Académique Documents

Professionnel Documents

Culture Documents

Machine Maintenance

Transféré par

Moustafa Mahmoud0 évaluation0% ont trouvé ce document utile (0 vote)

21 vues2 pagesMachine Maintenance

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentMachine Maintenance

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

21 vues2 pagesMachine Maintenance

Transféré par

Moustafa MahmoudMachine Maintenance

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

:Machine Maintenance ****

Introduction to machine elements -1

Introduction to Maintenance and Maintenance types -2

Maintenance costs and decision making -3

Maintenance management systems -4

)Breakdown vs preventive Maintenance and its applications (vibration analysis -5

Maintenance and reliability -6

)Total productive maintenance (TPM -7

Maintenance & Rotating Equipment Operation****

-:)Prime Movers Equipment & Objective one ( Fluid

:Pumps

maintenance & Pumps Theory, types, operation -

Centrifugal pumps workshop (Advanced centrifugal pump maintenance, repair and -

)overhaul

:Compressors

.maintenance & Compressors Theory, types, operation -

Overhaul & Reciprocating) maintenance & Compressors (Centrifugal -

: Gas Turbine

.Cycles & Gas Turbine Theory -

Advanced Gas turbine Operation and Maintenance -

-:)Objective Two ( Machine Elements

:Bearing

.Bearing Classification, identification, removal, installation and lubrication -

.Select the correct anti-friction bearing for a specific application -

.Learn how to perform the bearing maintenance and monitoring -

Seals

.Type of shaft seals -

.Basic Parts of mechanical seal -

.Pumps and Compressors Sealing-

:Lubrication

;Function of lubricants & Types-

;Proper lubricant minimizes wear-

;Viscosity of lubricants and the implications of varying viscosity-

. Why keeping the lubricating oil clean during storage-

The need to use the proper oil when lubricating equipment-

CMMS****

Introduction to Maintenance Management Systems .1

Functions of a typical Computerized Maintenance Management System .2

Maintenance Work Management .3

CMMS Life Cycle .4

CMMS Applications Review and Practice Exercise .5

PM Master Plan .6

Vous aimerez peut-être aussi

- Machine MaintenanceDocument2 pagesMachine MaintenanceMoustafa MahmoudPas encore d'évaluation

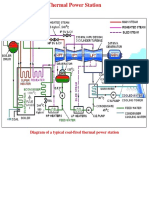

- Thermal Power Plant PDFDocument16 pagesThermal Power Plant PDFMoustafa MahmoudPas encore d'évaluation

- Thermal Power Plant PDFDocument16 pagesThermal Power Plant PDFMoustafa MahmoudPas encore d'évaluation

- Thermal Power Plant PDFDocument16 pagesThermal Power Plant PDFMoustafa MahmoudPas encore d'évaluation

- Thermal Power Plant PDFDocument16 pagesThermal Power Plant PDFMoustafa MahmoudPas encore d'évaluation

- SM Mass CommunicationDocument61 pagesSM Mass CommunicationpufuPas encore d'évaluation

- Basic Principles of Motor Controls: Unit 1-IntroductionDocument8 pagesBasic Principles of Motor Controls: Unit 1-IntroductionMoustafa MahmoudPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- MUFY Lesson Plan PhysicsDocument15 pagesMUFY Lesson Plan Physicsbookdotcom7221100% (1)

- Air Rifle Pellet Weights and Ballistic CoefficientsDocument4 pagesAir Rifle Pellet Weights and Ballistic Coefficientscharles blairPas encore d'évaluation

- ASA - Temperature Sensor - ILLZTT5069K - enDocument1 pageASA - Temperature Sensor - ILLZTT5069K - enKrum KashavarovPas encore d'évaluation

- Laser Telemetric SystemDocument2 pagesLaser Telemetric Systemdellibabu509Pas encore d'évaluation

- Solid State RF GeneratorDocument19 pagesSolid State RF GeneratorVaishali PatelPas encore d'évaluation

- C311 HMTDocument9 pagesC311 HMTGajendran A MECH KIOTPas encore d'évaluation

- Process Control FundamentalsDocument59 pagesProcess Control Fundamentalsaanouar77Pas encore d'évaluation

- En 10164-1993Document8 pagesEn 10164-1993Marija IvanovskaPas encore d'évaluation

- Introductory Physics: Classical Mechanics (Summary of Equations)Document6 pagesIntroductory Physics: Classical Mechanics (Summary of Equations)cra18100% (1)

- Soil ESE NotejDocument34 pagesSoil ESE NotejTarun100% (3)

- Unit 5Document48 pagesUnit 5rathiPas encore d'évaluation

- Study On The Effect of Ceria Concentration On The Silicon Oxide Removal Rate in Chemical Mechanical PlanarizationDocument18 pagesStudy On The Effect of Ceria Concentration On The Silicon Oxide Removal Rate in Chemical Mechanical PlanarizationAverage JoePas encore d'évaluation

- Comprehensive Fin Tube CatalogueDocument39 pagesComprehensive Fin Tube Cataloguemohammed moussPas encore d'évaluation

- Visible Spectra of Soft DrinksDocument6 pagesVisible Spectra of Soft Drinksfatin harris100% (1)

- Li Et Al 2006Document8 pagesLi Et Al 2006Ishu NuwaPas encore d'évaluation

- Seismic Story Shear Calculation StaadDocument23 pagesSeismic Story Shear Calculation StaadRajendra KamblePas encore d'évaluation

- IRJET Experimental Investigations of Double Pipe Heat Exchanger With Triangular Baffles PDFDocument5 pagesIRJET Experimental Investigations of Double Pipe Heat Exchanger With Triangular Baffles PDFRidhoQodriPas encore d'évaluation

- If The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1Document8 pagesIf The Misalignment Between The Head and Shell in A Pressure Vessel Exceeds The ASME Requirement1yogacruisePas encore d'évaluation

- BitumenDocument35 pagesBitumenamanbhu1991100% (5)

- Asmeptc19 3 04Document142 pagesAsmeptc19 3 04Angel LunaPas encore d'évaluation

- Transient Heat Transfer in PCM Particle Based CompositesDocument11 pagesTransient Heat Transfer in PCM Particle Based CompositesTấn PhạmPas encore d'évaluation

- OMNICELLDocument4 pagesOMNICELLOnn WongPas encore d'évaluation

- EET 3153: Physical Electronics: Job Kerosi EmailDocument77 pagesEET 3153: Physical Electronics: Job Kerosi EmailOdhiambo MeshackPas encore d'évaluation

- 2Document13 pages2VNSAramakiPas encore d'évaluation

- States of Matter (Gaseous & Liquid) : Gaseous State: Measurable Properties of Gases Gas Laws - Boyle's LawDocument6 pagesStates of Matter (Gaseous & Liquid) : Gaseous State: Measurable Properties of Gases Gas Laws - Boyle's LawIhtisham Ul HaqPas encore d'évaluation

- TEWI AnalysisDocument63 pagesTEWI Analysismirali74Pas encore d'évaluation

- 8 - Chemical FloodingDocument76 pages8 - Chemical FloodingSyafrina Putri100% (3)

- Diode XPDocument4 pagesDiode XPKaasamHarishKumarPas encore d'évaluation

- P-17004 - Final Report - Bearing LP Turbine 3&4Document18 pagesP-17004 - Final Report - Bearing LP Turbine 3&4Komang Khrisna Satya NarayanaPas encore d'évaluation

- Launch Vehicle Cavity Venting: Modeling Concepts & ValidationDocument16 pagesLaunch Vehicle Cavity Venting: Modeling Concepts & ValidationDimal PatelPas encore d'évaluation