Académique Documents

Professionnel Documents

Culture Documents

Blastal Coating Services Inc - Surface Preparation Standards

Transféré par

jorge_2012Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Blastal Coating Services Inc - Surface Preparation Standards

Transféré par

jorge_2012Droits d'auteur :

Formats disponibles

Surface Preparation Standards

CDN. Govt. Swedish British

System SSPC Codes NACE

(CGSB) Standard Standard

SSPC.SP1

Solvent Clean

SP1 Definition

SSPC.SP2

Hand Tool Clean 31 GP 401 St. 2 (approx.)

SP2 Definition

SSPC.SP3

Power Tool Clean 31 GP 402 St. 3

SP3 Definition

Flame Clean (new steel) SSPC.SP4 31 GP 403

White Metal Blast SSPC.SP5

31 GP 404 BS4232

SP5 Definition NACE #1 Sa. 3

Type 1 First Quality

SP5 Picture

Commercial Blast SSPC.SP6

31 GP 404 BS4232

SP6 Definition NACE #3 Sa. 2

Type 2 Third Quality

SP6 Picture

Brush Off Blast SSPC.SP7

31 GP 404

SP7 Definition NACE #4 Sa. 1 Light blast to brush-off

Type 3

SP7 Picture

Pickling SSPC.SP8

Weather and Blast SSPC.SP9

Near White Blast SSPC.SP10

SP10 Definition BS4232

NACE #2 Sa. 2 ½

SP10 Picture Second Quality

Power Tool Cleaning to Bare SSPC.SP11

Metal SP11 Definition

Non-Ferrous Metals

Aluminium Galvanized Metal

Brass, Bronze, Copper, Lead, Terne Definition

Definition Definition

Home page

Solvent Cleaning SSPC-SP1 Definition:

Solvents such as water, mineral spirits, xylol, toluol etc., are used to remove solvent-soluble foreign matter from the surface of ferrous metals. Rags and solvents must

be replenished frequently to avoid spreading the contaminant rather than removing it. Low-pressure (1500 - 4000 psi) high volume (3 - 5 gal/min.) water washing with

appropriate cleaning chemicals is a recognized "solvent cleaning" method. All surfaces should be should be cleaned per this specification prior to using hand tools or

blast equipment.

Hand Tool Cleaning SSPC-SP2 (SSI-St3) Definition:

A mechanical method of surface preparation involving wire brushing, scraping, chipping and sanding. Not the most desirable method of surface preparation, but can be

used for mild exposure conditions. Optimum performances of protective coatings should not be expected when hand tool cleaning is employed.

Power Tool Cleaning SSPC-SP3 (SSI-St3) Definition:

A mechanical method of surface preparation widely used in industry and involving the use of power sanders or wire brushes, power chipping hammers, abrasive grinding

wheels, needle guns etc. Although usually more effective than hand tool cleaning, it is not considered adequate for use under severe exposure conditions or for

immersion applications.

White Metal Blasting SSPC-SP5 (SSI-Sa3), or NACE #1 Definition:

The removal of all visible rust, mill scale, paint and contaminants, leaving the metal uniformly white or gray in appearance. This is the ultimate in blast cleaning. Use

where maximum performance of protective coatings is necessary due to exceptionally severe conditions such as constant immersion in water or liquid chemicals.

Commercial Blast SSPC-SP6 (SSI-Sa2), or NACE #3 Definition:

All oil, grease, dirt, rust scale and foreign matter are completely removed from the surface and all rust, mill scale and old paint are completely removed by abrasive

blasting except for slight shadows, streaks or discolorations caused by rust stain, mill scale oxides or slight, tight resides of paint or coating that remain. If the surface

is pitted, slight residue of rust or paint may be found in the bottom of pits; at least two-thirds of each square inch of surface area shall be free of all visible residues and

the remainder shall be limited to the light residues mentioned above.

Brush Off Blast SSPC-SP7 (SSI-Sa1), or NACE #4 Definition:

A method in which all oil, grease, dirt, rust scale, loose mill scale, loose rust and loose paint or coatings are removed completely. Tight mill scale and tightly-adhered

rust, paint and coatings are permitted to remain. However all mill scale and rust must have been exposed to the abrasive blast pattern sufficiently to expose numerous

flecks of the underlying metal fairly uniformly distributed over the entire surface.

Brush Off Blast SSPC-SP10 (SSI-Sa2 ½), or NACE #2 Definition:

In this method, all oil, grease, dirt, mill scale, rust, corrosion products, oxides, paint or other foreign matter have been completely removed from the surface by abrasive

blasting, except for very light shadows, very slight streaks or slight discolorations caused by rust stain, mill scale oxides or slight, tight residues of paint or coating. At

least 95% of each square inch of surface area shall be free of all visible residues, and the remainder shall be limited to the light discolorations mentioned above. From a

practical standpoint, this is probably the best quality surface preparation that can be expected to today for existing plant facility maintenance work.

Power Tool Cleaning to Bare Metal SSPC-SP11 Definition:

Utilizing same equipment as Power Tool Cleaning to remove all visible coatings and contaminants to bare metal substrate.

Aluminium Definition:

Remove water-soluble dirt and chemicals with water and detergent; solvent-soluble contaminants with solvent. Rinse, allow to dry, them power or hand abrade to

remove the thin film of aluminium oxide. Moderate exposures require only one or two topcoats. Avoid using lead pigmented primers and topcoats. Exposure to corrosive

chemicals calls for an epoxy primer followed by an appropriate topcoat for the environment.

Brass, Bronze, Copper, Lead, Terne Definition:

Remove contaminants with a combination of water, detergents and solvents (same as aluminium). Allow the metal to dry, then power or hand abrade to remove oxides.

Conventional oil and alkyd base primers or finishes may be used.

Galvanized Metal Definition:

Clean same as aluminium and Brass etc, or allow to weather for six months. Caution: Be sure the manufacturer of the galvanized metal has used a paintable "white

rust" preventative. Conventional coatings containing oil or alkyd resins must not be used. Specify only special primers made for use on galvanized metal. In severe Type

A environments, or in areas of high humidity or continuous condensation, brush blasting is recommended to assure maximum system adhesion and performance.

Vous aimerez peut-être aussi

- SSPC ChartDocument2 pagesSSPC ChartajuhaseenPas encore d'évaluation

- SSPC Chart PDFDocument2 pagesSSPC Chart PDFABHISHEK SINGHPas encore d'évaluation

- SPCCDocument2 pagesSPCCDeepak JainPas encore d'évaluation

- Surface Preparation StandardsDocument4 pagesSurface Preparation StandardsIAmaeyPas encore d'évaluation

- Surface Preparation StandardsDocument3 pagesSurface Preparation StandardsReyhand SaveroPas encore d'évaluation

- 1 Pig Gauge (Model OG204) / Elcometer 121: St2/St3 St2/St3Document19 pages1 Pig Gauge (Model OG204) / Elcometer 121: St2/St3 St2/St3Akansha SharmaPas encore d'évaluation

- 5 - Surface Prep - Ferrous and Non-Ferrous MetalDocument5 pages5 - Surface Prep - Ferrous and Non-Ferrous Metalkiran varghesePas encore d'évaluation

- Surface Preparation StandardsDocument3 pagesSurface Preparation StandardsSajeesh KrishnanPas encore d'évaluation

- Surface Preparation StandardDocument5 pagesSurface Preparation StandardKarthikeyan ShanmugavelPas encore d'évaluation

- Surface Preparation StandardsDocument7 pagesSurface Preparation Standardsazhar enggPas encore d'évaluation

- Surf. Prep. TableDocument1 pageSurf. Prep. TableSingaravelan KannanPas encore d'évaluation

- A6 EngDocument2 pagesA6 EngDiego InfantePas encore d'évaluation

- Surface Preparation Standards Cross ReferenceDocument1 pageSurface Preparation Standards Cross ReferencePanagiotis KatsirisPas encore d'évaluation

- CBT Test PreparationDocument29 pagesCBT Test PreparationAMALENDU PAULPas encore d'évaluation

- 06 International Standard For Surface PreparationDocument1 page06 International Standard For Surface Preparationgowtham_venkat_40% (1)

- Pages From SAES-H-001-5Document1 pagePages From SAES-H-001-5mohammed s fawabPas encore d'évaluation

- Inspection 4Document1 pageInspection 4Iftikhar AhmedPas encore d'évaluation

- Coating Inspection ProcessDocument2 pagesCoating Inspection ProcessIan PerdanaPas encore d'évaluation

- Dokumen - Tips - SSPC Pa 1 PDF Wordpresscom A SSPC Pa 1 PDF SSPC Pa 1 Shop Field and PDFDocument2 pagesDokumen - Tips - SSPC Pa 1 PDF Wordpresscom A SSPC Pa 1 PDF SSPC Pa 1 Shop Field and PDFAbhilashPas encore d'évaluation

- SSPC VIS-1 (2000) - Visual Standard For Abrasive Blast Cleaned SteelDocument2 pagesSSPC VIS-1 (2000) - Visual Standard For Abrasive Blast Cleaned SteelPubcrawlPas encore d'évaluation

- Kansai Paint System Guide: Environmental CorrosivelyDocument16 pagesKansai Paint System Guide: Environmental Corrosivelyscribdfreeasus100% (1)

- Surface PreparationDocument3 pagesSurface PreparationBamboo PosadasPas encore d'évaluation

- SSPC CS 29 PDFDocument5 pagesSSPC CS 29 PDFGaapchu100% (1)

- SOP Solvent Cleaning SSPCDocument3 pagesSOP Solvent Cleaning SSPCNindy FebrianiPas encore d'évaluation

- Guide To Sspc-Vis 3: SSPC: The Society For Protective CoatingsDocument4 pagesGuide To Sspc-Vis 3: SSPC: The Society For Protective CoatingsFreddy Carl FredricksenPas encore d'évaluation

- Test: Ambient Temperature (Wet/Dry), Dew Point, Peralatan: Sling Hygrometer, Dew Point Calculator, SurfaceDocument6 pagesTest: Ambient Temperature (Wet/Dry), Dew Point, Peralatan: Sling Hygrometer, Dew Point Calculator, SurfaceNurmalinda SihombingPas encore d'évaluation

- INS-000-SPE-0002 Rev.3 Specification For Painting and Coating, Structural Steel of Marine FacilitiesDocument25 pagesINS-000-SPE-0002 Rev.3 Specification For Painting and Coating, Structural Steel of Marine FacilitiesenriquePas encore d'évaluation

- Guide To Sspc-Vis 3: SSPC: The Society For Protective CoatingsDocument4 pagesGuide To Sspc-Vis 3: SSPC: The Society For Protective CoatingsTeymur RegenmaisterPas encore d'évaluation

- Painting System Guide: SSPC: The Society For Protective CoatingsDocument2 pagesPainting System Guide: SSPC: The Society For Protective CoatingsanoopkumarPas encore d'évaluation

- Surface Preparation PracticeDocument3 pagesSurface Preparation PracticeLandz GanzonPas encore d'évaluation

- Corrosion Company BrochureDocument12 pagesCorrosion Company BrochureMythri Metallizing Pvt Ltd ProjectsPas encore d'évaluation

- Flowchart Surface PreparationDocument1 pageFlowchart Surface PreparationHana KarimahPas encore d'évaluation

- Coating Standards PDFDocument5 pagesCoating Standards PDFHanuman RaoPas encore d'évaluation

- Current Active Standards June 2019Document8 pagesCurrent Active Standards June 2019Chaitanya SutharPas encore d'évaluation

- Corrosion, Surface Preparation - Blasting & PaintingDocument23 pagesCorrosion, Surface Preparation - Blasting & Paintingmd quasid rabbaniPas encore d'évaluation

- Coating Std. For Easy Reference July 2015Document25 pagesCoating Std. For Easy Reference July 2015Jahangir Khan100% (1)

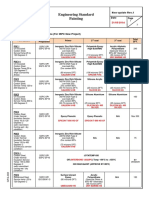

- Engineering Standard Painting: Date New Update Rev.1Document7 pagesEngineering Standard Painting: Date New Update Rev.1มิตร อันมาPas encore d'évaluation

- Draft WI Touch Up Coat RBrevDocument9 pagesDraft WI Touch Up Coat RBrevramdhaniPas encore d'évaluation

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument5 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarPas encore d'évaluation

- Current SSPC Standards June2019Document7 pagesCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- Vis stds02Document9 pagesVis stds02Hector Aldair Valle RiveraPas encore d'évaluation

- BTU-B520-QMP-PR-025 Coating & Repair Coating For Welding Area (Outside) of Steel Box GirderDocument15 pagesBTU-B520-QMP-PR-025 Coating & Repair Coating For Welding Area (Outside) of Steel Box GirderramdhaniPas encore d'évaluation

- S058-000659-20-Tub-Et-0001-02 Material Data SheetDocument193 pagesS058-000659-20-Tub-Et-0001-02 Material Data Sheetpjcs1974Pas encore d'évaluation

- Prepared & Presented by Technical Service - PT. HEMPEL IndonesiaDocument32 pagesPrepared & Presented by Technical Service - PT. HEMPEL IndonesiavvpvarunPas encore d'évaluation

- Jis g3454 Stpg370, Stpg410..Document3 pagesJis g3454 Stpg370, Stpg410..Mohd FadzliPas encore d'évaluation

- FIXATION - En6115 p5 Aerospace Series BoltspdfDocument16 pagesFIXATION - En6115 p5 Aerospace Series BoltspdfFred0% (1)

- Scopes of SSPC Surface Preparation Standards and SpecificationsDocument8 pagesScopes of SSPC Surface Preparation Standards and SpecificationsMark OglesbyPas encore d'évaluation

- CMPC Pulp: G.Navarrete P.StrodthoffDocument5 pagesCMPC Pulp: G.Navarrete P.StrodthoffCesar Eugenio Sanhueza ValdebenitoPas encore d'évaluation

- 2019 Catalogo Productos SSPCDocument16 pages2019 Catalogo Productos SSPCAdriana Barros OrellanaPas encore d'évaluation

- Surfacepreparation StandardDocument11 pagesSurfacepreparation StandardAri SupramonoPas encore d'évaluation

- Paint Specification of IRPC (Chugoku1)Document6 pagesPaint Specification of IRPC (Chugoku1)มิตร อันมาPas encore d'évaluation

- Dulux 1.1.2 Mild Steel - Surface PreparationDocument2 pagesDulux 1.1.2 Mild Steel - Surface PreparationHIPAPPas encore d'évaluation

- Materials Data for Cyclic Loading: Cast and Welded MetalsD'EverandMaterials Data for Cyclic Loading: Cast and Welded MetalsPas encore d'évaluation

- Materials Data for Cyclic Loading: Low-Alloy SteelsD'EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Smithells Metals Reference BookD'EverandSmithells Metals Reference BookE A BrandesPas encore d'évaluation

- Surface Plasmon Enhanced, Coupled and Controlled FluorescenceD'EverandSurface Plasmon Enhanced, Coupled and Controlled FluorescencePas encore d'évaluation

- Catalogo - General 340Document1 pageCatalogo - General 340jorge_2012Pas encore d'évaluation

- Reducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43Document1 pageReducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43jorge_2012Pas encore d'évaluation

- Reducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43Document1 pageReducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43jorge_2012Pas encore d'évaluation

- Reducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43Document1 pageReducciones Concéntricas y Excéntricas.: ANSI B-16.9 MSS-SP 43jorge_2012Pas encore d'évaluation

- Endmemo: Kilogram-Force/square Meter PsiDocument3 pagesEndmemo: Kilogram-Force/square Meter Psijorge_2012Pas encore d'évaluation

- Eutalloy 11496Document2 pagesEutalloy 11496jorge_20120% (1)

- D-Series Catalogue PDFDocument64 pagesD-Series Catalogue PDFandresboy123Pas encore d'évaluation

- DM ZG531-High Precision Manufacturing: M Tech Digital ManufacturingDocument48 pagesDM ZG531-High Precision Manufacturing: M Tech Digital Manufacturingnikhiljith o uPas encore d'évaluation

- Astm D1404M - 99Document4 pagesAstm D1404M - 99mancjaPas encore d'évaluation

- Jetblast™ Copper SlagDocument4 pagesJetblast™ Copper SlaglambtranPas encore d'évaluation

- Hardtop Flexi Technical Data SheetDocument5 pagesHardtop Flexi Technical Data SheetGurdeep Sungh AroraPas encore d'évaluation

- STP538 Eb.1415051 1 PDFDocument239 pagesSTP538 Eb.1415051 1 PDFpaola100% (2)

- Application Guide Phenoline Tank ShieldDocument10 pagesApplication Guide Phenoline Tank ShieldNaveed AhmedPas encore d'évaluation

- PFI ES 29 - 2006 EditionDocument5 pagesPFI ES 29 - 2006 EditionArcadio DuranPas encore d'évaluation

- Question Bank For Mid - I Unit - IDocument1 pageQuestion Bank For Mid - I Unit - I18R21A0310 BIYYALA SHESHAGIRIPas encore d'évaluation

- Dynabrade Right Angle Grinder.Document8 pagesDynabrade Right Angle Grinder.JunfengPas encore d'évaluation

- Standard Test Methods For Abrasion Resistance of Organic Coatings by Falling AbrasiveDocument5 pagesStandard Test Methods For Abrasion Resistance of Organic Coatings by Falling AbrasiveMaria Paulina Holguin PatiñoPas encore d'évaluation

- Acothane Twin Pack: Product DescriptionDocument3 pagesAcothane Twin Pack: Product DescriptionpazhanivelmuruganPas encore d'évaluation

- Instruction Storage of Glass Pilkington 2020Document4 pagesInstruction Storage of Glass Pilkington 2020KhaledAhmedPas encore d'évaluation

- Virginia Abrasives Bonded Abrasive CatalogDocument5 pagesVirginia Abrasives Bonded Abrasive Catalogmo2lsPas encore d'évaluation

- Merriam-Webster's Advanced Learner's English Dictionary (PDFDrive)Document393 pagesMerriam-Webster's Advanced Learner's English Dictionary (PDFDrive)Mohammed ArifPas encore d'évaluation

- Serviceability, Wear, and Abrasion ResistanceDocument6 pagesServiceability, Wear, and Abrasion ResistanceNiaz IslamPas encore d'évaluation

- Vitrified TilesDocument3 pagesVitrified Tilesamitdey_dey18164Pas encore d'évaluation

- Waha Oil Company: Specification For Factory Applied Internal Coating of Pipe Spools, and FittingsDocument12 pagesWaha Oil Company: Specification For Factory Applied Internal Coating of Pipe Spools, and FittingsRobert LiraPas encore d'évaluation

- 2 Specimen PreparationDocument5 pages2 Specimen PreparationjanakPas encore d'évaluation

- Unit IV - Abrasive Process and Broaching PDFDocument80 pagesUnit IV - Abrasive Process and Broaching PDFKanda SamyPas encore d'évaluation

- Hussain Rabia - Drill Bits (Chapter 9)Document44 pagesHussain Rabia - Drill Bits (Chapter 9)Andreas Ansen VitalisPas encore d'évaluation

- Making Accurate Straight-Edges From ScratchDocument2 pagesMaking Accurate Straight-Edges From ScratchLyle HornbakerPas encore d'évaluation

- Bicknell CatalogDocument68 pagesBicknell CatalogGunnie PandherPas encore d'évaluation

- AReviewof Cylindrical Grinding ProcessDocument12 pagesAReviewof Cylindrical Grinding ProcessSardar HamzaPas encore d'évaluation

- SOP For Abrasive WheelsDocument7 pagesSOP For Abrasive WheelsShreedharPas encore d'évaluation

- Coating Inspection BookDocument21 pagesCoating Inspection BookAlainTrudeau100% (10)

- SAEP-303: 2 Conflicts and DeviationsDocument19 pagesSAEP-303: 2 Conflicts and DeviationsnasirPas encore d'évaluation

- PDE-CMG-G00-EC-0001-000-05-DPP-1 PES-Y1 PaintingDocument36 pagesPDE-CMG-G00-EC-0001-000-05-DPP-1 PES-Y1 PaintingNamta GeorgePas encore d'évaluation

- The Effect of Hardness On The Transition of The Abrasive Wear Mechanism of SteelsDocument11 pagesThe Effect of Hardness On The Transition of The Abrasive Wear Mechanism of SteelsMatheus SoranzzoPas encore d'évaluation

- Master Thesis - Casing Wear in Multilateral Wells - Steven Ripman PDFDocument110 pagesMaster Thesis - Casing Wear in Multilateral Wells - Steven Ripman PDFBogdan StanciuPas encore d'évaluation