Académique Documents

Professionnel Documents

Culture Documents

SPIT Fix-II Zinc Coated

Transféré par

Ahmed SakrCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SPIT Fix-II Zinc Coated

Transféré par

Ahmed SakrDroits d'auteur :

Formats disponibles

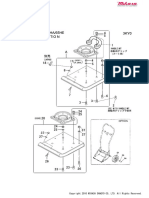

Fix II

Zinc Coated Steel 1/4

¬ Torque controlled expansion anchor, made of zinc

coated steel for use in non cracked concrete

European Technical Approval

ETA Option 7 Technical data

n° 01/0008

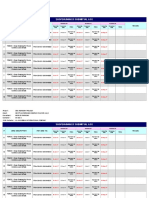

SPIT FIX II Minimum anchor depth Maximum anchor depth

Min. Depth Max thick Drilling Min thick Max. Depth Max thick Drilling Min thick Ø Ø Ø Total Max. Eurocode

Letter marking

anchor before of part to Depth of base anchor before of part to Depth of base thread drill clear- anchor tighten

depth expans be fixed material depth expans be fixed material bit ance length torque

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (Nm)

hef,min hnom tfix ho hmin hef,max hnom tfix ho hmin d dO df L Tinst

M6-5/45* 5 - 45 055000

M6-20/55* 25,6 35 20 41 100 35 45 10 51 100 6 6 8 55 10 055010

M6-50/85* 50 40 85 050530

M6/64 eyebolt* - - 64 056100

M8x55/5-0 - 5 - 55 050435

M8x70/20-7 C 20 7 70 056410

M8x90/40-27 E 35 42 40 52 100 48 55 27 65 100 8 8 9 90 15 056420

M8x110/60-47 F 60 47 110 052695

M8x130/80-67 H 80 67 130 056430

Pre-assembled anchor

M8x160/110-97 - 110 97 160 053894

M10x65/5-0 - 5 - 65 050436

M10x75/15-5 C 15 5 75 056530

Applications M10x95/36-26 E 42 50 36 62 100 52 60 26 72 104 10 10 12 96 30 056540

¬ Steel and timber framework M10x120/60-50 G 60 50 120 050375

M10x140/80-70 I 80 65 140 056550

and beams

M10x160/100-90 J 100 90 160 052696

¬ Lift guide rails M12x80/5-0 - 5 - 80 055334

¬ Industrial doors and gates M12x100/25-8 E 25 8 100 055335

M12x115/40-23 G 40 23 115 055336

¬ Brickwork support angles M12x140/65-48 I 50 60 65 75 100 68 78 48 93 136 12 12 14 140 50 056590

¬ Storage systems M12x160/85-68 J 85 68 160 050377

M12x180//105-88 L 105 88 180 056650

M12x220/145-128 O 145 128 220 056660

Material M16x100/5-0 - 5 - 100 050378

M16x125/30-8 G 30 8 125 100 056700

¬ Bolt M8-M20: Cold M16x150/55-33 I 64 78 55 95 128 86 100 33 117 172 16 16 18 150 050379

formed NFA 35-053 / Zinc M16x170/75-53 K 75 53 170 056710

electroplated (5 µm) M16x185/90-68 L 90 68 185 052698

M20x120/10-0 - 10 - 120 050382

¬ Sleeve: Cold formed, M20x160/50-25 J 74 89 50 110 148 100 115 25 136 200 20 20 22 160 160 056730

NFA 36-231 M20x215/105-80 N 105 80 215 056740

¬ Washer: Steel, DIN 513

* Does not conform to ETA

¬ Hexagonal nut: Steel strength

grade 6 or 8, NF EN 20898-2

Anchor mechanical properties

Installation

M6 M8 M10 M12 M16 M20

Cross-section above cone

fuk (N/mm2) Min. tensile strength 700 700 700 700 600 600

fyk(N/mm2) Yield strength 580 580 580 580 500 500

As (mm2) Stressed cross-section 23,76 40,72 55,42 103,87 172,03

Threaded part

fuk (N/mm2) Min. tensile strength 600 600 600 600 500 500

fyk(N/mm2) Yield strength 480 480 480 480 400 400

As (mm2) Stressed cross-section 20,1 36,6 58 84,3 157 245

Wel (mm3) Elastic section modulus 12,71 31,23 62,3 109,17 277,47 540,9

M0Rk,s (Nm) Characteristic bending moment 9 22 45 79 166 325

M (Nm) Recommended bending moment 3,7 9,0 18,4 32,2 67,8 132,7

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Fix II

Zinc Coated Steel 2/4

The loads specified on this page are derived from internal test results. For results derived from CC Methodology, please see overleaf.

The data given in the pages “CC - Method” have to be applied.

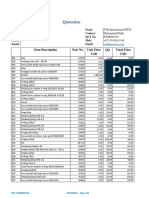

Ultimate (NRu,m, VRu,m) / characteristic loads (NRk, VRk) in kN

Mean Ultimate loads are derived from test results in admissible service conditions, and characteristic loads are statistically determined.

TENSILE SHEAR

Anchor size M6 M8 M10 M12 M16 M20 Anchor size M6 M8 M10 M12 M16 M20

Minimum anchorage depth VRu,m 6,8 10,8 18,2 30,8 44,7 70,5

hef 25 35 42 50 64 74 VRk 2,9 5,3 15,6 25,6 30,4 66,5

NRu,m 6,0 9,6 14,5 26,2 40,6 53,3

NRk 4,5 6,7 9,5 21,9 36,0 42,2

Maximum anchorage depth

hef 35 48 52 68 86 100

NRu,m 9,4 13,8 16,6 32,3 57,2 82,2

NRk 7,0 10,1 11,9 24,0 48,3 62,9

Design Loads (NRd, VRd) for one anchor without edge or spacing influence in kN

N Rk * VRk *

N Rd = VRd =

γ Mc γ Ms

*Derived from test results

TENSILE SHEAR

Anchor size M6 M8 M10 M12 M16 M20 Anchor size M6 M8 M10 M12 M16 M20

Minimum anchorage depth VRd 2,3 4,2 12,5 20,5 24,3 53,2

hef 25 35 42 50 64 74 γMs = 1,25

NRd 2,5 3,7 5,3 12,2 20,0 23,4

Maximum anchorage depth

hef 35 48 52 68 86 100

NRd 3,8 5,6 6,6 13,3 26,8 34,9

γMc = 1,8

Recommended loads (Nrec, Vrec) for one anchor without edge or spacing influence in kN

N Rk * VRk *

N Rec = VRec =

γ Mγ F γ M .γ F

*Derived from test results

TENSILE SHEAR

Anchor size M6 M8 M10 M12 M16 M20 Anchor size M6 M8 M10 M12 M16 M20

Minimum anchorage depth VRec 1,7 3,0 8,9 14,6 17,4 38,0

hef 25 35 42 50 64 74 γMs = 1,25

NRec 1,7 2,7 3,8 8,7 14,3 16,7

Maximum anchorage depth

hef 35 48 52 68 86 100

NRec 2,7 4,0 4,7 9,5 19,2 25,0

γF = 1,4 ; γMc = 1,8

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Fix II

Zinc Coated Steel 3/4

SPIT CC - Method (values issued from ETA)

TENSILE in kN SHEAR in kN

¬ Pull-out resistance ¬ Concrete edge resistance

VRd,c = VRd

O

,c .fb .fβ ,V .ΨS − C ,V

N Rd,p = N ORd , p .fb

V0Rd,c Design concrete edge resistance

at minimum edge distance (Cmin)

N0Rd,p Design pull-out resistance Anchor size M8 M10 M12 M16 M20

Anchor size M8 M10 M12 M16 M20 Minimum anchorage depth

Minimum anchorage depth hef 35 42 50 64 74

hef 35 42 50 64 74 Cmin 55 75 100 100 115

N0Rd,p (C20/25) 3,3 5,0 8,9 13,9 16,7 Smin 45 65 100 100 100

Maximum anchorage depth V0Rd,c (C20/25) 2,9 5,1 8,7 10,1 15,0

hef 48 52 68 86 100 Maximum anchorage depth

N0Rd,p (C20/25) 5,0 6,7 11,1 22,2 16,7 hef 48 52 68 86 100

γMc = 1,8 Cmin 60 65 90 105 125

Smin 50 55 75 90 105

¬ Concrete cone resistance V0Rd,c (C20/25) 3,7 4,4 8,2 11,8 18,1

γMc = 1,5

N Rd,c = N ORd ,c .fb .Ψs .Ψc, N

¬ Pryout failure

N0Rd,c Design cone resistance 0

VRd,cp = VRd ,cp .fb .Ψs .Ψc, N

Anchor size M8 M10 M12 M16 M20

Minimum anchorage depth V0Rd,cp Design pryout resistance

hef 35 42 50 64 74 Anchor size M8 M10 M12 M16 M20

N0Rd,c (C20/25) 5,8 7,6 9,9 14,3 17,8 Minimum anchorage depth

Maximum anchorage depth hef 35 42 50 64 74

hef 48 52 68 86 100 V0Rd,cp (C20/25) 7,0 9,1 11,9 34,4 42,8

N0Rd,c (C20/25) 9,3 10,5 15,7 22,3 28,0 Maximum anchorage depth

γMc = 1,8 hef 48 52 68 86 100

V0Rd,cp (C20/25) 11,2 12,6 37,7 53,6 67,2

γMcp = 1,5

¬ Steel resistance

¬ Steel resistance

NRd,s Design steel tensile resistance VRd,s Design steel shear resistance

Anchor size M8 M10 M12 M16 M20 Anchor size M8 M10 M12 M16 M20

NRd,s 9,3 16 22 34 57,3 VRd,s 3,8 11,2 18,2 18,9 49,0

γMs = 1,5 γMs = 1,25

NRd = min(NRd,p ; NRd,c ; NRd,s) VRd = min(VRd,c ; VRd,cp ; VRd,s)

βN = NSd / NRd ≤ 1 βV = VSd / VRd ≤ 1

βN + βV ≤ 1.2

fB Influence of Concrete fβ,V Influence of Shear Loading Direction

Concrete class fB Concrete class fB Angle β [°] fβ,V

C25/30 1,1 C40/50 1,41 0 to 55 1

C30/37 1,22 C45/55 1,48 60 1.1

C35/45 1,34 C50/60 1,55 70 1.2

80 1.5

90 to 180 2

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Fix II

Zinc Coated Steel 4/4

SPIT CC - Method (values issued from ETA)

Ψs Influence of spacing for concrete cone resistance in tensile load

spacing S Reduction factor Ψs spacing S Reduction factor Ψs

Minimum anchorage depth Maximum anchorage depth

M8 M10 M12 M16 M20 M8 M10 M12 M16 M20

45 0,71 50 0,67

65 0,81 0,76 55 0,69 0,68

100 0,98 0,90 0,83 0,76 0,73 75 0,76 0,74 0,68

110 1,00 0,94 0,87 0,79 0,75 90 0,81 0,79 0,72 0,67

s

ΨS = 0, 5 + 125 1,00 0,92 0,83 0,78 105 0,86 0,84 0,76 0,70 0,68

6.hef 150 1,00 0,89 0,84 145 1,00 0,96 0,86 0,78 0,74

180 0,97 0,91 180 1,00 0,94 0,85 0,80

Smin < S < Scr,N 192 1,00 0,93 205 1,00 0,90 0,84

Scr,N = 3.hef

222 1,00 240 0,97 0,90

ΨS must be used for each spacing

280 1,00 0,97

influenced the anchors group.

300 1,00

Ψc,N Influence of edge for concrete cone resistance in tensile load

EDGE C Reduction factor Ψc,N EDGE C Reduction factor Ψc,N

Minimum anchorage depth Maximum anchorage depth

M8 M10 M12 M16 M20 M8 M10 M12 M16 M20

55 1,00 60 0,87

75 1,00 65 0,92 0,87

100 1,00 70 0,97 0,92

100 1,00 75 1,00 0,97 0,79

115 1,00 100 1,00 0,98 0,82

125 1,00 0,97 0,87

Cmin < C < Ccr,N

130 1,00 0,89

Ccr,N = 1,5.hef

Ψc,N must be used for each distance 150 1,00

influenced the anchors group.

Ψs-c,V Influence of spacing and edge distance for concrete edge resistance in shear load

¬

For single anchor fastening Factor Ψs-c,V

Non-cracked concrete

C 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2

Cmin

Ψs-c,V 1,00 1,31 1,66 2,02 2,41 2,83 3,26 3,72 4,19 4,69 5,20 5,72

Ψs − c,V c c

¬ For 2 anchors Factor Ψs-c,V

= . Non-cracked concrete

cmin cmin C

Cmin

S

1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2

Cmin

1,0 0,67 0,84 1,03 1,22 1,43 1,65 1,88 2,12 2,36 2,62 2,89 3,16

1,5 0,75 0,93 1,12 1,33 1,54 1,77 2,00 2,25 2,50 2,76 3,03 3,31

2,0 0,83 1,02 1,22 1,43 1,65 1,89 2,12 2,38 2,63 2,90 3,18 3,46

2,5 0,92 1,11 1,32 1,54 1,77 2,00 2,25 2,50 2,77 3,04 3,32 3,61

3,0 1,00 1,20 1,42 1,64 1,88 2,12 2,37 2,63 2,90 3,18 3,46 3,76

Ψs − c,V 3.c + s c 3,5 1,30 1,52 1,75 1,99 2,24 2,50 2,76 3,04 3,32 3,61 3,91

= .

6.cmin cmin

4,0

4,5

1,62 1,86 2,10

1,96 2,21

2,36

2,47

2,62

2,74

2,89

3,02

3,17

3,31

3,46

3,60

3,75

3,90

4,05

4,20

5,0 2,33 2,59 2,87 3,15 3,44 3,74 4,04 4,35

5,5 2,71 2,99 3,28 3,71 4,02 4,33 4,65

6,0 2,83 3,11 3,41 3,71 4,02 4,33 4,65

¬ For 3 anchors or more

3.c + s1 + s2 + s3 + ... + sn −1 c

Ψs − c,V = .

3nc c

Technical Helpline UK: 0800 731 4924 Tsupport@itwcp.co.uk

Technical Helpline ROI: 1 800 882 388 www.itwcp.co.uk

Vous aimerez peut-être aussi

- Fix-Z-A4 Stainless Steel Design GuideDocument4 pagesFix-Z-A4 Stainless Steel Design GuidedineshPas encore d'évaluation

- Stainless steel m1tr and m1tr-C Throughbolt installation and performance dataDocument7 pagesStainless steel m1tr and m1tr-C Throughbolt installation and performance dataMohammed AnwarPas encore d'évaluation

- Spit Dynabolt PDFDocument4 pagesSpit Dynabolt PDFAchmad Zaki ZulkarnainPas encore d'évaluation

- Dynabolt Zinc Coated Steel Design Guide PDFDocument4 pagesDynabolt Zinc Coated Steel Design Guide PDFShadin Asari ArabaniPas encore d'évaluation

- Thread Size CalulationDocument4 pagesThread Size CalulationSandip JadhavPas encore d'évaluation

- m2 and m2-C ThroughboltDocument7 pagesm2 and m2-C ThroughboltAmir ElkassasPas encore d'évaluation

- Torque ChartDocument1 pageTorque Chartsylvain croteauPas encore d'évaluation

- Block Roller 2Document1 pageBlock Roller 2Juan Ismael Grave LolPas encore d'évaluation

- Electroplated Wedge Anchor: Feature and BenefitsDocument1 pageElectroplated Wedge Anchor: Feature and BenefitsKABIR CHOPRAPas encore d'évaluation

- ChevroletDocument22 pagesChevroletsmhaltinPas encore d'évaluation

- Technical Data Sheet For Electroplated Wedge Anchor: Does Not Require Precise Hole Depth or Hole Cleaning OutDocument1 pageTechnical Data Sheet For Electroplated Wedge Anchor: Does Not Require Precise Hole Depth or Hole Cleaning OutKABIR CHOPRAPas encore d'évaluation

- Torque Controlled Expansion Anchor, For Use in Cracked and Non-Cracked ConcreteDocument6 pagesTorque Controlled Expansion Anchor, For Use in Cracked and Non-Cracked ConcreteEsraa HarazPas encore d'évaluation

- Stainless Steel Throughbolt for Metal ProductsDocument1 pageStainless Steel Throughbolt for Metal ProductsLeo SerasinghePas encore d'évaluation

- Iso7005 FlangesDocument7 pagesIso7005 FlangesHaris StavrouPas encore d'évaluation

- DIN Flange ClassesDocument7 pagesDIN Flange ClassesSebastián Alexander Flores OroscoPas encore d'évaluation

- Wedge AnchorDocument10 pagesWedge AnchorDoreen PohPas encore d'évaluation

- Rawlbolt: Shield Anchor Loose BoltDocument2 pagesRawlbolt: Shield Anchor Loose BoltBappy IslamPas encore d'évaluation

- TWF TozenDocument6 pagesTWF TozenAri WibowoPas encore d'évaluation

- HILTI HST Catalogue PageDocument2 pagesHILTI HST Catalogue PageGoutam HotaPas encore d'évaluation

- Parker Fitting AssemblyDocument16 pagesParker Fitting AssemblyMechanical2022Pas encore d'évaluation

- Copper Tubes, Coils & Solder Fittings (Inch & Metric)Document43 pagesCopper Tubes, Coils & Solder Fittings (Inch & Metric)dffgfdg dfgdgPas encore d'évaluation

- Mechanical Anchoring TruBoltDocument3 pagesMechanical Anchoring TruBoltwokeoooPas encore d'évaluation

- SPRINT Cable Glands, Metric, Licence Acc. To EN 50262Document1 pageSPRINT Cable Glands, Metric, Licence Acc. To EN 50262ajee doPas encore d'évaluation

- Flange Bolt Chart and Flange Stud Size in MMDocument1 pageFlange Bolt Chart and Flange Stud Size in MMRodrigo Celes100% (1)

- ACO Multidrain - Part11Document1 pageACO Multidrain - Part11JosephRusselVizmanos100% (1)

- ACO Multidrain - Part11 PDFDocument1 pageACO Multidrain - Part11 PDFJosephRusselVizmanosPas encore d'évaluation

- Metric Thread Size Spanner Size A/F DIN (MM) Spanner Size A/F ISO (MM)Document3 pagesMetric Thread Size Spanner Size A/F DIN (MM) Spanner Size A/F ISO (MM)kianoush Volvo construction equipmentPas encore d'évaluation

- Cellpack Cross Section Table DINA5 ENDocument2 pagesCellpack Cross Section Table DINA5 ENHadiPas encore d'évaluation

- RSCI Manual enDocument4 pagesRSCI Manual endenisPas encore d'évaluation

- PN6 PN 10 PN 16 Flange Bolt Flange Bolt Flange Bolt PN 25 Flange BoltDocument1 pagePN6 PN 10 PN 16 Flange Bolt Flange Bolt Flange Bolt PN 25 Flange BoltStefanGramaPas encore d'évaluation

- Fisher - Anchor Bolt FAZDocument9 pagesFisher - Anchor Bolt FAZlazar_maria18Pas encore d'évaluation

- JCB DieselMax V08 Turbocharger 97-120kW Product CatalogDocument2 pagesJCB DieselMax V08 Turbocharger 97-120kW Product CatalogMarcial Jr. MilitantePas encore d'évaluation

- RPMMN21LNK700-Link PFA25 DN50-2000Document5 pagesRPMMN21LNK700-Link PFA25 DN50-2000ramon duldulaoPas encore d'évaluation

- Design Guide: Unicon Qwikfoot and Qwikfix Threaded InsertsDocument30 pagesDesign Guide: Unicon Qwikfoot and Qwikfix Threaded InsertsCora XuPas encore d'évaluation

- WEG W22 Terminal BoxDocument1 pageWEG W22 Terminal BoxTerry BaddeleyPas encore d'évaluation

- 02-10-3692 Cylinder, Lift - For h3 347 R7016Document1 page02-10-3692 Cylinder, Lift - For h3 347 R7016Juan Ismael Grave LolPas encore d'évaluation

- Multifix All Mechanical Anchor - Design GuideDocument28 pagesMultifix All Mechanical Anchor - Design GuideConstantino Ramirez (Cons)Pas encore d'évaluation

- QuoteDocument2 pagesQuoteGeorge GermanPas encore d'évaluation

- Tyre Coupling With Spacer UNEFLEX SD SeriesDocument3 pagesTyre Coupling With Spacer UNEFLEX SD SeriesGabriel MoreiraPas encore d'évaluation

- Catalogue Seal Kit-finalDocument334 pagesCatalogue Seal Kit-finalGustavo CardenasPas encore d'évaluation

- Avl PDFDocument52 pagesAvl PDFAhmet HamamcıoğluPas encore d'évaluation

- Wire TableDocument2 pagesWire Tablerfactor0976Pas encore d'évaluation

- Determine Max Stress Composite BeamDocument1 pageDetermine Max Stress Composite BeamThabiso MotalingoanePas encore d'évaluation

- Page 0012Document1 pagePage 0012Matteo BaldassariPas encore d'évaluation

- 32 HobartDocument44 pages32 HobartSinisa MalesevicPas encore d'évaluation

- Ancon QwikFoot and QwikFix Threaded Inserts Design GuideDocument36 pagesAncon QwikFoot and QwikFix Threaded Inserts Design GuideSam SPas encore d'évaluation

- Ampacity of Copper Conductors Including Wire in RacewayDocument2 pagesAmpacity of Copper Conductors Including Wire in RacewayTenda Kyojin0% (1)

- Fixing Sytems Products-176 - INKADocument105 pagesFixing Sytems Products-176 - INKAKhaled AbdelhamidPas encore d'évaluation

- T Mech Clamp CatalogueDocument29 pagesT Mech Clamp CatalogueKABIR CHOPRAPas encore d'évaluation

- Spit Epomax: Zinc Coated Steel (Standard Anchorage)Document12 pagesSpit Epomax: Zinc Coated Steel (Standard Anchorage)Sudhakar KrishnamurthyPas encore d'évaluation

- Tap Drill Sizes Chart for Forming TapsDocument1 pageTap Drill Sizes Chart for Forming Tapsamir.suljic23-1Pas encore d'évaluation

- Anamet Iecex-Atex Cable-Gland, Type RN, Nickel Plated BrassDocument2 pagesAnamet Iecex-Atex Cable-Gland, Type RN, Nickel Plated BrasschauduonguyenPas encore d'évaluation

- Jack / 100/90-750Document2 pagesJack / 100/90-750ESRAPas encore d'évaluation

- Pie y OpcionesDocument2 pagesPie y Opcionestalleres villaPas encore d'évaluation

- HP Fittings (MM) - Newprice - List05-10-2021Document6 pagesHP Fittings (MM) - Newprice - List05-10-2021nileshPas encore d'évaluation

- Color Hole - Fasten Enterprises (Pte) LTD - SingaporeDocument2 pagesColor Hole - Fasten Enterprises (Pte) LTD - SingaporeTran BdsPas encore d'évaluation

- Zydb004 22Document5 pagesZydb004 22Sherief MagdyPas encore d'évaluation

- P14 CX Hydr NippelsDocument11 pagesP14 CX Hydr NippelsasdfPas encore d'évaluation

- Bodywork 2Document42 pagesBodywork 2Garcia CruzPas encore d'évaluation

- WEEKLY - MEETING ReportDocument1 pageWEEKLY - MEETING ReportAhmed SakrPas encore d'évaluation

- Cost Estimator: Summary of PositionDocument1 pageCost Estimator: Summary of PositionAhmed SakrPas encore d'évaluation

- Claim Submissions and Dispute Resolution Under The New Fidic Conditions of ContractDocument4 pagesClaim Submissions and Dispute Resolution Under The New Fidic Conditions of ContractAhmed SakrPas encore d'évaluation

- Resource: Man-Hour Assignment To Get Man Hour Budget - Overhead Percentage From The Budget Man-HourDocument1 pageResource: Man-Hour Assignment To Get Man Hour Budget - Overhead Percentage From The Budget Man-HourAhmed SakrPas encore d'évaluation

- Direct vs IndirectDocument3 pagesDirect vs IndirectBahrin Ikram RedzuwanPas encore d'évaluation

- Claim Form Guidance Internet and IntranetDocument2 pagesClaim Form Guidance Internet and IntranetAhmed SakrPas encore d'évaluation

- Dry Cost & OHDocument16 pagesDry Cost & OHAhmed Sakr0% (1)

- Calculate OverheadDocument3 pagesCalculate Overheadjstan62Pas encore d'évaluation

- SikaTopSeal 107-Us PDFDocument2 pagesSikaTopSeal 107-Us PDFAhmed SakrPas encore d'évaluation

- More Cost ConceptsDocument15 pagesMore Cost Conceptsshailendra83100% (1)

- How Companies Use Budgeting to Achieve GoalsDocument14 pagesHow Companies Use Budgeting to Achieve GoalsAhmed SakrPas encore d'évaluation

- AL Hashemiah International Contracting Co.Document3 pagesAL Hashemiah International Contracting Co.Ahmed SakrPas encore d'évaluation

- Agile in ConstructionDocument67 pagesAgile in ConstructionbabaktavousiPas encore d'évaluation

- Administrative & Indirect CostDocument38 pagesAdministrative & Indirect CostAhmed SakrPas encore d'évaluation

- The UAE Civil Procedure Code, Federal Law No. (11) of 1992 Chapter (V) "Execution Procedures"Document1 pageThe UAE Civil Procedure Code, Federal Law No. (11) of 1992 Chapter (V) "Execution Procedures"Ahmed SakrPas encore d'évaluation

- Construction Drawings AbbreviationsDocument18 pagesConstruction Drawings AbbreviationsAhmed SakrPas encore d'évaluation

- Barbed Wire SupplierDocument1 pageBarbed Wire SupplierAhmed SakrPas encore d'évaluation

- ERC Refinery Fence Shop Drawing Submittal LogDocument5 pagesERC Refinery Fence Shop Drawing Submittal LogAhmed SakrPas encore d'évaluation

- RA-01 Resource Assignments, All Activities: User's NotesDocument4 pagesRA-01 Resource Assignments, All Activities: User's NotesAhmed SakrPas encore d'évaluation

- Project TemplatesDocument66 pagesProject TemplatesfouzunPas encore d'évaluation

- Transmittal FormDocument1 pageTransmittal FormAhmed SakrPas encore d'évaluation

- Numbering System - ERC ProjectDocument3 pagesNumbering System - ERC ProjectAhmed SakrPas encore d'évaluation

- Asphalt SpecsDocument9 pagesAsphalt SpecsAhmed SakrPas encore d'évaluation

- Financial PlanDocument1 pageFinancial PlanAhmed SakrPas encore d'évaluation

- Definitions & MeasurementDocument25 pagesDefinitions & MeasurementAhmed SakrPas encore d'évaluation

- Final-Kozara Jp54 5m BBL X 12 Month-12.23.14Document18 pagesFinal-Kozara Jp54 5m BBL X 12 Month-12.23.14Ahmed SakrPas encore d'évaluation

- Resources Assigned by ResourceDocument13 pagesResources Assigned by ResourceAhmed SakrPas encore d'évaluation

- Geometric Shapes CalculsDocument41 pagesGeometric Shapes CalculsAhmed SakrPas encore d'évaluation

- Density Table of Verious MaterialsDocument1 pageDensity Table of Verious MaterialsAhmed SakrPas encore d'évaluation

- Density TableDocument8 pagesDensity TableAhmed SakrPas encore d'évaluation

- Law of MotionDocument30 pagesLaw of MotionMark Francis HernandezPas encore d'évaluation

- Boylestad - Formula SheetDocument2 pagesBoylestad - Formula SheetZain AliPas encore d'évaluation

- This Study Resource WasDocument9 pagesThis Study Resource WasJacob ClintonPas encore d'évaluation

- Class 7 Mensuration - Perimeter, Area, Volume: All Questions Are 1 MarksDocument13 pagesClass 7 Mensuration - Perimeter, Area, Volume: All Questions Are 1 Markswb csPas encore d'évaluation

- Fx3U 4AD PTDocument3 pagesFx3U 4AD PTquân nguyễnPas encore d'évaluation

- QuST Sponsored MTechDocument1 pageQuST Sponsored MTechRahul RoushanPas encore d'évaluation

- 108590202A GU Basic Laboratory Skills A4 en LRDocument92 pages108590202A GU Basic Laboratory Skills A4 en LRΔΑΝΑΗ ΓΙΑΝΝΑΡΗPas encore d'évaluation

- PRACTICE PAPER - PHYSICS SECTION A SOLUTIONSDocument20 pagesPRACTICE PAPER - PHYSICS SECTION A SOLUTIONSAshmitPas encore d'évaluation

- NEA Short & Long Questions on Power Systems TopicsDocument1 pageNEA Short & Long Questions on Power Systems TopicsPhool Mohammad RayeenPas encore d'évaluation

- Singapore Historical Electricity TariffDocument2 pagesSingapore Historical Electricity TariffHaider Tyebally TyeballyPas encore d'évaluation

- M101NWT2 R2 Product Info GuideDocument30 pagesM101NWT2 R2 Product Info GuideFrei JerePas encore d'évaluation

- About SPAR SHSDocument13 pagesAbout SPAR SHSNash GPas encore d'évaluation

- Differential Equation Part 2Document25 pagesDifferential Equation Part 2ABHRANEEL KARMAKARPas encore d'évaluation

- Numeric Plasma Torch Height Controller Manual: (Type: RATE Series 1630)Document41 pagesNumeric Plasma Torch Height Controller Manual: (Type: RATE Series 1630)CiberPas encore d'évaluation

- Flooded Condenser & Distillation Column Pressure ControlDocument82 pagesFlooded Condenser & Distillation Column Pressure ControlMoca Phoenix100% (1)

- Theorems of SSLC Maths-7marksDocument21 pagesTheorems of SSLC Maths-7marksPRAJWAL GPas encore d'évaluation

- Waves and OpticsDocument249 pagesWaves and OpticsNabaneeta PalPas encore d'évaluation

- KDM Unit-1Document25 pagesKDM Unit-1Achyuth KrishnaPas encore d'évaluation

- Phase Diagrams and Heating-Cooling Curves of H2O and CO2Document31 pagesPhase Diagrams and Heating-Cooling Curves of H2O and CO2Marielle LabradoresPas encore d'évaluation

- KC 60335-2-11Document33 pagesKC 60335-2-11le duc huynhPas encore d'évaluation

- E3x ZD - E65z En5 01Document12 pagesE3x ZD - E65z En5 01Teguh WidiantoPas encore d'évaluation

- Boiler KpiDocument2 pagesBoiler KpiAbdallah AbdallahPas encore d'évaluation

- Anchorage - IDEA StatiCaDocument7 pagesAnchorage - IDEA StatiCaSyed Tauseef ShahPas encore d'évaluation

- Data Sheet RFQ - Modec - 1415Document1 pageData Sheet RFQ - Modec - 1415mauricio carvalhoPas encore d'évaluation

- Earth Science Theories and Planetary ClassificationDocument28 pagesEarth Science Theories and Planetary ClassificationJovi VillanuevaPas encore d'évaluation

- Wilo USA 2013 Product CatalogDocument40 pagesWilo USA 2013 Product CatalogAde ApriPas encore d'évaluation

- Boq InsulationDocument4 pagesBoq InsulationAman MehtaPas encore d'évaluation

- DE 2.1 Separation of VariablesDocument11 pagesDE 2.1 Separation of Variablesrishiko aquinoPas encore d'évaluation

- 50Q - AtomsDocument9 pages50Q - AtomsNaman MahawarPas encore d'évaluation

- Chemical BondingDocument19 pagesChemical BondingAman AntilPas encore d'évaluation