Académique Documents

Professionnel Documents

Culture Documents

FMC Conventional Wellhead Chart PDF

Transféré par

Dewy CoxTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FMC Conventional Wellhead Chart PDF

Transféré par

Dewy CoxDroits d'auteur :

Formats disponibles

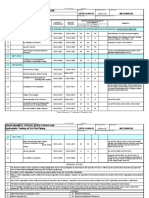

Conventional Wellhead Configuration Chart

Tubing Head Adapters

A-4-M A-4 B-2/P B-1 BO-2 BO-10 A-3-EC A-5-EC A-4-D

Couplings

BO-2 BO-10

Tubing

Hangers

Product Specification Levels

TC-1A-EMS TC-1A-EN TC-1A-ENS-DHCV TC-1A-ENS TC-1A TC-1W TC-EC TC-2C TC-60 TC-60-WD

Selection Chart for PSL — 15,000 psi

Nace? No Yes Yes Yes No Yes

Tubing Heads High H2S? No No Yes No No Yes

Gas Well? No No No Yes Yes Yes

TCM-ET TC-ET TC-60-ET TC-WD-ET

Recommended PSL 3 3 3G 3G 3G 3G

Secondary Seals

(optional)

Reducer Bushing Reducer Bushing PI-Seal SBMS-II FX-RCMS

Slick FS S/OD - FS/ID

Casing Hangers

C-21 C-22 C-122 C-121S C-24 C-29 C-129 C-229

Selection Chart for PSL — 10,000 psi

Nace? No Yes Yes Yes No Yes

Casing Spools

High H2S? No No Yes No No Yes

Gas Well? No No No Yes Yes Yes

C-22-EG C-29 C-29-ET Recommended PSL 2 2 3 3 3 3G

Secondary Seals

(optional)

Reducer Bushing Reducer Bushing PI-Seal SBMS-II FX-RCMS

Slick FS S/OD - FS/ID

Casing Hangers

C-21 C-22 C-24 C-29 Selection Chart for PSL — 5,000 psi

Nace? No Yes Yes Yes No Yes

Casing Heads

High H2S? No No Yes No No Yes

Gas Well? No No Yes Yes No Yes

C-22-EG C-29 C-29-ET

Recommended PSL 1 1 1 2 2 3

Base Plate Option

Bottom Prep Options

Slip-on-Weld Threaded Sliploc

API Reference Charts

Material Body, Bonnet, End, Pressure Controlling Parts,

Class Application & Outlet Stems, & Mandrel Hangers Temperature Class Temp (F) API 6A Testing Requirements

AA General Service Carbon/Alloy Steel Carbon/Alloy Steel K -75º to 180º PR1 PR2 PR2 (Annex F)

BB General Service Carbon/Alloy Steel Stainless Steel L -50º to 180º 1 cycle from 3 cycles from 3 cycles from minimum to

P -20º to 180º minimum to minimum to maximum rated load; 3

CC General Service Stainless Steel Stainless Steel Hangers maximum maximum temperature cycles on the seals

R -40º to 120º from top to bottom at high, low,

S 0 to 150º rated load rated load and ambient temperatures

DD Sour Service Carbon/Alloy Steel Carbon/Alloy Steel

T 0 to 180º 3 open-close 200 open-close

EE Sour Service Carbon/Alloy Steel Stainless Steel 200 open-close cycles at full

U 0 to 250º cycles at cycles at differential WP, including 160

V 35º to 250º Valves full full cycles at ambient, 20 at the

FF Sour Service Stainless Steel Stainless Steel maximum temperature and 20

X 0 to 350º differential differential at the minimum temperature.

HH Sour Service CRA’s CRA’s Y 0 to 650º WP WP

Vous aimerez peut-être aussi

- FMC Conventional Wellhead BreakdownDocument13 pagesFMC Conventional Wellhead BreakdownDewy Cox100% (1)

- TTS Packer and Straddle Setting ProcedureDocument12 pagesTTS Packer and Straddle Setting ProcedureISP100% (1)

- Wireline For Drilling EngineersDocument45 pagesWireline For Drilling EngineersDewy CoxPas encore d'évaluation

- 1" Valves Valve Type 1" 1.5": Taylormade Training Consultants Taylormade Training ConsultantsDocument1 page1" Valves Valve Type 1" 1.5": Taylormade Training Consultants Taylormade Training ConsultantsAnthony Lakpah100% (1)

- BOP Drawings by Sections, RevDocument10 pagesBOP Drawings by Sections, RevberrouiPas encore d'évaluation

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- DST Slip Joint PDFDocument8 pagesDST Slip Joint PDFcrni rokoPas encore d'évaluation

- 03 Coiled Tubing Rigless InterventionsDocument14 pages03 Coiled Tubing Rigless InterventionsRajatgarg0493Pas encore d'évaluation

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruPas encore d'évaluation

- Posiset Ds PDFDocument2 pagesPosiset Ds PDFariosabzPas encore d'évaluation

- 2014 TUBING Reference Tables: Listings For Pipe Sizes To 5 - In. OdDocument28 pages2014 TUBING Reference Tables: Listings For Pipe Sizes To 5 - In. OdOMSD-01 OPMPas encore d'évaluation

- Seal Bore Packer System - RetrievableDocument8 pagesSeal Bore Packer System - RetrievableFabio ParceroPas encore d'évaluation

- Kea Oilfield Engineering Pte LTDDocument9 pagesKea Oilfield Engineering Pte LTDFabio ParceroPas encore d'évaluation

- BHAG 144-01-106 Well Completion SchematicDocument1 pageBHAG 144-01-106 Well Completion Schematicnayakgeeta1966Pas encore d'évaluation

- Nigeria Slickline Operations ManualDocument226 pagesNigeria Slickline Operations ManualWilliam Evans100% (1)

- K10 Software Manual ENDocument12 pagesK10 Software Manual ENfarhad2004Pas encore d'évaluation

- Field Measurements of Annular Pressure and Temperature During Primary CementingDocument5 pagesField Measurements of Annular Pressure and Temperature During Primary CementingDoni KurniawanPas encore d'évaluation

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784Pas encore d'évaluation

- Cameron F FC BookletDocument4 pagesCameron F FC Booklettxlucky80Pas encore d'évaluation

- 7in 29ppf 13Cr-80 JFE BearDocument1 page7in 29ppf 13Cr-80 JFE BearYeit HauPas encore d'évaluation

- Successfully Drills Through Total Losses Zones, Saves 17.6 DaysDocument2 pagesSuccessfully Drills Through Total Losses Zones, Saves 17.6 DaysAriel Della TorrePas encore d'évaluation

- Understanding Sour Service Performace of Coiled TubingDocument12 pagesUnderstanding Sour Service Performace of Coiled TubingMubeenPas encore d'évaluation

- Rotary Cutters PDFDocument3 pagesRotary Cutters PDFAlleyson AkinPas encore d'évaluation

- Slickline: Slickline Refers To A Single Strand WireDocument40 pagesSlickline: Slickline Refers To A Single Strand Wirewilliam MadingPas encore d'évaluation

- 4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description FeaturesDocument1 page4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description Featureshamed1725Pas encore d'évaluation

- Wellhead - Saquib ErbilDocument109 pagesWellhead - Saquib ErbilYasir AhmedPas encore d'évaluation

- Casing Running and Drilling ToolsDocument33 pagesCasing Running and Drilling Toolsfffggg777Pas encore d'évaluation

- PCE Wireline Technology CatalogueDocument120 pagesPCE Wireline Technology CatalogueWaled Fekry100% (1)

- Section 2 - Downhole Tool SystemsDocument38 pagesSection 2 - Downhole Tool SystemsAlejandro ChavarriaPas encore d'évaluation

- Completion Tools CatalogDocument118 pagesCompletion Tools CatalogPavaniimc Mc100% (1)

- Part 2 Well DesignDocument12 pagesPart 2 Well DesignAbdelaziz Mohamed Abdelmoaty ArafaPas encore d'évaluation

- Tdas West Shell 091602Document15 pagesTdas West Shell 091602amin peyvandPas encore d'évaluation

- Completion 4Document36 pagesCompletion 4AboZaidPas encore d'évaluation

- Field Test Procedures Chemical Injection ValveDocument2 pagesField Test Procedures Chemical Injection ValveHua Tien Dung100% (1)

- MR86L - Drilling MontageDocument1 pageMR86L - Drilling MontageGabriel PlazasPas encore d'évaluation

- Sprint CTU ContigencyPlanDocument32 pagesSprint CTU ContigencyPlanJawad Khan100% (1)

- Unu-Gtp-Sc-06-42 Geothermal Drilling and Well PumpsDocument13 pagesUnu-Gtp-Sc-06-42 Geothermal Drilling and Well PumpsPrince MubaiwaPas encore d'évaluation

- Case Study of Wireline Fishing - Hany MetwallyDocument5 pagesCase Study of Wireline Fishing - Hany Metwallyazareiforoush100% (1)

- TV10 Bridge Plug BakerDocument5 pagesTV10 Bridge Plug BakerAlain AlemanPas encore d'évaluation

- Well Surface Equipment: Presented By: Submitted ToDocument17 pagesWell Surface Equipment: Presented By: Submitted ToShaykh AlthamasPas encore d'évaluation

- Drilling Practice Bridge PlugsDocument1 pageDrilling Practice Bridge PlugsJevi SeptiawanPas encore d'évaluation

- Assistant Slickline Operator 001Document3 pagesAssistant Slickline Operator 001Muhammad shehryar KhanPas encore d'évaluation

- CTD Liner Running & CementingDocument6 pagesCTD Liner Running & CementingAdel Ahmed AlkhaligyPas encore d'évaluation

- Kickover Tools KOT SeriesDocument6 pagesKickover Tools KOT SeriesfelipePas encore d'évaluation

- Section 4: Pressure Control EquipmentDocument47 pagesSection 4: Pressure Control Equipmentgonzalito777Pas encore d'évaluation

- 9 Monolock-HeDocument37 pages9 Monolock-HemsvaletPas encore d'évaluation

- Packer Technology: Joshua BeierDocument75 pagesPacker Technology: Joshua BeierOctopus100% (1)

- CPST Pressure Setting Tool PDFDocument1 pageCPST Pressure Setting Tool PDFmahsaPas encore d'évaluation

- 39 Packer Comparison ChartDocument1 page39 Packer Comparison ChartGhinet Teodor-ioan100% (2)

- B. P. Tapon MolibleDocument16 pagesB. P. Tapon Molibleolger nino100% (1)

- Slickline TenderDocument10 pagesSlickline Tender李四江Pas encore d'évaluation

- Evaluating Sustainable Annulus Pressure (SAP) in Sour Wells and The Possible Causes To Avoid RecurrenceDocument46 pagesEvaluating Sustainable Annulus Pressure (SAP) in Sour Wells and The Possible Causes To Avoid RecurrenceDaniel UmañaPas encore d'évaluation

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDocument15 pagesPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Pas encore d'évaluation

- Super Pack: Making The Packoff Super!Document2 pagesSuper Pack: Making The Packoff Super!Jeff NehmePas encore d'évaluation

- SS3100 2.375 DHSIT Valve Maintenance Manual Rev 7 10010661Document54 pagesSS3100 2.375 DHSIT Valve Maintenance Manual Rev 7 10010661Eduardo Oyarzun0% (1)

- Well Control Equipment - Stena DrillMaxDocument12 pagesWell Control Equipment - Stena DrillMaxazeazeazePas encore d'évaluation

- 15 Fishing Tools PDFDocument15 pages15 Fishing Tools PDFjoo123456789Pas encore d'évaluation

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsD'EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsPas encore d'évaluation

- FMC Conventional Wellhead ChartDocument1 pageFMC Conventional Wellhead Chartzapspaz100% (2)

- Mahsr WH 02Document3 pagesMahsr WH 02kukadiya127_48673372Pas encore d'évaluation

- Bit Sizes & Conn.Document1 pageBit Sizes & Conn.Dewy CoxPas encore d'évaluation

- UsingDocument16 pagesUsingガンディー サガールPas encore d'évaluation

- Chapter-2 Drilling Fluids: BariteDocument27 pagesChapter-2 Drilling Fluids: BariteAnggita Dwi LiestyosiwiPas encore d'évaluation

- Job Safety Analysis: Sample Written Program ForDocument27 pagesJob Safety Analysis: Sample Written Program ForniienPas encore d'évaluation

- Subsurface Prong and Plug AssembliesDocument68 pagesSubsurface Prong and Plug AssembliesDewy Cox100% (2)

- Drilling Calculation SheetDocument5 pagesDrilling Calculation SheetDewy CoxPas encore d'évaluation

- Mud EngineeringDocument21 pagesMud EngineeringJorge VidaurrePas encore d'évaluation

- DQS258 20232 A1 - Part A - FinaleDocument26 pagesDQS258 20232 A1 - Part A - Finalenur asyiqinPas encore d'évaluation

- Report On Bridge Development in PakistanDocument8 pagesReport On Bridge Development in Pakistankhawaja Ali100% (1)

- RAF10 - FLOAT CONTROL VALVE InlineDocument4 pagesRAF10 - FLOAT CONTROL VALVE InlineTeoxPas encore d'évaluation

- Manual For Hybrid StructureDocument102 pagesManual For Hybrid StructureVirat KoiliPas encore d'évaluation

- Determination of Soil Stiffness ParametersDocument24 pagesDetermination of Soil Stiffness ParametersVenkataLakshmiKorrapatiPas encore d'évaluation

- Quantity Surveyor Resumes SamplesDocument11 pagesQuantity Surveyor Resumes Samplesnaresh4mrktgPas encore d'évaluation

- CE522A 05 Flexible Pavement DesignDocument133 pagesCE522A 05 Flexible Pavement DesignFranz Ceniza100% (1)

- Masteremaco N 907 MsDocument2 pagesMasteremaco N 907 Msaruncg2Pas encore d'évaluation

- PSC (3 Unit)Document4 pagesPSC (3 Unit)Padma PinnamreddyPas encore d'évaluation

- Equipment Catalogue API Oil SeparatorDocument2 pagesEquipment Catalogue API Oil Separatorbesant vargheesPas encore d'évaluation

- LCT Shielded Primary UD Cable Jacketed: ApplicationsDocument5 pagesLCT Shielded Primary UD Cable Jacketed: ApplicationsLuis MartinezPas encore d'évaluation

- PTL RFQDocument8 pagesPTL RFQKAVISH VINAY MAGIAPas encore d'évaluation

- Streama 2Document3 pagesStreama 2JA MantalPas encore d'évaluation

- Revit MEP 2013 EssentialsDocument3 pagesRevit MEP 2013 EssentialsCADsoft ConsultingPas encore d'évaluation

- LT Pipeline Ball ValvesDocument19 pagesLT Pipeline Ball ValvessiswoutPas encore d'évaluation

- Tension Stiffening and Crack Formation in Reinforced Concrete Members With Fiber-Reinforced Polymer SheetsDocument8 pagesTension Stiffening and Crack Formation in Reinforced Concrete Members With Fiber-Reinforced Polymer SheetsMuhammad Fajrul FalahPas encore d'évaluation

- Concrete Construction Article PDF - The World's Tallest Freestanding Structure Is A Functional Landmark in ConcreteDocument3 pagesConcrete Construction Article PDF - The World's Tallest Freestanding Structure Is A Functional Landmark in ConcretegiovanniPas encore d'évaluation

- CVG 3106 Chp2 Site Studies 2018 Summer FinalDocument69 pagesCVG 3106 Chp2 Site Studies 2018 Summer FinalNathanPas encore d'évaluation

- Cere 131.2 EditedDocument3 pagesCere 131.2 EditedMary Elizabeth SolasPas encore d'évaluation

- Field Development PlanDocument11 pagesField Development PlanOKORIEPas encore d'évaluation

- Base Isolation For Multi Storey Buildings PDFDocument311 pagesBase Isolation For Multi Storey Buildings PDFRal GLPas encore d'évaluation

- Installation Instructions ISOnV ENGDocument48 pagesInstallation Instructions ISOnV ENGLuz BarradasPas encore d'évaluation

- History of Rigid Frame BridgesDocument36 pagesHistory of Rigid Frame BridgesTamaduianu IoanPas encore d'évaluation

- Memorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyDocument7 pagesMemorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyECI HyerPas encore d'évaluation

- Saudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingDocument10 pagesSaudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingAhdal NoushadPas encore d'évaluation

- Strength and Stress-Strain Characteristics of Traditional Adobe Block and Masonry PDFDocument9 pagesStrength and Stress-Strain Characteristics of Traditional Adobe Block and Masonry PDFmanish_shashikantPas encore d'évaluation

- CECR Proposal FormDocument9 pagesCECR Proposal FormAshish ShahPas encore d'évaluation

- Geomembranes For Geofoam Applications PDFDocument22 pagesGeomembranes For Geofoam Applications PDFΘανάσης ΓεωργακόπουλοςPas encore d'évaluation

- Power Plus-Power Plus Box en - 02-2016 - LowDocument124 pagesPower Plus-Power Plus Box en - 02-2016 - LowSorina VacarescuPas encore d'évaluation

- 0160Document1 page0160kevinkaradaPas encore d'évaluation