Académique Documents

Professionnel Documents

Culture Documents

D1203 94

Transféré par

HarleyBenavidesHenriquezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

D1203 94

Transféré par

HarleyBenavidesHenriquezDroits d'auteur :

Formats disponibles

Designation: D 1203 – 94 (Reapproved 2003)

Standard Test Methods for

Volatile Loss From Plastics Using Activated Carbon

Methods1

This standard is issued under the fixed designation D 1203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E 691 Practice for Conducting an Interlaboratory Study to

1.1 These test methods cover the determination of volatile Determine the Precision of a Test Method4

loss from a plastic material under defined conditions of time 2.2 Other Documents:

and temperature, using activated carbon as the immersion ISO 176-1976 Determination of the Loss of Plasticizers

medium. from Plastics by the Activated Carbon Method5

1.2 Two test methods are covered as follows:

3. Terminology

1.2.1 Test Method A, Direct Contact with Activated

Carbon—In this test method the plastic material is in direct 3.1 Definitions—Definitions are in accordance with Termi-

contact with the carbon. This test method is particularly useful nologies D 883 and D 1600 unless otherwise indicated.

in the rapid comparison of a large number of plastic specimens. 4. Significance and Use

1.2.2 Test Method B, Wire Cage—This test method pre-

scribes the use of a wire cage, which prevents direct contact 4.1 The test methods are intended to be rapid empirical tests

between the plastic material and the carbon. By eliminating the which may be useful in the relative comparison of materials

direct contact, the migration of the volatile components to the having the same nominal thickness.

surrounding carbon is minimized and loss by volatilization is NOTE 2—When the plastic material contains plasticizer, loss from the

more specifically measured. plastic is assumed to be primarily plasticizer. The effect of moisture is

1.3 The values stated in SI units are to be regarded as the considered to be negligible.

standard. 4.2 Correlation with ultimate application for various plastic

1.4 This standard does not purport to address all of the materials should be determined by the user. To obtain acceler-

safety concerns, if any, associated with its use. It is the ated tests that more nearly approach actual service conditions,

responsibility of the user of this standard to establish appro- reference should be made to Specification E 197.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 5. Apparatus

NOTE 1—This standard is similar in content (not technically equivalent) 5.1 Balance—An accurate analytical balance, equipped

to ISO 176-1976(E). with Class S weights or better.

5.2 Oven or Bath—A thermostatically controlled oven or

2. Referenced Documents bath capable of maintaining the temperature to within 61°C of

2.1 ASTM Standards: the test temperature, which normally will be in the range from

D 618 Practice for Conditioning Plastics for Testing2 50 to 150°C.

D 883 Terminology Relating to Plastics2 5.3 Containers—Metal cans or wide-mouth screw-top jars,

D 1600 Terminology of Abbreviated Terms Relating to of cylindrical form, approximately 100 mm in diameter and

Plastics2 approximately 1⁄2 L in capacity.

E 197 Specification for Enclosures and Servicing Units for 5.4 Micrometer—A micrometer capable of measuring to the

Tests Above and Below Room Temperature3 nearest 0.0025 mm for measuring the thickness of the test

specimens.

5.5 Metal Cages (for Test Method B)—Wire cages con-

1

These test methods are under the jurisdiction of ASTM Committee D20 on structed from approximately 30-mesh bronze gauze, in cylin-

Plastics and are the direct responsibility of Subcommittee D20.15 on Thermoplastic drical form, having a diameter of 60 mm and a height of 6 mm,

Materials (Section D20.15.11 on Plasticizers).

Current edition approved July 10, 2003. Published September 2003. Originally

approved in 1952. Last previous edition approved in 1999 as D 1203 – 94(99)e1. 4

Annual Book of ASTM Standards, Vol 14.02.

2 5

Annual Book of ASTM Standards, Vol 08.01. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

3

Discontinued. See 1982 Annual Book of ASTM Standards, Parts 40 and 41. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--`,,,````,,``,,,`,,`,,`,`,,,,`-`-`,,`,,`,`,,`---

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Universidad Nacional de Colombia/5965511001

No reproduction or networking permitted without license from IHS Not for Resale, 01/26/2007 12:27:05 MST

D 1203 – 94 (2003)

formed by soldering a strip of gauze at right angles to the migration between varying compositions.

periphery of a disk of bronze gauze. One of the bases acts as a 9.3 Place the container upright in the oven or bath. Unless

lid.

otherwise specified, the temperature of the oven or bath shall

6. Material be 70 6 1°C and the duration of the test 24 h.

6.1 Activated Carbon, 6⁄14 Mesh—It has been found that 9.4 At the end of the 24-h period, remove the container from

different types and grades of activated carbon give differing the oven or bath. Then, within 1 h, remove the specimens from

results, thus making it necessary for the purchaser and the the container, brush free of carbon, and recondition in accor-

seller to agree on the same type and grade in order to obtain dance with Section 8.

concordant results. Care should be taken that an airtight storage 9.5 After reconditioning, reweigh the specimens and desig-

container is used for the activated carbon and that fresh nate this weight as W2. Weight of individual specimens shall be

material is used for each test, unless it can be shown that reuse within a tolerance of 610 %.

--`,,,````,,``,,,`,,`,,`,`,,,,`-`-`,,`,,`,`,,`---

does not affect the results. The activated carbon shall be

screened through a 14-mesh screen immediately prior to use to 10. Procedure—Test Method B, Wire Cage

eliminate fines.

10.1 Proceed as in Section 9 (Test Method A), except place

7. Test Specimens every individual specimen in a small metal wire-mesh cage

constructed as indicated in 5.5, and maintain the temperature at

7.1 The test specimens shall be 50 mm diameter disks made

of the plastic material to be tested. Three specimens of each 100 6 1°C.

formulation shall be tested. NOTE 5—If other conditions of test are desired, they may be employed,

7.2 Thickness of the test specimens shall be 0.25 6 0.025 but shall be specified in the report.

mm.

11. Calculation

NOTE 3—If other thicknesses are desired due to purchase specifications

or other considerations, they may be used, but shall be specified in the 11.1 Calculate the volatile loss, expressed as percent weight

report. loss based on the original specimen weight, as follows:

7.3 Direct comparison of values between materials should weight loss, % 5 @~W 1 2 W2!/W1 # 3 100 (1)

not be made unless all specimens so compared do not vary by

more than 610 % from a given nominal thickness. This

precaution is necessary because of discrepancies that may arise where:

due to edge effects, depletion of volatiles, and the fact that the W 1 = initial weight of test specimen, and

percent weight loss is an inverse function of thickness. W2 = final weight of test specimen.

8. Conditioning 12. Report

8.1 Conditioning—Condition the test specimens at 23 6 12.1 Report the following information:

2°C and 50 6 5 % relative humidity for not less than 20 h prior 12.1.1 Complete identification of the material tested, includ-

to test in accordance with Procedure A of Practice D 618. ing type, source, manufacturer’s code number, and previous

Preferably, specimens shall be suspended to assure free air history,

circulation among the specimens. In cases of disagreement, the

tolerances shall be 61°C and 62 % relative humidity. 12.1.2 Actual thickness to the nearest 0.025 mm for each of

the three specimens tested, and the average of the three,

9. Procedure—Test Method A, Direct Contact with 12.1.3 Percent weight loss recorded to two significant fig-

Activated Carbon ures of each of the three specimens, and the average of the

9.1 Weigh the conditioned specimens individually on the three,

analytical balance and designate this weight as W 1. Weight of 12.1.4 Any observations as to distortion or change in

individual specimens shall be within a tolerance of 610 %. appearance of the specimens,

9.2 Spread 120 cm3 of activated carbon evenly on the 12.1.5 Type of activated carbon used, and

bottom of a container. Place one specimen on top of the 12.1.6 Test temperature and duration of test.

activated carbon and cover it with 120 cm3 of activated carbon.

Place a second specimen (Note 3) on top of the first and cover

it with 120 cm3 of the carbon, followed by a third specimen and

TABLE 1 Plasticizer Volatility–Round Robin Test

then 120 cm3 more of activated carbon. Place a cover on the

Average

container in such a manner that the container will be vented. Material Volatility

Loss,%

SrA SRB rC RD

This is necessary to assure that any possible pressure build-up

Sample 1 High 19.46 0.70 2.43 1.98 6.88

in the container during heating is relieved. Take care that in no Sample 2 Medium 3.83 0.35 0.87 0.98 2.48

case shall the carbon be packed by pressure other than the Sample 3 Low 0.81 0.12 0.42 0.35 1.20

weight of the composite sandwich in the container. A

Sr = within-laboratory standard deviation of the average.

B

SR = between-laboratories standard deviation of the average.

NOTE 4—Only specimens of the same composition or formulation shall C

r = 2.8 S r .

D

be tested in a single container, because of the possibility of cross- R = 2.8 SR .

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Universidad Nacional de Colombia/5965511001

No reproduction or networking permitted without license from IHS Not for Resale, 01/26/2007 12:27:05 MST

D 1203 – 94 (2003)

13. Precision and Bias Practice E 691 to generate data specific to their laboratory and materials,

or between specific laboratories. The principles of 13.1.2-13.1.2.3 would

13.1 Precision:6 then be valid for such data.

13.1.1 Table 1 is based on a round robin conducted in 1988

per Practice E 691, involving three materials tested by five 13.1.2 Concept of r and R—If S r and SR have been

laboratories. All tests were run by Test Method A for 24 h at calculated from a large enough body of data, and for test results

90°C. For each material, all the samples were prepared at one that were averages from testing 23 specimens:

source, but the individual specimens were prepared by the 13.1.2.1 Repeatability, r (comparing two test results for the

laboratory which tested them. Each test result was the average same material, obtained by the same operator using the same

of 23 individual determinations. Three laboratories obtained equipment on the same day)—The two test results should be

two test results for each material, whereas two test laboratories judged not equivalent if they differ by more than the r value of

obtained one test result for each material. the material.

13.1.1.1 The properties used in the analysis are volatility of 13.1.2.2 Reproducibility, R (comparing two test results for

plasticizer from the plastic. The three materials were selected the same material, obtained by different operators using differ-

to represent low, medium, and high volatility plasticizers. ent equipment on different days)—The two test results should

NOTE 6—Caution: The following explanations of r and R (13.1.2-

be judged not equivalent if they differ by more than the R value

13.1.2.3) are only intended to present a means of considering the for that material.

approximate precision of this test method. The data in Table 1 should not 13.1.2.3 Any judgment in accordance with 13.1.2.1 or

be rigorously applied to acceptance or rejection of material, as those data 13.1.2.2 would have approximate 95 % (0.95) probability of

are specific to this round robin and may not be representative of other lots, being correct.

conditions, materials, or laboratories. 13.2 Bias—There are no recognized standards by which to

Users of these test methods should apply the principles outlined in

estimate bias of these test methods.

6

14. Keywords

Supporting data are available from ASTM Headquarters. Request RR: D20-

--`,,,````,,``,,,`,,`,,`,`,,,,`-`-`,,`,,`,`,,`---

1129. 14.1 methanol extract; PVC resin

SUMMARY OF CHANGES

This section identifies the location of selected changes to these test methods. For the convenience of the user,

Committee D20 has highlighted those changes that may impact the use of these test methods. This section may

also include descriptions of the changes or reasons for the changes, or both.

D 1203–94 (1999)e1: (1) Removed all inch-pound units.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Universidad Nacional de Colombia/5965511001

No reproduction or networking permitted without license from IHS Not for Resale, 01/26/2007 12:27:05 MST

Vous aimerez peut-être aussi

- Combined Gas LawDocument19 pagesCombined Gas LawMyths Pinca LozanoPas encore d'évaluation

- You Be The Chemist - The Core of ChemistryDocument96 pagesYou Be The Chemist - The Core of ChemistryShrey AeronPas encore d'évaluation

- D 1125Document7 pagesD 1125Ashfaq AliPas encore d'évaluation

- Calibration of BalancesDocument7 pagesCalibration of BalancesebbasinghPas encore d'évaluation

- Q Lab Correlación Entre ASTM D 7869 e Intemperismo ExteriorDocument89 pagesQ Lab Correlación Entre ASTM D 7869 e Intemperismo ExteriorJuan Angel DechimaPas encore d'évaluation

- DVS205 Dual-Variable Sensor: Specification SheetDocument4 pagesDVS205 Dual-Variable Sensor: Specification SheetRachmi KartiniPas encore d'évaluation

- BS 2648-1955 OvenDocument10 pagesBS 2648-1955 OvenCarson Chow0% (1)

- Is.9573.1998 Rubber Hoses PDFDocument13 pagesIs.9573.1998 Rubber Hoses PDFJohnson BandaruPas encore d'évaluation

- Carboxyl End Group Content of Polyethylene Terephthalate (PET) YarnsDocument3 pagesCarboxyl End Group Content of Polyethylene Terephthalate (PET) YarnsLupita RamirezPas encore d'évaluation

- Form 4 - IGCSE Physics - ThermometersDocument13 pagesForm 4 - IGCSE Physics - ThermometersMr. Borges93% (57)

- Astm 4377-2011 Karl FischerDocument7 pagesAstm 4377-2011 Karl FischerManuel Peña BenavidesPas encore d'évaluation

- General SchenckDocument211 pagesGeneral Schenckingecontrol100% (2)

- D4603 1207332-1Document4 pagesD4603 1207332-1DianaPas encore d'évaluation

- Astm D792-20Document6 pagesAstm D792-20Александр ЛPas encore d'évaluation

- Lesson 01 - MeasurementDocument25 pagesLesson 01 - MeasurementmayureshrmahajanPas encore d'évaluation

- Astm D4603 - IvDocument4 pagesAstm D4603 - IvramPas encore d'évaluation

- Baking Rules Basic Rules of BakingDocument4 pagesBaking Rules Basic Rules of BakingGerry DayananPas encore d'évaluation

- Surveying-Part 1Document39 pagesSurveying-Part 1Marcelo AbreraPas encore d'évaluation

- Astm D2414-21Document9 pagesAstm D2414-21Rajdeep MalPas encore d'évaluation

- D 3465 - 00 Monomero Por CGDocument3 pagesD 3465 - 00 Monomero Por CGsbiasotoPas encore d'évaluation

- Coal Quality and Its Impact On Performance: Dr. D. BanerjeeDocument55 pagesCoal Quality and Its Impact On Performance: Dr. D. BanerjeeShubham PatelPas encore d'évaluation

- General Science MCQS Class First To Eight PDFDocument51 pagesGeneral Science MCQS Class First To Eight PDFMuhammad Youneeb88% (17)

- Standards For Polymer TestingDocument3 pagesStandards For Polymer TestingPramod PamuPas encore d'évaluation

- D 1709 - 03 Rde3mdkDocument9 pagesD 1709 - 03 Rde3mdkSGC POLYBAGPas encore d'évaluation

- Iso 4920 Water RepellencyDocument2 pagesIso 4920 Water RepellencySami Kocahan100% (1)

- D1240Document6 pagesD1240Ненад Кнежевић50% (2)

- E247Document3 pagesE247diego100% (1)

- Memmert WB14 D06981Document32 pagesMemmert WB14 D06981VerdanaPas encore d'évaluation

- F2183Document4 pagesF2183Gustavo SuarezPas encore d'évaluation

- E452 02 PDFDocument14 pagesE452 02 PDFHarleyBenavidesHenriquez100% (1)

- Temprature Hand Book - TempsensDocument182 pagesTemprature Hand Book - TempsensTempsens InstrumentsPas encore d'évaluation

- D 3045Document5 pagesD 3045practice rosPas encore d'évaluation

- Adhesion of PolymersDocument21 pagesAdhesion of PolymersKorso91087Pas encore d'évaluation

- 2.2. Iso 4892-2-2009 PDFDocument8 pages2.2. Iso 4892-2-2009 PDFKhin Khin ThawPas encore d'évaluation

- Iso 11357 2 2020Document9 pagesIso 11357 2 2020Lusy YunitamelPas encore d'évaluation

- 01 Fundamentals of GCMS PDFDocument41 pages01 Fundamentals of GCMS PDFKakaDewi75% (4)

- Astm D 3171-11Document11 pagesAstm D 3171-11PAOLO GIANNELLIPas encore d'évaluation

- NR-13 (English 2014)Document21 pagesNR-13 (English 2014)Ruano Andreola StumpfPas encore d'évaluation

- Matachana Esterilizadora PDFDocument70 pagesMatachana Esterilizadora PDFJustiniano Martel100% (1)

- ASTM D 3895 2007 8pDocument8 pagesASTM D 3895 2007 8psandrasilvabr2124100% (1)

- Solvent Selection GuideDocument17 pagesSolvent Selection GuideNajuma Abdul RazackPas encore d'évaluation

- Summary of ASTM D4628Document6 pagesSummary of ASTM D4628Dewi WulandhariPas encore d'évaluation

- Oven Heat Stability of Poly (Vinyl Chloride) Compositions: Standard Practice ForDocument3 pagesOven Heat Stability of Poly (Vinyl Chloride) Compositions: Standard Practice ForDiego100% (1)

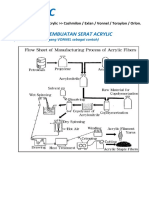

- Acrylic: Alur Proses Pembuatan Serat AcrylicDocument7 pagesAcrylic: Alur Proses Pembuatan Serat AcrylicFathimatuz ZahroPas encore d'évaluation

- Scorch Time in Rubber ProcessingDocument1 pageScorch Time in Rubber ProcessingBharat ChatrathPas encore d'évaluation

- ISO - 1628 - 2 - EN - PDF K-VALUEDocument8 pagesISO - 1628 - 2 - EN - PDF K-VALUEswapon kumar shillPas encore d'évaluation

- Iso 1675Document5 pagesIso 1675cenataliPas encore d'évaluation

- Color Fastness To Crocking AATCC 8-2005Document1 pageColor Fastness To Crocking AATCC 8-2005Hung LePas encore d'évaluation

- Determination of Moisture in Plastics by Relative Humidity SensorDocument4 pagesDetermination of Moisture in Plastics by Relative Humidity Sensorsagar thakkarPas encore d'évaluation

- ASTM D1500 Colour - eDocument2 pagesASTM D1500 Colour - elthyagu100% (1)

- D 5155 - 96 - Rduxntutoty - PDFDocument5 pagesD 5155 - 96 - Rduxntutoty - PDFMaeon LaboratoriesPas encore d'évaluation

- D 6400 - 99Document3 pagesD 6400 - 99Jetzayn Casas AmadorPas encore d'évaluation

- Combustion IC PDFDocument12 pagesCombustion IC PDFKhanza26Pas encore d'évaluation

- SBSS enDocument2 pagesSBSS enasfsdfPas encore d'évaluation

- Oil - ASTM D-1500Document2 pagesOil - ASTM D-1500joju0531Pas encore d'évaluation

- Wet Gas MeterDocument4 pagesWet Gas MeterFareez JamaliPas encore d'évaluation

- The Fundamental Aspects of Electroless Nickel Plating: Glenn MalloryDocument56 pagesThe Fundamental Aspects of Electroless Nickel Plating: Glenn MalloryPeter BergmannPas encore d'évaluation

- Sampling Nonferrous Metals and Alloys in Cast Form For Determination of Chemical CompositionDocument2 pagesSampling Nonferrous Metals and Alloys in Cast Form For Determination of Chemical Compositionaiurea92100% (1)

- Astm D 297Document36 pagesAstm D 297Navneeth KarmachandranPas encore d'évaluation

- Astm D6317 - 2000Document7 pagesAstm D6317 - 2000teymurPas encore d'évaluation

- Din 50018 Sulfur Dioxide Corrosion TestDocument3 pagesDin 50018 Sulfur Dioxide Corrosion TestJoao Pedro Rendeiro Correia de SousaPas encore d'évaluation

- Astm D92-12Document10 pagesAstm D92-12Jose Miguel Bautista Figueroa100% (1)

- Astm D1208 - 1 (En)Document3 pagesAstm D1208 - 1 (En)rezokaPas encore d'évaluation

- SpandexDocument56 pagesSpandexmonowar karimPas encore d'évaluation

- D5462 PDFDocument6 pagesD5462 PDFZamir Danilo Morera ForeroPas encore d'évaluation

- Handbook PolymeDocument9 pagesHandbook PolymeTrùm Dầu Mỏ BkPas encore d'évaluation

- Standart Astm+b311-17Document5 pagesStandart Astm+b311-17Kitana Hananda SuhattaPas encore d'évaluation

- Determination of Acid Values in Organic Solvents, Oils, Fats, PolymersDocument3 pagesDetermination of Acid Values in Organic Solvents, Oils, Fats, PolymersJotyajirao SuryawanshiPas encore d'évaluation

- Classification of DyesDocument2 pagesClassification of Dyesmd_baddrudduzatushar100% (1)

- Carbon Black: Professor Joe Greene Csu, ChicoDocument13 pagesCarbon Black: Professor Joe Greene Csu, Chicoviluk100% (1)

- 6440 PahDocument6 pages6440 PahPenelope MeloPas encore d'évaluation

- PDS Chemfos Liquid AdditiveDocument3 pagesPDS Chemfos Liquid AdditiveKenieta100% (1)

- D1203 22 8 01 Standard Test Methods For Volatile Loss From PlasticsDocument4 pagesD1203 22 8 01 Standard Test Methods For Volatile Loss From Plastics7620383tlPas encore d'évaluation

- Ash Content in Plastics: Standard Test Method ForDocument5 pagesAsh Content in Plastics: Standard Test Method ForSamuel Gaytan RamirezPas encore d'évaluation

- Accelerated Aging of Adhesive Joints by The Oxygen-Pressure MethodDocument8 pagesAccelerated Aging of Adhesive Joints by The Oxygen-Pressure MethodMiguel Legua100% (1)

- Volatile Loss From Plastics Using Activated Carbon Methods: Standard Test Methods ForDocument3 pagesVolatile Loss From Plastics Using Activated Carbon Methods: Standard Test Methods ForPyone Ei Zin100% (1)

- Rigid Poly (Vinyl Chloride) (PVC) Gelation in The Brabender Measuring Mixer. II. Description of PVC Gelation in The Torque in Ection PointDocument6 pagesRigid Poly (Vinyl Chloride) (PVC) Gelation in The Brabender Measuring Mixer. II. Description of PVC Gelation in The Torque in Ection PointHarleyBenavidesHenriquezPas encore d'évaluation

- Rigid Poly (Vinyl Chloride) (PVC) Gelation in The Brabender Measuring Mixer. I. Equilibrium State Between Sliding, Breaking, and Gelation of PVCDocument6 pagesRigid Poly (Vinyl Chloride) (PVC) Gelation in The Brabender Measuring Mixer. I. Equilibrium State Between Sliding, Breaking, and Gelation of PVCHarleyBenavidesHenriquezPas encore d'évaluation

- ASTM Liquid-in-Glass Thermometers: Standard Specification ForDocument64 pagesASTM Liquid-in-Glass Thermometers: Standard Specification ForHarleyBenavidesHenriquezPas encore d'évaluation

- E1104 98 (2003)Document2 pagesE1104 98 (2003)HarleyBenavidesHenriquezPas encore d'évaluation

- D5047 05Document3 pagesD5047 05HarleyBenavidesHenriquezPas encore d'évaluation

- D1676 03Document34 pagesD1676 03HarleyBenavidesHenriquez100% (1)

- D1593 99Document5 pagesD1593 99HarleyBenavidesHenriquezPas encore d'évaluation

- D1204 02Document2 pagesD1204 02HarleyBenavidesHenriquezPas encore d'évaluation

- Grade 5 Science Practice Test: Nebraska Department of Education 2012Document13 pagesGrade 5 Science Practice Test: Nebraska Department of Education 2012Ria SihombingPas encore d'évaluation

- Microlife FR1DZ1Document15 pagesMicrolife FR1DZ1Ky Lan100% (1)

- WISE Pressure Gauge P710, P720, P730Document8 pagesWISE Pressure Gauge P710, P720, P730KayesCjPas encore d'évaluation

- Test Bank For Introduction To General Organic and Biochemistry 10th Edition BettelheimDocument16 pagesTest Bank For Introduction To General Organic and Biochemistry 10th Edition BettelheimTimothy Espinoza100% (31)

- ISLR First PrintingDocument381 pagesISLR First PrintingAbhijeet srivastava100% (1)

- ELITECH ECS-974neo PRODUCT MANUAL (5-6-2021)Document6 pagesELITECH ECS-974neo PRODUCT MANUAL (5-6-2021)Сергей ШкляровPas encore d'évaluation

- G5 Q4W5 DLL MATH MELCsDocument9 pagesG5 Q4W5 DLL MATH MELCsJAIME PARCHAMENTOPas encore d'évaluation

- Topic: Applications of First Order Equations (A) Newton's Law of Cooling/Warming ProblemDocument2 pagesTopic: Applications of First Order Equations (A) Newton's Law of Cooling/Warming ProblemSadia afrinPas encore d'évaluation

- Chem111 Laboratory Activity No. 2Document8 pagesChem111 Laboratory Activity No. 2NeilJohnL.OrineoPas encore d'évaluation

- CP5 PressureDocument27 pagesCP5 PressureMohd IqbalPas encore d'évaluation

- Assembly Instructions SF OrionDocument3 pagesAssembly Instructions SF OrionSamim MaqsoodPas encore d'évaluation

- Termometro Digital de Oido GracoDocument40 pagesTermometro Digital de Oido GracoPaúl AliPas encore d'évaluation

- Heat Thermal Contact Thermal EquilibriumDocument7 pagesHeat Thermal Contact Thermal EquilibriumfariaienPas encore d'évaluation

- Narayana: Admission TestDocument7 pagesNarayana: Admission TestHimanshi DagarPas encore d'évaluation

- Ari Armaturen Relief ValveDocument4 pagesAri Armaturen Relief ValveDidit PandithaPas encore d'évaluation