Académique Documents

Professionnel Documents

Culture Documents

01.03.01 Coolant TR0199991209109 - en

Transféré par

Ebied Yousif AlyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

01.03.01 Coolant TR0199991209109 - en

Transféré par

Ebied Yousif AlyDroits d'auteur :

Formats disponibles

Technical Bulletin

0199 - 99 - 12091/09 EN

This Circular supersedes:

Coolant for plants with gas engines CG132, CG170, CG260

Contents:

- General information

- Cooling systems

- Cooling system protection agents

- Chemical corrosion protection agents

- Antifreezes with corrosion inhibitors

- Coolant conditioning

- Cooling water properties

- Addition of chemical corrosion protection agents

- Addition of antifreezes

- Limit values of the coolant

- Engine circuit

- Heating circuit

- Testing and changing the coolant

- Cleaning the cooling system

- Disposal of the coolant

- Released cooling system protection agents

- Chemical corrosion protection agents

- Antifreezes with corrosion inhibitors

Imprint: Note:

MWM GmbH The part numbers stated in this documentation are not subject to the modification service.

Service Documentation For identifying spare parts, the spare part documentation has to be referred to.

D. Haack, FS-K5T

Carl-Benz-Str. 1

D-68167 Mannheim

Phone: +49 621 384-8895

Fax: +49 621 384-8841

www.mwm.net

Copies to:

Date:

- TR

2012-04-10 - According to SIT 17010

OBJ_DOKU-38686-001.fm 1 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

General information

The owner is solely responsible for compliance with the regulations described in this

Technical Bulletin.

The owner is responsible for observance of the respective national legal provisions.

CAUTION

Danger of destruction

The manufacturer accepts no liability for damages caused by the use of non-approved cool-

ing system protection agents and components not belonging to the scope of delivery, or for

improper operation.

- Only the approved cooling system protection agents according to this bulletin may be

used for the gas engines CG132, CG170, CG260.

See also:

Caterpillar documentation - Layout of Power Plants (Planning and Installation Notes)

Note

All the data in this Technical Bulletin correspond to the latest state of knowledge. If you have

any queries, please contact your Caterpillar dealer.

The cooling water referred to in this bulletin is water with suitable properties for preparing

the coolant. See Colling water properties

The coolant consists of cooling water with cooling system protection agents added. See

Preparation of the coolant

The coolant must be suitable for all the components in the engine (different metals, elasto-

mers) and meet the different requirements in the engine circuit, heating circuit and mixture

cooling circuit. Appropriate properties of the coolant are necessary to avoid damage espe-

cially to the exhaust heat exchanger due to poor quality of the coolant. See Limit values

of the coolant

The products which are released as cooling system protection agents are listed in the chap-

ter Cooling system protection agents.

OBJ_DOKU-38686-001.fm 2 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Cooling systems

Cooling systems are designed differently depending on the requirements.

The designs of cooling circuits, which can normally be installed for the gas engines CG132,

CG170, CG260, are shown in simplified terms below:

A) Cooling system without heat utilisation:

1 Engine cooling circuit

2 Temperature sensor engine inlet

3 Engine

4 Temperature sensor engine outlet

5 Safety valve (3 bar)

6 Diaphragm expansion vessel

7 Coolant pump

8 Cooler

OBJ_DOKU-38686-001.fm 3 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

B) Cooling system with exhaust heat exchanger in the heating circuit:

1 Engine cooling circuit

2 Temperature sensor engine inlet

3 Engine

4 Temperature sensor engine outlet

5 Safety valve (3 bar)

6 Diaphragm expansion vessel

7 Coolant pump

8 Heat exchanger

9 Exhaust gas

10 Exhaust gas heat exchanger

11 Heating circuit

OBJ_DOKU-38686-001.fm 4 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

C) Cooling system with exhaust heat exchanger in the engine cooling circuit:

1 Engine cooling circuit

2 Temperature sensor engine inlet

3 Engine

4 Temperature sensor engine outlet

5 Safety valve (3 bar)

6 Diaphragm expansion vessel

7 Coolant pump

8 Heat exchanger

9 Exhaust gas

10 Exhaust gas heat exchanger

11 Heating circuit

12 Safety valve (10 bar)

13 Temperature sensor exhaust heat exchanger outlet

OBJ_DOKU-38686-001.fm 5 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Cooling system protection agents

CAUTION

Danger of destruction

Cooling system protection agents which are made from different raw products may not be

mixed.

When changing over the cooling circuit to a different product, the compatibility of the

products must be clarified. The cooling system must be purged if necessary before

changing over.

DANGER

Danger of poisoning

Mixing of agents containing amines is prohibited as these can generate carcinogenic nitros-

amines under certain circumstances.

In the system protection agents a distinction is made between:

Checmical corrosion protection agents which form a protective film on metal surfaces

by chemcial reactions and therefore prevent damage such as corrosion and cavitation

on the cooling system but do not act as an antifreeze.

Antifreezes with corrosion inhibitors which avoid freezing of the coolant and also offer

corrosion protection.

Chemical corrosion protection agents

Chemical corrosion protection agents have the following properties:

Properties

Corrosion protection good

Cavitation protection satisfactory

Antifreeze none

Care low

Operational reliability good

Chemical corrosion protection agents, which contain silicates, can damage the floating

seals of water pumps. These agents are therefore not listed under the released products.

OBJ_DOKU-38686-001.fm 6 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Antifreezes with corrosion protection inhibitors

Note

When using antifreezes the heat transition value (heat capacity and heat conductance) of

the coolant is reduced.

Make sure that the cooling systems are designed for it.

Antifreezes with corrosion inhibitors have the following properties:

Properties

Corrosion protection good

Cavitation protection satifactory

Antifreeze up to -45 °C depending on the mixing ratio

Care low

Operational reliability good

Note

Antifreezes with corrosion protection are used when sub-zero ambient temperatures can

occur, e.g. containers on dumps.

OBJ_DOKU-38686-001.fm 7 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Preparing the coolant

The coolant is prepared by adding a chemical corrosion protection agent or an antifreeze

with corrosion inhibitors to the cooling water.

Cooling water properties

CAUTION

Danger of destruction

Sea water, river water, brackish water or industrial waste water is unsuitable as cooling wa-

ter for the gas engines CG132, CG170, CG260 and systems.

Depending on the structure of the cooling circuit, the following limit values must be ob-

served when preparing the cooling water.

The local water board will provide information about the properties of the water and can also

be determined by means of an MWM test set, or in a suitable chemical laboratory.

Sampling and water analysis must be carried out with great care and accuracy.

Only clean and odourless water with the following properties may be used as a cooling wa-

ter:

Limit values of the cooling water for the cooling systems A and B without exhaust

heat exchanger

pH value at 25 °C 6.5 to 8.5

Chloride-ion content maximum 100 mg/l

Sulphate-ion content maximum 100 mg/l

Total hardness 3 to 12 °dH

Carbonate hardness proportion of the total hard- at least 3 °dH

ness

Limit values of the cooling water for cooling system C with exhaust heat exchanger

pH value at 25 °C 6.5 to 8.5

Chloride-ion content less than 20 mg/l

Sulphate-ion content maximum 100 mg/l

Total hardness less than 1 °dH

Carbonate hardness proportion of the total hard- less than 1 °dH

ness

OBJ_DOKU-38686-001.fm 8 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Note

In line with the SI dimension system, the water hardness is specified in mol per litre or, for

low concentrations, in millimol per litre (mmol/l).

The unit degree German hardness (°dH) is still the most commonly used in Germany.

The degree German hardness (°dH) is converted into mmol/l as follows:

1 °dH = 0.178 mmol/l, 1 mmol/l = 5.6 °dH

In case of deviation from the limit values listed above the cooling water is prepared as fol-

lows:

pH value too low:

Addition of diluted sodium or potassium lye. It is advisable to make small sample mix-

tures before adding.

Total hardness and/or carbonate hardness too low:

Mixing with harder water

Harder water is usually available in the form of drinking water (city mains water).

Total hardness, chloride and/or sulphates too high:

Mixing with softened water

Softened water is distilled water or water treated with an ion exchanger.

Another water analysis must be carried out after preparing the cooling water.

OBJ_DOKU-38686-001.fm 9 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Addition of chemical corrosion protection agents

The corrosion protection agent is mixed with the cooling water first and then filled into the

cooling system as described in job card B 9-0-4 Emptying and filling the cooling sys-

temin the appropriate operating manual.

The necessary concentrations of the chemical corrosion protection agent in cooling circuits

are determined according to the specifications of the manufacturer or supplier.

CAUTION

Danger of destruction

An under-concentration of the chemical corrosion protection agent has a damaging effect

on the cooling system, especially aluminium parts.

Observe the correct dosing of the chemical corrosion protection agent.

Addition of antifreezes with corrosion inhibitors

The antifreeze is mixed with the cooling water first and then filled into the cooling system

as described in job card B 9-0-4 Emptying and filling the cooling systemin the appropri-

ate operating manual.

The coolant must be checked for the necessary freezing protection after preparation.

The freezing protection of the antifreeze depends on the mixing ratio with the water:

Antifreeze Cooling water Freezing protection up to

35% 65% -23 °C

40% 60% -29 °C

45% 55% -35 °C

50% 50% -40 °C

Note

The concentration of the antifreeze must be at least 35% to ensure an adequate corrosion

protection.

When using an antifreeze with corrosion inhibitors for corrosion protection the antifreeze

must stay in the cooling system even at temperatures above freezing point.

CAUTION

Danger of destruction

Pure antifreeze may not be filled into the cooling system.

Freezing protection below -40 °C is only possible in consultation with the Caterpillar

dealer.

The limits values of the coolant listed below must be observed:

OBJ_DOKU-38686-001.fm 10 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Limit values of the coolant

Engine circuit

Limit values of the coolant for the cooling systems A and B without exhaust heat

exchanger in the engine circuit

If the specifications for cooling water quality of the cooling system protection agent are

complied with, the quality of the coolant is sufficient.

Limit values of the coolant for the cooling system C with exhaust heat exchanger in

the engine circuit

pH value at 25 °C 7.5 to 8.5

Chloride-ion content less than 20 mg/l

Total hardness less than 1 °dH

Filling volumes maximum 2 m3

Temperature at exhaust heat exchanger outlet maximum 110 °C

Note

The filling volume is limited to 2 m3 to avoid heat build-up deposits due to escaping carbon-

ate at the limit surfaces of the exhaust heat exchanger.

Heating circuit

CAUTION

Danger of destruction

This coolant, which is exclusively for use in heating circuits of iron materials, is unsuitable

for an engine cooling circuit.

The manufacturer will not be liable for damage caused by using this coolant in an engine

cooling circuit.

Limit values of the coolant for the heating circuit

pH value at 25 °C 9 to 10.5

Electrical conductivity less than 0.1 mS/cm

Oxygen (O2) less than 0.05 mg/l

Chloride less than 20 mg/l

Copper (Cu) less than 0.05 mg/l

Total iron (Fe) less than 0.05 mg/l

Phosphate (PO4) 5 to 10 mg/l

Earth alkalis less than 0.02 mmol/l

Total hardness less than 0.1 °dH

OBJ_DOKU-38686-001.fm 11 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Testing and changing the coolant

The cooling system must be inspected regularly and maintained at the given intervals. This

also includes inspecting the properties of the coolant and the concentrations of the cooling

system protection agents as well as refilling and changing the coolant.

The cooling system protection agent in the coolant must be checked and the concentration

corrected according to job card B 9-1-1 Checking corrosion protection agents or anti-

freezes in coolant in the appropriate operating manual.

When checking the chemical corrosion protection agents using a refractometer, the manu-

facturer's instructions for the conversion of %Brix to Vol.% must be observed.

Note

The specifications of the cooling system protection agent manufacturer must be observed

when checking the coolant.

All inspections must be documented in the log book according to the maintenance sched-

ule.

The coolant in cooling circuits must be inspected at least every 6 months and changes at

least every two years.

Also change the coolant in case of:

in case of penetration by lubricating oil

lubricating oil penetration

in case of heavy turbidity due to corrosion residue or other foating particles

CAUTION

Danger of destruction

Non-observance of these instructions and requirements when producing and using the

coolants will lead to increased component wear and damage.

The same product must be used again when refilling the coolant.

If a product change is necessary, check the compatibility of the products (note manu-

facturer specifications and composition of the products).

In case of incompatibility the entire cooling system must be cleaned thoroughly before

changing the product.

Obviously only products released by the manufacturer may be used.

OBJ_DOKU-38686-001.fm 12 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Cleaning the cooling system

Clean the entire cooling system in case of:

soiling

lubricating oil penetration

in case of penetration by lubricating oil

product change (incompatible products)

maintenance work

The coolant must be drained completely and purged with a cleaning agent released by the

manufacturer. Those are given in the Technical Bulletin 0199-99-12147.

OBJ_DOKU-38686-001.fm 13 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Disposal of the coolant

Coolant and cooling system protection agents may not be disposed of in the environment.

They must be disposed properly according to the respective, national, legal regulations and

specifications of the manufacturer or supplier by a licenced disposal company.

OBJ_DOKU-38686-001.fm 14 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Released cooling system protection agents

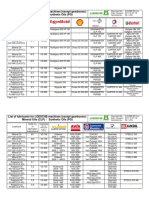

Chemical corrosion protection agents

Valid for: CG132, CG170, CG260

Addinol

Protect Extra

Aqua-Concept

CORACON BL2

CORACON BL6

Arteco

Havoline XLI

Caltex

XL Corrosion Inhibitor Concentrate

Chevron/Texaco

Extended Life Corrosion Inhibitor

Total

Total WT Supra

OBJ_DOKU-38686-001.fm 15 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Antifreezes with corrosion protection inhibitors

Note

The released antifreezes with corrosion inhibitors are divided into product groups A and B

due to their different compositions.

CAUTION

Danger of destruction

Non-observance of these instructions and requirements when producing and using the

coolants will lead to increased component wear and damage.

Products of group A may not be used with products of group B.

Valid for: CG132, CG170, CG260

Product group A

Aral

Antifreeze Extra

BASF

Glysantin G48 / Protect Plus

BP

BP anti-frost Code No. X 2270 A

Castrol

Antifreeze NF

Fuchs Europe

MAINTAIN FRICOFIN

INEOS

Napgel C2270/1

Mobil

Antifreeze Extra

OMV

Coolant plus

Shell

Glyco Shell

TOTAL

Glacelf MDX

OBJ_DOKU-38686-001.fm 16 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

Product group B

Addinol

Antifreeze Extra

Aqua-Concept

CORACON BF6

ARTECO

Havoline XLC

Havoline XLC-PG

Caltex

Extended Life Coolant

Chevron/Texaco

Havoline Extended Life Coolant HELAC (no nitrite or molybdate)

Extended Life Coolant TELC (with nitrite and molybdate)

DELO Extended Life Coolant/Antifreeze PG

Fuchs

Maintain Fricofin LL

TOTAL

Glacelf CHP Supra

Glacelf Supra

Note

Some manufacturers also offer ready mixtures. These mixtures can also be used if they are

made with the above mentioned products in the respective necessary concentration.

Service Information

This document has been created digitally and is valid without a signature.

OBJ_DOKU-38686-001.fm 17 © MWM GmbH

Technical Bulletin

0199 - 99 - 12091/09 EN

OBJ_DOKU-38686-001.fm 18 © MWM GmbH

Vous aimerez peut-être aussi

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Document42 pagesTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiPas encore d'évaluation

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezPas encore d'évaluation

- Machinery Lubrication November December 2017 PDFDocument89 pagesMachinery Lubrication November December 2017 PDFJorge Cuadros BlasPas encore d'évaluation

- The Next Generation Gas Engine Oil Mobil Pegasus 1005Document46 pagesThe Next Generation Gas Engine Oil Mobil Pegasus 1005Sandeep100% (1)

- ANALEX PQL Datasheet PDFDocument2 pagesANALEX PQL Datasheet PDFmaye palominoPas encore d'évaluation

- Common Position Paper 2012 Signed B7 PDFDocument5 pagesCommon Position Paper 2012 Signed B7 PDFcarbasemyPas encore d'évaluation

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Document8 pagesList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaPas encore d'évaluation

- Auma GreaseDocument1 pageAuma GreaseQuoc HungPas encore d'évaluation

- Warning: Recommended Lube Oil Change Intervals Taking An Oil SampleDocument6 pagesWarning: Recommended Lube Oil Change Intervals Taking An Oil SamplegalaxiprincePas encore d'évaluation

- Clean Oil GuideDocument28 pagesClean Oil GuideAlex VulpePas encore d'évaluation

- Shell Melina S30: Performance, Features & BenefitsDocument2 pagesShell Melina S30: Performance, Features & BenefitsStefas DimitriosPas encore d'évaluation

- ATF LubricantDocument35 pagesATF LubricantTung NguyenPas encore d'évaluation

- Fuchs - Titan Race PRO S Full Syn PAO EsterDocument2 pagesFuchs - Titan Race PRO S Full Syn PAO EsterB3NPas encore d'évaluation

- Approved Lubrication DDocument2 pagesApproved Lubrication DMostafa MohamedPas encore d'évaluation

- Engine Oil MythsDocument2 pagesEngine Oil Mythshpss77Pas encore d'évaluation

- Construction Lube Apps 18 Jan 16Document46 pagesConstruction Lube Apps 18 Jan 16José Cesário NetoPas encore d'évaluation

- CEP VFD ManualDocument234 pagesCEP VFD ManualUsama ZubairPas encore d'évaluation

- Natural Gas Engines LubricationDocument9 pagesNatural Gas Engines Lubricationjameel babooramPas encore d'évaluation

- Section 5 - Fuel, Lubricating Oil, and CoolantDocument11 pagesSection 5 - Fuel, Lubricating Oil, and CoolantRamon100% (1)

- Ss Mobilith SHCDocument2 pagesSs Mobilith SHCFarrukh JamalPas encore d'évaluation

- Ficha Técnica Cat DEO - 15W40 & 10W30Document2 pagesFicha Técnica Cat DEO - 15W40 & 10W30RhuanPas encore d'évaluation

- The Role of Soot Particles in The Tribological Behavior of Engine Lubricating OilsDocument10 pagesThe Role of Soot Particles in The Tribological Behavior of Engine Lubricating OilsSebastian JosephPas encore d'évaluation

- Lubrication of Power Plant Equipment PDFDocument34 pagesLubrication of Power Plant Equipment PDFRavinder SharmaPas encore d'évaluation

- Lubimax 1606 - MSDSDocument7 pagesLubimax 1606 - MSDSkarthibenPas encore d'évaluation

- Shell Albida EMS2Document1 pageShell Albida EMS2Muhammad Haris BaigPas encore d'évaluation

- TribologiaDocument40 pagesTribologiaKevin Diaz NoriegaPas encore d'évaluation

- 3 - Pertaabi, 29 November 2021Document28 pages3 - Pertaabi, 29 November 2021Noviandra SallasaPas encore d'évaluation

- Presentation STLE 2015 v4Document25 pagesPresentation STLE 2015 v4Carlos ZapataPas encore d'évaluation

- Viscosity ClassificationsDocument6 pagesViscosity ClassificationsDarmawan PutrantoPas encore d'évaluation

- Report On Oil Types and Applications: 3 YearDocument5 pagesReport On Oil Types and Applications: 3 YearMahmoud KassabPas encore d'évaluation

- Synthetic Gear Oil SelectionDocument9 pagesSynthetic Gear Oil Selectionsmallik3Pas encore d'évaluation

- LT32599 10Document38 pagesLT32599 10Angela BaileyPas encore d'évaluation

- Lubricant Base Stocks: OutlineDocument23 pagesLubricant Base Stocks: OutlineJahmia Coralie100% (1)

- General Discussions On Lubricating OilsDocument59 pagesGeneral Discussions On Lubricating OilsHari PurwadiPas encore d'évaluation

- Fire-Resistant, Water-Free Hydraulic Re90222 - 2012-05 - 2 PDFDocument16 pagesFire-Resistant, Water-Free Hydraulic Re90222 - 2012-05 - 2 PDFDennis Huanuco CcamaPas encore d'évaluation

- Product Information Navigo 6 So: DescriptionDocument2 pagesProduct Information Navigo 6 So: DescriptionCOMITYPas encore d'évaluation

- 12B OilAnalysisDocument2 pages12B OilAnalysisMuhamad BadarPas encore d'évaluation

- Aceites Lubricantes para Motores Diesel Sep-2015Document28 pagesAceites Lubricantes para Motores Diesel Sep-2015Carlos Andres BonillaPas encore d'évaluation

- Klüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain BearingsDocument4 pagesKlüberlub BE 71-501: Special Lubricating Grease For Rolling and Plain Bearingsphucdc095041Pas encore d'évaluation

- Mil L 2105DDocument17 pagesMil L 2105Dkamal arabPas encore d'évaluation

- Worm Gear LubricationDocument4 pagesWorm Gear LubricationEr Mishal GandhiPas encore d'évaluation

- Velvex Industrial Oil - Nandan Petrochem LTDDocument27 pagesVelvex Industrial Oil - Nandan Petrochem LTDNandan Petrochem Ltd0% (1)

- How To Select and Service Turbine OilsDocument5 pagesHow To Select and Service Turbine OilsmvanzijpPas encore d'évaluation

- Overview of Rotating Disc Electrode (RDE) Optical Emission Spectroscopy For In-Service Oil AnalysisDocument6 pagesOverview of Rotating Disc Electrode (RDE) Optical Emission Spectroscopy For In-Service Oil AnalysisenioleaoPas encore d'évaluation

- Lubrication Best Practices For Better Asset ManagementDocument12 pagesLubrication Best Practices For Better Asset ManagementJango69100% (1)

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshPas encore d'évaluation

- Berutox FB 22: Technical Product InformationDocument1 pageBerutox FB 22: Technical Product InformationMauricio SánchezPas encore d'évaluation

- The Cooling SystemDocument20 pagesThe Cooling SystemHari PurwadiPas encore d'évaluation

- SS-150 Servo System Oil Details PDFDocument1 pageSS-150 Servo System Oil Details PDFJagadeesh SharanPas encore d'évaluation

- EIC N 1001 0 Hydraulic FluidsDocument13 pagesEIC N 1001 0 Hydraulic FluidsCharitha LiyanagamaPas encore d'évaluation

- Design Engineer's Guide - Selecting A Lubricant For Ball ScrewsDocument10 pagesDesign Engineer's Guide - Selecting A Lubricant For Ball ScrewsDat RomanPas encore d'évaluation

- Whitepaper - Particle Counters For Oil Analysis - Design & Specifications PDFDocument4 pagesWhitepaper - Particle Counters For Oil Analysis - Design & Specifications PDFAhmed El-ShafeiPas encore d'évaluation

- Chapter 6 LubricationDocument24 pagesChapter 6 Lubricationchala nigussiePas encore d'évaluation

- A Comprehensive Solution For Extreme and Specialty ApplicationsDocument7 pagesA Comprehensive Solution For Extreme and Specialty ApplicationsAmjedPas encore d'évaluation

- Audit, Develop and ImplementDocument8 pagesAudit, Develop and ImplementVishal MadooPas encore d'évaluation

- Shovel Lubrication PDFDocument2 pagesShovel Lubrication PDFSounak SasmalPas encore d'évaluation

- The Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?D'EverandThe Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?Pas encore d'évaluation

- Plano Cat D6RDocument2 pagesPlano Cat D6Redhuam100% (4)

- RENR5806Document2 pagesRENR5806Ebied Yousif AlyPas encore d'évaluation

- Senr 8570Document2 pagesSenr 8570Ebied Yousif AlyPas encore d'évaluation

- 16H Motor Grader Hydraulic System: 6ZJ1-UPDocument2 pages16H Motor Grader Hydraulic System: 6ZJ1-UPTino B OLPas encore d'évaluation

- RENR5353Document2 pagesRENR5353Ebied Yousif AlyPas encore d'évaluation

- MEGECHA Head WORK (Revised) 2Document159 pagesMEGECHA Head WORK (Revised) 2Abiued EjiguePas encore d'évaluation

- Building Services Planning Manual 2007Document120 pagesBuilding Services Planning Manual 2007Shehzad Ahmed100% (2)

- SANS 1936-2 Geotechnical Investigations and DeterminationsDocument37 pagesSANS 1936-2 Geotechnical Investigations and Determinationsdran100% (2)

- Underwater WindmillDocument21 pagesUnderwater Windmillbhagyashree behera100% (1)

- Foamed Concrete ProposalDocument7 pagesFoamed Concrete ProposalDawit SolomonPas encore d'évaluation

- Helmut - Jeske - Krepseoppdrett - PPT (KompatibilitetsmoDocument63 pagesHelmut - Jeske - Krepseoppdrett - PPT (KompatibilitetsmoRenato GavanPas encore d'évaluation

- Spectrus OX1201: Liquid Bromine Microbiological Control Agent PrecursorDocument2 pagesSpectrus OX1201: Liquid Bromine Microbiological Control Agent Precursorengr.shahid041Pas encore d'évaluation

- Kikuyu: Isitasbadas Environmentalists Suggest?Document32 pagesKikuyu: Isitasbadas Environmentalists Suggest?CompleatGolferPas encore d'évaluation

- Part 2 2018 Answer KeyDocument11 pagesPart 2 2018 Answer KeyMeljun Gementiza0% (1)

- Semester 2 Final ReflectionDocument6 pagesSemester 2 Final Reflectionapi-202153663Pas encore d'évaluation

- Slop Oil and Oily Sludge Recovery Brochure - tcm11 68550Document16 pagesSlop Oil and Oily Sludge Recovery Brochure - tcm11 68550Irelena RomeroPas encore d'évaluation

- Drawing Boiler PartsDocument1 pageDrawing Boiler PartsAnonymous FZs3yBHh7Pas encore d'évaluation

- Sayano-Shushenskaya Hydro Power Station Accident - 2009Document5 pagesSayano-Shushenskaya Hydro Power Station Accident - 2009aikohananPas encore d'évaluation

- Shell Gadus S2 OG 40: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 OG 40: Performance, Features & BenefitsAmanPas encore d'évaluation

- SOALDocument4 pagesSOALjnt exenticPas encore d'évaluation

- Before The FloodDocument31 pagesBefore The FloodMonika Nina NodaloPas encore d'évaluation

- Hydraulic JumpDocument10 pagesHydraulic JumpnaeemPas encore d'évaluation

- 3999WS-Zink Spray 80 81GB-EnDocument11 pages3999WS-Zink Spray 80 81GB-Enhvdb72Pas encore d'évaluation

- Merck - CromatografiaDocument406 pagesMerck - CromatografiaechorossiPas encore d'évaluation

- Drain Pump DaikinDocument2 pagesDrain Pump DaikinJonathan GanPas encore d'évaluation

- Chapter 1: Introduction: 1.1 GeneralDocument19 pagesChapter 1: Introduction: 1.1 GeneralGautamPas encore d'évaluation

- Biomass Technology Brochure - Babcock Wilcox VolundDocument24 pagesBiomass Technology Brochure - Babcock Wilcox VolundAlex MartayanPas encore d'évaluation

- Ansi Asabe S424.1 - 1992 (R2012)Document8 pagesAnsi Asabe S424.1 - 1992 (R2012)StephanPas encore d'évaluation

- Aquaculture Systems: Presented By: M.F.Sc. I YearDocument18 pagesAquaculture Systems: Presented By: M.F.Sc. I Yearshivani vermaPas encore d'évaluation

- UHM LandscapeMasterPlan2016Document114 pagesUHM LandscapeMasterPlan2016joycemjjPas encore d'évaluation

- Extraction of Ce and TH From Monazite Using REE Tolerant Aspergillus NigerDocument10 pagesExtraction of Ce and TH From Monazite Using REE Tolerant Aspergillus Nigerjay9037Pas encore d'évaluation

- Case Study 1 Expanded WATERS OF KERALAM For Initial RoundDocument6 pagesCase Study 1 Expanded WATERS OF KERALAM For Initial RoundbensunPas encore d'évaluation

- Literature ReviewDocument2 pagesLiterature ReviewMc Cleve Christopher FooPas encore d'évaluation

- Executive MBA Project - Self Help Allowance - FinalDocument55 pagesExecutive MBA Project - Self Help Allowance - FinalKumar SourabhPas encore d'évaluation

- SP Nature Based SolutionsDocument5 pagesSP Nature Based SolutionsLídia SilvaPas encore d'évaluation