Académique Documents

Professionnel Documents

Culture Documents

Small Drip Legs Cause Big Problem

Transféré par

JohnTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Small Drip Legs Cause Big Problem

Transféré par

JohnDroits d'auteur :

Formats disponibles

Carefully designed drip legs enable steam traps to

properly drain condensate from mains

stream as it forms on pipe walls. These water able to use a steam separator to provide flow

droplets are carried along, mixed with steam, reduction, and drain with an adequate drip

at velocities that can exceed 100 mph. To sep- leg.

arate the condensate from high-velocity If condensate accumulates in the flowing

steam, the drip leg must be large enough to steam, it reduces steam quality. This reduces

provide expansion in the flow area, reducing the amount of heat transferred from the steam

gas velocity and allowing condensate to drop delivered downstream and increases operat-

out. If the drip leg is not large enough, the ing costs. The erosive force of condensate

pressure drop created at the interface of the droplets being whipped along at 100 mph is

steam line and the drip leg draws condensate roughly analogous to a major hurricane. As

out of the drip leg and steam trap. In applica- pipe walls and heat exchanger surfaces are

tions where dry steam is essential, it is prefer- eroded by the water blast, they begin to leak

or fail. Control valves, ends of mains, and

Recommended Steam Main and expansion loops also become eroded and

Branch Line Drip Leg Sizing eventually fail when subjected to these forces.

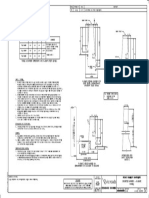

M D H Drip Leg Design

-- ~ ,: Oflfi~C~g:~r;~nQth_,-;:-_-~J~~, :J.J1-~: Given these three flow dynamics, it is

Steam Main Drip '-~g Supervi$ed Automatic · obvious that, to be effective, a drip leg must

Size, in.··.. Dic:tmeter, in. Warlll-Up Warm-.Up be as carefully designed as the rest of the

steam system. Following a few simple sizing

~ 10 28 guidelines enables the steam trap to drain

% 10 28 condensate from the main throughout the

1 10 28 operating cycle of any steam system.

2 2 10 28 In general, for steam mains up to 4 in. in

10 28

diameter, the drip leg should be constructed

3 3

from the same size pipe as the main. For

4 4 10 28 steam mains larger than 4 in., the drip leg

6 4 10 28 should be half the diameter of the main but

8 4 12 28 never less than 4 in. The distance from the

10 6 15 28 bottom of the main to the top of the trap, in

12 6 18 28 inches, divided by 28 yields the amount of sta-

14 8 21 28 tic head, in psi, available to push condensate

Fig. 4. Drip legs 16 8 24 28 through the trap on startup. The accompany-

must be large 18 10 27 28 ing table gives recommendations for sizing of

enough to allow 20 10 30 30 steam mains and branch drip legs when the

condensate to drop trap discharges to a gravity return.

out of the stream at 24 12 36 36 On automatic startup, when return lines are

the pipe bottom. elevated or pressurized, special precautions

should be taken to prevent flooding. The best

method is to collect the trap discharge in a

Effect Of Drip Leg Size nonpressurized receiver and use a pump or a

pumping trap to raise condensate or overcome

back pressure.

The best way to trap drip legs is by using an

inverted bucket (LB.) steam trap. This trap

effectively handles accumulations of dirt and

slugs of condensate. The I.B. trap drains con-

densate as it forms, has low maintenance

requirements, and has a long operating life. If

the trap does fail, it usually fails open, pre-

cluding system flooding and dangerous water

hammer.

Reprinted from PLANT ENGINEERING September 9, 1993

© 1993 by CAHNERS PUBLISHING COMPANY

Eliminating Condensate Pools

preferably beyond the point of change in Right

direction, at the end of mains, ahead of expan-

sion joints or bends, and ahead of valves or

regulators.

After choosing the proper location, drip

legs must be designed so condensate freely

enters throughout the operating cycle of the

system. During normal operation, any steam

system is subject to one or more conditions

that must be taken into account in the sizing Eccentric Reducer Coupling

of drip legs to avoid problems.

Startup Conditions

During startup, high condensate loads are

created when steam condenses after encoun-

tering cool piping and equipment. At the same

time, the high condensing rate leaves little

steam pressure in the piping. If the system is

well designed, gravity pulls condensate into

the drip leg. On supervised startups, a valve is Concentric Reducer Coupling

manually opened to drain and gravity alone is

adequate to drain condensate.

On automatic startups, however, there may sate stream is allowed to build to sufficient Fig. 2. An eccentric reduc-

not be sufficient differential pressure to pro- levels in the pipe, waves are formed on the er precludes the forming of

vide flow through a steam trap orifice. In surface by gases passing above at a relatively a condensate pool that can

these cases, the drip leg must be sufficiently high velocity. These waves can rise and block form behind a concentric

long to provide the necessary static head the entire pipe. With system pressure reducer.

(dimension H, Fig. 3) to push condensate upstream of this slug, and collapsing steam

through the trap. downstream, the slug is accelerated in the

There are applications where condensate pipe and can reach velocities as high as 90

must be lifted. The drip leg must provide mph. A great deal of damage can be done to

ample volume for water to accumulate until piping and equipment when a slug is forced to

there is sufficient pressure to elevate conden- stop or change direction. Fig. 3. Typical trap-drain-

sate to the level of the return (about 1 psi for ing drip leg is installed on

every 2 ft of lift). Entrained Flow Conditions steam main. Values forM, D,

If the system is not properly drained, it In low-load, high-velocity service, most of and H are provided in the

takes an excessive amount of time to reach the condensate is picked up by the passing gas table on the next page.

operating temperature, increasing operating

costs. Insufficient drainage during startup can

result in live steam being injected into pock- Trap Draining Drip Leg

ets of cool condensate, creating thermal

shock, a form of water hammer.

Perimeter Flow Conditions

With relatively large condensate loads and

lower velocities, commonly found in low

pressure, modulated heating systems or

upstream of any control valves, condensate

flow usually takes place on inside pipe walls.

Stearn constantly condenses on the wall of the

t

H

pipe and flows by gravity to the bottom where

it forms a stream that is pushed along by the

forces of gravity and friction with gas flowing

over its surface. The drip leg must be sized so

the entire stream is drained away as it flows

J

over the top of the opening. Partial drainage

is likely when the common practice of "hot

tapping" a small pipe into the steam main is

used to provide a drip leg (Fig. 4).

As the condensate stream flows past each

drip station, it accumulates and robs the pipe

of steam space and the steam of some of its

heat, increasing operating cost. If the conden-

Vous aimerez peut-être aussi

- Complete ComparisonDocument22 pagesComplete ComparisonMalcolm DadinaPas encore d'évaluation

- Piping Design Articles by Robert Kern PDFDocument53 pagesPiping Design Articles by Robert Kern PDFDiego IQ100% (1)

- Water Hammer in Steam LinesDocument5 pagesWater Hammer in Steam LinesVijaita Vikas GandhiPas encore d'évaluation

- 560 000 GC P 009Document36 pages560 000 GC P 009wesqui100% (1)

- PipingDocument15 pagesPipingPoonam Ashwin100% (1)

- Ship Structural StrengthDocument13 pagesShip Structural StrengthZhihao LiPas encore d'évaluation

- (510-C-002) PDS For Absorber I - R0Document14 pages(510-C-002) PDS For Absorber I - R0idilfitriPas encore d'évaluation

- Saw PlansDocument19 pagesSaw PlansAnthony TwardowskiPas encore d'évaluation

- ICM-SU-5102-C.3 - Control ValvesDocument67 pagesICM-SU-5102-C.3 - Control ValvesShivani DubeyPas encore d'évaluation

- Pi Ups 1004Document39 pagesPi Ups 1004JOEL ARNAO CORTEGANAPas encore d'évaluation

- MSS SP90Document26 pagesMSS SP90Andres Camilo BenitezPas encore d'évaluation

- Class M1C2Document10 pagesClass M1C2SalimPas encore d'évaluation

- 14.4.sizing Condensate Return LinesDocument18 pages14.4.sizing Condensate Return LinesBayu100% (1)

- BS StandardsDocument13 pagesBS StandardsShyam Prasad K S100% (3)

- New Sulfur Melting Technology Mark Gilbreath - USADocument51 pagesNew Sulfur Melting Technology Mark Gilbreath - USARenalyn Torio100% (1)

- Weld Flange To PipeDocument1 pageWeld Flange To PipeGraham MoorePas encore d'évaluation

- Praxair en 55Document34 pagesPraxair en 55StefanoPas encore d'évaluation

- Toyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpDocument4 pagesToyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpNicolas Celis Perez100% (1)

- Caepipe: TutorialDocument42 pagesCaepipe: TutorialCharles FariasPas encore d'évaluation

- Piping Material ClassesDocument98 pagesPiping Material ClassesLuis Pottozen VillanuevaPas encore d'évaluation

- 1.0 Scope: Welding of Carbon Steel PipingDocument3 pages1.0 Scope: Welding of Carbon Steel PipingandhucaosPas encore d'évaluation

- C 10flangesDocument11 pagesC 10flangesrajesh119100% (1)

- Piping Class SpecificationDocument6 pagesPiping Class Specificationcitra puspita sariPas encore d'évaluation

- AB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersDocument1 pageAB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersTrung NguyenPas encore d'évaluation

- Autodesk Navisworks Manage 2011 User Guide PDFDocument536 pagesAutodesk Navisworks Manage 2011 User Guide PDFkuttyPas encore d'évaluation

- Hoffman Specialty Steam Traps: - Application - Selection - Installation - Piping DiagramsDocument50 pagesHoffman Specialty Steam Traps: - Application - Selection - Installation - Piping DiagramsPrashant SinghPas encore d'évaluation

- StallDocument16 pagesStallbhalchandrak1867100% (1)

- Plant Layout-CompressorsDocument19 pagesPlant Layout-Compressorshalder_kalyan9216Pas encore d'évaluation

- Conveyor Belt Catalog 2010Document50 pagesConveyor Belt Catalog 2010ganesh_350% (2)

- Durco Pressure Leaf Sulfur FiltrationDocument3 pagesDurco Pressure Leaf Sulfur FiltrationBhusarapu SrinivasPas encore d'évaluation

- New - Lecture 2 Introduction To S&TDocument31 pagesNew - Lecture 2 Introduction To S&TWael ElArinyPas encore d'évaluation

- FW Utility Boiler PDFDocument12 pagesFW Utility Boiler PDFChandan AulakhPas encore d'évaluation

- Uf FloatingDocument20 pagesUf Floatingmhidayat108100% (1)

- 943025-806 Strainers Rev01Document3 pages943025-806 Strainers Rev01studyendlessPas encore d'évaluation

- Safety Procedures in ConstructionDocument21 pagesSafety Procedures in ConstructionMalith De Silva100% (1)

- ST104 FinalforPosting2018Document5 pagesST104 FinalforPosting2018imtinanPas encore d'évaluation

- Rotary Dryer Handbook PDFDocument34 pagesRotary Dryer Handbook PDFNichol Salas ManioPas encore d'évaluation

- C2 - RevADocument16 pagesC2 - RevAChirag ShahPas encore d'évaluation

- Unit Operations Thumb RulesDocument9 pagesUnit Operations Thumb RuleshibhavuPas encore d'évaluation

- Steam Traps - Engineering Data ManualDocument50 pagesSteam Traps - Engineering Data ManualThitikorn Wassanarpheernphong100% (1)

- Steam TurbinesDocument83 pagesSteam Turbinesvasudev palaganiPas encore d'évaluation

- Advanced Reading Guide To The Selection BP Rp44-11Document54 pagesAdvanced Reading Guide To The Selection BP Rp44-11vicopip100% (1)

- Zinq - AnalysisDocument116 pagesZinq - AnalysisAimiPas encore d'évaluation

- 4.11.4 Steam Pipe Sizing and DesignDocument3 pages4.11.4 Steam Pipe Sizing and DesignSaurabh VijPas encore d'évaluation

- Steam Mains and Drainage Module 10.3 Block 10 Steam DistributionDocument14 pagesSteam Mains and Drainage Module 10.3 Block 10 Steam DistributionTushar LanjekarPas encore d'évaluation

- Slideshow What Your Screw Designer Never Told You.Document39 pagesSlideshow What Your Screw Designer Never Told You.tabassimPas encore d'évaluation

- Granulation of MAPDocument3 pagesGranulation of MAPIrvan Key RizkyPas encore d'évaluation

- SulphurDocument3 pagesSulphurbonda_gtvPas encore d'évaluation

- The Rotary DryerDocument1 pageThe Rotary DryerAulia RahmaturPas encore d'évaluation

- Engineering Standard - Piping Material Specification - Table of Contents PDFDocument3 pagesEngineering Standard - Piping Material Specification - Table of Contents PDFSoniPas encore d'évaluation

- MD 510 0000 Eg Pi SPC 0004Document17 pagesMD 510 0000 Eg Pi SPC 0004SathishkumarPas encore d'évaluation

- ClydeBergemannSootblowers PrinceGeorge06Document36 pagesClydeBergemannSootblowers PrinceGeorge06Arun YogaPas encore d'évaluation

- Bomba SihiDocument24 pagesBomba SihiCristian PovedaPas encore d'évaluation

- Vertical Flash TankDocument2 pagesVertical Flash Tankkingathur26681Pas encore d'évaluation

- Belt Tensioning Methods For Small Package ConveyorsDocument13 pagesBelt Tensioning Methods For Small Package ConveyorsAdin SoftićPas encore d'évaluation

- AIChE 2018 Improving Catalytic Reformer Heaters Using Split Flow TechnologyDocument31 pagesAIChE 2018 Improving Catalytic Reformer Heaters Using Split Flow Technologyashutosh_garg_10Pas encore d'évaluation

- 400 Shell and Tube Exchanger Design and Selection: Chevron Corporation 400-1 December 1989Document22 pages400 Shell and Tube Exchanger Design and Selection: Chevron Corporation 400-1 December 1989Esteban CastellanoPas encore d'évaluation

- Regulator Control Valves - Series 5000Document12 pagesRegulator Control Valves - Series 5000Miriam bragaPas encore d'évaluation

- Corrosion Resistance of Nickel-Containing Alloys in Phosphoric Acid (CEB-4)Document41 pagesCorrosion Resistance of Nickel-Containing Alloys in Phosphoric Acid (CEB-4)GagrigorePas encore d'évaluation

- Heat Exchanger Reference TheoryDocument23 pagesHeat Exchanger Reference TheoryMurugan VeluPas encore d'évaluation

- Design Handbooks Table of ContentsDocument1 pageDesign Handbooks Table of ContentsForcus onPas encore d'évaluation

- Symphos-Devco Presentation May 2015 FinalDocument51 pagesSymphos-Devco Presentation May 2015 FinalIrsan Bin MustaminPas encore d'évaluation

- FFM800 Surge Pressure PDFDocument7 pagesFFM800 Surge Pressure PDFThiruThirunavukkarasuPas encore d'évaluation

- Steam Trap Vs Steam SeparatorDocument2 pagesSteam Trap Vs Steam Separatorsaxadi4814Pas encore d'évaluation

- Small Drip Legs Cause Big ProblemDocument1 pageSmall Drip Legs Cause Big ProblemJohnPas encore d'évaluation

- Steam Mains and Drainage: Piping LayoutDocument11 pagesSteam Mains and Drainage: Piping Layouthej hejPas encore d'évaluation

- Column Design Ecp203 VS Aci VS BS8110Document37 pagesColumn Design Ecp203 VS Aci VS BS8110MAPas encore d'évaluation

- Devi Heating CalculationDocument2 pagesDevi Heating CalculationJohn AriesPas encore d'évaluation

- Metal Ceramic Crown Lab ManualDocument25 pagesMetal Ceramic Crown Lab ManualchusbPas encore d'évaluation

- General Principles of Foundation Design: To Prepare A Plan of The Base of The StructureDocument119 pagesGeneral Principles of Foundation Design: To Prepare A Plan of The Base of The StructureTashi TamangPas encore d'évaluation

- Feed 8Document15 pagesFeed 8TAHER AMMARPas encore d'évaluation

- 00 AWWA StandardsDocument3 pages00 AWWA Standardsliviu_dovaPas encore d'évaluation

- Axial Capacity of Pile FoundationDocument32 pagesAxial Capacity of Pile FoundationChowdhury Priodeep100% (1)

- Thesis RCCDocument16 pagesThesis RCCcricketloversiitPas encore d'évaluation

- Casing WellDocument26 pagesCasing Wellزين العابدين هيثم لفته جابرPas encore d'évaluation

- Metal: Ferrous and Mild SteelDocument74 pagesMetal: Ferrous and Mild SteelRoshan MauryaPas encore d'évaluation

- Statement of Account (Soa)Document8 pagesStatement of Account (Soa)dexter guanzon serotPas encore d'évaluation

- SSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurDocument6 pagesSSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurMohit DagaPas encore d'évaluation

- Finishes 4 - ExternalDocument24 pagesFinishes 4 - ExternalMuhammad FakhriPas encore d'évaluation

- Development of A Device For Brazing Copper Pipes in HVAC InstallationsDocument8 pagesDevelopment of A Device For Brazing Copper Pipes in HVAC InstallationsJournal of Interdisciplinary PerspectivesPas encore d'évaluation

- Lab ReportDocument2 pagesLab ReportNayhomi PenaPas encore d'évaluation

- AEC CatalogeDocument156 pagesAEC CatalogeSanjiv ShahPas encore d'évaluation

- JIS FlangesDocument9 pagesJIS FlangesKhairulUmamPas encore d'évaluation

- 3.3 Replacement Analysis and Sensitivity AnalysisDocument5 pages3.3 Replacement Analysis and Sensitivity Analysisrobel popPas encore d'évaluation

- Forming AnalysisDocument8 pagesForming AnalysisShanu KumarPas encore d'évaluation

- Finite Element Based Dynamic Analysis of Multilayer Fibre Composite Sandwich Plates With Interlayer DelaminationsDocument14 pagesFinite Element Based Dynamic Analysis of Multilayer Fibre Composite Sandwich Plates With Interlayer DelaminationsAhmet EcevitPas encore d'évaluation

- De La Cruz, J. C., Del Campo, J. M., & Colorado, D. (Mayo de 2014)Document7 pagesDe La Cruz, J. C., Del Campo, J. M., & Colorado, D. (Mayo de 2014)Jorge GonzalezPas encore d'évaluation

- Standard Drawing 3901 Concrete Barriers F Shape Profile May 2019Document1 pageStandard Drawing 3901 Concrete Barriers F Shape Profile May 2019Amr Adel HameedPas encore d'évaluation

- BG153 Rev 1Document1 pageBG153 Rev 1SyPas encore d'évaluation

- FP 400e-3dc PDFDocument4 pagesFP 400e-3dc PDFTessa CHPas encore d'évaluation