Académique Documents

Professionnel Documents

Culture Documents

Woodworking - Basics-Shopjigs PDF

Transféré par

v00d00bluesTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Woodworking - Basics-Shopjigs PDF

Transféré par

v00d00bluesDroits d'auteur :

Formats disponibles

Plans N O W ®

TOOLS & TECHNIQUES SERIES

w w w. p l a n s n o w. c o m

7 MUST-HAVE SHOP JIGS

O ver the past twenty

years, we’ve made quite

a few jigs in our shop. Some

much that we’ve even had

to replace some of them —

they’ve been worn out.

or two and pretty soon

you’ll be asking yourself

how you ever got along

more satisfaction out of

your woodworking.

But these jigs have some-

of them were designed for Jigs that are this handy without them. thing else in common. They

a specific purpose, used actually become extensions You’ll discover that they can each be built in under

once, and then hung on the of the power tools they’re transform your everyday an hour, and usually with

wall where they’ve gath- used with, making the tool power tools into real per- pieces pulled from the

ered dust ever since. all the more useful. formers, making your scrap bin. So even though

But there are a few jigs That’s what all the jigs on woodworking faster, easi- you’ll find them invaluable

that get used all the time. the next few pages have in er, safer, and more accurate. in your shop, the initial

In fact, they get used so common. Try building one And as a result, you’ll get investment is quite small.

1 Auxiliary Fence

In addition to cutting work-

pieces to size, I also use

my table saw for cutting

joints. And one of the joints

that I make most fre-

quently is a rabbet.

Typically, I use a dado

blade to cut rabbets. But to

do this, part of the blade

needs to be “buried” in a

wood auxiliary fence, see

first photo at right.

Clamping a piece of onds — without having to consists of two plywood here is a nice, snug fit,

wood to the side of your rip fuss with clamps. sides glued and screwed to allowing the auxiliary fence

fence is one way to do this, And by making one side a pair of plywood spacer to slip over the rip fence

but I prefer to use a slip-on of the fence 7" high, it dou- strips, see Fig. 1. easily, but without any play.

auxiliary fence. The nice bles as a tall support fence When cutting the spacer STOPS. Finally, to hold the

thing about this fence is when cutting tall pieces, see strips, it’s important to fence in place, a couple of

that it can be dropped down second photo. make them the same width plywood stops are added to

over my rip fence in sec- CONSTRUCTION. The fence as your rip fence. The goal the ends, see Fig. 2.

1 2

a.

From Woodsmith Magazine page 1 © August Home Publishing Co.

2 Push Block

I’ve seen a lot of push block gives you plenty of

blocks or push sticks that control. And instead of fit-

are thin and narrow. This ting between the fence and

allows you to maneuver the the blade, this push block is

push stick between the designed to ride right over

blade and the rip fence the blade, see Fig. 2.

when ripping thin pieces. After a while, the bottom

But I find that trying to of the push block will get

guide a workpiece through “chewed up.” When this

a saw with one of these happens, just throw it out

push sticks is a little like and make a new one.

trying to push a brick with

a straw. This is one case 1 2

where wider is better.

That’s why I like this

push block design. It’s noth-

ing more than an 8"-long

block with a shallow notch

cut on the bottom, see Fig.

1. The notch fits over the

back edge of the workpiece

that’s being cut.

The wide profile of the

3 Crosscut Sled

The miter gauge that for the base. (I made mine

comes with most table saws about 16" x 30".)

is fine for crosscutting nar- Next cut a hardwood

row pieces. But if you try runner to fit in the miter

to use it to crosscut a wide gauge slot of your table saw.

panel, you’ll quickly dis- Size the runner so it slides

cover how inadequate it is. smoothly in the slot. Then

It rocks back and forth glue and screw it to the bot-

in the slot or bumps into tom of the base.

the edge of the table saw To keep the jig aligned, a

top, making crosscutting second runner is added to

not only difficult, but poten- the bottom of the base. This your saw and trim off the dust relief, see Fig. 1a.

tially dangerous as well. one rides against the edge right edge of the base. To position the fence so

That’s why I like to use a of the table saw extension FENCE. For the fence, I that it’s square to the blade,

crosscut sled when cutting wing, see photo. used a piece of “2-by” stock use a framing square, see

large panels. This jig works Once both runners are with a chamfer routed on Fig. 1. Then just screw the

like a giant miter gauge, attached, place the jig on the bottom edge for a saw- fence to the base.

allowing you to crosscut

wider pieces. 1

The large, flat base of the a.

sled provides plenty of sup-

port for wide panels. A pair

of runners guides the sled

and the workpiece smooth-

ly through the saw. And a

fence on the trailing edge

of the sled ensures that

every cut will be square.

CONSTRUCTION. To build

the jig, start by cutting a

piece of 3/4"-thick plywood

From Woodsmith Magazine page 2 © August Home Publishing Co.

4 Miter Gauge Fence

Using a miter gauge with- JIG CONSTRUCTION. The

out an auxiliary fence is like “adjustable” part of the

wearing a pair of trousers fence is made up of two slid-

without suspenders (or a ing pieces, see Fig. 1. A rab-

belt) — you just don’t get bet cut on each piece allows

the support you need. the two pieces to interlock.

And while it’s pretty easy The top piece has a cou-

to just screw a piece of ple of threaded inserts so

wood to the front of your it can be attached to the

miter gauge, I think it’s miter gauge with machine

worth taking just a couple screws, see Fig. 1a.

minutes to make an The bottom piece will “pinch” the bottom chewed up, you can make

adjustable auxiliary fence. “floats” under the top one piece in place, see Fig. 1a. a new one.

This way, you can move the (until the two machine A replaceable face is STOP BLOCK. To make the

fence as close to the blade screws are tightened). By screwed to the front of the fence even more useful, you

{ To make repeat as you want, even when sanding the top piece 1/32" bottom sliding piece. This can clamp a stop block to

cuts, clamp a stop mitering, see Fig. 2. thinner than the bottom, it way, when the fence gets the face, see margin photo.

block to the fence.

1 2

a.

5 Plywood Edge Guide

Sometimes it’s easier to use your router and a straight

a circular saw to cut a full bit, see detail 'a.'

sheet of plywood than it is To use the jig, just place

to balance a 4x8 sheet on the edge of the base on

the table saw. This plywood your layout line and clamp

edge guide will give you the jig in place. (Note: If

table saw accuracy using you’re using a router, make

either a circular saw or a sure to use the same diam-

router. eter bit that you used to

The construction of the trim the edge of the jig.)

jig is remarkably simple.

It’s just a piece of 1/4" hard-

board screwed to a narrow

plywood fence, see draw-

ing. (I made mine 4 ft. long

for cross-cutting a full sheet a.

of plywood.)

The trick to making the

jig is to start off with an

extra-wide base. Then

after attaching the

fence, trim one side

with your circular

saw, the other side with

From Woodsmith Magazine page 3 © August Home Publishing Co.

6 Drill Press Table

Most drill presses seem to fence is essential when bottom edge of

be designed more for met- you need to drill a series the fence pro-

alworking than for wood- of holes all the same dis- vides a relief for

working. They’re equipped tance from the edge of a sawdust.

with dinky tables that lack workpiece. And by clamp- The carriage

any fences or guides. ing a stop block to the bolt allows the

Fortunately, it doesn’t take fence, you can drill identi- fence to pivot back and

much to transform an ordi- cally positioned holes in forth in relationship to the

nary drill press into a “real” multiple workpieces. drill bit. When the fence is cou-

woodworking tool. This fence is just a piece positioned where you want ple of extra

To increase the working of “2-by” stock that is con- it, a small clamp can be holes along the end of

surface area of the drill nected to one end of the used to secure the other the table so the fence

press, I add an auxiliary table with a carriage bolt end of the fence to the table. can be repositioned for

table, see Fig. 1. This and a wing nut, see Fig. 1a. To make the fence even wider or narrower

“table” is really nothing A chamfer routed along the more adjustable, I drilled a workpieces.

more than a piece of 3/4"

thick plywood that is 1

screwed or bolted to the a.

drill press table.

When determining the

size of the auxiliary table,

be careful not to make it so

large that it sags or makes

the drill press unstable. (I

made mine 16" x 30".)

FENCE. The larger work

surface is nice, but what

really makes this jig useful

is the fence, see photo. A

7 Band Saw Pivot Block

A band saw is a great tool- clamp it to the table so it’s

for resawing thick lumber just slightly in front of the

into thinner stock. But blade, see Fig. 2.

because most band saw The distance between

blades have a tendency to the block and the blade

“wander,” controlling a cut should equal the desired

can be difficult. thickness of the stock you

One solution is to use a are cutting. Now just guide

simple support block, see the workpiece through the

photo. The nice thing about saw, pivoting it against the

this block is that it allows block as needed. W

you to pivot the workpiece

as you push it through the 1 2

saw to “follow” the direc-

tion the blade is wandering.

The guide is nothing

more than a block of wood

that has been beveled on

one end to create a “V”

point, see Fig. 1. On the

other end, the top of the

block is cut away to make

it easier to clamp it to the

table of the band saw.

To use the block, simply

From Woodsmith Magazine page 4 © August Home Publishing Co.

Vous aimerez peut-être aussi

- Table Saw Miter Sled PDFDocument8 pagesTable Saw Miter Sled PDF88No1Fan100% (2)

- 7 Tips For Working With Plywood: © 2009 August Home Publishing CoDocument5 pages7 Tips For Working With Plywood: © 2009 August Home Publishing ColordkyoriPas encore d'évaluation

- Pocket Hole JoineryDocument5 pagesPocket Hole JoineryJessica Sanders100% (3)

- Make Your Own Cutting Boards: Smart Projects & Stylish Designs for a Hands-On KitchenD'EverandMake Your Own Cutting Boards: Smart Projects & Stylish Designs for a Hands-On KitchenÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolD'EverandThe Essential Handsaw Book: Projects & Techniques for Mastering a Timeless Hand ToolPas encore d'évaluation

- Boxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopD'EverandBoxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopPas encore d'évaluation

- Table Saw Ripping JigDocument5 pagesTable Saw Ripping Jiggmand68100% (1)

- Woodsmith - 032Document24 pagesWoodsmith - 032rsotoqp100% (2)

- Adega ModularDocument15 pagesAdega ModularJairoViolinistaPas encore d'évaluation

- Band Saw Blade Rack: ©2019 Cruz Bay Publishing, Inc. An Active Interest Media CompanyDocument2 pagesBand Saw Blade Rack: ©2019 Cruz Bay Publishing, Inc. An Active Interest Media CompanyMariano100% (1)

- Portable Sandpaper StorageDocument3 pagesPortable Sandpaper Storagegmand68100% (1)

- Clamp RackDocument5 pagesClamp RackLuis100% (3)

- 5 Router Table UpgradesDocument3 pages5 Router Table Upgradesgmand68100% (3)

- Router Table - SledDocument6 pagesRouter Table - SledBen Gerez100% (3)

- Build-It Starterkit ManualDocument6 pagesBuild-It Starterkit ManualrraattaarrrraattaaPas encore d'évaluation

- Season: © 2016 Cruz Bay Publishing, IncDocument8 pagesSeason: © 2016 Cruz Bay Publishing, IncGeoPas encore d'évaluation

- 103 Tablesaw Sled PDFDocument3 pages103 Tablesaw Sled PDFMarvin Fernando Gomez100% (1)

- Adjustable Taper Ripping JigDocument6 pagesAdjustable Taper Ripping Jiggmand68Pas encore d'évaluation

- Table Saw JigsDocument16 pagesTable Saw Jigscyclonium100% (9)

- Shop CartDocument3 pagesShop Cartgmand68Pas encore d'évaluation

- Woodsmith - Router Techniques PDFDocument10 pagesWoodsmith - Router Techniques PDFkeatz100% (2)

- Router Table Upgrade PDFDocument52 pagesRouter Table Upgrade PDFpiedrahec100% (5)

- Woodworking Plans - Box-Joint JigDocument8 pagesWoodworking Plans - Box-Joint Jig_Godfather100% (3)

- Woodsmith Drill Press TableDocument3 pagesWoodsmith Drill Press Tablericheklund100% (6)

- Wood Magazine - Issue 247 - July 2017 - Full PDFDocument78 pagesWood Magazine - Issue 247 - July 2017 - Full PDFKen Lock100% (4)

- Cordless Tool ShelfDocument1 pageCordless Tool ShelfjuicePas encore d'évaluation

- Woodsmith - 076Document32 pagesWoodsmith - 076rsotoqp100% (1)

- 4 Handy Table Saw Jigs Unlock Potential With Simple DIY ProjectsDocument11 pages4 Handy Table Saw Jigs Unlock Potential With Simple DIY Projectsmargalaz100% (1)

- 038 Ring BoxesDocument32 pages038 Ring BoxesLic. Luis Calderón PérezPas encore d'évaluation

- Hank Ou: Get More From Your Table SawDocument12 pagesHank Ou: Get More From Your Table Sawrefsocrd1Pas encore d'évaluation

- Cordless Drill Charging StationDocument6 pagesCordless Drill Charging StationJerryPas encore d'évaluation

- American Woodworker 140 (FebMar 2009)Document84 pagesAmerican Woodworker 140 (FebMar 2009)Emilian Baluta100% (8)

- Win a FREE Trip to Italy! Contest Runs Sept 15 - Jan 15Document84 pagesWin a FREE Trip to Italy! Contest Runs Sept 15 - Jan 15Ramon Coelho100% (1)

- Chapter One: A Simple Lift-Lid Box: Excerpted FromDocument20 pagesChapter One: A Simple Lift-Lid Box: Excerpted FromChuck Osuchowski0% (1)

- Wood Magazine 138 2001 PDFDocument68 pagesWood Magazine 138 2001 PDFcgsharp100% (2)

- Woodsmith Precision Crosscut SledDocument10 pagesWoodsmith Precision Crosscut Sledssnvet86% (7)

- TIPSseason11 - Season 11 Tips Collection Woodsmith Shop PDFDocument12 pagesTIPSseason11 - Season 11 Tips Collection Woodsmith Shop PDFMariano100% (1)

- Finger Joints: Fast and EasyDocument4 pagesFinger Joints: Fast and EasyIlberto FortunaPas encore d'évaluation

- Exact Width Dado Jig PlanDocument5 pagesExact Width Dado Jig PlanMarco100% (1)

- Wall Storage SystemDocument5 pagesWall Storage SystemsaefulPas encore d'évaluation

- Curso de Cromagem - Parte 2Document10 pagesCurso de Cromagem - Parte 2Anízio Luiz Freitas de MesquitaPas encore d'évaluation

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliPas encore d'évaluation

- Mitersawstation PDFDocument9 pagesMitersawstation PDFJose Amenta100% (1)

- ShopNotes No. 138 FullDocument52 pagesShopNotes No. 138 FullKen Lock100% (3)

- Table Saw Ripping JigDocument5 pagesTable Saw Ripping JigFranciscoCoto100% (1)

- ShopNotes No. 137 FullDocument31 pagesShopNotes No. 137 FullKen Lock100% (3)

- 5hopnotes #85 - Router Table PDFDocument55 pages5hopnotes #85 - Router Table PDFpiedrahec100% (2)

- Router Table Micro-AdjusterDocument2 pagesRouter Table Micro-Adjustergmand68100% (1)

- Clamping & AssemblyDocument8 pagesClamping & AssemblyGsmHelp100% (1)

- Drill Press TableDocument3 pagesDrill Press Tablehomer35100% (2)

- Router Table - Projects - American WoodworkerDocument12 pagesRouter Table - Projects - American Woodworkermarcoskelpen100% (1)

- CMP Plansnow DeskDocument15 pagesCMP Plansnow Desk김성곤100% (2)

- Rool AroundDocument6 pagesRool AroundMiguel Oyarzabal100% (1)

- Clean Plywood CutsDocument3 pagesClean Plywood CutsGsmHelpPas encore d'évaluation

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsD'EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsÉvaluation : 5 sur 5 étoiles5/5 (1)

- How to Build Garden Furniture: Plans and Complete Instructions for Making Lawn Chairs, Benches, Settees and a Chaise Longue, Tables, Dinettes and Picnic Sets, Portable and Folding Pieces of All Kinds for Outdoor UseD'EverandHow to Build Garden Furniture: Plans and Complete Instructions for Making Lawn Chairs, Benches, Settees and a Chaise Longue, Tables, Dinettes and Picnic Sets, Portable and Folding Pieces of All Kinds for Outdoor UsePas encore d'évaluation

- Tandy KitDocument1 pageTandy Kitv00d00bluesPas encore d'évaluation

- Makesupply Passport Case Template Set Rounded CornersDocument3 pagesMakesupply Passport Case Template Set Rounded Cornersv00d00blues0% (1)

- Makesupply Passport Case Template Set Rounded CornersDocument3 pagesMakesupply Passport Case Template Set Rounded Cornersv00d00blues0% (1)

- Amatuer WoodworkerDocument230 pagesAmatuer Woodworkerv00d00bluesPas encore d'évaluation

- Morris Chair PlanDocument16 pagesMorris Chair Planv00d00blues100% (1)

- D&D 5th Ed Starter Set - CharactersDocument10 pagesD&D 5th Ed Starter Set - CharactersJeremy CastilloPas encore d'évaluation

- PDC Permaculture BookletDocument14 pagesPDC Permaculture BookletAlexandru GornaraPas encore d'évaluation

- Woodworking - Jointer's MalletDocument4 pagesWoodworking - Jointer's Malletv00d00bluesPas encore d'évaluation

- Elminster's Forgetten RealmsDocument194 pagesElminster's Forgetten RealmsJosh N Oregonia100% (29)

- Gary Gygax - Role Playing MasteryDocument174 pagesGary Gygax - Role Playing Mastery6at0100% (9)

- WoodPlans Online - Coffe Table & OttomanDocument13 pagesWoodPlans Online - Coffe Table & OttomanЧедомир Арнаут100% (3)

- Handmade Try Square PDFDocument7 pagesHandmade Try Square PDFv00d00bluesPas encore d'évaluation

- Taunton's Home Furniture #01Document112 pagesTaunton's Home Furniture #01v00d00blues100% (3)

- 15 Wooden Jack Fore Plane Plans by Caleb James PDFDocument2 pages15 Wooden Jack Fore Plane Plans by Caleb James PDFv00d00bluesPas encore d'évaluation

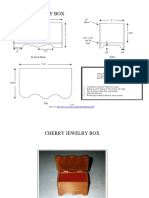

- Woodworking Plans - Cherry Jewelry BoxDocument2 pagesWoodworking Plans - Cherry Jewelry Boxv00d00bluesPas encore d'évaluation

- Hakama TyingDocument2 pagesHakama Tyingv00d00bluesPas encore d'évaluation

- Make Woodwork Tools PDFDocument0 pageMake Woodwork Tools PDFstolar2007100% (3)

- Blanket ChestDocument3 pagesBlanket ChestkhunchaiyaiPas encore d'évaluation

- PenTest Extra 04 2013 1Document8 pagesPenTest Extra 04 2013 1v00d00bluesPas encore d'évaluation

- English Layout SquareDocument2 pagesEnglish Layout Squarev00d00bluesPas encore d'évaluation

- 2504 - DIY Try SquareDocument4 pages2504 - DIY Try Squarev00d00bluesPas encore d'évaluation

- AC30 1962 Layout 1Document1 pageAC30 1962 Layout 1v00d00bluesPas encore d'évaluation

- Pentest Auditing Standards 09 2012-MdpDocument10 pagesPentest Auditing Standards 09 2012-Mdpv00d00bluesPas encore d'évaluation

- Ki Aikido HandbookDocument15 pagesKi Aikido Handbookhrizi100% (5)

- Beginner Pentesting BasicsDocument7 pagesBeginner Pentesting Basicsv00d00bluesPas encore d'évaluation

- The Grand Illusionist's DelusionDocument15 pagesThe Grand Illusionist's Delusionv00d00bluesPas encore d'évaluation

- US Army Ranger Handbook 2011 EditionDocument357 pagesUS Army Ranger Handbook 2011 Editionbovine splendor100% (10)

- Static Exciter Aux Fed Vs Terminal FedDocument6 pagesStatic Exciter Aux Fed Vs Terminal Fedavikrisad100% (1)

- Duraband Information Vs 300XTDocument4 pagesDuraband Information Vs 300XTanhlhPas encore d'évaluation

- 2009-12-29 224215 01 Escape Steering Squeek TSB 06-23-03Document2 pages2009-12-29 224215 01 Escape Steering Squeek TSB 06-23-03Randy SmithPas encore d'évaluation

- Grosvenor Full Product Range & Technical Nformation CatalogueDocument87 pagesGrosvenor Full Product Range & Technical Nformation CatalogueDylan LopezPas encore d'évaluation

- Pipe Fittings & ValvesDocument15 pagesPipe Fittings & ValvesRam MurtyPas encore d'évaluation

- Aditya Series Ws 325 350 144 CellsDocument2 pagesAditya Series Ws 325 350 144 CellsEureka SolarPas encore d'évaluation

- Tech Data Sheet 6600Document1 pageTech Data Sheet 6600Shubhankar MenonPas encore d'évaluation

- Extended End Plate Moment Connections PDFDocument47 pagesExtended End Plate Moment Connections PDFManvitha Reddy100% (1)

- Uniclass2015 PR v1 18Document229 pagesUniclass2015 PR v1 18abdullah sahibPas encore d'évaluation

- External NCR MonitoringDocument7 pagesExternal NCR MonitoringGhayas JawedPas encore d'évaluation

- Elite Precommissioning Procedures and Formats For SS Bay EquipmentDocument92 pagesElite Precommissioning Procedures and Formats For SS Bay EquipmentSurya Mvs100% (1)

- Electronic Pressure Switch EDS 3400 W IO-Link InterfaceDocument2 pagesElectronic Pressure Switch EDS 3400 W IO-Link InterfacefreddyjoertyPas encore d'évaluation

- Smart Labels in Waste ManagementDocument20 pagesSmart Labels in Waste ManagementDaisyPas encore d'évaluation

- Research Interests:: Focus On Applied Electronic and Optical Materials (Many of Which Are Ceramics) "Document8 pagesResearch Interests:: Focus On Applied Electronic and Optical Materials (Many of Which Are Ceramics) "Abdul Majeed ChiyyanoorPas encore d'évaluation

- Voice 487Document1 pageVoice 487Momen AyassrhPas encore d'évaluation

- Masterseal ADocument6 pagesMasterseal Aapi-283891975Pas encore d'évaluation

- Lesson 3: Lesson 3:: Properties of Steel & Timber Properties of Steel & TimberDocument23 pagesLesson 3: Lesson 3:: Properties of Steel & Timber Properties of Steel & TimberMaria CincoPas encore d'évaluation

- Repair Parts List 417.94702300: - Product Type - Part Number - Model Number - Part DescriptionDocument16 pagesRepair Parts List 417.94702300: - Product Type - Part Number - Model Number - Part DescriptionRiks GarcesPas encore d'évaluation

- 3.0. CementDocument10 pages3.0. CementJohn luckyPas encore d'évaluation

- Permeability of Geopolymer Concrete With PDFDocument7 pagesPermeability of Geopolymer Concrete With PDFSuhas RamachandraPas encore d'évaluation

- 4r100 Plano de La CajaDocument12 pages4r100 Plano de La CajaproyectorodrigoleonPas encore d'évaluation

- Simulation Analysis of Spinning Forming of D6AC Ultrahigh-Strength Low-Alloy SteelDocument8 pagesSimulation Analysis of Spinning Forming of D6AC Ultrahigh-Strength Low-Alloy SteelmikojmPas encore d'évaluation

- Geosynthetic Reinforced Pile Supported Embankments PlaxisDocument121 pagesGeosynthetic Reinforced Pile Supported Embankments PlaxisAnonymous 5exSerPas encore d'évaluation

- Polypropylene (PP) Plastic - Types, Properties, Uses & Structure InfoDocument11 pagesPolypropylene (PP) Plastic - Types, Properties, Uses & Structure InfoPrashant SinghPas encore d'évaluation

- Centrometal Touch TechnicalDocument58 pagesCentrometal Touch TechnicalLuka BardicPas encore d'évaluation

- Nagpur Cetp - Butibori - Member - ListDocument7 pagesNagpur Cetp - Butibori - Member - ListKv SatishPas encore d'évaluation

- Fuel From Plastic WasteDocument13 pagesFuel From Plastic Waste18Pa1A0325 Duba Ajay BabuPas encore d'évaluation

- Reproduction of Thesis on Grinding Wheel Wear with Missing PagesDocument148 pagesReproduction of Thesis on Grinding Wheel Wear with Missing PageswondwosenAyelePas encore d'évaluation

- Abu Dhabi Oil Refining Doors and Windows SpecDocument16 pagesAbu Dhabi Oil Refining Doors and Windows SpecHalim KazdarPas encore d'évaluation

- 2 - DupaDocument96 pages2 - DupaRoge CaractaPas encore d'évaluation