Académique Documents

Professionnel Documents

Culture Documents

Stone Sizing Criteria

Transféré par

chutton681Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stone Sizing Criteria

Transféré par

chutton681Droits d'auteur :

Formats disponibles

Technical Stone Sizing Criteria

Supplement 14C

(210–VI–NEH, August 2007)

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

Issued August 2007

Cover photo: Stone may be needed as a foundation on which to imple-

ment other restoration features such as soil bioengineering

practices. Stone may also be needed to form an erosion re-

sistant layer. How large, how thick, and how deeply keyed-in

are questions that are addressed in the design.

Advisory Note

Techniques and approaches contained in this handbook are not all-inclusive, nor universally applicable. Designing

stream restorations requires appropriate training and experience, especially to identify conditions where various

approaches, tools, and techniques are most applicable, as well as their limitations for design. Note also that prod-

uct names are included only to show type and availability and do not constitute endorsement for their specific use.

(210–VI–NEH, August 2007)

Technical Stone Sizing Criteria

Supplement 14C

Contents Purpose TS14C–1

Introduction TS14C–1

Basic concepts TS14C–1

Description of forces on a stone...................................................................TS14C–1

Flow conditions..............................................................................................TS14C–2

Sizing techniques TS14C–3

Summary guide of selected techniques TS14C–11

Factor of safety TS14C–12

Example calculations...................................................................................TS14C–12

Conclusion TS14C–13

Tables Table TS14C–1 High-energy vs. low-energy conditions TS14C–2

Table TS14C–2 Federal Highway Administration techniques TS14C–11

Table TS14C–3 Summary of techniques TS14C–11

Figures Figure TS14C–1 Forces on a submerged stone TS14C–1

Figure TS14C–2 Riprap used to control a headcut TS14C–2

Figure TS14C–3 Riprap used to prevent erosion from flow from a TS14C–2

side inlet to a channel

Figure TS14C–4 Toe of the slope lined with stone to control TS14C–2

erosion

Figure TS14C–5 Rock size based on Isbash Curve TS14C–3

Figure TS14C–6 Graphical solution for Isbash technique TS14C–4

Figure TS14C–7 Rock chute spreadsheet TS14C–9

Figure TS14C–8 Lane’s method TS14C–10

(210–VI–NEH, August 2007) TS14C–i

Technical Stone Sizing Criteria

Supplement 14C

Purpose Basic concepts

Many channel protection techniques involve rock or Description of forces on a stone

stone as a stand-alone treatment or as a component

of an integrated system. Stone used as riprap can also A rock will be stable until the lift and drag forces of

be a component of many streambank soil bioengineer- moving water exceed a critical value or threshold.

ing projects. Many Federal and state agencies have Therefore, for a given rock size subjected to a given

developed methods and approaches for sizing riprap, force of moving water, there is some unit discharge

and several of those techniques are briefly described where the rock will move and become unstable.

in this document. Stone sizing methods are normally Forces on a submerged stone, as indicated in figure

developed for a specific application, so care should be TS14C–1, typically consist of the force exerted by the

exercised in matching the selected method with the flowing water (FF), drag force (FD) associated with

intended use. While many of these were developed for flow around the object (skin friction and form drag),

application with stone riprap revetments, they are also lift force (FL) associated with flow around the particle

applicable for other designs involving rock, as well. (pressure differences caused by streamline curvature

and increased velocity around a particle), submerged

weight of the stone (FW), and resisting force due to the

Introduction particle interlock and/or contact between stones (FC).

While some methods are based on a particle force bal-

When the attacking forces of flowing water exceed ance, all rock sizing methods are essentially empirical

the resisting forces of the existing channel material, techniques. Field performance data, physical models,

channel protection is needed as part of a restoration and theoretical developments have all contributed to

design. Channel protection typically ranges from soil the diverse set of approaches used to determine stable

bioengineering treatments to more traditional armor- stone sizes for restoration designs.

ing methods. Numerous methods have been developed

for the design and sizing of riprap. Several common Velocity-based approaches and boundary shear or

techniques for estimating the required stone size are stress-based approaches are the two prominent

briefly outlined in this document. The designer is classes of methods that have been used to evaluate the

encouraged to review the complete development of a erosion resistance of materials. While shear or stress-

selected method and assess the relevance of the as- based approaches are considered more academically

sumptions behind that selected method to their appli- correct, velocity-based methods are still widely used.

cation. In this document, the words rock and stone are The design stress and the design discharge do not

used interchangeably. necessarily represent the same conditions.

Size is one of many considerations when designing

riprap for use in protecting channel bed and banks.

The designer must also address issues such as material Figure TS14C–1 Forces on a submerged stone

strength, density, angularity, durability, length-to-width

ratio, gradation, bedding, piping potential, and channel Flow direction

curvature. These important design and construction

considerations are addressed in NEH654 TS14K. FL

FD FF

FC

FW

(210–VI–NEH, August 2007) TS14C–1

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

Flow conditions Figure TS14C–2 Riprap used to control a headcut

The flow conditions associated with a particular ap-

plication will have a major influence on selecting the

right rock sizing method. While it is difficult to select

a single criterion that separates rock sizing methods,

high energy and low energy are used in this develop-

ment. For example, a technique developed for the

design of a riprap blanket revetment in a low-energy

environment would not necessarily be suitable for esti-

mating the minimum stone size in a high-energy envi-

ronment, where the stone projects into the flow. Such

applications, including instream habitat boulders,

grade stabilization, and stream barbs, should be ad-

dressed with impinging flow design techniques. Table

TS14C–1 lists some of the flow descriptors that can be

associated with high- and low-energy flow conditions.

Photographs of the different energy conditions where Figure TS14C–3 Riprap used to prevent erosion from

stone is applied as part of the solution are shown in flow from a side inlet to a channel

figures TS14C–2 through 4. In figure TS14C–2, riprap is

used to control a headcut. Riprap chutes can be used

to control erosion from a headcut in a channel or in

a side inlet to a channel. Riprap for this type of struc-

ture would fall in the steep-slope, high-energy design.

Figure TS14C–3 shows riprap used to prevent erosion

from flow from a side inlet to a channel. This structure

also prevents a headcut from moving into the field. As

illustrated in figure TS14C–4, if the toe of the slope is

eroding, and it cannot be controlled with bioengineer-

ing alone, lining the toe of the slope with stone may be

a solution. Riprap for this type of structure would fall

in the mild slope, low-energy design.

The appropriate rock sizing method must consider the

flow energy associated with the particular application. Figure TS14C–4 Toe of the slope lined with stone to

control erosion

While there are exceptions, most rock sizing methods

were developed for either a high- or low-energy flow

condition.

Table TS14C–1 High-energy vs. low-energy conditions

High energy Low energy

Supercritical flow Subcritical flow

Steep slope Mild slope

High turbulence Low turbulence

Impinging flow Parallel flow

Rapidly varied flow Uniform or gradually varied

flow

Unsteady flow Steady flow

TS14C–2 (210–VI–NEH, August 2007)

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

Sizing techniques where:

Vc = critical velocity (ft/s)

C = 0.86 for high turbulence

There are many techniques for sizing stone, and each C = 1.20 for low turbulence

method has advantages and disadvantages. Many g = 32.2 ft/s2

techniques were derived under specific conditions and γs = stone density (lb/ft3)

developed for particular applications. While this list γw = water density (lb/ft3)

is not complete and the description is not exhaustive, D50 = median stone diameter (ft)

several commonly used methods are presented. The

designer should review the applicability of a technique A graphical solution is provided in figure TS14C–5 (ch.

before choosing it to size stone for a particular project. 16 of the Engineering Field Manual) This graph should

Following is a brief description of several rock sizing be used only for quick estimates at a conceptual de-

techniques. sign level.

Isbash method The U.S. Army Corps of Engineers (USACE) provides

The Isbash formula (Isbash 1936) was developed for additional guidance for the use of the Isbash technique

the construction of dams by depositing rocks into in EM 1110–2–1601. The required inputs are channel

moving water. The Isbash curve should only be used velocity, specific gravity of the stone, and a turbulence

for quick estimates or for comparisons. A coefficient is coefficient. The turbulence coefficient has two values

provided to target high- and low-turbulence flow con- that represent either high turbulence or low turbu-

ditions, so this method can be a high- or low-energy lence. The graphical solution for this is shown in figure

application. The equation is: TS14C–6(a) and (b).

0.50

γ − γw

× (D50 )

0.50

Vc = C × 2 × g × s (eq. TS14C–1)

γ w

Figure TS14C–5 Rock size based on Isbash curve

60 15,000

Estimate the design velocity 10,000

Note γs=165 lb/ft3

Weight of stone at 165 lb/ft3 (lb)

Procedure:

1. Estimate the design velocity 5,000

Diameter of stone (in)

40 2. Track right to the basic rock size

1,000

20 500

250

100

50

0

0 2 4 6 8 10 12 14 16 18 20

Velocity (ft/s)

(210–VI–NEH, August 2007) TS14C–3

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

Figure TS14C–6 Graphical solution for Isbash technique

(a)

1,000

800 135

145 205

γs in lb/ft3

600 155 185

γs in lb/ft3

165 165

400 185 155

Minimum W50 stone weight (lb)

205 145

300 High turbulence 135

(stilling basins)

200

135

145

γs in lb/ft3

155 Low turbulence

100

165 (river closures)

80 185

60 205

40

30

20

10

5 6 7 8 9 10 14 18 22 04 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.6 2.0 2.4

Average velocity (ft/s) Spherical diameter, D50 (ft)

Basic equations : where: V = Velocity, ft/s Stone stability

1 γs = Specific stone weight, lb/ft3 velocity vs. stone

γ − γw 1 2

diameter

Vc = C 2g s ( D 50 ) 2 γw = Specific weight of water, 62.5 lb/ft3

γ w W50 = Weight of stone, subscript denotes Hydraulic design

Percent of total weight of material chart 712–1

1

containing stone of less weight

8W50 3

D50 = Spherical diameter of stone having

(Sheet 1 of 2)

D50 =

πγ s the same weight as W50

C = Isbash constant (0.86 for high

turbulence level flow and 1.20

for low turbulence level flow)

g = Acceleration of gravity, ft/s2

TS14C–4 (210–VI–NEH, August 2007)

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

Figure TS14C–6 Graphical solution for Isbash technique—Continued

(b)

10,000

80,000 135 205

145 185

γs in lb/ft3

γs in lb/ft3

60,000 155 165

165 155

40,000 185 145

Minimum W50 stone weight (lb)

205 135

30,000 High turbulence

(stilling basins)

20,000

135

145

10,000

155 γs in lb/ft3 Low turbulence

165 (river closures)

8,000 185

6,000 205

4,000

3,000

2,000

1,000

10 12 14 16 18 20 30 40 48 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.010.0

Average velocity (ft/s) Spherical diameter, D50 (ft)

Basic equations : where: V = Velocity, ft/s Stone stability

1

γs = Specific stone weight, lb/ft3 velocity vs. stone

γ − γw 1 2

Vc = C 2g s (D50 ) 2 γw = Specific weight of water, 62.5 lb/ft3 diameter

γ w W50 = Weight of stone, subscript denotes Hydraulic design

1 Percent of total weight of material chart 712-1

8W50 3 containing stone of less weight (Sheet 2 of 2)

D50 =

πγ s D50 = Spherical diameter of stone having

the same weight as W50

C = Isbash constant (0.86 for high

turbulence level flow and 1.20

for low turbulence level flow)

g = Acceleration of gravity, ft/s2

(210–VI–NEH, August 2007) TS14C–5

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

National Cooperative Highway Research Pro- Cv = velocity distribution coefficient (1.0 for straight

gram Report 108 channels or inside of bends, calculate for out-

This method (Anderson, Paintal, and Davenport 1970) side of bends)

is suggested for design of roadside drainage channels CT = thickness coefficient (use 1.0 for 1 D100 or 1.5

handling less than 1,000 cubic foot per second and a D50, whichever is greater))

maximum slope of 0.10 foot per foot. Therefore, this γw = specific weight of water (lb/ft3)

application can be used for high- or low-energy appli- γs = specific weight of stone (lb/ft3)

cations. Photo documentation shows that most of the V = local velocity; if unknown use 1.5 Vaverage

research was done on rounded stones. This method g = 32.2 ft/s2

will give more conservative results if angular rock is K1 = side slope correction as computed below

used.

sin 2 θ (eq. TS14C–6)

K1 = 1 −

τ o = γRSe (eq. TS14C–2) sin 2 φ

where:

θ = angle of rock from the horizontal

τ c = 4D50 (eq. TS14C–3)

φ = angle of repose (typically 40º)

therefore,

Note that the local velocity can be 120 to 150 percent

γRSe (eq. TS14C–4) of the average channel velocity or higher. The outside

D50 =

4 bend velocity coefficient and the side slope correction

can be calculated:

τc = critical tractive stress

γ = 62.4 lb/ft3 R

C V = 1.283 − 0.2 log (eq. TS14C–7)

R = hydraulic radius (ft) W

Se = energy slope (ft/ft) where:

D50 = median stone diameter (ft) R = centerline bend radius

W = water surface width

A similar approach has been proposed by Newbury

and Gaboury (1993) for sizing stones in grade control In the analysis used to develop this formula, failure

structures. This relationship is: was assumed to occur when the underlying material

became exposed. It should be noted that while many

tractive force (kg/m2) = incipient diameter (cm) of the other techniques specify a D50, Maynord (1992)

specifies a D30 which will typically be 15 percent small-

USACE—Maynord method er than the D50. This assumes a specific gradation of:

This low-energy technique for the design of riprap is

used for channel bank protection (revetments). This 1.8D15 < D85 < 4.6D15 (eq. TS14C–8)

method is outlined in USACE guidance as provided in

EM 1110–2–1601, and is based on a modification to the The USACE developed this method for the design of

Maynord equation: riprap used in either constructed or natural channels

2.5

which have a slope of 2 percent or less and Froude

γ

0.5

V numbers less than 1.2. As a result, this technique is not

D30 = FS × CS × C v × CT × d × W

× appropriate for high-turbulence areas.

γ S − γ w K 1 × g × d

(eq. TS14C–5) Maynord’s side-slope and invert equation is for cases

where the protective blanket is constructed with a

where: relatively smooth surface and has no significant pro-

Dm = stone size in ft; m percent finer by weight jections. It is appropriate for use to size stone-toe

d = water depth (ft) protection. However, it has been suggested that with

FS = factor of safety (usually 1.1 to 1.5), suggest 1.2 some adjustment to the coefficients (typically using a

Cs = stability coefficient Z=2 or flatter C=0.30, (0.3 velocity coefficient of 1.25 and a local velocity equal to

for angular rock, 0.375 for rounded rock) 160% of the channel velocity), Maynord’s method can

TS14C–6 (210–VI–NEH, August 2007)

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

be used for exposed boulders or stones exposed to However, the side slopes should be 1V:2.5H or flatter.

impinging flow. A typical application would be a rock-lined chute. The

formula is:

U.S. Bureau of Reclamation method 2

This high-energy technique is outlined in U.S. Bureau 1.95S 0.555 (Cq ) 3

D30 = (eq. TS14C–12)

of Reclamation (USBR) EM–25 (Peterka 1958) and 1

was developed for sizing riprap below a stilling basin. g3

where:

It was empirically developed using 11 prototype instal-

D30 = stone size; m percent finer by weight

lations with velocities ranging from 1 foot per second

S = channel slope

to 20 foot per second. The formula is:

q = unit discharge (q = Q/b, where b = bottom

D50 = 0.0122 V 2.06 (eq. TS14C–9) width of chute and Q is total flow)

where: C = flow concentration factor (usually 1.25, but can

D50 = median stone diameter (ft) be higher if the approach is skewed)

V = average channel velocity (ft/s) g = gravitational constant

U.S. Geological Survey method (Blodgett 1981) This equation is applicable to thickness = 1.5 D100,

This technique is based on analysis of field data of 39 angular rock, unit weight of 167 pounds per cubic foot,

large events from sites in Arizona, Washington, Or- D85/D15 from 1.7 to 2.7, slopes from 2 to 20 percent,

egon, Nevada, and California. Riprap protection failed and uniform flow on a downslope with no tailwater.

in 14 of the 39 cases. An envelope curve was empirical- This equation typically predicts conservative sizes.

ly developed to represent the difference between sites

that performed without damage and those that were USACE habitat boulder design

damaged by particle erosion. The formula is: This technique is outlined in USACE guidance provid-

ed in EMRRP–SR–11. It is developed for sizing boulder

D50 = 0.01V 2.44 (eq. TS14C–10) clusters in a channel for habitat enhancement. This

high-energy relationship is an incipient motion relation

where: for fully immersed boulders in turbulent flow on a flat

D50 = median stone diameter (ft) bed. This method is for impinging flow. The formula is:

V = average channel velocity (ft/s)

18(depth )S f (eq. TS14C–13)

This method typically provides overly conservative D=

(SG − 1)

results.

where:

Tillatoba model study D = minimum stone size

This study (Blaisdell 1973) provides an equation for depth = channel depth

sizing stone to remain stable in the turbulent flow Sf = channel friction slope

found below stilling basins. This high-energy technique SG = specific gravity of the stone

results in an estimate for D50.

This equation has also been used to size stones for use

V3 (eq. TS14C–11) in low instream weirs. However, estimating the friction

D50 = 0.00116

d slope across a drop can be difficult.

where:

V = velocity (ft/s) Abt and Johnson (1991)

d = flow depth (ft) Abt and Johnson (1991) conducted near-prototype

D50 = stone diameter (ft) flume studies to determine riprap stability when sub-

jected to overtopping flows such as in spillway flow or

USACE steep slope riprap design in sloping loose-rock grade control structures. Slopes

This high-energy technique is outlined in standard varied from 2 to 20 percent. Riprap design criteria for

USACE guidance as provided in EM 1110–2–1601. It overtopping flows were developed for two conditions:

is designed for use on slopes from 2 to 20 percent. stone movement and riprap layer failure. Criteria were

(210–VI–NEH, August 2007) TS14C–7

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

developed as a function of median stone size, unit dis- This method is best used in steep slopes for grade

charge, and embankment slope. The equation is: control, embankment overtopping, or on side inlets

from fields to a major drainage outlet. The spreadsheet

( ) provides much additional information related to rock

0.56

D50 = q design × S 0.43 × 5.23 (eq. TS14C–14)

chutes such as guidance on inlet and outlet conditions,

where: quantity estimates, and hydrology.

D50 = stone size in inches; m percent finer by

weight California Department of Transportation RSP

qdesign = unit discharge (ft3/s/ft) This technique was developed by the California De-

S = channel slope (ft/ft) and S between 0.02 and partment of Transportation (CALTRANS) for designing

0.20 ft/ft rock slope protection (RSP) for streams and river-

banks. Unlike most of the other available techniques,

(q design ) = ( q0.74 ) = 1.35q

failure

failure (eq. TS14C–15) it results in a recommended minimum weight of the

stone. The equation is:

Stone movement occurred at approximately 74 per-

cent of the flow, causing layer failure. It was deter- 0.00002 VM × V 6 × G S

W= × (eq. TS14C–18)

mined from testing that rounded stone should be (G S − 1)

3

sin 3 ( r − a )

oversized by approximately 40 percent to provide the

same protection as angular stone. where:

W = minimum rock weight (lb)

V = velocity (ft/s)

ARS rock chutes

VM = 0.67 if parallel flow

This design technique (Robinson, Rice, and Kadavy

VM = 1.33 if impinging flow

1998) is primarily targeted at high-energy applications.

GS = specific gravity of rock (typically 2.65)

Loose riprap with a 2 D50 blanket thickness composed

r = angle of repose (70° for randomly placed rock)

of relatively uniform, angular riprap was tested to a = outside slope face angle to the horizontal (typi-

overtopping failure in models and field scale struc- cally a maximum of 33°)

tures. This method applies to bed slopes of 40 percent

and less. This technique can be used for low slope, and The weight indicated by this method should be used in

thus, low-energy applications, but it is particularly use- conjunction with standard CALTRANS specifications

ful for slopes greater than 2 percent. A factor of safety and gradations.

appropriate for the project should be applied to the

predicted rock size. The equations are: Far West states (FWS)—Lane’s Method

Vito A. Vanoni worked with the Northwest E&WP Unit

for S <0.1 to develop the procedure from the ASCE paper enti-

tled “Design of Stable Alluvial Channels” (Lane 1955a).

( )

0.529

D50 = 12 1.923qS1.5 (eq. TS14C–16) The equation is:

3.5

0.10<S<0.40 D75 = × γ w × D × Sf (eq. TS14C–19)

C×K

( )

0.529

D50 = 12 0.233qS 0.58 (eq. TS14C–17) where:

D75 = stone size, (in)

where: C = correction for channel curvature

D50 = median stone size (in) K = correction for side slope

q = highest stable unit discharge (ft3/s/ft) Sf = channel friction slope (ft/ft)

S = channel slope (ft/ft) d = depth of flow (ft)

γw = density of water

A spreadsheet program (Lorenz, Lobrecht, and Robin-

son 2000) is available to assist in sizing riprap on steep This is generally considered to be a conservative

slopes. A screen capture of this spreadsheet program technique. It assumed that the stress on the sides of

is shown in figure TS14C–7. the channel were 1.4 times that of the bottom. This

TS14C–8 (210–VI–NEH, August 2007)

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

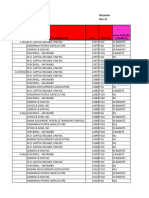

Figure TS14C–7 Rock chute spreadsheet

Rock Chute Design Data

(Version 4.01 - 04/23/03, Based on Design of Rock Chutes by Robinson, Rice, Kadavy, ASAE, 1998)

Project: Spillway protection County: Woodbury

Designer: Jim Villa Checked by:

Date: 3/30/2006 Date:

Input Channel Geometry

Inlet Channel Chute Outlet Channel

Bw = 20.0 ft. Bw = 20.0 ft. Bw = 40.0 ft.

Side slopes = 4.0 (m:1) Factor of safety = 1.20 (Fs) Side slopes = 4.0 (m:1)

n-value = 0.035 Side slopes = 4.0 (m:1) 2.0:1 max. n-value = 0.045

Bed slope = 0.0060 ft./ft. Bed slope (5:1) = 0.200 ft./ft. 2.5:1 max. Bed slope = 0.0050 ft./ft.

Freeboard = 0.5 ft. Outlet apron depth, d = 1.0 ft. Base flow = 0.0 cfs

Design Storm Data (Table 2, NHCP, NRCS Grade Stabilization Structure No. 410)

Drainage area = 450.0 acres Rainfall = 0 - 3 in. 3 - 5 in. 5+ in. Note : The total required capacity is routed

Apron elev. --- Inlet = 105.0 ft. --- Outlet = 99.0 ft. --- (Hdrop = 5 ft.) through the chute (principal spillway) or

Chute capacity = Q5-year Minimum capacity (based on a 5-year, in combination with an auxiliary spillway.

Total capacity = Q10-year 24-hour storm with a 3 - 5 inch rainfall) Input tailwater (Tw) :

Qhigh= 330.0 cfs High flow storm through chute Tw (ft.) = Program 0.20

Qlow = 75.0 cfs Low flow storm through chute Tw (ft.) = Program

Profile and Cross Section (Output)

Notes:

hpv = 0.38 ft. (0.18 ft.) 1) Output given as High Flow (Low Flow) values.

Hpe = 2.67 ft. hcv = 0.71 ft. (0.32 ft.) 2) Tailwater depth plus d must be at or above the

Energy Grade Line Hce = 2.51 ft. hydraulic jump height for the chute to function.

3) Critical depth occurs 2y c - 4yc upstream of crest.

0.715yc = 1.28 ft. 4) Use min. 8 oz. non-woven geotextile under rock.

Hp = 2.3 ft. (0.52 ft.)

Inlet (0.93 ft.) yc = 1.8 ft. z1 = 1.07 ft. Hydraulic Jump

Channel

Slope = 0.00 (0.72 ft.) (0.44 ft.) Height, z2 = 2.76 ft. (1.09 ft.)

6 ft./ft. Inlet Apron

1y =

n 2.34 ft. 10yc = 18 ft. Tw+d = 3.04 ft. - Tw o.k.

(1.03 ft.) n=

Hdrop = 5 ft. (1.86 ft.) - Tw o.k.

40(D50) = 45 ft. 0.0

54

Velocityinlet = 4.79 fps radius (0 2.04 ft. (0.86 ft.) Outlet

.04

at normal depth 9) 2.5 Channel

8 oz. Min. 1 1 Slope = 0.005 ft./ft.

Geotextile

1 Note: When the normal depth (yn) in the inlet 5 Outlet Apron

channel is less than the weir head (Hp), ie., the weir capacity is less 20 ft. d = 1 ft. {1 ft. minimum

than the channel capacity, restricted flow or ponding will occur. This Rock 15(D50)(Fs) suggested}

reduces velocity and prevents erosion upstream of the inlet apron. Chute Bedding Velocityoutlet = 3.37 fps

at normal depth

Profile Along Centerline of Chute

Auxiliary Spillway qt = 13.65 cfs/ft. Equivalent unit discharge

Freeboard = 0.5 ft. FS = 1.20 Factor of safety (multiplier)

Berm

z1 = 1.07 ft. Normal depth in chute

8 oz. Min. n-value = 0.054 Manning's roughness coefficient

Geotextile

D50(Fs) = 16.2 in. (309 lbs. - 50% round / 50% angular)

Hp*

1 Rock Chute 2(D50)(Fs) = 32.4 in. Rock chute thickness

m=4 Bedding Tw + d = 3.04 ft. Tailwater above outlet apron

* Use Hp along chute 20 ft. Rock thickness = 32.4 in. z2 = 2.76 ft. Hydraulic jump height

but not less than z2. (Bw) *** The outlet will function adequately

Typical Cross Section High Flow Storm Information

(210–VI–NEH, August 2007) TS14C–9

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

is about 1.8 times the actual stress on the sides of a Step 1 Enter figure TS14C–8 with energy slope

straight channel. It is very close to the stresses on the (channel grade) and flow depth.

sides in a curved channel reach. The curved correc-

tions included in the procedure only make the con- Step 2 Track right to side slope.

servative answer even more conservative. In addition, Step 3 Track up to ratio of curve radius to water

it was developed for stones with a specific gravity of surface width.

2.56. However, it has been successfully applied on

many projects. This procedure may be used with figure Step 4 Track right to estimate required riprap

TS14C–8 and is: size.

Figure TS14C–8 Lane’s method

D75= 3.5 × γw × d × S

C×K

Notes 0

D75 (nominal diameter (in)). Size of rock

1. Ratio of channel bottom width to depth

(d) greater than 4 Ratio of curve radius to

for which 25% by weight is larger

2. Specific gravity of rock not less than 2.56 water surface width

3. Additional requirements for stable riprap

10

include fairly well-graded rock, stable

foundation, and minimum section thickness

(normal to slope) not less than D75 at maximum

S

water surface elevation and 3 D75 at the base.

=0 =1.

4. Where a filter blanket is used, design filter material .90 0 20

=0

grading in accordance with criteria in NRCS Soil St

ra

.75

=0

Mechanics Note I. ig

.60

ht

9- cha

Rc/Ws C Side slope K

4–6 0.6 1-1/2H:1V .52 12 nn

6–9 0.75 1-3/4H:1V .63 el 30

6-9

9–12 0.90 2H:1V .72

straight channel 1.0 2-1/2H:1V .80 10

4-6

3H:1V .87

Rc = Curve radius

Ws = Water surface width 8 40

S = Energy slope or channel grade

w = 62.4 ft)

d( 6 :1V

ow 3H V

o f fl :1

2H

pth 0.87

De 4

K = 0.72 H:1V

= 52 1 1/2

= 0.

2

Side slope

0.005 0.010 0.015 0.020

Channel slope, S (ft/ft)

TS14C–10 (210–VI–NEH, August 2007)

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

U.S. Department of Transportation Federal Summary guide of selected

Highway Administration techniques

Several additional computational techniques for de- techniques

signing riprap are available from the U.S. Department

of Transportation Federal Highway Administration Attributes of selected methods are summarized in

(FHWA). While these are not described in detail, a table TS14C–3 to allow the user to quickly select a

brief description of each is provided in table TS14C–2. method.

Review the references (FHWA HEC 1987, 1988, 2001a, The designer should not be surprised if the different

2001b) to obtain the design relationships and applica- techniques produce different answers. The user needs

tion manuals for these methods. to recognize the limits and applicability of each tech-

nique and match it to the site and project conditions.

Table TS14C–2 Federal Highway Administration techniques

HEC–11 This technique was developed for use on natural streams or rivers with a flow greater than 50 ft3/s. It is limited

to straight or mildly curving reaches with relatively uniform cross sections. This method calculates a D50 based

on average channel velocity, side slope, riprap angle of repose, specific gravity of the stone, and average channel

depth

HEC–15 This technique was developed for use on small, constructed channels with a flow less than 50 ft3/s

HEC–18 This technique was developed for design of stone at bridge piers and abutments

Table TS14C–3 Summary of techniques

High or low

Technique energy Slopes Typical application(s)

Isbash Both Not specified Rock revetment, stilling basins, river closures

108 Report Both <10% Quick assessments for stable stone requirements

Maynord Low <2% Rock revetment, bank protection, stone toe

Abt and Johnson High 2% to 20% Overtopping, grade protection

ARS – rock chute High 2% to 40% Overtopping, rock chutes, grade protection

USBR High Not specified Riprap below a stilling basin

USGS Blodgett Both Not specified Riprap stability

USACE Steep Slope Riprap High 2% to 20% Rock chutes, grade protection

USACE Habitat Boulder High Not specified Instream boulders for habitat enhancement

CALTRANS RSP Low <2% Rock revetment, bank protection, stone toe

Lane's (FWS) Low <2% Stone bank protection, stream barbs with adjustments

(210–VI–NEH, August 2007) TS14C–11

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

Factor of safety Discussion: The computed critical depth indicates that

this is a subcritical flow. The design calls for a revetment-

type protection, so the stones are not projecting into the

Stone sizing should be approached with care because flow. Therefore, this is a low-energy flow condition. The

rock treatments can be expensive and can give a false Isbash (1936) and the Maynord (1992) methods both indi-

sense of security if not applied appropriately. A factor cate a D50 of about 5.5 to 6.5 inches. These methods were

of safety is often advisable to account for unknowns developed for conditions that are similar to those in the

and uncertainty. In some cases, the factor of safety is problem statement. Therefore, a stone size of 6 inches

part of the sizing formulas provided. Where a factor with an appropriate factor of safety should be accept-

of safety is not built into the procedure, the designer able.

should multiply the resulting size by an appropriate

value. Appropriate engineering judgment should be Lane’s (1955a) FWS method provides a conservative

applied when assigning a factor of safety. Maynord estimate of 12.7 inches. While this technique is used in

(1992) suggests a minimum factor of safety of 1.1. similar situations, a conservative answer is expected.

Typically, a factor of safety will range from 1.1 to 1.5. The Abt and Johnson (1991) method and the ARS meth-

The risk and uncertainty associated with a project od (Robinson, Rice, and Kadavy 1998) were developed

should be reflected in the factor of safety. for steeper high-energy flow conditions (>2%); therefore,

use of these methods would not be advisable for this

Example calculations application.

Example calculations are presented for selected meth- Example problem: Steep slope

ods to illustrate the variability associated with rock

sizing methods. The examples may also provide a new Problem: For the following flow conditions, determine

user with confirmation that they are correctly applying the required rock size for a rock chute.

a method.

Gs = 2.65 or γs=165.36 lb/ft3

Width = 40 ft

Example problem: Mild slope

n = 0.045

Slope = 0.06 ft/ft

Problem: For the following flow conditions, determine

Depth = 3.5 ft

the required rock size for stone toe protection.

Gs = 2.65 or γs=165.36 lb/ft3 Solution: Solve relevant hydraulic parameters

Width = 40 ft Vel = 16.7 ft/s

n = 0.045 Q = 2,340 ft3/s

Slope = 0.01 ft/ft Ycrit = 4.7 ft

Depth = 6 ft

The riprap size determined from several methods is:

Solution: Solve relevant hydraulic parameters

Isbash D50 = 1.6 ft

Vel = 9.1 ft/s Maynord D30 = 1.6 ft, D50 = 1.9 ft

Q = 2,200 ft3/s Lane’s (FWS) D75 = 3.7 ft, D50 = 3.2 ft

Ycrit = 4.54 ft Abt and Johnson D50 = 1.3 ft

ARS rock chute D50 = 1.1 ft

The riprap size determined from several methods is:

Discussion: The computed critical depth indicates that

this is a supercritical flow. While similar in prediction,

Isbash D50 = 6.5 in

the Isbash and the Maynord (1992) methods were not de-

Maynord D30 = 4.6 in, D50 = 5.5 in

veloped for conditions that are described in the problem

Lane’s (FWS) D75 = 15 in, D50 = 12.7 in

statement. The Abt and Johnson (1991), as well as the

Abt and Johnson D50 = 8.1 in

ARS rock chute methods (Robinson, Rice, and Kadavy

ARS rock chute D50 = 3.6 in 1998), were derived for similar conditions to the problem

statement. Therefore, the 1.1 to 1.3 foot D50 riprap with

an appropriate factor of safety should be acceptable.

TS14C–12 (210–VI–NEH, August 2007)

Technical Supplement 14C Stone Sizing Criteria Part 654

National Engineering Handbook

Conclusion

Rock is often used where long-term durability is

needed, velocities are high, periods of inundation are

long, and there is a significant threat to life and prop-

erty. Whether a streambank project involves the use of

rock as part of a stand-alone treatment or as a com-

ponent of an integrated system, the determination of

the required stone size requires engineering analysis.

Stone sizing should be approached with care because

rock treatments can be expensive and can give a false

sense of security if not applied appropriately. Since

stone sizing methods are normally developed for a spe-

cific application, care should be exercised matching

the selected method with the project purpose and site

condition. Therefore, the intended application should

dictate which rock sizing technique is used. By using

several methods, the designer will often see a conver-

gence of rock sizes for a given application.

(210–VI–NEH, August 2007) TS14C–13

Vous aimerez peut-être aussi

- Handbook CMA PDFDocument8 pagesHandbook CMA PDFEmilianoPas encore d'évaluation

- Evaluation of Longshore Sediment Transport Formulas Using Large-Scale Model DataDocument14 pagesEvaluation of Longshore Sediment Transport Formulas Using Large-Scale Model DatajmmPas encore d'évaluation

- Design of Soil Nail Zamboanga CityDocument30 pagesDesign of Soil Nail Zamboanga CityJasonCooPas encore d'évaluation

- Rubble Mound Breakwater: Christian Linde OlsenDocument11 pagesRubble Mound Breakwater: Christian Linde OlsenFoong Tong WengPas encore d'évaluation

- Civl2210 2008 NotesDocument26 pagesCivl2210 2008 NotesJackLikesTomatoesPas encore d'évaluation

- Do 050 S2007-Mse SpecsDocument12 pagesDo 050 S2007-Mse SpecsCarol SantosPas encore d'évaluation

- Frequency AnalysisDocument29 pagesFrequency Analysisheyru abdoPas encore d'évaluation

- Coastal Infrastructure Design Course Chapter on Structural DesignDocument57 pagesCoastal Infrastructure Design Course Chapter on Structural Designvasanthk81Pas encore d'évaluation

- A Plasticity Model For Swedish Weight Sounding TestsDocument8 pagesA Plasticity Model For Swedish Weight Sounding TestsKieu Le Thuy ChungPas encore d'évaluation

- A-Pile Description SheetDocument2 pagesA-Pile Description SheetUnwanus Sa'adahPas encore d'évaluation

- PS LoggingDocument5 pagesPS LoggingrajneeshPas encore d'évaluation

- Riprap Shear Stress DesignDocument5 pagesRiprap Shear Stress DesignphatmatPas encore d'évaluation

- GAPS Guidelines: Special Extinguishing System ReviewDocument2 pagesGAPS Guidelines: Special Extinguishing System Reviewasad khanPas encore d'évaluation

- ESALDocument8 pagesESALfaizalramadhan16100% (1)

- Optimization of Water Reuse Network Using Water Pinch Technology WPT by Considering Single Contaminant For Kaduna Refinery and Pet 2375 4397 1000173Document6 pagesOptimization of Water Reuse Network Using Water Pinch Technology WPT by Considering Single Contaminant For Kaduna Refinery and Pet 2375 4397 1000173Brario AninditoPas encore d'évaluation

- Dinamic Force On An Elbow Caused by A Traveling Liquid SlugDocument11 pagesDinamic Force On An Elbow Caused by A Traveling Liquid SlugshaffetiPas encore d'évaluation

- GWIS Data Dictionary v1.6 20140411Document68 pagesGWIS Data Dictionary v1.6 20140411disgusting4allPas encore d'évaluation

- DHI Nonlinear Channel Optimisation Simulator (NCOS)Document4 pagesDHI Nonlinear Channel Optimisation Simulator (NCOS)jbloggs2007Pas encore d'évaluation

- Wave Reflection by Submerged Vertical and Semicircular BreakwatersDocument8 pagesWave Reflection by Submerged Vertical and Semicircular BreakwatersJohn Paul Abad100% (1)

- @ - Breakwater Foundation StabilityDocument9 pages@ - Breakwater Foundation Stabilityapi-3709579100% (1)

- Rock Riprap Design Methods and Their Applicability To Long-Term Protection of Uranium Mill Tailings ImpoundmentsDocument98 pagesRock Riprap Design Methods and Their Applicability To Long-Term Protection of Uranium Mill Tailings ImpoundmentsAhmed Samir SalimPas encore d'évaluation

- Burland BridgeDocument8 pagesBurland BridgeSheril ChandrabosePas encore d'évaluation

- DEME Anual Report 2015Document72 pagesDEME Anual Report 2015Frank MartinezPas encore d'évaluation

- Coastal Engineering Exercise on Siltation in Rotterdam HarbourDocument4 pagesCoastal Engineering Exercise on Siltation in Rotterdam HarbourDora LePas encore d'évaluation

- CHAPTER 3 Shear StrengthDocument30 pagesCHAPTER 3 Shear StrengthnurhaslizanaPas encore d'évaluation

- Volume I Main Report - S PDFDocument234 pagesVolume I Main Report - S PDFJesperPas encore d'évaluation

- Triaxial Test 2850Document2 pagesTriaxial Test 2850Mostafa MagdyPas encore d'évaluation

- Seismic Design and Liquefaction Policy for Transportation InfrastructureDocument74 pagesSeismic Design and Liquefaction Policy for Transportation InfrastructureNadim527Pas encore d'évaluation

- Manual: ShoreDocument164 pagesManual: Shorenonopimentel100% (1)

- Seepage and Slope Stability Modelling of Rainfall Induced Slope Failures in Topographic HollowsDocument27 pagesSeepage and Slope Stability Modelling of Rainfall Induced Slope Failures in Topographic HollowsAgditya PriksawanPas encore d'évaluation

- Derrick LighterDocument2 pagesDerrick Lighterhessian123Pas encore d'évaluation

- Ocean Wave Forecasting at Ecmwf Version 201402Document58 pagesOcean Wave Forecasting at Ecmwf Version 201402Arnel DodongPas encore d'évaluation

- New guidance for predicting wave forces on exposed jettiesDocument21 pagesNew guidance for predicting wave forces on exposed jettiessergioPas encore d'évaluation

- Basic Floating Dock CheckDocument30 pagesBasic Floating Dock CheckKelly RutkowskiPas encore d'évaluation

- Wave Runup and Overtopping HazardsDocument25 pagesWave Runup and Overtopping Hazards허윤호Pas encore d'évaluation

- Chapter22 Penetration TestingDocument58 pagesChapter22 Penetration TestingBlackcat FreeManPas encore d'évaluation

- Wave Height Distributions in Shallow Waters: A Test of Battjes-Groenendijk ParameterizationDocument6 pagesWave Height Distributions in Shallow Waters: A Test of Battjes-Groenendijk ParameterizationlollazzoPas encore d'évaluation

- Crest Modifications To Reduce Wave OvertDocument20 pagesCrest Modifications To Reduce Wave OvertDinar IstiyantoPas encore d'évaluation

- Manual HS 2023 - BS VersionDocument416 pagesManual HS 2023 - BS VersionSander KosterPas encore d'évaluation

- Otc 10711 MSDocument12 pagesOtc 10711 MSAnonymous pNgdUM2x8Pas encore d'évaluation

- ASCE Guidelines For Case Study PublishingDocument2 pagesASCE Guidelines For Case Study PublishingarpitPas encore d'évaluation

- Otc 2001Document72 pagesOtc 2001talabizPas encore d'évaluation

- Chapter 10. Hydraulic Failure 185Document1 pageChapter 10. Hydraulic Failure 185Yasonsky CaptainPas encore d'évaluation

- AGT2012-Vessel Blowdown Systems - Assurance Framework For Operate PhaseDocument17 pagesAGT2012-Vessel Blowdown Systems - Assurance Framework For Operate Phasearunperth0% (1)

- Open Path Gas DetectionDocument4 pagesOpen Path Gas Detectionslipped_discPas encore d'évaluation

- TrelleborgDocument10 pagesTrelleborgrofiqq4Pas encore d'évaluation

- Empirical Equations For Deformation Capacity of Conventional RC Shear WallsDocument12 pagesEmpirical Equations For Deformation Capacity of Conventional RC Shear WallsCarsonBakerPas encore d'évaluation

- Safety Aspects Affecting The Berthing Operations of Tankers To Oil and Gas TerminalsDocument98 pagesSafety Aspects Affecting The Berthing Operations of Tankers To Oil and Gas TerminalsAydin şahankayaPas encore d'évaluation

- M21MT SciDocDocument42 pagesM21MT SciDocAhmad Safii MaarifPas encore d'évaluation

- GAPS Guidelines: Drop-In-Pressure Waterflow AlarmsDocument2 pagesGAPS Guidelines: Drop-In-Pressure Waterflow AlarmsAsad KhanPas encore d'évaluation

- Alternatives Analysis For The Straits Pipeline - Final ReportDocument379 pagesAlternatives Analysis For The Straits Pipeline - Final ReportAnonymous gsQyliX100% (1)

- Practical Vacuum Journal Contamination Sources RemediesDocument4 pagesPractical Vacuum Journal Contamination Sources RemediesBenjamin BrownPas encore d'évaluation

- Company Profile and Marine Guide - SILI PUMPDocument5 pagesCompany Profile and Marine Guide - SILI PUMPArrijal PratamaPas encore d'évaluation

- 7359 PDFDocument44 pages7359 PDFlebrixPas encore d'évaluation

- Stream Barbs Design and Installation GuideDocument24 pagesStream Barbs Design and Installation GuidepparejaPas encore d'évaluation

- Scour CalculationsDocument44 pagesScour CalculationsKirukimon KirukimoPas encore d'évaluation

- Foundaiton On Sloping GroundDocument18 pagesFoundaiton On Sloping GroundTheo PhilusPas encore d'évaluation

- Chapter 9 - Rock MassDocument116 pagesChapter 9 - Rock MassZulaikha Kamal50% (2)

- Blast Design OptimizationDocument22 pagesBlast Design OptimizationTao XiaoPas encore d'évaluation

- Seabed Seismic Techniques: QC and Data Processing KeysD'EverandSeabed Seismic Techniques: QC and Data Processing KeysÉvaluation : 5 sur 5 étoiles5/5 (2)

- Training Wall Height On Convergent Stepped SpillwaysDocument10 pagesTraining Wall Height On Convergent Stepped Spillwayschutton681Pas encore d'évaluation

- Dams On Rock Foundations - DeereDocument16 pagesDams On Rock Foundations - Deerechutton681Pas encore d'évaluation

- Dynamic Properties of Mass Concrete Obtained From Dam Cores Harris & DolenDocument7 pagesDynamic Properties of Mass Concrete Obtained From Dam Cores Harris & Dolenchutton681Pas encore d'évaluation

- Concrete Dam Foundation InvestigationsDocument6 pagesConcrete Dam Foundation Investigationschutton681Pas encore d'évaluation

- Durability of Hydropower Concrete Strs With OverlaysDocument204 pagesDurability of Hydropower Concrete Strs With Overlayschutton681Pas encore d'évaluation

- Laboratory Evaluation of Concrete Thin Repair Materials MERL-2009-36Document15 pagesLaboratory Evaluation of Concrete Thin Repair Materials MERL-2009-36chutton681Pas encore d'évaluation

- Nonlinear Concrete Material Models in Dam FEADocument87 pagesNonlinear Concrete Material Models in Dam FEAchutton681Pas encore d'évaluation

- Investigating Structural Safety of Cracked Concrete DamsDocument14 pagesInvestigating Structural Safety of Cracked Concrete Damschutton681Pas encore d'évaluation

- Drainage For DamsDocument10 pagesDrainage For Damschutton681Pas encore d'évaluation

- Dynamic Properties of Mass Concrete Obtained From Dam Cores Harris & DolenDocument7 pagesDynamic Properties of Mass Concrete Obtained From Dam Cores Harris & Dolenchutton681Pas encore d'évaluation

- Correlation Between Tensile Splitting Strength and Flexural Strength of ConcreteDocument12 pagesCorrelation Between Tensile Splitting Strength and Flexural Strength of Concretechutton681Pas encore d'évaluation

- Properties of Aged Concrete DSO-98-03 - HarrisDocument46 pagesProperties of Aged Concrete DSO-98-03 - Harrischutton681Pas encore d'évaluation

- Repairng Leaking Expansion Joints USBR CRBMarApr13 - VonFay-JoyDocument4 pagesRepairng Leaking Expansion Joints USBR CRBMarApr13 - VonFay-Joychutton681Pas encore d'évaluation

- Surface Preparation For Bond USBRDocument190 pagesSurface Preparation For Bond USBRchutton681Pas encore d'évaluation

- Spall Repair REMRDocument12 pagesSpall Repair REMRchutton681Pas encore d'évaluation

- Surface Preparation For Bond USBRDocument190 pagesSurface Preparation For Bond USBRchutton681Pas encore d'évaluation

- Guide to Protective Coatings: Inspection and MaintenanceDocument118 pagesGuide to Protective Coatings: Inspection and MaintenanceAnilkumar Gurram100% (1)

- Guide To Chemical Grouting of Joints and Cracks in Concrete MERL-2013-58Document38 pagesGuide To Chemical Grouting of Joints and Cracks in Concrete MERL-2013-58chutton681Pas encore d'évaluation

- Chemical Grouts For Use On USBR Projects GR8613Document42 pagesChemical Grouts For Use On USBR Projects GR8613chutton681Pas encore d'évaluation

- Analysis of Hydraulic Pressure Transients in The Waterways of Hydropower StationsDocument77 pagesAnalysis of Hydraulic Pressure Transients in The Waterways of Hydropower Stationskamran1340Pas encore d'évaluation

- Three Dimensional Behavior of Retaining Wall Systems PDFDocument257 pagesThree Dimensional Behavior of Retaining Wall Systems PDFศิวาเวช อบมาPas encore d'évaluation

- Structural Design of Flexible ConduitsDocument126 pagesStructural Design of Flexible ConduitsDenisR9Pas encore d'évaluation

- Increase in Youngs Modulus Under Compression TestDocument38 pagesIncrease in Youngs Modulus Under Compression Testchutton681Pas encore d'évaluation

- Soil Cement Spec NRCS 21308Document8 pagesSoil Cement Spec NRCS 21308chutton681Pas encore d'évaluation

- Strength of Open Graded Aggregates For Structural BackfillDocument154 pagesStrength of Open Graded Aggregates For Structural Backfillchutton681Pas encore d'évaluation

- Numerical Modeling of Buried Pipes With Flowable Fill As A BackfiDocument168 pagesNumerical Modeling of Buried Pipes With Flowable Fill As A Backfichutton681Pas encore d'évaluation

- Workshop Soil Structure Interation and Retainin Walls PDFDocument210 pagesWorkshop Soil Structure Interation and Retainin Walls PDFchutton681Pas encore d'évaluation

- USDA Engineering Classification of Rock MaterialsDocument61 pagesUSDA Engineering Classification of Rock MaterialsTanPas encore d'évaluation

- Understanding Native Flowable Fill Underground ConstructionDocument3 pagesUnderstanding Native Flowable Fill Underground Constructionchutton681Pas encore d'évaluation

- Use of Flowable Fill As A Backfill Material Around Buried PipesDocument161 pagesUse of Flowable Fill As A Backfill Material Around Buried Pipeschutton681Pas encore d'évaluation

- Operation & Service Manual For Cable Tensiometer: SeriesDocument28 pagesOperation & Service Manual For Cable Tensiometer: SeriesJonatan BernalPas encore d'évaluation

- Coordinated Interference Management (Low-Frequency TDD) (5G RAN6.1 - Draft A)Document28 pagesCoordinated Interference Management (Low-Frequency TDD) (5G RAN6.1 - Draft A)VVLPas encore d'évaluation

- Mechanical Engineering Conference ProgramDocument40 pagesMechanical Engineering Conference Programirinuca12Pas encore d'évaluation

- Network of Global Corporate Control. Swiss Federal Institute of Technology in ZurichDocument36 pagesNetwork of Global Corporate Control. Swiss Federal Institute of Technology in Zurichvirtualminded100% (2)

- Proportional Chopper Amplifier VB-3A: Min MaxDocument5 pagesProportional Chopper Amplifier VB-3A: Min MaxryujoniPas encore d'évaluation

- DMF360 Tandem Lift With ForkliftDocument4 pagesDMF360 Tandem Lift With Forkliftreda mesbahPas encore d'évaluation

- Biology Notes HSCDocument107 pagesBiology Notes HSCGouri DasPas encore d'évaluation

- Nov. AbwDocument50 pagesNov. Abwjbyarkpawolo70Pas encore d'évaluation

- Fault Report - Inventory Cpf1 Vs Caño LimomDocument37 pagesFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraPas encore d'évaluation

- Solutions For Statistics and Probability For EngineersDocument6 pagesSolutions For Statistics and Probability For EngineersPHPas encore d'évaluation

- ASME - Performance Test CodesDocument1 pageASME - Performance Test CodesanoopkntpcPas encore d'évaluation

- Research BulletsDocument18 pagesResearch BulletsVong Albios DogomeoPas encore d'évaluation

- BS 2995-1966 PDFDocument15 pagesBS 2995-1966 PDF윤규섭Pas encore d'évaluation

- TM View Software User - S ManualDocument190 pagesTM View Software User - S ManualLuis SánchezPas encore d'évaluation

- NEO PGM 'AND'/'OR' FunctionalityDocument5 pagesNEO PGM 'AND'/'OR' FunctionalityAndre EinsteinPas encore d'évaluation

- JasminDocument125 pagesJasminudoraboxPas encore d'évaluation

- TR2400 HF SSB Transceiver FeaturesDocument4 pagesTR2400 HF SSB Transceiver FeaturesAravind VinduPas encore d'évaluation

- Aeration PaperDocument11 pagesAeration PapersehonoPas encore d'évaluation

- Rac NotesDocument16 pagesRac NotesJohnRay LominoquePas encore d'évaluation

- Math10 Week3Day4 Polynomial-EqnsDocument44 pagesMath10 Week3Day4 Polynomial-EqnsMark Cañete PunongbayanPas encore d'évaluation

- Booklet Momentum BWFDocument22 pagesBooklet Momentum BWFReem AshrafPas encore d'évaluation

- Arm Assembly Language ProgrammingDocument170 pagesArm Assembly Language ProgrammingAnup Kumar Yadav100% (4)

- Code - Aster: Multiaxial Criteria of Starting in FatigueDocument44 pagesCode - Aster: Multiaxial Criteria of Starting in FatigueYoyoPas encore d'évaluation

- 1-Newton Second Law-ForMATDocument5 pages1-Newton Second Law-ForMATVAIBHAV KUMARPas encore d'évaluation

- Etap Help PDFDocument2 pagesEtap Help PDFRebeccaPas encore d'évaluation

- 478 - Phs 242 NotesDocument61 pages478 - Phs 242 NotesSovan ChakrabortyPas encore d'évaluation

- Mediburn 30Document35 pagesMediburn 30Vsee EnkoPas encore d'évaluation

- Grade 6 Term1 Properties of 2-D Shapes Lesson 7Document4 pagesGrade 6 Term1 Properties of 2-D Shapes Lesson 7Ayanda Siphesihle NdlovuPas encore d'évaluation

- Visual Studio Add-Ins SuccinctlyDocument124 pagesVisual Studio Add-Ins SuccinctlyJosias GonzálezPas encore d'évaluation

- FT 539G Eng 01Document4 pagesFT 539G Eng 01lmw_arunPas encore d'évaluation