Académique Documents

Professionnel Documents

Culture Documents

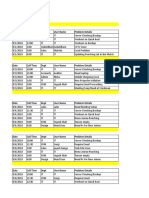

Shipping KPI Quick Sheet, Version 2.5: Health and Safety Performance

Transféré par

shivarachappaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Shipping KPI Quick Sheet, Version 2.5: Health and Safety Performance

Transféré par

shivarachappaDroits d'auteur :

Formats disponibles

Shipping KPI Quick Sheet, Version 2.

5

SPI KPI KPI Value Formula* KPIMinReq KPITarget PI

𝑨 A: Number of PSC inspections resulting in zero deficiencies

Flawless Port state control performance 0.33 1

𝑩 B: Number of PSC inspections

A: Number of fatalities due to work injuries

B: Number of lost workday cases

𝑨+𝑩+𝑪+𝑫

Lost Time Injury Frequency 2.5 0.5 C: Number of permanent total disabilities (PTD)

𝑬 ∗ 𝟏𝟎−𝟔

D: Number of permanent partial disabilities (PPD)

Health and Safety E: Total exposure hours

Performance 𝑨 A: Number of health and safety related deficiencies

Health and Safety deficiencies 5 0

𝑩 B: Number of recorded external inspections

A: Number of cases where a crew member is sick for more than 24 hours

𝑨+𝑩

Lost Time Sickness Frequency 2.5 0.5 B: Number of fatalities due to sickness

𝑪 ∗ 𝟏𝟎−𝟔

C: Total exposure hours

𝑨 A: Number of passengers injured

Passenger Injury Ratio 2 0.2

𝑩 ∗ 𝟏𝟎−𝟔 B: Passenger exposure hours

A: Number of absconded crew

B: Number of charges of criminal offences

Crew disciplinary frequency 𝑨+𝑩+𝑪+𝑫+𝑬 C: Number of cases where drugs or alcohol is abused

∗ 𝟐𝟒 ∗ 𝟑𝟔𝟓 0.02 0

𝑭 D: Number of dismissed crew

E: Number of logged warnings

F: Total exposure hours

A: Number of seafarers not relieved on time

Crew planning 𝑨+𝑩 15 0

B: Number of violation of rest hours

𝑨 A: Number of HR related deficiencies

HR deficiencies 5 0

HR Management 𝑩 B: Number of recorded external inspections

Performance 𝑨 A: Number of cadets under training with the ship manager

Cadets per ship 0 3

𝑩 B: Number of ships operated under DOC holder

A: Number of officer terminations from whatever cause

𝑨 − (𝑩 + 𝑪) B: Number of unavoidable officer terminations

Officer retention rate 𝟏𝟎𝟎% − ∗ 𝟏𝟎𝟎% 70 95

𝑫 C: Number of beneficial officer terminations

D: Average number of officers employed

𝑨 A: Number of officer experience points

Officers experience rate 0.6 0.9

𝟒∗𝑩 B: Number of officers onboard

𝑨 A: Number of officer trainee man days

Training days per officer 0 0.03

𝑩 B: Number of officer days onboard all ships under technical management (DOC)

Releases of substances as def by MARPOL A: Number of releases of solid substances to the environment

𝑨+𝑩 1 0

Annex 1-6 B: Number of oil spills

Environmental Ballast water management violations 𝑨 1 0 A: Number of ballast water management violations

Performance Contained spills 𝑨 3 0 A: Number of contained spills of liquid

𝑨 A: Number of environmental related deficiencies

Environmental deficiencies 5 0

𝑩 B: Number of recorded external inspections

𝑨 A: Number of navigational related deficiencies

Navigational deficiencies 5 0

𝑩 B: Number of recorded external inspections

Navigational Safety A: Number of collisions

Performance

Navigational incidents 𝟐𝑨 + 𝑩 + 𝟐𝑪 1 0 B: Number of allisions

C: Number of groundings

A: Last year’s running cost budget

|𝑨 − (𝑩 − 𝑪)|

Budget performance ∗ 𝟏𝟎𝟎% 10 2 B: Last year’s actual running costs and accruals

𝑨

C: Last year’s AAE (Additional Authorized Expenses)

A: Agreed drydocking duration

𝑩−𝑨 𝑫−𝑪 B: Actual drydocking duration

Drydocking planning performance** (| |+| |) ∗ 𝟏𝟎𝟎 10 2

𝑨 𝑪 C: Agreed drydocking budget

D: Actual drydocking costs

Cargo related incidents 𝑨 2 0 A: Number of cargo related incidents

Operational 𝑨 A: Number of operational related deficiencies

Operational deficiencies 5 0

Performance 𝑩 B: Number of recorded external inspections

𝑨 A: Number of passengers injured

Passenger injury ratio 2 0.2

𝑩 B: Passenger exposure hours

A: Number of PSC detentions

Port state control detention 𝑨 (if B > 0) 1 0

B: Number of PSC inspections

(𝟐𝟒 ∗ 𝟑𝟔𝟓 − 𝑩) − 𝑨 A: Actual unavailability

Ship availability ∗ 𝟏𝟎𝟎% 97 100

𝟐𝟒 ∗ 𝟑𝟔𝟓 − 𝑩 B: Planned unavailability

𝑨 A: Number of observations during commercial inspections

Vetting deficiencies 5 0

𝑩 B: Number of commercial inspections

𝑨 A: Number of PSC inspections resulting in zero deficiencies

Port State Control performance 0.33 1

Security 𝑩 B: Number of PSC inspections

Performance 𝑨 A: Number of security related deficiencies

Security deficiencies 5 0

𝑩 B: Number of recorded external inspections

Technical Condition of class 𝑨 1 0 A: Number of conditions of class

Performance Failure of critical equipment and systems 𝑨 1 0 A: Number of failures of critical equipment and systems

Shipping KPI Quick Sheet, V 2.5 09 January 2017

Shipping KPI Quick Sheet, Version 2.5

SPI KPI KPI Value Formula KPIMin Req KPITarget PI

𝑨 A: Emitted mass of CO2[ton]

CO2 efficiency [g/tonmile] 84 36

𝑩 ∗ 𝟏𝟎−𝟔 B: Transport work

A: Number of fire incidents

Fire and Explosions 𝑨+𝑩 1 0

B: Number of explosion incidents

These KPIs has no 𝑨 A: Emitted mass of NOx[kg]

NOx efficiency [g/Cargo Unit] mile 2.2 0.9

association to an SPI 𝑩 ∗ 𝟏𝟎−𝟑 B: Transport work

𝑨 A: Number of PSC deficiencies

Port state control deficiency ratio 8 0

𝑩 B: Number of PSC inspections

𝑨 A: Emitted mass of SOx[kg]

SOx efficiency [g/Cargo Unit] mile 1.5 0.6

𝑩 ∗ 𝟏𝟎−𝟑 B: Transport work

The Rating and Aggregation formulas

𝐾𝑃𝐼𝑉𝑎𝑙𝑢𝑒 − 𝐾𝑃𝐼𝑀𝑖𝑛𝑅𝑒𝑞 The KPIrating formula is valid for all KPIvalues and will convert the

KPI Rating Formula 𝐾𝑃𝐼𝑅𝑎𝑡𝑖𝑛𝑔 = 100 ∗

𝐾𝑃𝐼𝑇𝑎𝑟𝑔𝑒𝑡 − 𝐾𝑃𝐼𝑀𝑖𝑛𝑅𝑒𝑞 KPIvalue into a rating between 0-100.

𝑛

1 An SPI is calculated as the average of the KPIrating which is

SPI 𝑆𝑃𝐼 = ∗ ∑ 𝐾𝑃𝐼𝑖 incorporated in the SPI

𝑛

𝑖=1

NOTE:

KPITarget is the KPIvalue which give KPIrating =100

KPIMin Req is the KPIvalue which give KPIrating =0

* To see the reporting and calculation periods, please refer to the www.shipping-kpi.org

Need more info ?

For further information about the system please refer to the web site www.shipping-kpi.org

In case of questions, please use the feedback form on the website or email us. support@shipping-kpi.org

Shipping KPI Quick Sheet, V 2.5 09 January 2017

Vous aimerez peut-être aussi

- Shipping KPI System V2.2.1Document158 pagesShipping KPI System V2.2.1Tiara Figur AlfenzaPas encore d'évaluation

- Final ABS Performance MGMT - EEVPSeminar - 10nov14 - EADocument52 pagesFinal ABS Performance MGMT - EEVPSeminar - 10nov14 - EAMeleti Meleti MeletiouPas encore d'évaluation

- TSI DefiningTreasuryMetricsDocument12 pagesTSI DefiningTreasuryMetricsBernardCharoPas encore d'évaluation

- International Journal of ManPowerDocument141 pagesInternational Journal of ManPowerAdesti KomalasariPas encore d'évaluation

- Compliance InfographicDocument1 pageCompliance InfographicJohn N. AllegroPas encore d'évaluation

- Tanker Management and Self Assessment 3 (TMSA 3)Document89 pagesTanker Management and Self Assessment 3 (TMSA 3)soner100% (3)

- JOb Description - Logistics Procurement ManagerDocument3 pagesJOb Description - Logistics Procurement ManagergghgPas encore d'évaluation

- Appendix 1 - Survey Planning Questionnaire - Bulk CarrierDocument9 pagesAppendix 1 - Survey Planning Questionnaire - Bulk CarrierkasemosmanPas encore d'évaluation

- Performance Appraisals: Directors' Briefing Human Resources ManagementDocument4 pagesPerformance Appraisals: Directors' Briefing Human Resources ManagementJignesh PatelPas encore d'évaluation

- What Is A Computerized Maintenance Management System (CMMS) ?Document11 pagesWhat Is A Computerized Maintenance Management System (CMMS) ?JIO DADI100% (2)

- White Paper KPIsDocument9 pagesWhite Paper KPIsmitsosPas encore d'évaluation

- Group 10 Accident Investigation UpdatedDocument6 pagesGroup 10 Accident Investigation UpdatedAikovin ClerigoPas encore d'évaluation

- (Draft) Preliminary Report BG GOLDEN WAY 2516 (AY FS)Document19 pages(Draft) Preliminary Report BG GOLDEN WAY 2516 (AY FS)Tobias Taylor WeberPas encore d'évaluation

- CorGov Competency - FrameworkDocument28 pagesCorGov Competency - Frameworkmarielantonio.hrPas encore d'évaluation

- EY Treasury Management Services PDFDocument16 pagesEY Treasury Management Services PDFKathir KPas encore d'évaluation

- 0621 Pocket Guide PrintoutDocument8 pages0621 Pocket Guide PrintoutMuhammadPas encore d'évaluation

- Machinery Failure Analysis Nadeem Six Sigma MBBDocument4 pagesMachinery Failure Analysis Nadeem Six Sigma MBBSyedNadeemAhmedPas encore d'évaluation

- C KPI CertifiedDocument1 pageC KPI CertifiedDARA HAMEEDPas encore d'évaluation

- Crew Resource Management - The Role of Human Factors and Bridge Resource Management in Reducing Maritime CasualtiesDocument6 pagesCrew Resource Management - The Role of Human Factors and Bridge Resource Management in Reducing Maritime CasualtiesgulsumPas encore d'évaluation

- LM1080 Ship Superintendency (ENQ) PDFDocument8 pagesLM1080 Ship Superintendency (ENQ) PDFmajdirossrossPas encore d'évaluation

- Disaster Recovery in Cloud Computing SystemsDocument9 pagesDisaster Recovery in Cloud Computing SystemsAdeyeye adewumiPas encore d'évaluation

- Date Call Time Dept User Name Problem DetailsDocument6 pagesDate Call Time Dept User Name Problem DetailsVijay NikamPas encore d'évaluation

- ARGUS Global Compliance PolicyDocument8 pagesARGUS Global Compliance Policyxiaoshuang duanPas encore d'évaluation

- Risk Register SSD 2012 - 2013Document8 pagesRisk Register SSD 2012 - 2013irri_social_sciencesPas encore d'évaluation

- Lean Compliance ManagementDocument49 pagesLean Compliance Managementandruta1978Pas encore d'évaluation

- ShipNet Newsletter 1st EditionDocument6 pagesShipNet Newsletter 1st EditionlavrikPas encore d'évaluation

- Date: 17 March 2010: Performance Appraisals of Employees Are Necessary To Understand Each Employee's AbilitiesDocument21 pagesDate: 17 March 2010: Performance Appraisals of Employees Are Necessary To Understand Each Employee's AbilitiesRekha GaikwadPas encore d'évaluation

- Majalah IA Dec2018 PDFDocument72 pagesMajalah IA Dec2018 PDFmariazesualdaPas encore d'évaluation

- Smith, Ricky A. (2003) - Why CMMS Implementations FailDocument13 pagesSmith, Ricky A. (2003) - Why CMMS Implementations FailSalam Al-HafezPas encore d'évaluation

- The Determination of Performance Measures by UsingDocument14 pagesThe Determination of Performance Measures by Usingمروة مبروكيPas encore d'évaluation

- Amtr Job DescriptionsDocument5 pagesAmtr Job Descriptionsapi-278713240Pas encore d'évaluation

- Port Performance IndicatorsDocument7 pagesPort Performance IndicatorsVictor Ose MosesPas encore d'évaluation

- An Overview of Strategic Management Practices - Palladan-2018Document5 pagesAn Overview of Strategic Management Practices - Palladan-2018Cuong100% (1)

- Testing Effort Estimates - TestCasesDocument23 pagesTesting Effort Estimates - TestCasesAdriana MarquesPas encore d'évaluation

- What Is Business Administration All AboutDocument8 pagesWhat Is Business Administration All AboutMukhtar MaxamedPas encore d'évaluation

- Company Name Skill Matrix: Scoring Criteria 9-10 Outstanding 7-8 Excellent 5-6 Good 3-4 Average 1-2 PoorDocument1 pageCompany Name Skill Matrix: Scoring Criteria 9-10 Outstanding 7-8 Excellent 5-6 Good 3-4 Average 1-2 PoorKodamShruthiPas encore d'évaluation

- Internship Evaluation FormDocument3 pagesInternship Evaluation FormAsad AftabPas encore d'évaluation

- Delegation of Authority: Duluxgroup LimitedDocument7 pagesDelegation of Authority: Duluxgroup LimitedGaurav WadhwaPas encore d'évaluation

- Corporate Classic PDFDocument4 pagesCorporate Classic PDFironhide404Pas encore d'évaluation

- SCRIPT Competency Framework Dictionary-EnglishDocument9 pagesSCRIPT Competency Framework Dictionary-EnglishfasihPas encore d'évaluation

- #1 Introduction To HRMDocument19 pages#1 Introduction To HRMRahulRPas encore d'évaluation

- Pre and Post Merger AnalysisDocument84 pagesPre and Post Merger AnalysisMano BernardPas encore d'évaluation

- Quality Assurance Framework Revised April 2017 With AnnexesDocument33 pagesQuality Assurance Framework Revised April 2017 With AnnexesFikreab Markos Dolebo100% (1)

- What Is I-O?: Consultant: Leadership Development and Assessment About The OrganizationDocument3 pagesWhat Is I-O?: Consultant: Leadership Development and Assessment About The OrganizationklatifdgPas encore d'évaluation

- DRAFT - Resource Capacity & Demand Management Strategy v0.2Document16 pagesDRAFT - Resource Capacity & Demand Management Strategy v0.2sumathiakkaPas encore d'évaluation

- Order Accuracy KPI: On-Time in Full Delivery KPI Inventory Accuracy KPIDocument6 pagesOrder Accuracy KPI: On-Time in Full Delivery KPI Inventory Accuracy KPIAddisu TsegayePas encore d'évaluation

- S3-Shared Services Model - August 14 - 2010Document15 pagesS3-Shared Services Model - August 14 - 2010Rahul DhokPas encore d'évaluation

- Adil CV.Document2 pagesAdil CV.adil abdulkhaderPas encore d'évaluation

- Technology Vendor Transition StrategyDocument7 pagesTechnology Vendor Transition StrategyasadnawazPas encore d'évaluation

- Succession Planning: Jonathan P. Ruff, P.E. Environmental Manager City of Plattsburgh, NYDocument64 pagesSuccession Planning: Jonathan P. Ruff, P.E. Environmental Manager City of Plattsburgh, NYBelPas encore d'évaluation

- Building Peformance Plans: ActsheetDocument2 pagesBuilding Peformance Plans: ActsheetAli KhanPas encore d'évaluation

- UK Home Office: Probation Bench Handbook 2nd Edition 2007Document92 pagesUK Home Office: Probation Bench Handbook 2nd Edition 2007UK_HomeOfficePas encore d'évaluation

- Gms Ins Hazmat Ihm Frequently Ask en r2Document4 pagesGms Ins Hazmat Ihm Frequently Ask en r2Mostafa IsmaelPas encore d'évaluation

- AuditingDocument81 pagesAuditingAnkit KumarPas encore d'évaluation

- Getting Smart About Your Workforce WP FinalDocument26 pagesGetting Smart About Your Workforce WP FinalAvishek MohantaPas encore d'évaluation

- Shipping KPI Quicksheet V2.1.2Document2 pagesShipping KPI Quicksheet V2.1.2Arthur OliveiraPas encore d'évaluation

- Shipping KPI Quick Sheet, Version 3.0: SPI001: Environmental PerformanceDocument2 pagesShipping KPI Quick Sheet, Version 3.0: SPI001: Environmental PerformanceMOORTHY.KEPas encore d'évaluation

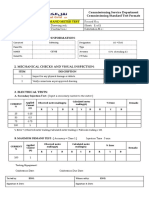

- Commissioning Service Department Commissioning Standard Test Formats Description: Maximum Demand Meter TestDocument1 pageCommissioning Service Department Commissioning Standard Test Formats Description: Maximum Demand Meter TestDinesh PitchaivelPas encore d'évaluation

- Construction of Bridge Over Rupsha River For Khulna Mongla Railway Line and Implementation of EMP Mis Report For The Month of January-18Document1 pageConstruction of Bridge Over Rupsha River For Khulna Mongla Railway Line and Implementation of EMP Mis Report For The Month of January-18RS MahbubPas encore d'évaluation

- FD Bonds Interest RatesDocument5 pagesFD Bonds Interest RatesshivarachappaPas encore d'évaluation

- Special Currency ReportDocument12 pagesSpecial Currency ReportshivarachappaPas encore d'évaluation

- 7-9 April 2014, Al Khobar, Kingdom of Saudi Arabia: Featured Presentation byDocument11 pages7-9 April 2014, Al Khobar, Kingdom of Saudi Arabia: Featured Presentation byshivarachappaPas encore d'évaluation

- Life Is What You Make ItDocument111 pagesLife Is What You Make ItshashankniecPas encore d'évaluation

- AHA CMRP HandbookDocument32 pagesAHA CMRP HandbookshivarachappaPas encore d'évaluation

- 185 Powerful Verbs That Will Make Your Resume Awesome: Resumes & Cover LettersDocument9 pages185 Powerful Verbs That Will Make Your Resume Awesome: Resumes & Cover LettersshivarachappaPas encore d'évaluation

- The Pi Cheatsheet Version 2.5: Id Name Unit Scope Period DescriptionDocument9 pagesThe Pi Cheatsheet Version 2.5: Id Name Unit Scope Period DescriptionshivarachappaPas encore d'évaluation

- Healthy Diet Plan For During PregnancyDocument12 pagesHealthy Diet Plan For During PregnancyshivarachappaPas encore d'évaluation

- Nutrition During Pregnancy and Lactation: Mohan Lal Ramavath NutritionistDocument18 pagesNutrition During Pregnancy and Lactation: Mohan Lal Ramavath NutritionistshivarachappaPas encore d'évaluation

- Ocimf TankDocument18 pagesOcimf TankshivarachappaPas encore d'évaluation

- Hatch Cover Maintenance and Operation PDFDocument72 pagesHatch Cover Maintenance and Operation PDFshivarachappa100% (1)

- Mooring ChainsDocument12 pagesMooring ChainsshivarachappaPas encore d'évaluation

- RA Templates - Tank Cleaning PDFDocument26 pagesRA Templates - Tank Cleaning PDFJunMamauagDelaCruzPas encore d'évaluation

- Photo: Benjamin Von WongDocument3 pagesPhoto: Benjamin Von WongXian An MohPas encore d'évaluation

- Build A 10-Year Plan To Make The World Safer From Natural HazardsDocument3 pagesBuild A 10-Year Plan To Make The World Safer From Natural HazardsDiana Mae BarcomaPas encore d'évaluation

- GRC Model Letter PDFDocument2 pagesGRC Model Letter PDFMd. Badrul IslamPas encore d'évaluation

- Safety in Sulfuric Acid Storage Tanks - Chemical Engineering - 1Document2 pagesSafety in Sulfuric Acid Storage Tanks - Chemical Engineering - 1Vahid Sarfaraz0% (1)

- MSDS Natural Gas Condensate - SweetDocument10 pagesMSDS Natural Gas Condensate - SweetMuhammad Naufal Nazhib KhanPas encore d'évaluation

- Geo Mud Disaster ChapterDocument7 pagesGeo Mud Disaster Chapterapi-583183683Pas encore d'évaluation

- Nuclear PowerDocument38 pagesNuclear Powermskishan26Pas encore d'évaluation

- Cause and Effect DiagramDocument3 pagesCause and Effect DiagramSomya Harsh100% (3)

- NGCC Plant Case FClass 051607Document4 pagesNGCC Plant Case FClass 051607AjiPas encore d'évaluation

- Aluminum Internal Floating Roofs Perimeter Seal Systems Oil / Water Separator Covers For Api Separator BasinsDocument8 pagesAluminum Internal Floating Roofs Perimeter Seal Systems Oil / Water Separator Covers For Api Separator BasinsLDPPas encore d'évaluation

- Draft Revised Irr - RA 9729 PDFDocument27 pagesDraft Revised Irr - RA 9729 PDFAmelouPas encore d'évaluation

- Perceived Effects of Drainage System in Brgy. Bamban (Final Output)Document26 pagesPerceived Effects of Drainage System in Brgy. Bamban (Final Output)JANSKIE ESMANEPas encore d'évaluation

- Weld BriteDocument10 pagesWeld BriteKinjal PatelPas encore d'évaluation

- LEDC Volcano Case StudyDocument14 pagesLEDC Volcano Case StudyleobutterflyPas encore d'évaluation

- BP Deepwater Horizon Oil Spill Incident Specific Preparedness Review (ISPR) Final ReportDocument167 pagesBP Deepwater Horizon Oil Spill Incident Specific Preparedness Review (ISPR) Final Reportcgreport100% (1)

- HUD Environmental AssessmentDocument58 pagesHUD Environmental AssessmentIndiana Public Media NewsPas encore d'évaluation

- NSTP 2Document7 pagesNSTP 2Andrew SanchezPas encore d'évaluation

- Liquid Cargo Discharge Plan - FINALDocument14 pagesLiquid Cargo Discharge Plan - FINALNaresh Sharma100% (3)

- Emergency Planning and Response ManagementDocument20 pagesEmergency Planning and Response ManagementjyfthgrefdwsfghjPas encore d'évaluation

- Arc 504 Final Review in The Age of Covid-19: Alejandro Zaera-Polo With Joon MaDocument3 pagesArc 504 Final Review in The Age of Covid-19: Alejandro Zaera-Polo With Joon MadodmaddodPas encore d'évaluation

- Environmental Chemistry PDFDocument3 pagesEnvironmental Chemistry PDFSagnik MitraPas encore d'évaluation

- Continuous Particle MonitoringDocument37 pagesContinuous Particle MonitoringhaggPas encore d'évaluation

- Prevention of Flood in Brgy. 293, Binondo, Manila Through Waste ManagementDocument55 pagesPrevention of Flood in Brgy. 293, Binondo, Manila Through Waste ManagementSidney MarianoPas encore d'évaluation

- Đề thi học kì 2 lớp 9 môn Tiếng AnhDocument4 pagesĐề thi học kì 2 lớp 9 môn Tiếng AnhMin MinPas encore d'évaluation

- Contingency Plan AttachmentDocument6 pagesContingency Plan AttachmentGuilherme SantosPas encore d'évaluation

- MsdsDocument1 pageMsdsHamdi RafiekPas encore d'évaluation

- Forest ConservationDocument5 pagesForest Conservationapi-302652063Pas encore d'évaluation

- Unit 16 Emerging Trends in Disaster Miteation: 16.0 Learning OutcomeDocument14 pagesUnit 16 Emerging Trends in Disaster Miteation: 16.0 Learning OutcomeHardik JainPas encore d'évaluation

- Social Problems 14Th Edition Eitzen Solutions Manual Full Chapter PDFDocument43 pagesSocial Problems 14Th Edition Eitzen Solutions Manual Full Chapter PDFsarclescaladezk3tc100% (8)