Académique Documents

Professionnel Documents

Culture Documents

CMHC - Details of House Construction

Transféré par

Gregor0 évaluation0% ont trouvé ce document utile (0 vote)

2K vues1 pageDETAILS OF HOUSE CONSTRUCTION.

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDETAILS OF HOUSE CONSTRUCTION.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

2K vues1 pageCMHC - Details of House Construction

Transféré par

GregorDETAILS OF HOUSE CONSTRUCTION.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

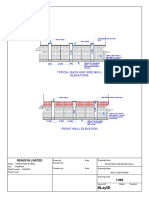

DETAILS OF HOUSE CONSTRUCTION

Foundation Excavation Brick

1 Excavation to 1200 mm min. below grade but 43 Metal brick tie straps @ 400 x 600 mm o.c.

not less than depth of frost penetration 44 Brick sill flashing

2 200 x 450 mm concrete footing with key 45 Steel angle brick lintel

3 100 mm perforated perimeter drain tile 46 Brick veneer

4 150 mm crushed stone with soil filter cloth over 47 Brick sill course

5 Galvanized steel basement window well

76 6 Vertical drain to drain tile Partition Walls

77 7 Clean, free-draining backfill material 48 38 x 89 mm partition wall framing

68 8 Slope ground for surface drainage 49 Double floor joist bearing under partition wall

61

50 0.15 mm polyethylene vapour barrier to continue

59 Basement Floor across partition at intersections with exterior wall and ceiling

58

33

34 9 75 mm concrete floor slab 51 Seal holes through partition studs for electric wiring at

48 67

49 10 0.15 mm polyethylene dampproofing exterior wall joint

51 62 11 38 x 1000 mm extruded polystyrene insulation, RSI 1.3

50

32 12 125 mm crushed stone Roof and Ceiling Framing

65

52 38 x 89 mm wood ladder framing to extend overhang of gable

55 Foundation Wall and Sill end soffit

13 Bituminous dampproofing to exterior side of foundation wall 53 Pre-engineered gable end roof truss shortened to receive

57 14 200 mm poured concrete foundation wall ladder framing

64 15 25 mm rigid board insulation, RS1 0.8, to interior side of 54 Pre-engineered roof truss

71 foundation wall 55 Pre-engineered typical full width roof truss @ 600 mm o.c.

63 16 38 x 89 mm wood framing @ 600 mm o.c. 56 Truss heel can be varied in height to accommodate insulation

73

60 17 89 mm mineral fibre batt insulation, RSI 2.1 without compression

40 18 Closed cell foam sill gasket 57 9.5 mm plywood roof sheathing with metal “H” clips

56

19 38 x 89 mm wood sill plate with 12 mm anchor bolts set in 58 19 x 64 mm wood strapping @ 400 mm o.c.

37

39 concrete wall @ 2400 mm o.c. max. 59 400 mm blown in place insulation, cellulose or mineral fibre, RSI 7.0

38

60 Insulation stop to retain insulation and to maintain 63 mm vent space

41 Floor Platforms and Headers

42

52 36 20 50 mm rigid board insulation, RSI 1.7, to exterior side Roof Finishes

53 31 of header 61 Prefinished metal ridge vent

43 21 38 x 235 mm wood header/band joist 62 Asphalt roofing shingles

54 30 22 89 mm mineral fibre batt insulation, RSI 2.1 63 Metal drip edge

23 38 x 235 mm wood floor joists @ 400 mm o.c. with 64 Self-sealing composite eave protection extending at least

66 74 cross blocking 900 mm up the roof slope and not less than 300 mm inside

72 24 15.5 mm tongue-and-grooved plywood subflooring the inner face of the exterior walls

44

65 100 mm ABS plastic plumbing vent stack with neoprene rubber

Exterior Wall Framing roof collar on vent stack

75 25 38 x 140 mm wood stud framing @ 600 mm o.c. 66 Metal valley flashing

26 Double top plate, cross-lapped at corners 67 Metal flashing at chimney to roof joints

27 Lintel, double wood headers, cavity to be insulated 68 Metal chimney capping

42 28 Jack stud bearing under lintel

29 140 mm mineral fibre batt insulation, RSI 3.5 Fascia and Soffit

29 30 7.9 mm oriented strand board wall sheathing 69 38 x 89 mm wood blocking between truss soffit plates

25

26 31 Spunbonded polyolefin air and moisture barrier, tape 70 38 x 140 mm wood fascia plate

42 27 and seal all joints 71 Prefinished aluminum fascia cladding

28 32 Electric receptacles and switches penetrating air barrier 72 Perforated vented aluminum soffit with J-trim on wall

45

5 on exterior walls and ceilings to be mounted in airtight, 73 Gable end roof vent

20

69 21 moulded plastic boxes

22

70

42 19 Ventilation and Mechanical Equipment

18

47

13 6

Interior Finishes 74 Exhaust air vent hood with screen and insulated duct from

46 14

35 34 33 12.7 mm gypsum board interior finish on walls and ceilings central exhaust air system or Heat Recovery Ventilator

24 16 75 Fresh air supply vent hood with screen and insulated duct

8 17 34 0.15 mm polyethylene air/vapour barrier, lapped and sealed

23 15

33 at all joints to central fresh air system or Heat Recovery Ventilator

9

10 35 Floor finish (carpet, hardwood, resilient or ceramic tile) 76 Insulated stainless steel chimney flue with rain cap from

12

7 11 pre-fabricated, zero clearance, fireplace

1 2

4 3 Siding Finish and Trim 77 Double wall stainless steel furnace flue with rain cap

36 Drip cap flashing over window head

37 19 x 64 mm vertical wood strapping, aligned over studs;

61009 24-02-14

25 mm air space at butt joints

38 J-trim under soffit and around window moulding

39 Prefinished wood trim

40 Prefinished siding (hardboard, wood, vinyl or aluminum)

41 Brick cap flashing

42 Sill flashing with end dams

Vous aimerez peut-être aussi

- PlansDocument24 pagesPlansjoshm89100% (1)

- 1 Residential - Construction - DetailsDocument308 pages1 Residential - Construction - DetailssamaaPas encore d'évaluation

- Carpentry Notes On Basic Roof Ceiling FramingDocument85 pagesCarpentry Notes On Basic Roof Ceiling Framingbekirm175% (4)

- TimberDocument30 pagesTimberMaica De ChavezPas encore d'évaluation

- Sample Plan: Chic CottageDocument8 pagesSample Plan: Chic CottageB R Paul FortinPas encore d'évaluation

- Carpentry Notes On Basic Roof & Ceiling FramingDocument85 pagesCarpentry Notes On Basic Roof & Ceiling FramingBenessa Rose Quiambao100% (16)

- Building Construction - DOORS, WINDOWDocument40 pagesBuilding Construction - DOORS, WINDOWKrishna 1Pas encore d'évaluation

- Greatminds Architectural SpecificationDocument6 pagesGreatminds Architectural SpecificationAr John Bernard AbadPas encore d'évaluation

- The Essential Guide To FramingDocument121 pagesThe Essential Guide To Framingpawkom100% (7)

- General Notes Jobsite Map Drawing Index: Salem HomeDocument12 pagesGeneral Notes Jobsite Map Drawing Index: Salem HomeChad BPas encore d'évaluation

- Section Showing Plinth Protection and Flooring DetailsDocument1 pageSection Showing Plinth Protection and Flooring DetailsarjunmahajanPas encore d'évaluation

- Legend Heritage Walk Project Material Finishes ListDocument9 pagesLegend Heritage Walk Project Material Finishes Listk.o.m channel (kmeng)Pas encore d'évaluation

- Foundation DesignDocument7 pagesFoundation Designdinu69inPas encore d'évaluation

- The Essential Kitchen Design Checklist 2021Document5 pagesThe Essential Kitchen Design Checklist 2021David Brainard100% (1)

- Detail 2006 10Document28 pagesDetail 2006 10filipgavrilPas encore d'évaluation

- Architects Pocket Book - PP 64-85 PDFDocument26 pagesArchitects Pocket Book - PP 64-85 PDFAlphaGrace Elizaga Apalla100% (1)

- Framing Roofs NAVEDTRA 14044 PDFDocument46 pagesFraming Roofs NAVEDTRA 14044 PDFreotan gulmatzPas encore d'évaluation

- A4-20 - Roof DetailsDocument1 pageA4-20 - Roof DetailsBleriPas encore d'évaluation

- M400 Advanced Framing Construction GuideDocument24 pagesM400 Advanced Framing Construction GuideAndyPalmerPas encore d'évaluation

- Different types of doors and windows explainedDocument24 pagesDifferent types of doors and windows explainedPrescilo Nato Palor IVPas encore d'évaluation

- 1968 Building Code v1Document520 pages1968 Building Code v1mayukixdPas encore d'évaluation

- Architectural working detailsDocument38 pagesArchitectural working detailsArkitek HafadzPas encore d'évaluation

- Understanding Architectural Details - Book 1: SampleDocument47 pagesUnderstanding Architectural Details - Book 1: SampleAhmed FaraedoonPas encore d'évaluation

- Dreaming Creek Architectural Technical Specifications Timber FramesDocument151 pagesDreaming Creek Architectural Technical Specifications Timber FramesMat Gai100% (1)

- Robust Details Manual 2015Document463 pagesRobust Details Manual 2015Ben Beach100% (1)

- Ibeam CostructionDocument28 pagesIbeam CostructionJaco100% (3)

- Wall Sections-Built ExamplesDocument21 pagesWall Sections-Built ExamplesRoma Vadola100% (2)

- Construction Drawings Symbols and Conventions PDFDocument6 pagesConstruction Drawings Symbols and Conventions PDFRahul Singh BhartiPas encore d'évaluation

- BuildingDocument368 pagesBuildinganbertjonathanPas encore d'évaluation

- Types of Walls & Hatching PatternsDocument3 pagesTypes of Walls & Hatching PatternsBharathVenkatachalam0% (1)

- Low RiseResidentialConstructionDetailsDocument104 pagesLow RiseResidentialConstructionDetailsGeorgeEdwardPas encore d'évaluation

- 10.staircase DetailDocument1 page10.staircase Detailveer chhayaPas encore d'évaluation

- 100 Plans and Elevations Dhome MagazineDocument101 pages100 Plans and Elevations Dhome MagazinejoycePas encore d'évaluation

- Doors and Windows InstallationDocument84 pagesDoors and Windows InstallationKian InductivoPas encore d'évaluation

- Architects, Desginers and Certified TimberDocument6 pagesArchitects, Desginers and Certified TimberPEFC InternationalPas encore d'évaluation

- Roof DetailsDocument147 pagesRoof DetailsMartin FoxPas encore d'évaluation

- Roof Tile: Insulated Panel SystemDocument48 pagesRoof Tile: Insulated Panel SystemCormac DooleyPas encore d'évaluation

- Wood-Frame House Construction PDFDocument241 pagesWood-Frame House Construction PDFVio Gălan100% (1)

- Interior Hardware and Finishes GuideDocument7 pagesInterior Hardware and Finishes GuideDeepika RanaPas encore d'évaluation

- Abbreviation in ArchitectureDocument2 pagesAbbreviation in ArchitectureThai NguyenPas encore d'évaluation

- Perspective Rendering Five-12 Kitchen Design & Ceiling OptionsDocument6 pagesPerspective Rendering Five-12 Kitchen Design & Ceiling OptionsCarla GarchiPas encore d'évaluation

- Wood Frame House ConstructionDocument241 pagesWood Frame House Constructioneglyph100% (13)

- Andrews Watts Modern Construction Roofs PDFDocument194 pagesAndrews Watts Modern Construction Roofs PDFVăn NguyễnPas encore d'évaluation

- Kitchen and Bathroom Renovation GuideDocument79 pagesKitchen and Bathroom Renovation Guideuptotheminute100% (9)

- Residential Building ConstructionDocument434 pagesResidential Building Constructionvelarajan100% (21)

- KENT Year 5 1 20 Tower DetailingDocument1 pageKENT Year 5 1 20 Tower DetailingRalph KentPas encore d'évaluation

- Window Detail Scale1: 50: Front Elevation Scale 1: 100 Side Elevation Scale 1: 100Document1 pageWindow Detail Scale1: 50: Front Elevation Scale 1: 100 Side Elevation Scale 1: 100Themba Mhlanga MposekiePas encore d'évaluation

- Raised floor details for UPS and server roomsDocument1 pageRaised floor details for UPS and server roomsFaisal NasimPas encore d'évaluation

- Class Exercise DrawingDocument3 pagesClass Exercise DrawingMotheo MophulePas encore d'évaluation

- Specification and Estimation Assignment 2Document3 pagesSpecification and Estimation Assignment 2Ashwin RamadesikanPas encore d'évaluation

- Entebbe Perimeter FenceDocument1 pageEntebbe Perimeter Fenceapi-408492798Pas encore d'évaluation

- Type 1 - 43sqmDocument1 pageType 1 - 43sqmRandall MayPas encore d'évaluation

- Housing Blocks 1 and 2 Facade DetailsDocument4 pagesHousing Blocks 1 and 2 Facade DetailsMarius Timofte100% (1)

- BAUER Diaphragm and Cut Off WallsDocument16 pagesBAUER Diaphragm and Cut Off Wallsshahramk80100% (1)

- Materials Schedule for 1x3 Classroom Block ConstructionDocument5 pagesMaterials Schedule for 1x3 Classroom Block ConstructionEng Hinji Rudge100% (4)

- Finshing BOQ - RevDocument14 pagesFinshing BOQ - RevAmmar HattabPas encore d'évaluation

- Taking Off Internal Floor Finishes-Example (Updated200421)Document6 pagesTaking Off Internal Floor Finishes-Example (Updated200421)faizsyam01Pas encore d'évaluation

- Ali House Plan - Sheet - A104 - UnnamedDocument1 pageAli House Plan - Sheet - A104 - Unnamedmasumba patrickPas encore d'évaluation

- KNAUF 3.3.3 Timber Separating Walls PDFDocument10 pagesKNAUF 3.3.3 Timber Separating Walls PDFBrad RimmPas encore d'évaluation

- Renovation Works at Mr. Augustus Arkonor'S Residence at Adenta-Accra, GhanaDocument1 pageRenovation Works at Mr. Augustus Arkonor'S Residence at Adenta-Accra, GhanaNana BarimaPas encore d'évaluation

- Ye R. .NET MAUI Cross-Platform Application Development 2023Document400 pagesYe R. .NET MAUI Cross-Platform Application Development 2023Yuliyan Topalov100% (4)

- Bayesian Methods For The Physical Sciences - Learning From Examples in Astronomy and PhysicsDocument245 pagesBayesian Methods For The Physical Sciences - Learning From Examples in Astronomy and PhysicsGregorPas encore d'évaluation

- (Undergraduate Lecture Notes in Physics) Albrecht Lindner, Dieter Strauch - A Complete Course on Theoretical Physics_ From Classical Mechanics to Advanced Quantum Statistics-Springer International PubDocument655 pages(Undergraduate Lecture Notes in Physics) Albrecht Lindner, Dieter Strauch - A Complete Course on Theoretical Physics_ From Classical Mechanics to Advanced Quantum Statistics-Springer International PubJuan Felipe Bravo100% (11)

- Design of Timber Structures 3 2016Document64 pagesDesign of Timber Structures 3 2016GregorPas encore d'évaluation

- CMHC Canadian Wood-Frame House Construction 2014Document378 pagesCMHC Canadian Wood-Frame House Construction 2014purple_onionPas encore d'évaluation

- Design of Timber Structures 1 2016Document316 pagesDesign of Timber Structures 1 2016Gregor100% (1)

- CMHC GlossaryOfHousingTermsDocument205 pagesCMHC GlossaryOfHousingTermsDaniel HardyPas encore d'évaluation

- Design of Timber Structures 2 2016Document64 pagesDesign of Timber Structures 2 2016GregorPas encore d'évaluation

- CMHC - About Your HouseDocument10 pagesCMHC - About Your HouseGregorPas encore d'évaluation

- Creating A Timber Frame House v1Document77 pagesCreating A Timber Frame House v1Gregor100% (2)

- DI79Document1 pageDI79Erln LimaPas encore d'évaluation

- Thyristor Bridge, SCR, Bridge: Stud DiodeDocument3 pagesThyristor Bridge, SCR, Bridge: Stud Diodesergio honoresPas encore d'évaluation

- EB27A construction hintsDocument8 pagesEB27A construction hintsPisu Miau Pisu MiauPas encore d'évaluation

- Maitriya Foundation Nepal: Summary of CostDocument62 pagesMaitriya Foundation Nepal: Summary of CostRoshan KejariwalPas encore d'évaluation

- VSFDDocument3 pagesVSFDZheng LongPas encore d'évaluation

- Lecture Notes: Switchgear and ProtectionDocument20 pagesLecture Notes: Switchgear and ProtectionMohammed AL-MaaitahPas encore d'évaluation

- Pinout PCM 2Document6 pagesPinout PCM 2Gạt Tàn ĐầyPas encore d'évaluation

- P1icic03 Ic Engines SyllabusDocument8 pagesP1icic03 Ic Engines SyllabusSriramulu JaichandarPas encore d'évaluation

- KNX House & Building Automation Smart Home Luxorliving PreciseDocument401 pagesKNX House & Building Automation Smart Home Luxorliving PreciseShine VasanthPas encore d'évaluation

- Short Circuit IEC For Electrical PractitionerDocument27 pagesShort Circuit IEC For Electrical PractitionerJOHN PAUL JAVIERPas encore d'évaluation

- Metasol MC E 170915Document188 pagesMetasol MC E 170915Ashby KbPas encore d'évaluation

- 400kV Line Relay SettingDocument50 pages400kV Line Relay Settingmv_mallik100% (3)

- Elc 202 Module 1Document28 pagesElc 202 Module 1maxene jadePas encore d'évaluation

- Diode Ratings - How To Understand A Diode DatasheetDocument9 pagesDiode Ratings - How To Understand A Diode DatasheetcesarinigillasPas encore d'évaluation

- Most Enhanced Lighting Solution: EntecDocument10 pagesMost Enhanced Lighting Solution: EntecAdib Darul QuthniPas encore d'évaluation

- High Voltage SubstationDocument25 pagesHigh Voltage SubstationRavi Kumar PabbuPas encore d'évaluation

- Spoke Wheel HubDocument5 pagesSpoke Wheel Hubgestada023Pas encore d'évaluation

- Omron SRS1TDocument4 pagesOmron SRS1TtetsPas encore d'évaluation

- D2n Relay: The Best Rela TionDocument11 pagesD2n Relay: The Best Rela TionИгорьPas encore d'évaluation

- Weights and Loads - ElfaDocument2 pagesWeights and Loads - ElfaEtibar AliyevPas encore d'évaluation

- Roofing Fixer 5 J-Bolt To Purlin & G.I Sheet Connection Detail 6 Anchor Bolt Detail 2Document1 pageRoofing Fixer 5 J-Bolt To Purlin & G.I Sheet Connection Detail 6 Anchor Bolt Detail 2John michael Del rosarioPas encore d'évaluation

- Manual Cumins OnanDocument170 pagesManual Cumins OnanFelipe Uzabal100% (1)

- Upvc File MDocument19 pagesUpvc File Mmustafagillani2021Pas encore d'évaluation

- Electrical Wire Hardness, CATIADocument28 pagesElectrical Wire Hardness, CATIArmsh301Pas encore d'évaluation

- HVSI804T WGD 83Document6 pagesHVSI804T WGD 83mnezamiPas encore d'évaluation

- Outdoor wall lights provide energy-efficient illuminationDocument1 pageOutdoor wall lights provide energy-efficient illuminationYasser FathiPas encore d'évaluation

- Engine Control System PDFDocument1 300 pagesEngine Control System PDFAriel Mercocha100% (2)

- ITT American Electric Contempo Post Top Series 245 & 246 Spec Sheet 3-81Document8 pagesITT American Electric Contempo Post Top Series 245 & 246 Spec Sheet 3-81Alan MastersPas encore d'évaluation

- Replacing2 The Diode Pack On A Denso AlternatorDocument7 pagesReplacing2 The Diode Pack On A Denso AlternatorKirkPas encore d'évaluation

- 40/60 2Document139 pages40/60 2አአ መ. ብ. ኤ.99% (75)