 étoiles1/5 (1)

- Aci sp-215-2003Document446 pagesAci sp-215-2003Abigael Valles RamirezPas encore d'évaluation

- Road Design Standards 2021Document56 pagesRoad Design Standards 2021Engr.Towhidul IslamPas encore d'évaluation

- 01.unit 1 - Specification & Specification WritingDocument26 pages01.unit 1 - Specification & Specification WritingDhineshPas encore d'évaluation

- Concrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorDocument23 pagesConcrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorAshok amlapure75% (4)

- Vetonit PlasterMix-S PLS222Document2 pagesVetonit PlasterMix-S PLS222toni mujiyonoPas encore d'évaluation

- SANS5861-3 - Making and Curing of Test SpecimensDocument5 pagesSANS5861-3 - Making and Curing of Test SpecimensBrendon GovaPas encore d'évaluation

- Joints in Concrete Buildings: Planning, Design and PerformanceDocument8 pagesJoints in Concrete Buildings: Planning, Design and PerformanceHossam Al-Dein Mostafa Helmy100% (1)

- Materials and Design Processes in Zumthor's ArchitectureDocument10 pagesMaterials and Design Processes in Zumthor's ArchitectureDeuttzaa DeaPas encore d'évaluation

- Warehouse Construction Project ActivitiesDocument9 pagesWarehouse Construction Project ActivitiesHannah GoPas encore d'évaluation

- Masterkure 106 TdsDocument2 pagesMasterkure 106 TdsEmre ErdoğanPas encore d'évaluation

- Masterkure 107: Description Typical PropertiesDocument2 pagesMasterkure 107: Description Typical PropertiesShihab AhamedPas encore d'évaluation

- TDS WaterprDocument2 pagesTDS WaterprKIPas encore d'évaluation

- Rockcure O2pDocument2 pagesRockcure O2pInam Ul HaqPas encore d'évaluation

- Masterseal 555S: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 555S: Flexible, Polymer Cement Waterproofing SlurryshashiPas encore d'évaluation

- Constructive concrete curing compoundDocument2 pagesConstructive concrete curing compoundAstc AfaqPas encore d'évaluation

- CMCI Concrete Curing - KureNsealDocument2 pagesCMCI Concrete Curing - KureNsealPrabhakar SvPas encore d'évaluation

- Masterkure 300CRDocument2 pagesMasterkure 300CRDoby YuniardiPas encore d'évaluation

- Mastertop 566: Self Smoothing Cementitious Based Floor LevellerDocument2 pagesMastertop 566: Self Smoothing Cementitious Based Floor LevellerDoby YuniardiPas encore d'évaluation

- Masterkure 107: Water Based Concrete Curing Compound, White Pigmented For Solar ReflectanceDocument2 pagesMasterkure 107: Water Based Concrete Curing Compound, White Pigmented For Solar ReflectanceNidDouPas encore d'évaluation

- TDS-Brushbond-Roofguard-India FosrocDocument2 pagesTDS-Brushbond-Roofguard-India Fosrocyash shahPas encore d'évaluation

- Brushbond Roofguard BFL3Document2 pagesBrushbond Roofguard BFL3peashPas encore d'évaluation

- Masterkure 260-V1-Asean-0614 - Concrete - Building EngineeringDocument4 pagesMasterkure 260-V1-Asean-0614 - Concrete - Building Engineeringkpher29Pas encore d'évaluation

- Brushbond Roofguard high build fiber reinforced acrylic renderDocument2 pagesBrushbond Roofguard high build fiber reinforced acrylic renderreshmitapallaPas encore d'évaluation

- Concure ADocument4 pagesConcure AtalatzahoorPas encore d'évaluation

- Fosroc Concure A: (Formerly Cureseal)Document4 pagesFosroc Concure A: (Formerly Cureseal)Shaik QutubuddinPas encore d'évaluation

- Emaco s188 AseanDocument2 pagesEmaco s188 AseanDoby YuniardiPas encore d'évaluation

- Tds Kansai Conducoat 209 WBDocument2 pagesTds Kansai Conducoat 209 WBAdam FauzanPas encore d'évaluation

- masterkure_106j_tdsDocument2 pagesmasterkure_106j_tdsmh8188339Pas encore d'évaluation

- Pds - Floor Hardener NMDocument2 pagesPds - Floor Hardener NMkasivisanadhPas encore d'évaluation

- Basf Masterkure 107 Tds PDFDocument2 pagesBasf Masterkure 107 Tds PDFHaseeb ShadPas encore d'évaluation

- Concure RB90Document4 pagesConcure RB90m.elsanee.cubicPas encore d'évaluation

- Emaco Nanocrete AP PDS ASEAN 060409Document2 pagesEmaco Nanocrete AP PDS ASEAN 060409EkoAndriAntoPas encore d'évaluation

- Curing Compound MasterKure 106JDocument2 pagesCuring Compound MasterKure 106JMebepure GazePas encore d'évaluation

- Masterfill™ 300: Semi - Flexible Epoxy Joint SealantDocument2 pagesMasterfill™ 300: Semi - Flexible Epoxy Joint SealantDoby YuniardiPas encore d'évaluation

- Concure A: Multi-Purpose, Pliolite Resin, Curing CompoundDocument3 pagesConcure A: Multi-Purpose, Pliolite Resin, Curing CompoundRyan Joseph QuebrarPas encore d'évaluation

- Arkifloor SLE 2MDocument2 pagesArkifloor SLE 2MChristinaPas encore d'évaluation

- Brush BondDocument4 pagesBrush BondAcho SupraholicPas encore d'évaluation

- High Quality Resin Curing Compound for ConcreteDocument4 pagesHigh Quality Resin Curing Compound for ConcreteBrian MbathaPas encore d'évaluation

- Masteremaco N 303 TdsDocument2 pagesMasteremaco N 303 TdsChaitanya MehtaPas encore d'évaluation

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiPas encore d'évaluation

- Concrete SolutionDocument6 pagesConcrete SolutionMohamed KhanPas encore d'évaluation

- Fairmate Waterproofing - PunjabDocument128 pagesFairmate Waterproofing - PunjabAyush GoyalPas encore d'évaluation

- Expancure 90Document3 pagesExpancure 90Amar Wadood KhanPas encore d'évaluation

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINPas encore d'évaluation

- Nitobond AR: Constructive SolutionsDocument2 pagesNitobond AR: Constructive SolutionsMohammad ArslanPas encore d'évaluation

- Mastertop 102: Natural Aggregate Concrete Surface HardenerDocument2 pagesMastertop 102: Natural Aggregate Concrete Surface HardenerDoby YuniardiPas encore d'évaluation

- Masteremaco N 303 - KsaDocument2 pagesMasteremaco N 303 - KsaSaadPas encore d'évaluation

- Non-shrink cement grout for foundation platesDocument4 pagesNon-shrink cement grout for foundation platesLftea AdiPas encore d'évaluation

- Weber - Tec MC1Document2 pagesWeber - Tec MC1rangarajan1989Pas encore d'évaluation

- Arkifloor AWDocument2 pagesArkifloor AWChristinaPas encore d'évaluation

- Sikagrout 214 - 11: High Strength Non-Shrink Cementitious GroutDocument2 pagesSikagrout 214 - 11: High Strength Non-Shrink Cementitious GroutDani LerviPas encore d'évaluation

- Concure WB : Water Based Concrete Curing CompoundDocument2 pagesConcure WB : Water Based Concrete Curing CompoundVenkat Eswarlu BPas encore d'évaluation

- Fosroc Concure A: (Formerly Cureseal)Document4 pagesFosroc Concure A: (Formerly Cureseal)Vincent JavatePas encore d'évaluation

- Konsol PDFDocument2 pagesKonsol PDFCiput MardiantoPas encore d'évaluation

- Concrete Coating Technical Data SheetDocument2 pagesConcrete Coating Technical Data SheetCiput MardiantoPas encore d'évaluation

- Nitobond ArDocument2 pagesNitobond Aradilabad newsPas encore d'évaluation

- iKOTE CM 40X (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhPas encore d'évaluation

- Nitobond ArDocument46 pagesNitobond ArGavriel NgPas encore d'évaluation

- MasterSeal® AWB 661IDocument3 pagesMasterSeal® AWB 661IRACHED ABBOUDPas encore d'évaluation

- Emaco S74: Shrinkage Controlled Micro-Concrete For All Types of Structural RepairsDocument2 pagesEmaco S74: Shrinkage Controlled Micro-Concrete For All Types of Structural RepairsFrancois-Pas encore d'évaluation

- Masteremaco S 466 TdsDocument4 pagesMasteremaco S 466 TdsverPas encore d'évaluation

- 02.masteremaco N 907 TdsDocument2 pages02.masteremaco N 907 TdsPriceMarkPas encore d'évaluation

- AQUASHIELD PU PLUS December 2018Document2 pagesAQUASHIELD PU PLUS December 2018Anoop ShankarPas encore d'évaluation

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanPas encore d'évaluation

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloPas encore d'évaluation

- Intercure 99Document4 pagesIntercure 99Doby YuniardiPas encore d'évaluation

- Masterflex 828: Hot Pour Joint Sealant, ASTM D1190Document2 pagesMasterflex 828: Hot Pour Joint Sealant, ASTM D1190Doby YuniardiPas encore d'évaluation

- Tabel Konversi SatuanDocument1 pageTabel Konversi SatuanSutopo AhmadPas encore d'évaluation

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloPas encore d'évaluation

- MBrace Putty ASEANDocument2 pagesMBrace Putty ASEANDoby YuniardiPas encore d'évaluation

- Mastertop Primer 9Document3 pagesMastertop Primer 9Doby YuniardiPas encore d'évaluation

- ProdukDocument3 pagesProdukDoby YuniardiPas encore d'évaluation

- Intergard 774Document4 pagesIntergard 774Doby YuniardiPas encore d'évaluation

- HIT Rebar Fatigue enDocument7 pagesHIT Rebar Fatigue enWalter CastilloPas encore d'évaluation

- Preco EAC-SDocument2 pagesPreco EAC-SDoby YuniardiPas encore d'évaluation

- Intercryl 520Document4 pagesIntercryl 520Doby YuniardiPas encore d'évaluation

- Interlac 826Document4 pagesInterlac 826Doby YuniardiPas encore d'évaluation

- Nitoplate FRC: Constructive SolutionsDocument2 pagesNitoplate FRC: Constructive SolutionsDoby YuniardiPas encore d'évaluation

- Preco EAC-SDocument2 pagesPreco EAC-SDoby YuniardiPas encore d'évaluation

- FOR DOCUMENTDocument2 pagesFOR DOCUMENTDoby YuniardiPas encore d'évaluation

- Ucrete Ud200 AseanDocument2 pagesUcrete Ud200 AseanDoby YuniardiPas encore d'évaluation

- Renderoc HB25: Constructive SolutionsDocument4 pagesRenderoc HB25: Constructive SolutionsDoby YuniardiPas encore d'évaluation

- Masterflex 3000Document2 pagesMasterflex 3000Doby YuniardiPas encore d'évaluation

- Mastertop 566: Self Smoothing Cementitious Based Floor LevellerDocument2 pagesMastertop 566: Self Smoothing Cementitious Based Floor LevellerDoby YuniardiPas encore d'évaluation

- Mastertop 102: Natural Aggregate Concrete Surface HardenerDocument2 pagesMastertop 102: Natural Aggregate Concrete Surface HardenerDoby YuniardiPas encore d'évaluation

- Mastertop 1240 AseanDocument2 pagesMastertop 1240 AseanDoby YuniardiPas encore d'évaluation

- Mastertop 1220 AseanDocument3 pagesMastertop 1220 AseanDoby YuniardiPas encore d'évaluation

- Conbextra EUW: Water Insensitive Epoxy MaterialDocument2 pagesConbextra EUW: Water Insensitive Epoxy MaterialDoby YuniardiPas encore d'évaluation

- Masterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDocument3 pagesMasterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDoby YuniardiPas encore d'évaluation

- Masterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDocument3 pagesMasterflex 3000: Masterflex Sealing System For Irregular and Unconventional JointsDoby YuniardiPas encore d'évaluation

- Backer RodDocument2 pagesBacker RodDoby YuniardiPas encore d'évaluation

- Mastertop 1240 AseanDocument2 pagesMastertop 1240 AseanDoby YuniardiPas encore d'évaluation

- Intergard 774Document4 pagesIntergard 774Doby YuniardiPas encore d'évaluation

- Intergard 774Document4 pagesIntergard 774Doby YuniardiPas encore d'évaluation

- Etag 001 Part 5 Bonded Anchors 2013 04 08 PDFDocument33 pagesEtag 001 Part 5 Bonded Anchors 2013 04 08 PDFKhoonShihHsienPas encore d'évaluation

- NovoQuad Brochure - ND-SV009 - 20220520Document3 pagesNovoQuad Brochure - ND-SV009 - 20220520Mohammad AkifPas encore d'évaluation

- Standby Sru & Additional Tanks: Indian Oil Corporation LTDDocument5 pagesStandby Sru & Additional Tanks: Indian Oil Corporation LTDkhandelwalaPas encore d'évaluation

- Nitocote SN522: Constructive SolutionsDocument2 pagesNitocote SN522: Constructive Solutionsمحمد عزتPas encore d'évaluation

- Seismic Rehabilitation of Damaged Reinforced Concrete Frames Using Combined Metallic Yielding Passive DevicesDocument16 pagesSeismic Rehabilitation of Damaged Reinforced Concrete Frames Using Combined Metallic Yielding Passive DevicesLuis Vilca AsenciosPas encore d'évaluation

- R-KEX II SubmittalDocument93 pagesR-KEX II SubmittalThilan SenarathnePas encore d'évaluation

- Easy Wall System Load Bearing PanelsDocument20 pagesEasy Wall System Load Bearing PanelssherazzzPas encore d'évaluation

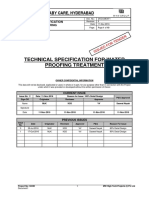

- Technical Specification For Water Proofing Treatment: Baby Care, HyderabadDocument10 pagesTechnical Specification For Water Proofing Treatment: Baby Care, HyderabadPrateek ModyPas encore d'évaluation

- Tds CPD Sika Epoxy 7300 Us PDFDocument2 pagesTds CPD Sika Epoxy 7300 Us PDFyoupick10Pas encore d'évaluation

- Concrete Aggregates: Standard Specification ForDocument8 pagesConcrete Aggregates: Standard Specification ForHasanalmahmudPas encore d'évaluation

- 575 Tech Specs Placenta Pit FinalDocument9 pages575 Tech Specs Placenta Pit FinalJohn Aries Almelor SarzaPas encore d'évaluation

- Astm C90Document7 pagesAstm C90Jairo MendezPas encore d'évaluation

- Summary of works to construct haul roads and repair damaged roadsDocument11 pagesSummary of works to construct haul roads and repair damaged roadsIshara CoorayPas encore d'évaluation

- Pundit PL 200 PE Brochure1Document4 pagesPundit PL 200 PE Brochure1Rony YudaPas encore d'évaluation

- Ready Mix ConcreteDocument14 pagesReady Mix ConcreteYog Aiyappa100% (1)

- Plumb Conc.Document28 pagesPlumb Conc.Muhammad AwaisPas encore d'évaluation

- Unit 528 Concrete Design Task 1Document14 pagesUnit 528 Concrete Design Task 1Shine AungPas encore d'évaluation

- Aluminum FormworkDocument80 pagesAluminum FormworkWall-Ties & Forms, Inc.Pas encore d'évaluation

- Geogrid-Techgrid Technical LiteratureDocument13 pagesGeogrid-Techgrid Technical Literaturesachindagrawal90440% (1)

- Bridport House London's First CLT BuildingDocument2 pagesBridport House London's First CLT BuildingDennis Willy Salazar AmbichoPas encore d'évaluation