Académique Documents

Professionnel Documents

Culture Documents

Grease Static Oil Bleed Technical Topic

Transféré par

David PomaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Grease Static Oil Bleed Technical Topic

Transféré par

David PomaDroits d'auteur :

Formats disponibles

B:8.

5”

T:8.25”

Technical Topic

Grease Static Oil Bleed

If you have ever opened a grease container and found a puddle occur during storage conditions as a result of temperature

of free oil, you almost certainly may have wondered whether changes or vibration (static oil bleed or oil puddling). These

the grease is still fit for use. The phenomenon described is stresses are extremely weak compared to the mechanical

called static oil bleed, and some in-depth review of grease stress in the application but can still result in the release of small

fundamentals is needed to comprehend the root cause of this amounts of oil. And thus, over time, puddles of oil are formed.

and its potential impact on grease performance.

ASTM International defines lubricating grease as “a semifluid

to solid...dispersion of a thickener in a liquid lubricant.... Other

ingredients are commonly included to impart special properties”

(ASTM D4175 Rev A).

In other words, a grease is made by dispersing a thickening

agent in lubricating oil.

• The lubricating oil composition is dictated by the application

T:11.75”

B:12”

needs, including load, temperature, speed, surface

roughness, and others. It is the oil that provides the lubrication.

• The grease thickener is a matrix of fibers or platelets forming

a large surface area with many holes (voids). It is in these voids

or adhered-to surfaces that the oil is held until it is needed

to lubricate.

A lubricating grease can be thought of as a sponge, saturated Grease contains a thickener like the soap fibers pictured

with the lubricating oil, which must be liberated from within the above, which hold a lubricating oil in suspension.

thickening matrix to provide lubrication. The sponge analogy

is rather appropriate, as the grease thickener matrix imparts So, is the grease still suitable for use? Yes, with the following

no lubricating characteristics. As the sponge releases water conditions:

when squeezed, the grease releases oil under the mechanical • The amount of oil is small, covering only low spots in the

stress in the application. If the thickener did not release the surface of the grease.

oil when stressed, the grease could not perform its lubricating • The grease readily absorbs the oil upon stirring.

duties. Additionally, as the stress is removed, the grease can

absorb some of the released oil back into the thickener.

If you’re in doubt or want to know more about ExxonMobil

While releasing some oil under conditions of the application is greases, contact your ExxonMobil Technical Help Desk or

a prerequisite for sufficient lubrication, oil release can also Field Engineer for assistance.

For more information on all Mobil Industrial Lubricants and services, contact your local company representative

or visit mobilindustrial.com.

© 2012 Exxon Mobil Corporation

All trademarks used herein are trademarks or registered trademarks of Exxon Mobil Corporation or one of its subsidiaries unless indicated otherwise. In this document, the term ExxonMobil is used

for convenience only and may refer to Exxon Mobil Corporation or one of its affiliates. Nothing in this material is intended to override the corporate separateness of local entities.

1014_EXOD_Grease_Static_TT.indd 1 4/3/12 8:53 PM

Job #: EXOD1014 LH: In Progress Cyan

Client: ExxonMobil Save Date: 4-3-2012 8:52 PM Magenta

Job Name: Grease Tech Topic Previous User: ipgna\Tammy.Rafaniello Yellow

Studio Artist: dsoto Document Path: Macintosh HD:Users:david:D Black

Proof #: 2_RELEASE esktop:D...r:Mech:1014_EXOD_Grease_Stat-

ic_TT.indd

Vous aimerez peut-être aussi

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Brochure HouillonDocument2 pagesBrochure HouillonDavid PomaPas encore d'évaluation

- GLXXNuto H SeriesDocument2 pagesGLXXNuto H SeriesDavid PomaPas encore d'évaluation

- Gulf TEC Plus 10W-40 (06.2012)Document1 pageGulf TEC Plus 10W-40 (06.2012)David PomaPas encore d'évaluation

- TD Operators ManualDocument2 pagesTD Operators ManualDavid PomaPas encore d'évaluation

- ISO & DIN Specs - Greases - FinalDocument1 pageISO & DIN Specs - Greases - FinalDavid PomaPas encore d'évaluation

- TDS - G-Profi - SGE 40 NAB - All Lubricating Oil For Type 2, 3, 4 and 6 Jenbacher Gas EnginesDocument1 pageTDS - G-Profi - SGE 40 NAB - All Lubricating Oil For Type 2, 3, 4 and 6 Jenbacher Gas EnginesDavid PomaPas encore d'évaluation

- Gulf Powertrac 4T Oct16 - 20161005040210Document1 pageGulf Powertrac 4T Oct16 - 20161005040210David PomaPas encore d'évaluation

- ISO & DIN Specs - Hydraulic - Final PDFDocument3 pagesISO & DIN Specs - Hydraulic - Final PDFDavid Poma100% (2)

- API Spec S Petrol Engine FinalDocument1 pageAPI Spec S Petrol Engine FinalDavid PomaPas encore d'évaluation

- ISO & DIN Specs - Hydraulic - FinalDocument3 pagesISO & DIN Specs - Hydraulic - FinalDavid Poma100% (1)

- Recomendación de Productos Mercedes-Benz Clase A W176 A 200 CDI (OM 651, 2.0) 176.008 (2014-2015)Document2 pagesRecomendación de Productos Mercedes-Benz Clase A W176 A 200 CDI (OM 651, 2.0) 176.008 (2014-2015)David PomaPas encore d'évaluation

- GLXXMobilux EP 2 MolyDocument4 pagesGLXXMobilux EP 2 MolyDavid PomaPas encore d'évaluation

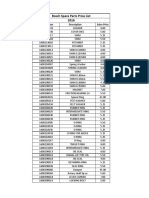

- Bosch Spare Parts Price List 2016Document113 pagesBosch Spare Parts Price List 2016David PomaPas encore d'évaluation

- Gulf-Syngear-Fe-75w-80 - 20-Dec-16 - 20161222052228Document1 pageGulf-Syngear-Fe-75w-80 - 20-Dec-16 - 20161222052228David PomaPas encore d'évaluation

- Captiva Manual MY13Document380 pagesCaptiva Manual MY13David PomaPas encore d'évaluation

- 05 CSG ProceduralDocument86 pages05 CSG ProceduralDavid PomaPas encore d'évaluation

- Gulf TEC Plus 10W-40 (06.2012)Document1 pageGulf TEC Plus 10W-40 (06.2012)David PomaPas encore d'évaluation

- Lubricant Recommendations ChecklistDocument2 pagesLubricant Recommendations ChecklistDavid PomaPas encore d'évaluation

- Lubrizol Additives Fact SheetDocument2 pagesLubrizol Additives Fact SheetDavid PomaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- DC GeneratorDocument26 pagesDC GeneratorAbhijith Mohanan NPas encore d'évaluation

- GEIT 40008GB Widelatitude Film AGFADocument2 pagesGEIT 40008GB Widelatitude Film AGFARolando Nuñez MonrroyPas encore d'évaluation

- Link-Belt: Cylindrical Roller BearingsDocument32 pagesLink-Belt: Cylindrical Roller BearingsHendra GunawanPas encore d'évaluation

- STEM - Physics 1 CG - With Tagged Sci EquipmentDocument15 pagesSTEM - Physics 1 CG - With Tagged Sci EquipmentAndres Kalikasan Sara100% (8)

- Solidstatephysics PDFDocument608 pagesSolidstatephysics PDFTomislav Octenjak100% (1)

- 624-1e Techn Data BE 1Document29 pages624-1e Techn Data BE 1maxilencinaPas encore d'évaluation

- Hydraulics LaboratoryDocument5 pagesHydraulics LaboratoryBernard PalmerPas encore d'évaluation

- Damping Dissipation AbsorbtionDocument3 pagesDamping Dissipation AbsorbtionLia MatiasPas encore d'évaluation

- 2023-24 Exemplar Problems Chemistry Class 11Document188 pages2023-24 Exemplar Problems Chemistry Class 11Sai KarthiPas encore d'évaluation

- Effectively Control Column PressureDocument11 pagesEffectively Control Column PressureRashesh Shah0% (1)

- 11 - Macroscopic Balances For Non-Isothermal Systems Part 1Document6 pages11 - Macroscopic Balances For Non-Isothermal Systems Part 1Monica TuwaidanPas encore d'évaluation

- FinalExam MEC3451 2015Document9 pagesFinalExam MEC3451 2015siamak1438Pas encore d'évaluation

- Ground Response Analysis, NoteDocument56 pagesGround Response Analysis, NoteMuluPas encore d'évaluation

- Mech Eng DsDocument11 pagesMech Eng Ds路人丁Pas encore d'évaluation

- Principles of Semiconductor Devices-L10Document23 pagesPrinciples of Semiconductor Devices-L10LIAKMANPas encore d'évaluation

- Design of Partition Plate BonnetDocument2 pagesDesign of Partition Plate BonnetbytestefPas encore d'évaluation

- Motion Chp. NumericalsDocument6 pagesMotion Chp. NumericalsSatwik AroraPas encore d'évaluation

- Air Cooled Condenser (Acc) and Air Evacuation SystemDocument4 pagesAir Cooled Condenser (Acc) and Air Evacuation SystemCo-gen ManagerPas encore d'évaluation

- Introduction To Seismic Interpretation El AmalDocument33 pagesIntroduction To Seismic Interpretation El AmalFredrick Oshogbunu Ovakporaye100% (1)

- Handouts On DOMDocument10 pagesHandouts On DOMGitanj ShethPas encore d'évaluation

- Chemical EquilibriumDocument14 pagesChemical EquilibriumAman PDPas encore d'évaluation

- NAIRAS Aircraft Radiation Model Development, Dose Climatology, and Initial ValidationDocument33 pagesNAIRAS Aircraft Radiation Model Development, Dose Climatology, and Initial ValidationneizwestnoPas encore d'évaluation

- Kallsner (2009) - Analysis of Fully Anchored Light-Frame Timber Shear Walls-Elastic ModelDocument20 pagesKallsner (2009) - Analysis of Fully Anchored Light-Frame Timber Shear Walls-Elastic ModelIonFlorenta100% (1)

- Buku Introduction To Oceanography PDFDocument276 pagesBuku Introduction To Oceanography PDFmuhammad gilang ramadhanPas encore d'évaluation

- Convecc Ao Forc Ada Externa: Vicente Luiz ScalonDocument18 pagesConvecc Ao Forc Ada Externa: Vicente Luiz ScalonMaria VitóriaPas encore d'évaluation

- Silvaco TCAD Athena User ManualDocument438 pagesSilvaco TCAD Athena User Manualindrajit_0804Pas encore d'évaluation

- Kinematics PDFDocument28 pagesKinematics PDFAmar Ackbar AnthonyPas encore d'évaluation

- Course Specification: Bachelor of Science in Marine TransportationDocument29 pagesCourse Specification: Bachelor of Science in Marine TransportationEjay Rich ReglosPas encore d'évaluation

- Why Kinetics Is Very Important in PharmacyDocument13 pagesWhy Kinetics Is Very Important in PharmacyRavi KantPas encore d'évaluation