Académique Documents

Professionnel Documents

Culture Documents

FMEA Rating Scale

Transféré par

Sridharan Venkat0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues2 pagesThe document defines criteria for assessing the severity, occurrence, and detection of issues. For severity, it rates issues from none to hazardous without warning based on the impact on products and repair needs. Occurrence is rated from remote to very high based on the frequency of problems per thousand pieces. Detection ratings range from very high to almost impossible based on the method used to detect errors, including automatic gauging, inspection layers, and visual checks.

Description originale:

Jxjudiffj djjcifkhx djdj

Copyright

© © All Rights Reserved

Formats disponibles

XLS, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe document defines criteria for assessing the severity, occurrence, and detection of issues. For severity, it rates issues from none to hazardous without warning based on the impact on products and repair needs. Occurrence is rated from remote to very high based on the frequency of problems per thousand pieces. Detection ratings range from very high to almost impossible based on the method used to detect errors, including automatic gauging, inspection layers, and visual checks.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme XLS, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues2 pagesFMEA Rating Scale

Transféré par

Sridharan VenkatThe document defines criteria for assessing the severity, occurrence, and detection of issues. For severity, it rates issues from none to hazardous without warning based on the impact on products and repair needs. Occurrence is rated from remote to very high based on the frequency of problems per thousand pieces. Detection ratings range from very high to almost impossible based on the method used to detect errors, including automatic gauging, inspection layers, and visual checks.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme XLS, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

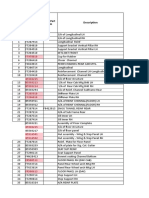

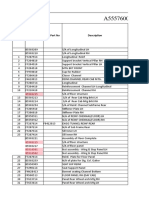

SEVERITY

S.No Description Criteria

1 None Slight inconvenience to operation or operator or no effect.

A portion (less than 100%) of the product may have to be reworked, with

2 Very minor

no scrap, on-line but in-station.

A portion (less than 100%) of the product may have to be reworked, with

3 Minor

no scrap, on-line but out-of-station.

The product may have to be sorted, with no scrap, an a portion (less than

4 Very low

100%) reworked

100% of product may have to be reworked, or vehicle/item repaired

5 Low

offline but does not go to repair department.

A portion (less than 100%) of the product may have to be scrapped with

6 Moderate no sorting, or vehicle/item repaired in repair department with repair time

less than half an hour.

Product may have to be sorted an a portion (less than 100%) scrapped,or

7 High vehicle/item repaired in repair department with repair time between half

an hour and an hour.

100% of product may have to be scrapped, or vehicle/item repaired in

8 Very high

repair department with a repair time greater than one hour.

Hazardous

9 May endanger operator (machine or assembly) with warning.

with warning

Hazardous

10 without May endanger operator (machine or assembly) without warning.

warning

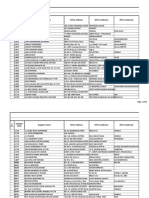

OCCURRENCE

S.No Description Criteria

1 Remote <= 0.01 per thousand pieces

2 Low 0.1 per thousand pieces

3 Low 0.5 per thousand pieces

4 Moderate 1 per thousand pieces

5 Moderate 2 per thousand pieces

6 Moderate 5 per thousand pieces

7 High 10 per thousand pieces

8 High 20 per thousand pieces

9 Very high 50 per thousand pieces

10 Very high => 100 per thousand pieces

DETECTION

S.No Description Criteria

Discrepant parts cannot be made because item has been error proofed by

1 Very high

process/product design.

Error Proofed or Gauging Inspection. Error detection in-station

2 Very high (automatic gauging with automatic stop feature). Cannot pass discrepant

part.

Error Proofed or Gauging Inspection. Error detection in-station, OR in

3 High subsequent operations by multiple layers of acceptance: supply, select,

install, verify. Cannot accept discrepant part.

Error Proofed or Gauging Inspection. Error detection in subsequent

Moderately

4 operations, OR gauging performed on setup and first-piece check (for

high

setup causes only).

Gauging Inspection. Control is based on variable gauging after parts have

5 Moderate left the station, OR Go/No Go gauging performed on 100% of the parts

after parts have left the station.

Gauging or Manual Inspection. Control is achieved with charting

6 Low

methods, such as SPC (Statistical Process Control)

7 Very low Manual Inspection. Control is achieved w/ double visual inspection only.

8 Remote Manual Inspection. Control is achieved w/ visual inspection only.

Manual Inspection. Control is achieved w/ indirect or random checks

9 Very Remote

only.

Almost

10 Manual Inspection. Cannot detect or is not checked.

impossible

Vous aimerez peut-être aussi

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1D'EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Évaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Effect Criteria Rank: Typical Rankings of Severity Indices (Ford Motor Company, 2001)Document4 pagesEffect Criteria Rank: Typical Rankings of Severity Indices (Ford Motor Company, 2001)ain liyanaPas encore d'évaluation

- FMEA StandardDocument4 pagesFMEA Standardjawahar ramPas encore d'évaluation

- Pfmea TableDocument1 pagePfmea TableAlberto CastelanPas encore d'évaluation

- Process Fmea: Table 6 Suggested Pfmea Severity Evaluation CriteriaDocument4 pagesProcess Fmea: Table 6 Suggested Pfmea Severity Evaluation CriteriaSelvakumaran Dhandapani100% (1)

- Fmea RatingDocument6 pagesFmea RatingjanaprathapPas encore d'évaluation

- Suggested Pfmea Evaluation CriteriaDocument2 pagesSuggested Pfmea Evaluation Criteriatrfcprop100% (1)

- Copia de FORMATO AmefDocument2 pagesCopia de FORMATO AmefDavid SaucedoPas encore d'évaluation

- Tablas FmeaDocument4 pagesTablas FmeaPalmer Dionicio100% (1)

- Sevrity Reating Table Old & NewDocument26 pagesSevrity Reating Table Old & NewSibaram DasPas encore d'évaluation

- PFMEA Ranking Table Rating Criteria Action GuidelineDocument10 pagesPFMEA Ranking Table Rating Criteria Action GuidelineEnrico Miguel AquinoPas encore d'évaluation

- SeverityDocument10 pagesSeverityVijayamalar AmruthalingamPas encore d'évaluation

- Fmea TableDocument4 pagesFmea TableAfzal RPas encore d'évaluation

- SOD Machinery FMEADocument3 pagesSOD Machinery FMEAUmashankar Gautam100% (1)

- Xfmea PfmeaDocument7 pagesXfmea PfmearkhaireenPas encore d'évaluation

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- PFMEA EncodeDocument4 pagesPFMEA EncodeBooniz-bonice EliasPas encore d'évaluation

- "Fmea & Case Study": Kelompok: Rohmat Setiawan Titin NuryawatiDocument41 pages"Fmea & Case Study": Kelompok: Rohmat Setiawan Titin Nuryawatirohmat_setiawan77Pas encore d'évaluation

- SOD: Table SOD: Table: Failure Mode and Effects Analysis Failure Mode and Effects AnalysisDocument4 pagesSOD: Table SOD: Table: Failure Mode and Effects Analysis Failure Mode and Effects AnalysisGaurav NagpalPas encore d'évaluation

- FMEA Scoring GuidelinesDocument3 pagesFMEA Scoring Guidelineskalpesh prajapatiPas encore d'évaluation

- Failure Mode and Effect AnalysisDocument25 pagesFailure Mode and Effect AnalysislokelooksPas encore d'évaluation

- Detection ScaleDocument1 pageDetection ScaleSergio LoayzaPas encore d'évaluation

- Severity Ranking (Sev) : Score Criteria 10 9 8 7 6 5 4 3 2 1Document2 pagesSeverity Ranking (Sev) : Score Criteria 10 9 8 7 6 5 4 3 2 1Sushil Kr ChaurasiaPas encore d'évaluation

- Failure Mode and Effect Analysis Severity RatingDocument5 pagesFailure Mode and Effect Analysis Severity RatingRemus CicuPas encore d'évaluation

- FEMEA Ranking TablesDocument3 pagesFEMEA Ranking TablesAhmed KsibiPas encore d'évaluation

- Severity Table - AIAG-VDA Process FMEADocument1 pageSeverity Table - AIAG-VDA Process FMEARaajha Munibathiran100% (2)

- MeasureDocument51 pagesMeasureAshwani KumarPas encore d'évaluation

- AIAG FMEA TemplateDocument25 pagesAIAG FMEA TemplateIqbal Singh SandhuPas encore d'évaluation

- Product or Process Failure Mode Failure Effects Causes: S E V O C CDocument6 pagesProduct or Process Failure Mode Failure Effects Causes: S E V O C CKocic BalicevacPas encore d'évaluation

- FMEA RankingDocument2 pagesFMEA RankingDaviPas encore d'évaluation

- Design and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Document19 pagesDesign and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Mohammed KassemPas encore d'évaluation

- FMEA SeverityDocument3 pagesFMEA SeverityMechaheb MassinissaPas encore d'évaluation

- Boleh Merevisi Kriteria Severity, Kecuali 9 Dan 10Document3 pagesBoleh Merevisi Kriteria Severity, Kecuali 9 Dan 10Reza WijayaPas encore d'évaluation

- PFMEA Reference CardDocument2 pagesPFMEA Reference Cardkeyoor_pat100% (2)

- Failure Mode Effect Analysis: Dr. Ir. Muhammad SabriDocument42 pagesFailure Mode Effect Analysis: Dr. Ir. Muhammad Sabricalvin100% (1)

- Delphi Supplier Quality Fmea Severity RankingsDocument3 pagesDelphi Supplier Quality Fmea Severity Rankingsmani317Pas encore d'évaluation

- Table P1 For Severity RatingDocument2 pagesTable P1 For Severity RatingAhmad Bin Ismail KhanPas encore d'évaluation

- Six Sigma - FMEA - Detection CriteriaDocument1 pageSix Sigma - FMEA - Detection CriteriagmichalPas encore d'évaluation

- All+Rating+Guidelines ManufacturingDocument4 pagesAll+Rating+Guidelines ManufacturingSegu PratheekPas encore d'évaluation

- PFMEA AIAG VDA Severity Rating PDFDocument1 pagePFMEA AIAG VDA Severity Rating PDFRamdas PaithankarPas encore d'évaluation

- Pfmea Ranking TableDocument3 pagesPfmea Ranking TableKrunal Pandya100% (3)

- Detection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionDocument1 pageDetection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionaslamPas encore d'évaluation

- ScoringDocument2 pagesScoringrose_almontePas encore d'évaluation

- RPN RankingsDocument5 pagesRPN RankingsThế PhongPas encore d'évaluation

- FMEA - 4th EditionsDocument3 pagesFMEA - 4th Editionsmezal rdPas encore d'évaluation

- Severity, Occurrence, and Detection Criteria For Design FMEADocument2 pagesSeverity, Occurrence, and Detection Criteria For Design FMEAtejashraj93Pas encore d'évaluation

- Failure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveDocument19 pagesFailure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveBalan SelvanPas encore d'évaluation

- AFA GuideDocument5 pagesAFA GuideAnish KarthikeyanPas encore d'évaluation

- The 4 Components of ZDQDocument37 pagesThe 4 Components of ZDQMuhammad Gullraiz ChohanPas encore d'évaluation

- Test Result Status 13 Apr 17:02 Aulispro Something To TestDocument5 pagesTest Result Status 13 Apr 17:02 Aulispro Something To Testhulk87Pas encore d'évaluation

- Atom Incu I Service Manual & Parts List P2Document54 pagesAtom Incu I Service Manual & Parts List P2Diego DiazPas encore d'évaluation

- Fmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. StamperDocument23 pagesFmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. Stamperhasan_taşkınPas encore d'évaluation

- GM PFMEA RankingsDocument1 pageGM PFMEA RankingssathyabalaramanPas encore d'évaluation

- Building a Successful Board-Test StrategyD'EverandBuilding a Successful Board-Test StrategyÉvaluation : 4 sur 5 étoiles4/5 (1)

- TNIGRS - CHALLANDec 26 - 194300Document1 pageTNIGRS - CHALLANDec 26 - 194300Sridharan VenkatPas encore d'évaluation

- Defect Identification in CNC Manufactured Products and Their Control MeasureDocument7 pagesDefect Identification in CNC Manufactured Products and Their Control MeasureSridharan VenkatPas encore d'évaluation

- Wholesale Dealer Price Selling To Retail Shop OwnerDocument3 pagesWholesale Dealer Price Selling To Retail Shop OwnerSridharan VenkatPas encore d'évaluation

- Acer Aspire 3 A315-41: Model HP 15q-dy0004AU Acer Aspire 3 A315-53 Lenovo Ideapad S145 Price Acer Aspire 3 A315-33Document4 pagesAcer Aspire 3 A315-41: Model HP 15q-dy0004AU Acer Aspire 3 A315-53 Lenovo Ideapad S145 Price Acer Aspire 3 A315-33Sridharan VenkatPas encore d'évaluation

- Fir Issue of Duplicate Cheque in Lieu of Lost or Misplaced Cheque / Individual DepositDocument5 pagesFir Issue of Duplicate Cheque in Lieu of Lost or Misplaced Cheque / Individual DepositSridharan VenkatPas encore d'évaluation

- Form 21 PDFDocument1 pageForm 21 PDFSridharan VenkatPas encore d'évaluation

- FGGDocument12 pagesFGGSridharan VenkatPas encore d'évaluation

- DealersDocument2 pagesDealersSridharan Venkat100% (1)

- Automotive Coaches and Components LTDDocument2 pagesAutomotive Coaches and Components LTDSridharan VenkatPas encore d'évaluation

- Sheet Metal Probelm BendingDocument3 pagesSheet Metal Probelm BendingSridharan VenkatPas encore d'évaluation

- A4Z01200PH63Document31 pagesA4Z01200PH63Sridharan VenkatPas encore d'évaluation

- List of Approved Suppliers JanDocument58 pagesList of Approved Suppliers JanSridharan VenkatPas encore d'évaluation

- Customer Specification Rport 12 FCDocument12 pagesCustomer Specification Rport 12 FCSridharan VenkatPas encore d'évaluation

- Customer Specific Requirements AL FormatDocument1 pageCustomer Specific Requirements AL FormatSridharan VenkatPas encore d'évaluation

- Mail CpiDocument13 pagesMail CpiSridharan VenkatPas encore d'évaluation

- MAILDocument1 pageMAILSridharan VenkatPas encore d'évaluation

- Paint Consumption: Final Trim Body SL, NO Consumption Day Shift Consumption Night ShiftDocument7 pagesPaint Consumption: Final Trim Body SL, NO Consumption Day Shift Consumption Night ShiftSridharan VenkatPas encore d'évaluation

- Eol CHKLSTDocument6 pagesEol CHKLSTSridharan VenkatPas encore d'évaluation

- A 5562500 PH 207Document37 pagesA 5562500 PH 207Sridharan VenkatPas encore d'évaluation

- A5557600PH79Document31 pagesA5557600PH79Sridharan VenkatPas encore d'évaluation

- Inspection Report: Automotive Coaches and Components LTDDocument4 pagesInspection Report: Automotive Coaches and Components LTDSridharan VenkatPas encore d'évaluation

- Sl. No Process Status Target Concerns ResponsibilityDocument1 pageSl. No Process Status Target Concerns ResponsibilitySridharan VenkatPas encore d'évaluation

- May' 18 Side Panel Top Weld Joint Poor Putty Finish A: Month Concern Concern CategoryDocument2 pagesMay' 18 Side Panel Top Weld Joint Poor Putty Finish A: Month Concern Concern CategorySridharan VenkatPas encore d'évaluation

- Mass Customisation: Mass Customisation Strategies Lean and Agile Strategies Generic' Operations StrategiesDocument3 pagesMass Customisation: Mass Customisation Strategies Lean and Agile Strategies Generic' Operations StrategiesautumntaitPas encore d'évaluation

- Challenges in Requirements TraceabilityDocument6 pagesChallenges in Requirements Traceabilityadvait_moghe100% (2)

- Sun WindDocument18 pagesSun WindAnand Prakash Jha100% (2)

- OM Ind. Assignment AnswerDocument5 pagesOM Ind. Assignment AnswerGlobal internet100% (2)

- Classical: Production FunctionDocument44 pagesClassical: Production FunctionOmprakash MishraPas encore d'évaluation

- Production Control Objectives: ITTS-QMS-PR13-F04Document2 pagesProduction Control Objectives: ITTS-QMS-PR13-F04zainahmedscribdPas encore d'évaluation

- Just in Time (Jit) Production and Supply Chain ManagementDocument7 pagesJust in Time (Jit) Production and Supply Chain ManagementZeynep AykulPas encore d'évaluation

- Management Accounting Wilkerson Company CasestudyDocument3 pagesManagement Accounting Wilkerson Company CasestudysamacsterPas encore d'évaluation

- DevelopmentThatPays TheLeanStartup CheatSheet 1 - 0 PDFDocument1 pageDevelopmentThatPays TheLeanStartup CheatSheet 1 - 0 PDFHamed KamelPas encore d'évaluation

- Machine(s) : Date: Product: Shift: Availability: Min Min: Page 1 of 1Document3 pagesMachine(s) : Date: Product: Shift: Availability: Min Min: Page 1 of 1chteo1976Pas encore d'évaluation

- ERP (Enterprise Resource Planning)Document32 pagesERP (Enterprise Resource Planning)NasikhuddinPas encore d'évaluation

- Erp Implementation at LandirenzoDocument15 pagesErp Implementation at LandirenzobumbiazarkaPas encore d'évaluation

- Lean Supply Chain & Logistics ManagementDocument8 pagesLean Supply Chain & Logistics ManagementjosegarreraPas encore d'évaluation

- PM 9Document57 pagesPM 9Nurdan SarıkayaPas encore d'évaluation

- Escl Iso Quality Manual Rev. 01Document52 pagesEscl Iso Quality Manual Rev. 01adiqualityconsultPas encore d'évaluation

- TQM MCQsDocument8 pagesTQM MCQsrattan billawaria100% (1)

- Mrp1 Mrp2 ErpDocument14 pagesMrp1 Mrp2 ErpAarti Ck100% (1)

- Guidelines Fmea - Dyadem Press - 2003Document143 pagesGuidelines Fmea - Dyadem Press - 2003Cali MelendezPas encore d'évaluation

- Annexure D - SPIR PDFDocument4 pagesAnnexure D - SPIR PDFharmlesdragonPas encore d'évaluation

- Presented By:: Vijayendra Pratap Singh (C-59) Vijendra Rana (C-40)Document16 pagesPresented By:: Vijayendra Pratap Singh (C-59) Vijendra Rana (C-40)vjranajPas encore d'évaluation

- Production in SCMDocument12 pagesProduction in SCMSonia LawsonPas encore d'évaluation

- Spcimen of Cost Sheet For A Manufacturing CompanyDocument2 pagesSpcimen of Cost Sheet For A Manufacturing CompanySaurabh Krishna SinghPas encore d'évaluation

- Calibration Procedure For Measuring and Testing EquipmentDocument5 pagesCalibration Procedure For Measuring and Testing Equipmentade_sofyanPas encore d'évaluation

- Iguzzini Programmübersicht 2010 - DeutschDocument420 pagesIguzzini Programmübersicht 2010 - DeutschiGuzzini illuminazione SpAPas encore d'évaluation

- Lean and Jit Systems: Originated From: Operations Management, 8 Edition, William J Stevenson Mcgraw-HillDocument33 pagesLean and Jit Systems: Originated From: Operations Management, 8 Edition, William J Stevenson Mcgraw-HillMuhammad HarizPas encore d'évaluation

- Managing The Operations FunctionDocument35 pagesManaging The Operations FunctionMylene Candido50% (2)

- Creating Competitive Advantage Through The Supply Chain - Insights On IndiaDocument23 pagesCreating Competitive Advantage Through The Supply Chain - Insights On IndiaRohitGuptaPas encore d'évaluation

- SCM Interview QuestionsDocument2 pagesSCM Interview QuestionsMuhammad Kashif ArshadPas encore d'évaluation

- Sample On Operation Management in Business by Instant Essay WritingDocument18 pagesSample On Operation Management in Business by Instant Essay WritingInstant Essay Writing100% (1)

- 9.excel Template Production Report With OEE Graphical Dashboard.v.2Document249 pages9.excel Template Production Report With OEE Graphical Dashboard.v.2pankaj66668Pas encore d'évaluation