Académique Documents

Professionnel Documents

Culture Documents

Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL Procedure

Transféré par

Prashant PuriTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL Procedure

Transféré par

Prashant PuriDroits d'auteur :

Formats disponibles

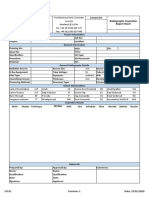

Electrode Brad qualification procedure as per ASME section II part c along with

NPCIL Procedure

Part A Activities part

Sr. Type of test/ As per ASME Sec-II C SFA E 7018 – E 8018-B2 E 9018- Remark

No. activities 5.5 (Low alloy steel A1 B3

electrode)

1 Draw electrode Min two size

sample from Stock of electrode to

list. be selected

(Normally take last (4mm & 5mm)

three month list.)

2 Selected electrode Check oven

put into oven for calibration and

backing backing

temperature&

time

3 Test piece Dimension Require as per Base A387 Grade A387 Separate sheet

and material TC material 11 Grade 11 for each

clause No 9& for A204 grade or 22 L electrode

base material A

selection as per

table no 6

4 Preparation of test As per table no 5

requirement sheet

4 Chemical test Require as per for 4 mm for 4 mm for 4 mm Type of

only as only as per only as current:- AC or

clause No 9.3 and per table table no 5 per table DC

Table no 2 for 4 no 5 no 5

mm only as per

table no 5

Mechanical Required as per As per As per Table As per Type of

Table No 3 No 3 & Table No current:- AC or

Test clause No 9.1 & PWHT (as 3& DC

(All Weld test) prepare as per fig PWHT (as per table no AW (E

per table 7) 9018 M *)

no 4 no 7)

(Two test for each

As per Table no 3)

(AC or DC)

Radiographic Required as per clause No 11 table no 9 table no 9 table no 9

, table no 9 Grade 1 Grade 1 Grade 1 Grade 1

Test

Fillet weld ( For 4 mm Dai As per As per table As per Type of

table no 8 no 8 table no 8 current:- AC or

Test electrod V & OH DC

and for 5 mm Dia

Only H) as per table

8 (other size can

also done)

Impact test To be done for

Reporting purpose(

Value not

mentioned) as per

Table No 04

Dimension (Standard Length

and size, Core wire

and covering,

Exposed core

gripping Size) as per

Cl. No 19, 20& 21.

Table no 13

IGC Test Not Required

Moisture Test As per Clause no 15

table 11 and AWS A

4.4 M

Diffusible As per Clause no 17

Hydrogen Test table 12 and AWS A

4.3

Part B documents review

Documents to be reviewed as per NPCIL Procedure welding Consumables (Procedure No. QAD/Proc./Welding

Consumables/002, R1).

Sr. no Activities Remark

1 All equipment calibration documents

2 RT qualified person certificate

3 Inward material control Process As per NPCIL procedure

4 In process control As per NPCIL procedure

5 Finish product control As per NPCIL procedure

6 Stage 1 and Stage 2 documents As per NPCIL procedure

7 Audit as per check sheet As per audit report

Vous aimerez peut-être aussi

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibPas encore d'évaluation

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónPas encore d'évaluation

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaPas encore d'évaluation

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTAPas encore d'évaluation

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTPas encore d'évaluation

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387Pas encore d'évaluation

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepPas encore d'évaluation

- Fit Up ReportDocument5 pagesFit Up ReportAkash Singh Tomar100% (1)

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingPas encore d'évaluation

- ASME IX QW (Welding General Requirements)Document12 pagesASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- Dissimilar Base Metal ThicknessDocument5 pagesDissimilar Base Metal ThicknessFERNANDO MIRANDA100% (2)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasPas encore d'évaluation

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraPas encore d'évaluation

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghPas encore d'évaluation

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadPas encore d'évaluation

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizPas encore d'évaluation

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyPas encore d'évaluation

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 pagesWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabPas encore d'évaluation

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorPas encore d'évaluation

- WPS SUMMARYDocument10 pagesWPS SUMMARYbhavin178Pas encore d'évaluation

- NPCIL Tube Fitting SpecificationsDocument22 pagesNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiPas encore d'évaluation

- 202 1sp 0 Saw Cs CsDocument8 pages202 1sp 0 Saw Cs CskrishimaPas encore d'évaluation

- WPQ WELDER PERFORMANCE QUALIFICATIONDocument2 pagesWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasPas encore d'évaluation

- Clad PQRDocument5 pagesClad PQRRinshadPas encore d'évaluation

- Flans ASME B16.5 PDFDocument47 pagesFlans ASME B16.5 PDFMircea Dan StanciuPas encore d'évaluation

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaPas encore d'évaluation

- SNIS UT 578 - Steel PlatesDocument14 pagesSNIS UT 578 - Steel PlatesShailesh DeshmukhPas encore d'évaluation

- API 577: Tube-to-Tubesheet Welding Procedures and Welder QualificationsDocument1 pageAPI 577: Tube-to-Tubesheet Welding Procedures and Welder Qualificationsramzi5ben5ahmedPas encore d'évaluation

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberPas encore d'évaluation

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welder Qualification Form for Rana Pratap ChouhanDocument1 pageWelder Qualification Form for Rana Pratap ChouhanMahendra singhPas encore d'évaluation

- SS WPSDocument1 pageSS WPSMOHAMEDABBASPas encore d'évaluation

- Difference Between ASTM A435 and ASTM A578Document1 pageDifference Between ASTM A435 and ASTM A578Vijay BedakihalePas encore d'évaluation

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirPas encore d'évaluation

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedPas encore d'évaluation

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYPas encore d'évaluation

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusPas encore d'évaluation

- 4260Document10 pages4260Lipika GayenPas encore d'évaluation

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraPas encore d'évaluation

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcPas encore d'évaluation

- Radiographic Inspection Report SheetDocument1 pageRadiographic Inspection Report SheetMike BoyesPas encore d'évaluation

- Welder Qualification Test RequestDocument1 pageWelder Qualification Test RequestgoguluPas encore d'évaluation

- Aws d1.1 Tubular Vs Non TubularDocument1 pageAws d1.1 Tubular Vs Non TubularrendraPas encore d'évaluation

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Sample API 1104 WpsDocument3 pagesSample API 1104 WpsMuhammadShabbir0% (1)

- Long Seam and Circumference Seam SetupDocument4 pagesLong Seam and Circumference Seam Setuppriti kumariPas encore d'évaluation

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarPas encore d'évaluation

- ASME V Article 7 Magnetic Particle ExaminationDocument1 pageASME V Article 7 Magnetic Particle ExaminationAmanda Ariesta Aprilia100% (4)

- Magnetic Particle Testing Report SummaryDocument4 pagesMagnetic Particle Testing Report Summarypankaj ranaPas encore d'évaluation

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriPas encore d'évaluation

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- BHEL, Tiruchirapalli-620014. Quality Assurance TECHNICAL DELIVERY CONDITION Product: Steel Castings. (Valves)Document7 pagesBHEL, Tiruchirapalli-620014. Quality Assurance TECHNICAL DELIVERY CONDITION Product: Steel Castings. (Valves)abdulPas encore d'évaluation

- BHEL steel casting technical delivery conditionsDocument7 pagesBHEL steel casting technical delivery conditionspl_arunachalam79Pas encore d'évaluation

- BHEL steel casting technical delivery conditionsDocument6 pagesBHEL steel casting technical delivery conditionsalex hutaurukPas encore d'évaluation

- 150kV Outdoor Current Transformer Technical SpecificationsDocument45 pages150kV Outdoor Current Transformer Technical SpecificationsNAM PHẠM LÊPas encore d'évaluation

- PM IS 14399 Part 1 and 2 MAY 2020Document10 pagesPM IS 14399 Part 1 and 2 MAY 2020ishtiaqPas encore d'évaluation

- NDE Personnel Qualification and Certification SystemsDocument18 pagesNDE Personnel Qualification and Certification SystemsSyarif IrwantoPas encore d'évaluation

- ASNT Is WhatDocument2 pagesASNT Is WhatPrashant PuriPas encore d'évaluation

- NDE Personnel Qualification and Certification SystemsDocument18 pagesNDE Personnel Qualification and Certification SystemsSyarif IrwantoPas encore d'évaluation

- PWR Pressure Vessel InspectionDocument9 pagesPWR Pressure Vessel InspectionPrashant PuriPas encore d'évaluation

- Teoria SurgeDocument13 pagesTeoria Surgeparthapaul2000Pas encore d'évaluation

- ASNT-TC1A About PDFDocument20 pagesASNT-TC1A About PDFPrashant PuriPas encore d'évaluation

- Pitting Corrosion A ReviewDocument25 pagesPitting Corrosion A ReviewPrashant PuriPas encore d'évaluation

- Documented InformationDocument5 pagesDocumented InformationbkssdgPas encore d'évaluation

- UT Certication What RequiredDocument22 pagesUT Certication What RequiredPrashant PuriPas encore d'évaluation

- 09 Chapter4Document29 pages09 Chapter4Prashant PuriPas encore d'évaluation

- UT Certication What RequiredDocument22 pagesUT Certication What RequiredPrashant PuriPas encore d'évaluation

- ECT Signal Effect Noise To Signal RationDocument6 pagesECT Signal Effect Noise To Signal RationPrashant PuriPas encore d'évaluation

- Documented InformationDocument5 pagesDocumented InformationbkssdgPas encore d'évaluation

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoPas encore d'évaluation

- 09 Chapter4Document29 pages09 Chapter4Prashant PuriPas encore d'évaluation

- Sri Hanuman Chalisa in HindiDocument3 pagesSri Hanuman Chalisa in HindiSrivatsa97% (31)

- BHEL - Manufacturing Process of 500MW Turbo Generator Bars - Electrical Engg. (EE) Summer TrainingDocument47 pagesBHEL - Manufacturing Process of 500MW Turbo Generator Bars - Electrical Engg. (EE) Summer TrainingVinnie SinghPas encore d'évaluation

- Condenser CondenserDocument47 pagesCondenser CondenserPrashant Puri100% (1)

- La Ko Sure Unsa NiDocument3 pagesLa Ko Sure Unsa NiJeromePas encore d'évaluation

- Sceince DirectDocument6 pagesSceince DirectPrashant PuriPas encore d'évaluation

- Question On CondenserDocument2 pagesQuestion On CondenserPrashant PuriPas encore d'évaluation

- Ultrasonic Testing of Steel CastingDocument38 pagesUltrasonic Testing of Steel CastingPARK, SANGYEOLPas encore d'évaluation

- Manufacturing of InsulationDocument9 pagesManufacturing of InsulationPrashant PuriPas encore d'évaluation

- Steam Turbine and Deposits Problems and SolutionsDocument18 pagesSteam Turbine and Deposits Problems and Solutionsjerezg25100% (2)

- 4 3 LMTD With TutorialDocument5 pages4 3 LMTD With TutorialAfrooneyPas encore d'évaluation

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- Ultrasonic Testing of Steel CastingDocument38 pagesUltrasonic Testing of Steel CastingPARK, SANGYEOLPas encore d'évaluation

- MalariaDocument15 pagesMalariaMary ShermanPas encore d'évaluation

- Parliamenary Quewstion For Nuclear Power PlantDocument3 pagesParliamenary Quewstion For Nuclear Power PlantPrashant PuriPas encore d'évaluation

- Indian Electrical Motors LimitedDocument12 pagesIndian Electrical Motors LimitedPrashant PuriPas encore d'évaluation

- Case Study Forms of Corrosion: Chemical Engineering DeptDocument41 pagesCase Study Forms of Corrosion: Chemical Engineering DeptBAKRPas encore d'évaluation

- Welding - Made EasyDocument102 pagesWelding - Made EasyRohan Gupta100% (3)

- Corrosion Metals For ResistanceDocument7 pagesCorrosion Metals For ResistanceMuhammad ImranPas encore d'évaluation

- Effect of Postweld Heat Treatment On Microstructures and Hardness of TIG Weldment Between P22 and P91 Steels With Inconel 625 Filler MetalDocument7 pagesEffect of Postweld Heat Treatment On Microstructures and Hardness of TIG Weldment Between P22 and P91 Steels With Inconel 625 Filler MetalParmodSharmaPas encore d'évaluation

- Stainless Steel Pipe and Tube SpecificationsDocument10 pagesStainless Steel Pipe and Tube SpecificationsDIBYENDU MONDALPas encore d'évaluation

- Pipes. Pressure and Wall Thickness of A Straight Pipe. ASME B31.1 and B31.3Document100 pagesPipes. Pressure and Wall Thickness of A Straight Pipe. ASME B31.1 and B31.3safiragina100% (1)

- Arbor Press Drawings PDFDocument16 pagesArbor Press Drawings PDFCalixto Milla EsauPas encore d'évaluation

- METAL CASTING TECHNOLOGY: CONTINUOUS, SLUSH & ELECTRO-SLAGDocument13 pagesMETAL CASTING TECHNOLOGY: CONTINUOUS, SLUSH & ELECTRO-SLAGGoutham ReddyPas encore d'évaluation

- Weld Deposition DataDocument5 pagesWeld Deposition Datachetan85100% (4)

- 15B41HDocument4 pages15B41HGil CabreraPas encore d'évaluation

- Magical Metals (Parts 1-4) by MortdredDocument28 pagesMagical Metals (Parts 1-4) by MortdredGnomeMadeIon100% (1)

- Wps Register Last Updated May 12Document1 pageWps Register Last Updated May 12Abdullah Al JubayerPas encore d'évaluation

- Periodic Table of Elements and X-Ray Energies: Innovation With IntegrityDocument2 pagesPeriodic Table of Elements and X-Ray Energies: Innovation With Integritystudentbrn100% (1)

- R7 210306 Metallurgy & Material ScienceDocument1 pageR7 210306 Metallurgy & Material SciencesivabharathamurthyPas encore d'évaluation

- Excelente Welding Inspection Qualifications Testing Procedures PDFDocument117 pagesExcelente Welding Inspection Qualifications Testing Procedures PDFravi00098Pas encore d'évaluation

- Welding Inspection ReportDocument14 pagesWelding Inspection ReportManoj KumarPas encore d'évaluation

- DIT Cutting DataDocument2 pagesDIT Cutting DataMuhammed ShoaibPas encore d'évaluation

- Quantification of Residual Stresses in External Attachment Welding ApplicationDocument16 pagesQuantification of Residual Stresses in External Attachment Welding ApplicationAnonymous GhPzn1xPas encore d'évaluation

- Section 07Document42 pagesSection 07christos1157Pas encore d'évaluation

- Armstrong Bollhoff HeliCoilDocument28 pagesArmstrong Bollhoff HeliCoilThor InternationalPas encore d'évaluation

- Carbon Steel Bolt Chemical Analysis ReportDocument1 pageCarbon Steel Bolt Chemical Analysis ReportSainath AmudaPas encore d'évaluation

- (Scale Modelling) - (AFV Modeller Nâ°07) (P34-49) - T-34-76 - Naked Desperation Part 2 - ConstructionDocument17 pages(Scale Modelling) - (AFV Modeller Nâ°07) (P34-49) - T-34-76 - Naked Desperation Part 2 - ConstructionFernando Soto100% (1)

- Electrode Dan Welding Wires 1646204294Document7 pagesElectrode Dan Welding Wires 1646204294Gibran RamadhanPas encore d'évaluation

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentPas encore d'évaluation

- Destructive and Non-Destructive Testing of The Weldment of Dissimilar MetalsDocument9 pagesDestructive and Non-Destructive Testing of The Weldment of Dissimilar MetalsAlbertPas encore d'évaluation

- 3 Ways To Melt Gold - WikiHowDocument3 pages3 Ways To Melt Gold - WikiHowgedfire100% (1)

- 8B Alloy Fabrication and ProcessingDocument16 pages8B Alloy Fabrication and ProcessingAhmed AliPas encore d'évaluation

- Electrolytic Refining of Copper ProcessDocument2 pagesElectrolytic Refining of Copper ProcessAslam PAPas encore d'évaluation

- Fastener Academy Basics PDFDocument94 pagesFastener Academy Basics PDFKiran BathiniPas encore d'évaluation

- Chemistry Imp1Document3 pagesChemistry Imp1minePas encore d'évaluation